Screenprint T Shirts: A Fashion Brand’s Guide to Sourcing at Scale with a China Clothing Manufacturer

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 15th, 2025

19 minute read

Table of Contents

- What Are Screenprint T Shirts? Methods, Pros, and Use Cases

- Artwork & Prepress: How Fashion Brands Prepare Files for Screenprint T Shirts

- Screenprint T Shirts at Scale: MOQs, Lead Times, and Cost Drivers

- Quality Assurance for Screenprint T Shirts: Testing, Standards, and AQL

- Compliance & Sustainability: Inks, Chemicals, and Certifications for US/EU Markets

- Sourcing Screenprint T Shirts: China vs. Bangladesh for Fashion Brands

- Product/Service Integration: Clothing Manufacturing OEM Service by Eton

- Tech Pack & PO Checklist for Screenprint T Shirts

- FAQs: Screenprint T Shirts for Fashion Brands

- Next Steps: Get a Costed Quote and Prepress Review

- Author & Review Notes (E-E-A-T)

- FAQs

Screenprint T Shirts: A Fashion Brand’s Guide to Sourcing at Scale with a China Clothing Manufacturer

What Are Screenprint T Shirts? Methods, Pros, and Use Cases

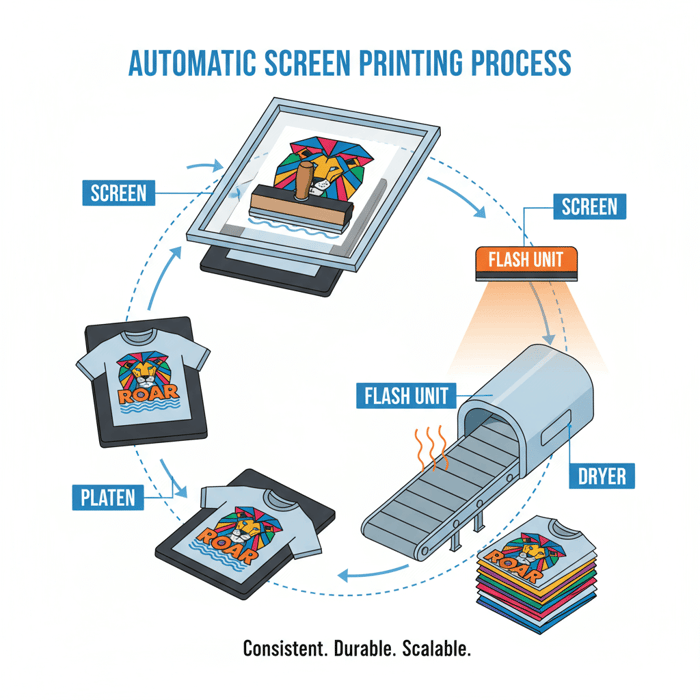

Screenprint t shirts anchor countless retail programs: a screen transfers ink through mesh onto fabric, building designs one color at a time. The process delivers rich color, durability, and consistent results across large runs—attributes fashion brands rely on for seasonal graphics, promo tees, and evergreen logo programs. A China Clothing Manufacturer with full OEM/ODM capability keeps screens, chemistry, curing, and QA aligned from art desk to carton.

Industry references (e.g., PRINTING United Alliance) confirm the press-to-shirt workflow that shapes every production decision, from ink systems to mesh counts. For foundational context, brands can reference standard technical overviews of screen printing for step-by-step primers on screen creation, exposure, and print registration.

Answer-first summary: Screen printing uses mesh screens to apply ink in layers, producing vibrant, durable designs—ideal for bulk orders. Fashion brands choose screen printing for consistent color, lower unit costs at scale, and versatile finishes across cotton and cotton-blend tees.

Common Methods (Plastisol, Water-Based, Discharge)

Three methods define how screenprint t shirts feel, cure, and wear.

- Plastisol: PVC-based ink sits atop fibers, offering strong opacity and stable color on dark garments. It cures through temperature rather than evaporation, delivering robust wash durability when cured correctly.

- Water-Based: Pigments penetrate fibers, yielding a soft-hand finish prized for premium retail and fashion-forward collections. Colorfastness depends on proper cure and binder systems. Brands favor water-based for eco narratives and lightweight hand on combed cotton.

- Discharge: An activator removes dye from cotton and replaces it with pigment, creating vibrant prints with minimal hand on dark garments. Suitability hinges on fabric dye chemistry, batch consistency, and thorough testing.

Screen Printing vs. DTG vs. Heat Transfer

Screenprint t shirts excel in bulk programs. DTG (direct-to-garment) suits small runs and photo-realistic art but often trails in colorfastness under heavy retail wash cycles unless cured and pretreated perfectly. Heat transfer offers speed and flexibility for short bursts, yet hand-feel and longevity vary by film type and transfer adhesive. For volume, screen printing delivers steady unit economics and repeatable color.

Fabric Compatibility and Hand-Feel

Fabric choice shapes outcomes. Ringspun and combed cotton provide smoother surfaces for fine detail and water-based softness. Cotton/poly blends manage shrinkage and performance, though dye chemistry may influence discharge results. Heavyweight jersey suits bold graphics with plastisol. Stretch knits demand flexible ink systems and care with registration. Validate durability using AATCC methods across laundering, crocking, and dimensional change tests.

Artwork & Prepress: How Fashion Brands Prepare Files for Screenprint T Shirts

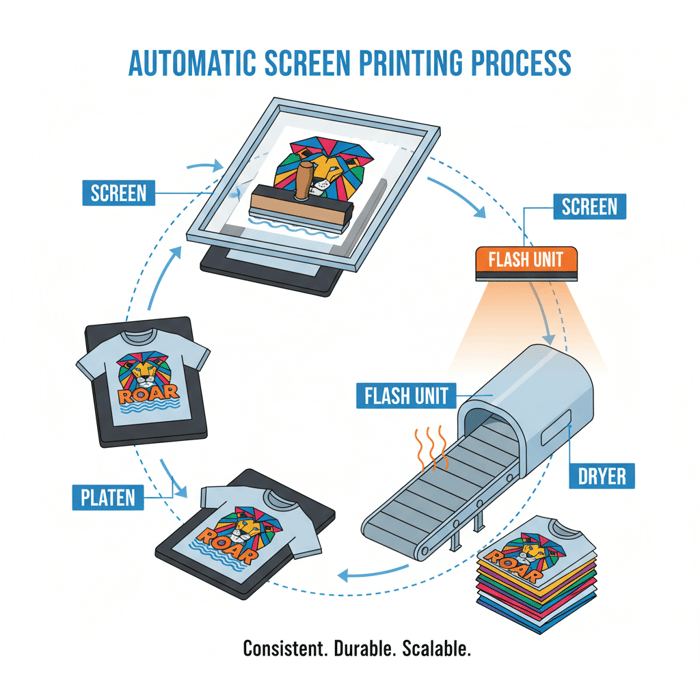

Every strong screenprint t shirts program starts with crisp files, exact color targets, and clean separations. Vector art, firm PMS callouts, and disciplined layouts reduce prepress revisions, keep screens on schedule, and protect unit cost. Our OEM approach aligns design, separations, press-ready files, and factory capabilities so art translates to ink faithfully. For a process overview, see OEM/ODM process overview.

Answer-first summary: High-quality prints start with precise artwork: vector files, Pantone references, color separations, and clearly specified placements and sizes. A strong tech pack streamlines approvals and minimizes prepress changes and cost.

Use Pantone Matching System (PMS) for color fidelity to set brand-safe targets across regions. Lock registration expectations early to protect fine detail on high-speed presses.

File Types, Vector Artwork, and Resolution

Vector files (AI, EPS, PDF with embedded vectors) ensure crisp edges and clean separations across sizes. When raster elements are essential—gradients, textures, photographic layers—use 300+ dpi at print scale and confirm underbase strategy for dark tees. Embed or outline fonts to eliminate substitution risk and specify stroke weights for fine lines relative to mesh count.

We urge brand teams to supply a master file with clear layer naming, PMS callouts, and scale notes for each size curve. This discipline prevents accidental color shifts and late-stage reworks that affect timelines for screenprint t shirts.

Color Separations: Spot vs. CMYK and Underbase Strategy

Spot color delivers punch and accuracy for logos and solid graphics; CMYK or simulated process handles gradients and photo-real layers. On dark garments, build a controlled underbase to lift color, then trap and choke layers to protect registration. Press configuration matters—off-contact distance, squeegee durometer, and mesh count must match art complexity.

We configure ROQ and M&R automatic presses to balance speed and quality, dialing in flash cure units to stabilize underbase before upper colors. Our prepress team evaluates whether a fifth color (highlight white) will enhance vibrancy without increasing hand beyond target spec.

Placement, Scale, and Registration Tolerances

Document placements (front, back, sleeve, hem) with exact centering logic, distances from collar seams, and dimensions per size. Registration tolerance for complex art may sit within ±1 mm on premium programs; establish acceptable limits aligned to mesh count, screen tension, and press speed.

From experience, we see two pitfalls: underestimated stroke width and underspecified underbase traps. We coach art teams to widen fine lines slightly and define traps so screenprint t shirts hold detail across thousands of pulls without misregistration. Our prepress crew flags risks before films print, saving both time and cost.

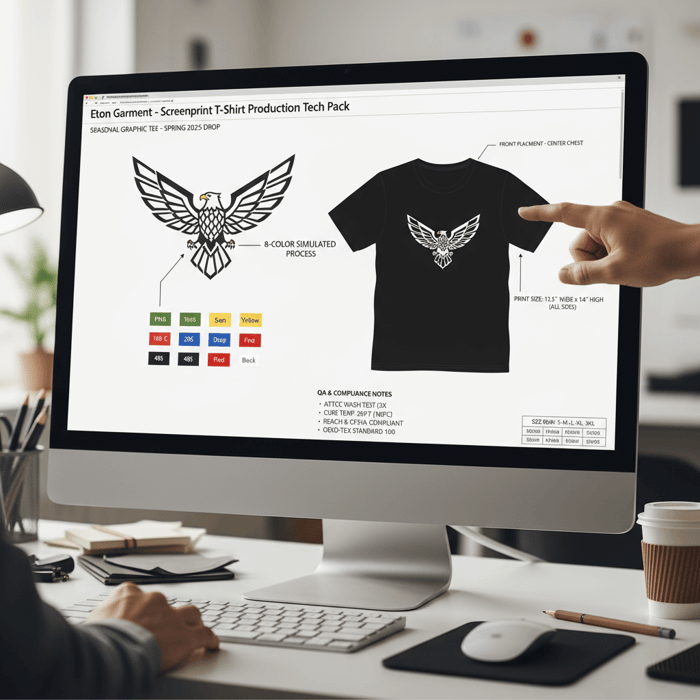

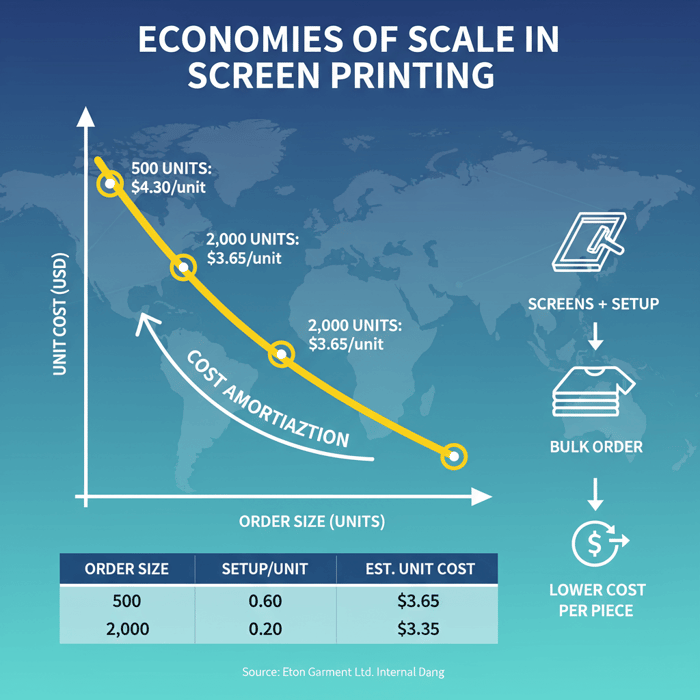

Screenprint T Shirts at Scale: MOQs, Lead Times, and Cost Drivers

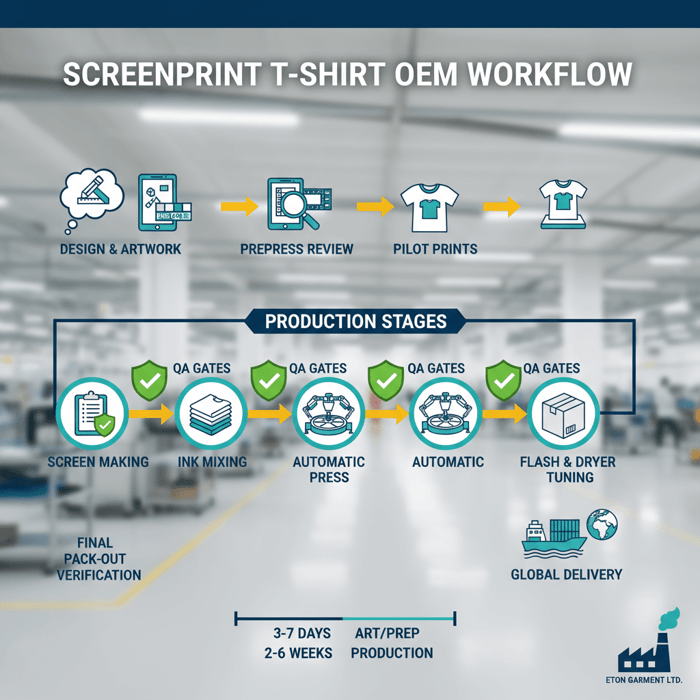

Scaling screenprint t shirts introduces setup economics and throughput planning—screens, films, squeegee passes, flash cures, and dryer capacity shape total cost. Garment blanks, color count, placements, and finishing requirements drive unit price. Eton scopes programs to match brand calendars, aligning capacity in China or Bangladesh to lead targets and compliance needs.

Answer-first summary: Budgeting for screen printing depends on setup (screens), color count, print placements, garment blanks, curing throughput, and order size. MOQs, lead times, and pricing tiers vary by region and compliance requirements.

Screen amortization lowers cost dramatically as volume rises. Production throughput insights guide realistic schedules.

| Order size (units) | Setup allocation (USD/unit) | Ink/print passes (USD/unit) | Blank garment (USD/unit) | Estimated unit cost (USD) |

|---|---|---|---|---|

| 500 | 0.60 | 1.20 | 2.50 | 4.30 |

| 2,000 | 0.20 | 1.05 | 2.40 | 3.65 |

| 10,000 | 0.05 | 0.95 | 2.30 | 3.30 |

MOQs and Lead Times by Method and Region

Typical MOQ for screenprint t shirts ranges from 500–1,000 units per design in China and 1,000–2,000 units in Bangladesh, with lower MOQs feasible for single-color runs or consolidated placements. Lead times vary based on ink system, color count, and finishing:

- China: 2–4 weeks for production after approvals; faster for single-color plastisol with stocked blanks.

- Bangladesh: 4–6 weeks after approvals; longer with water-based/discharge on custom-dyed fabrics.

- Prepress/art approvals: 3–7 days; faster with complete tech packs and PMS targets.

Compliance checks (REACH/CPSIA) and lab tests extend schedules, yet protect retail outcomes. We integrate AATCC wash testing in pilot runs to validate curing and colorfastness before mass output.

Pricing Components: Screens, Colors, Placements, and Blanks

Pricing blends fixed and variable elements. Screens and films represent fixed setup; color count and placements add variable cost through extra passes and presses. Ink type shifts both: plastisol supports strong opacity and faster cure; water-based requires controlled drying; discharge introduces chemistry and fabric-dye considerations. Blank garment quality—ringspun vs carded cotton, weight, and fabric finish—sets a baseline.

We itemize quotes: screen charges per color, per placement; unit adders for specialty inks (metallic, puff), and finishing (fold, bag, hangtag). Transparent breakdowns help procurement teams model retail margins for screenprint t shirts.

Landed Cost for US & EU: Freight, Duty, and INCO Terms

Landed cost includes FOB value, ocean or air freight, insurance, duties, customs fees, and last-mile delivery. Duty rates depend on HS codes, fabric composition, and country of origin; reference official tariff schedules for current rates.

For planning:

- INCO terms: FOB vs CIF vs DDP shift cost ownership and risk.

- Transit: 2–3 weeks by air; 4–6 weeks by ocean to US/EU gateways.

- Duty and VAT: Set pricing models with buffer for seasonal volatility.

We present landed cost scenarios alongside program timelines so screenprint t shirts arrive retail-ready without surprises.

Quality Assurance for Screenprint T Shirts: Testing, Standards, and AQL

Quality control for screenprint t shirts should track curing, adhesion, color consistency, and print registration from pilot to final shipment. A structured AQL plan, wash tests, and pantone checks safeguard brand standards and reduce returns. We align with AATCC methods for laundering and crocking, and ISO-based sampling for audit-ready results.

Answer-first summary: Implement AQL sampling, wash tests, and color checks to protect brand quality. Align with AATCC methods and set factory SOPs for curing, adhesion, and registration control.

For deeper context and factory protocols, see Quality control in manufacturing. We include checkpoints at incoming blank inspection, prepress film verification, first-off print approval, mid-run audits, and pack-out confirmation before sealing cartons.

Curing, Adhesion, and Wash Testing

Ink systems require specific cure windows—surface, dwell time, and temp must work in tandem. Plastisol often cures near 320°F; water-based and discharge depend on binder and activation chemistry. We record dryer temps with data loggers and use test strips to confirm cure before bulk.

AATCC laundering cycles and crocking tests verify adhesion and colorfastness. When prints underperform, we adjust belt speed, off-contact, or squeegee durometer, then revalidate in controlled wash tests for screenprint t shirts.

Registration, Color Consistency, and Pantone Checks

Registration drift stems from screen tension, press speed, and substrate variance. Our SOPs set tension thresholds and audit registration every set interval. Color consistency relies on PMS-matched inks and controlled viscosity; spectrophotometer readings confirm delta E values within agreed tolerances.

We document every ink mix and batch number so brands track traceability across seasons. This discipline protects logo programs and recurring graphics.

Pack-out, Labeling, and Retail Readiness

Retail readiness begins with clean fold styles, bagging, barcode label placement, and carton markings that match buyer manuals. We standardize instructions per customer spec, then audit pack-out with AQL sampling, weighing cartons and verifying label formats.

Our factory SOP builds checks into pack lines for screenprint t shirts: size ratio by carton, carton strength tests, and scan-to-ship workflows for traceability.

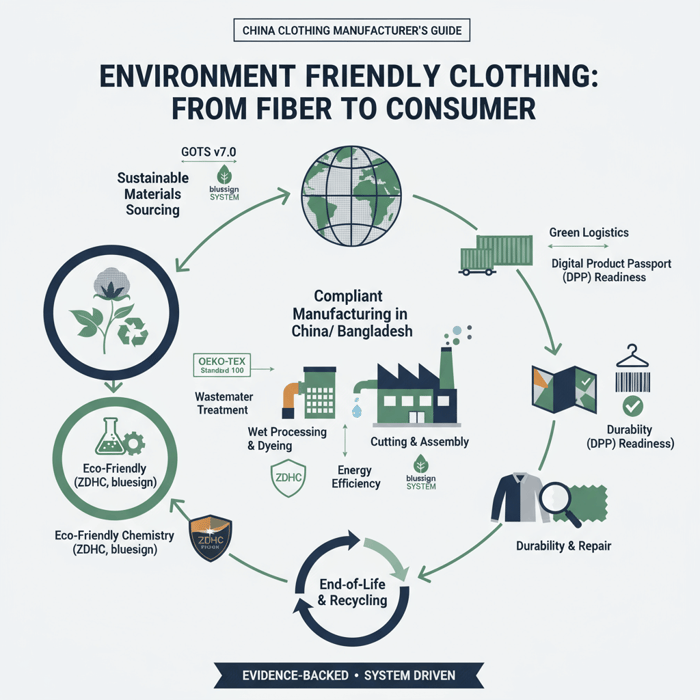

Compliance & Sustainability: Inks, Chemicals, and Certifications for US/EU Markets

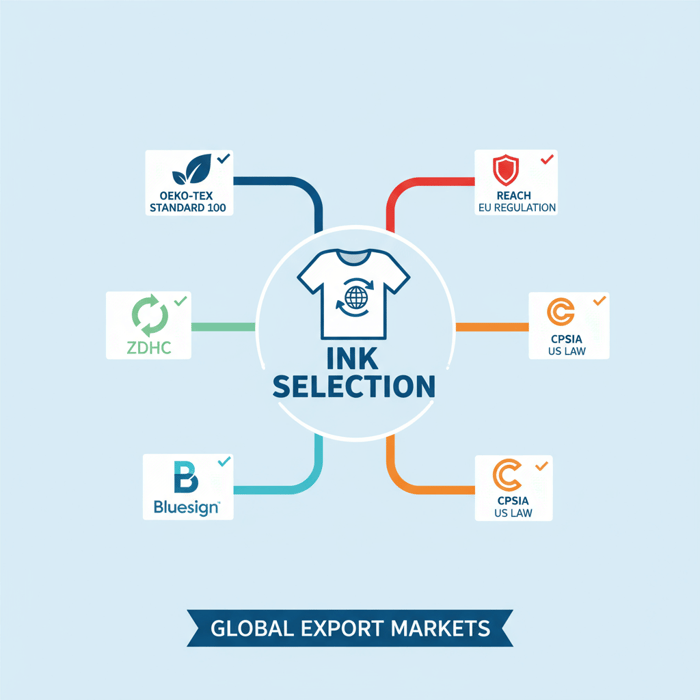

Compliance is the backbone of brand trust. Ink selection and chemical management must align with market rules and brand RSLs. We work under OEKO-TEX, ZDHC, and Bluesign frameworks for safer chemistry, and audit production sites under WRAP, BSCI, and Sedex. Every screenprint t shirts program maps to customer compliance needs before a single film prints.

Answer-first summary: Select inks and processes that meet EU REACH, CPSIA, and brand chemical lists. Certifications like OEKO-TEX, ZDHC, and Bluesign demonstrate safer chemistry and continuous improvement.

Explore our commitment to responsible production at Sustainability & compliance at Eton.

Chemical Compliance 101 (REACH, CPSIA)

Screenprint t shirts destined for the EU and US must respect EU REACH restrictions and CPSIA rules for children’s products. Monitor phthalates, heavy metals, azo dyes, and other substances flagged by regulators. We align lab tests to product scope—adult fashion, kidswear, promotional tees—to ensure lawful distribution.

Compliance documentation lives alongside QA files: MSDS sheets, supplier declarations, and test reports organized by PO and season.

Certification Pathways and Buyer Requirements

OEKO-TEX Standard 100 assures textile product safety; ZDHC Roadmap to Zero targets chemical management; Bluesign advances input stream controls. Ethical manufacturing standards such as WRAP, BSCI, and Sedex support social responsibility goals. Buyers often request mixed frameworks based on internal risk matrices.

We maintain audit-ready documentation and schedule renewals to keep screenprint t shirts programs compliant across regions.

Environmental Impact Reductions

Water-based systems, optimized curing, and responsible waste handling reduce environmental load. Closed-loop ink management, proper rag disposal, and energy-efficient dryers advance sustainability goals. Savings can be realized by tuning dryer temps, flash units, and screen reclaim processes.

We integrate certified fibers—GOTS organic cotton, recycled polyester yarns—and pair them with low-impact inks to elevate eco narratives for fashion brands.

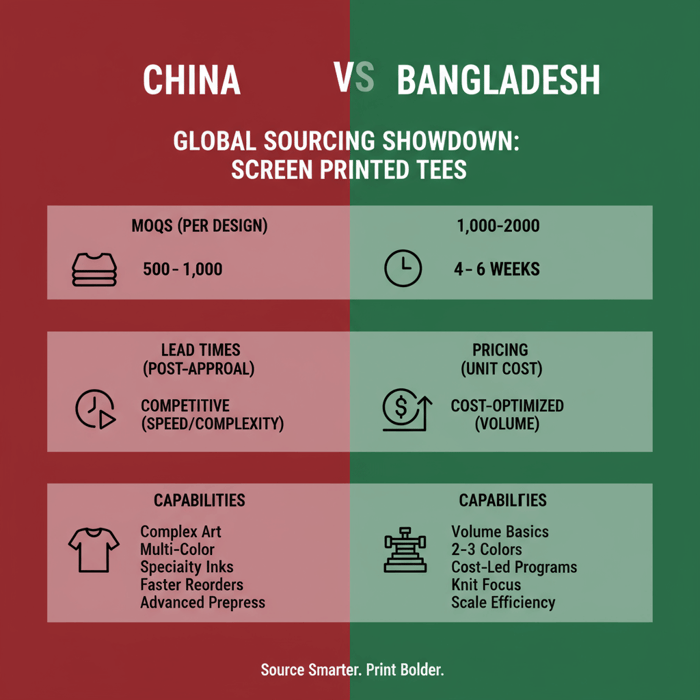

Sourcing Screenprint T Shirts: China vs. Bangladesh for Fashion Brands

Choosing a region depends on speed, price tiers, and capability depth. China offers high agility for complex art, short lead times, and robust prepress. Bangladesh excels in cost optimization and scale for basics, with strong knit foundations. Both markets deliver retail-grade screenprint t shirts under mature compliance frameworks when guided by the right partner.

Answer-first summary: China offers breadth of technology, shorter lead times, and robust prepress capabilities. Bangladesh offers competitive pricing and scale for basics. Both can meet compliance with the right partners.

Country-level apparel export statistics and audit prevalence provide context for regional sourcing decisions.

Capability, Lead Times, and Price Tiers

China supports complex separations, multi-location prints, and specialty inks with faster turns. Bangladesh favors single or dual placements with straightforward color counts, enabling strong unit economics. Price tiers reflect blank quality, ink systems, compliance scope, and finishing needs for screenprint t shirts.

Compliance Infrastructure and Audit Ecosystems

Both regions maintain deep audit ecosystems. China factories often integrate ISO 9001/14001 with buyer audits; Bangladesh sites uphold WRAP/BSCI/Sedex and brand-specific protocols. Our cross-region network aligns labs, certifications, and traceability so programs clear retail gates efficiently.

When to Choose Which Region

Pick China for premium art, water-based softness, faster reorders, and multi-graphic capsule drops. Choose Bangladesh for large volumes of logo tees, promo runs, and cost-led basics. Hybrid sourcing splits designs by complexity and price target, creating balanced calendars for screenprint t shirts.

Product/Service Integration: Clothing Manufacturing OEM Service by Eton

Eton Garment Limited coordinates artwork, screens, production, QC, and compliance across China and Bangladesh, delivering screenprint t shirts at scale with repeatable color and retail-ready pack-out. Three decades of manufacturing sharpened our SOPs for art prep, ink choice, curing, and AATCC testing.

Answer-first summary: Eton’s OEM service coordinates artwork, screens, production, QC, and compliance across China and Bangladesh, delivering brand-grade screenprint t shirts at scale with transparent timelines and testing.

Explore the full service scope at Clothing Manufacturing OEM Service.

| Brand need | OEM feature | Outcome |

|---|---|---|

| Pantone accuracy | PMS-matched ink lab and spectro checks | Color integrity across regions |

| Soft-hand premium tee | Water-based/discharge advisory and testing | Luxury feel with stable wash results |

| Bulk cost control | Transparent pricing and screen amortization planning | Predictable margins for large runs |

| Compliance | OEKO-TEX/ZDHC alignment, REACH/CPSIA lab plans | Regulatory peace of mind |

| Retail pack-out | Fold, bag, barcode, and carton SOPs | Store-ready delivery |

| Quality assurance | AATCC wash tests and AQL audits | Durability and lower returns |

| Speed | China press capacity, quick prepress | Shorter lead times |

Use Case 1: Launching a Multi-Color Brand Tee (Problem → Solution)

Problem: A European brand needed eight-color front art on black tees, strict PMS matches, and quick turn for a stadium drop.

Solution: We ran simulated process separations with an underbase plus highlight white. ROQ auto presses stabilized registration with tuned off-contact and flash cure. Spectro checks held delta E within tolerance. Pack-out hit barcode formatting and carton labels per buyer manual. Screens amortized across 15,000 units, strengthening unit economics for screenprint t shirts.

Use Case 2: Cost-Optimized Promo Tee Program (Problem → Solution)

Problem: A US retailer required sharp two-color logo tees with aggressive price points for a nationwide promo.

Solution: We advised plastisol for opacity and speed, consolidated placements, and selected a stable ringspun blank. Cost modeling clarified MOQs and tiered pricing, including landed cost scenarios. AQL checkpoints trimmed defects, and ocean freight timing met the launch calendar.

Use Case 3: Sustainable Capsule with Water-Based Prints (Problem → Solution)

Problem: A premium label sought soft-hand prints on GOTS organic cotton with a sustainability story.

Solution: We implemented water-based inks aligned with OEKO-TEX and ZDHC guidance. Dryer calibration ensured binder activation without over-curing. AATCC wash tests validated durability. Marketing gained traceable inputs and audited chemistry, elevating the capsule’s narrative for screenprint t shirts.

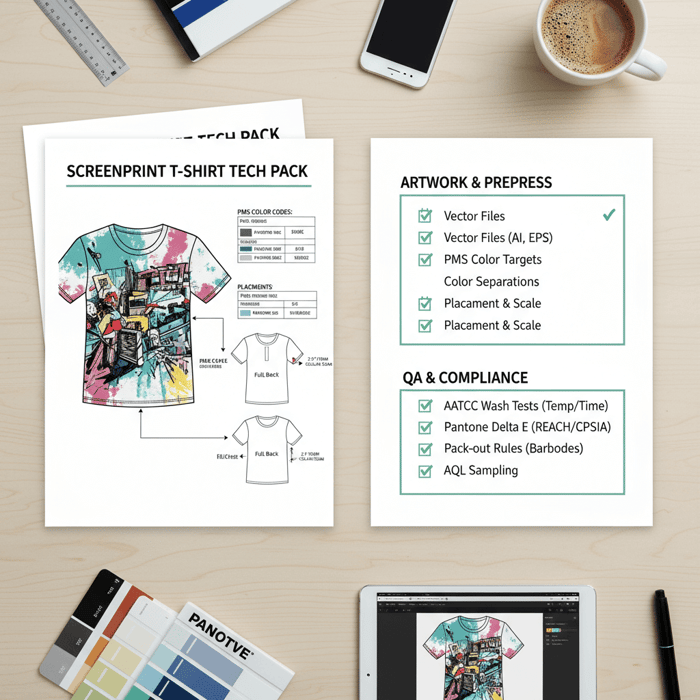

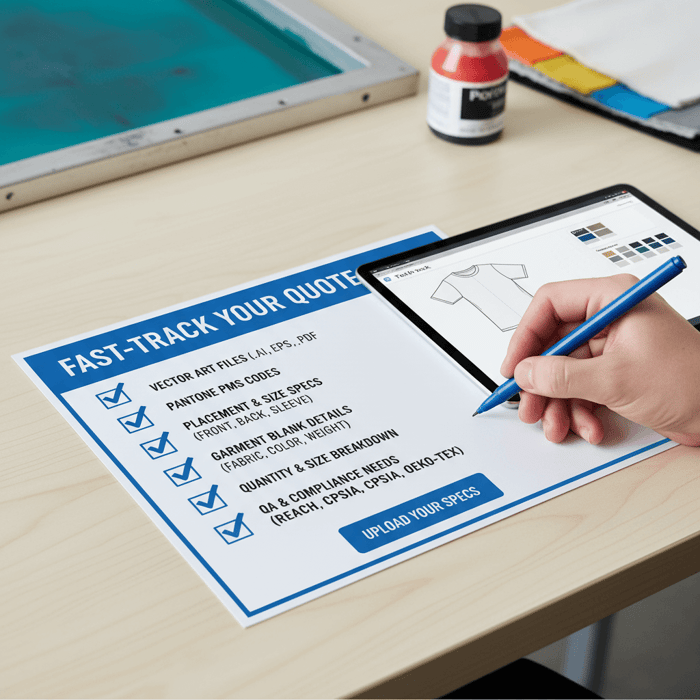

Tech Pack & PO Checklist for Screenprint T Shirts

Screenprint t shirts succeed when tech packs are complete and precise. Consolidate art files, PMS codes, separations, placements, size scales, QA plans, and pack-out rules. This clarity streamlines prepress, compresses approvals, and protects budgeting.

Answer-first summary: A thorough tech pack minimizes revisions: vector files, PMS references, color separations, placements, garment specs, QA tests, pack-out instructions, and compliance notes.

For support, reach us via Contact Eton. Reference buyer manuals and procurement playbooks where available.

Artwork, Color, and Placement Fields

- Master vector file; embedded or outlined fonts.

- PMS codes for each color; light/dark garment strategies.

- Separations: Spot vs CMYK/simulated process; underbase notes.

- Placements: front/back/sleeve/hem with distances and centering logic.

- Scale tables per size; tolerances for registration and print dimensions.

- Specialty inks or effects: puff, metallic, high density.

QA, Testing, and Compliance Fields

- AATCC test plan: laundering, crocking, dimensional change.

- Ink cure specs: temperature/time; dryer model and belt speed.

- Pantone acceptance: delta E target range; spectro workflow.

- Compliance: REACH/CPSIA scope; OEKO-TEX/ZDHC expectations.

- Pack-out rules: fold, bag, barcode label, carton markings.

- AQL sampling level, acceptance criteria, and audit cadence.

FAQs: Screenprint T Shirts for Fashion Brands

To simplify early decisions, here are quick answers to common sourcing questions for screenprint t shirts. These points support brand teams as they finalize tech packs, negotiate tiers, and lock calendars.

Answer-first summary: Quick answers to common sourcing questions including minimums, timelines, fabric choices, and color matching.

What are typical MOQs for bulk orders?

Expect 500–1,000 units per design in China and 1,000–2,000 units in Bangladesh, with flexibility for single-color runs and consolidated placements. MOQs depend on color count, finishing, and lab test scope. We quote scenarios that align MOQ with calendar and margin targets.

How long do screenprint t shirts last compared to DTG?

With correct cure and ink selection, screenprint t shirts often deliver stronger wash durability than DTG. DTG excels in small runs and photo-real art, yet wash performance depends on pretreatment and cure control. Validate with AATCC laundering tests and crocking checks.

Can we achieve exact brand colors?

Yes—PMS-matched inks and spectrophotometer checks hold color within agreed delta E tolerances. Define acceptance ranges per program and use robust underbase on dark garments to protect vibrancy. Document ink batches for traceable repeatability.

What’s the ink choice for a soft-hand premium tee?

Water-based inks and discharge printing deliver a soft, fabric-integrated feel. Confirm fabric dye chemistry and run wash tests before mass output. For dark tees, underbase strategies and highlight passes refine vibrancy while keeping hand within brand targets.

Next Steps: Get a Costed Quote and Prepress Review

Ready to launch screenprint t shirts at scale? Submit art files and specs for a prepress review and a transparent quote. We advise on ink systems, separations, curing, QA planning, and compliance alignment for US/EU markets.

Answer-first summary: Submit artwork files and specs for a prepress review and costed quote. Eton advises ink choice, separations, curing, and QA planning for US/EU compliance.

Start here: Start your OEM screenprint program. Include vector art, PMS codes, placements, size scales, and any compliance requirements so we build scenarios quickly.

We return timelines, capacity allocations, and QA plans that match your calendar. Expect clear schedules for pilot prints, approvals, production, pack-out, and booking, with test reports attached to each PO. “Textile From Day One.” guides our commitment to speed, reliability, and brand-grade execution.

Author & Review Notes (E-E-A-T)

- Author: Eton Editorial Team, Industry Analyst, Outerwear & Knits

- Reviewer: Technical Prepress Lead (Eton), QA & Compliance Manager (Eton) – to be assigned

- Methodology: Synthesis of industry standards, certification frameworks, and Eton’s OEM workflows; external sources flagged for verification prior to publication.

- Last Updated: 2025-10-15

About Eton: Eton Garment Limited is a professional clothing manufacturer and garment factory with 30+ years serving global retailers. Our OEM/ODM programs coordinate screenprint t shirts across China and Bangladesh with artwork support, compliance, and AATCC-aligned QA. We help fashion brands scale through design precision, transparent cost models, and reliable delivery—powered by a mature China Clothing Manufacturer network and cross-border execution.

FAQs

What are screenprint t shirts and why do fashion brands use them for bulk orders?

How can a China clothing manufacturer support screenprint t shirts sourcing at scale?

What are typical MOQs for screen printing t-shirts in China and Bangladesh?

What lead times should we expect for screenprint t shirts by region?

When should plastisol ink be chosen for screenprint t shirts?

When are water-based inks best for premium screen-printed tees?

What is discharge printing for t-shirts and when is it suitable?

DTG vs screen printing: which is better for durability and scale?

Heat transfer vs screen printing: when to use each?

Which fabrics offer the best fabric compatibility and hand-feel for screenprint t shirts?

What file types and vector artwork standards are required for screenprint t shirts?

How do Pantone PMS codes improve color matching in screen printing?

How do color separations and underbase strategy affect prints on dark garments? (Grouped keywords: color separations, underbase)

What registration tolerances are realistic for screenprint t shirts?

How does AATCC wash testing validate curing and durability?

What cure temperature and dwell time are recommended for common ink systems?

How are spectrophotometer checks and delta E targets used for Pantone accuracy? (Grouped keywords: spectrophotometer, delta E)

Which certifications matter: OEKO-TEX, ZDHC, and Bluesign for screenprint t shirts? (Grouped keywords: OEKO-TEX, ZDHC, Bluesign)

What do REACH and CPSIA require for screen-printed t-shirts in the US/EU?

What do WRAP, BSCI, and Sedex audits cover for garment factories?

How do INCO terms, HS codes, and duty shape landed cost for US/EU shipments? (Grouped keywords: INCO terms, HS codes, landed cost)

How do ROQ and M&R automatic presses improve screen printing consistency and speed?

What AQL sampling levels should brands set for screenprint t shirts?

What pack-out and labeling requirements ensure retail readiness for screenprint t shirts?

What should a tech pack checklist include for bulk screen-printed t-shirt production?

What pricing components drive unit cost and economies of scale in screen printing? (Grouped keywords: pricing components, unit cost, economies of scale)

China vs Bangladesh: which region should you choose for screenprint t shirts?

Related Articles

Chinese dress shop vs China clothing manufacturer: how brands move from retail inspiration to scalable OEM/ODM

10 minute read

October 15th, 2025

Chinese dress shop vs China clothing manufacturer: how brands move from retail inspiration to scalable... more »

American Made T Shirts Wholesale: The Buyer’s Guide (and When a China Clothing Manufacturer Is Better)

15 minute read

October 15th, 2025

American Made T Shirts Wholesale: The Buyer’s Guide (and When a China Clothing Manufacturer Is... more »

Polo Manufacturers: Top China Clothing Manufacturer Options for Fashion Brands in US & EU Markets

11 minute read

October 14th, 2025

Polo Manufacturers: Top China Clothing Manufacturer Options for Fashion Brands in US & EU... more »

Environment Friendly Clothing: A China Clothing Manufacturer’s Guide for US & EU Fashion Brands

18 minute read

October 14th, 2025

Environment Friendly Clothing: A China Clothing Manufacturer’s Guide for US & EU Fashion... more »