Environment Friendly Clothing: A China Clothing Manufacturer’s Guide for US & EU Fashion Brands

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 14th, 2025

18 minute read

Table of Contents

- What Is Environment Friendly Clothing? Definitions, Standards, and Scope

- Materials & Lifecycle Impacts for Environment Friendly Clothing

- How to Build an Environment Friendly Clothing Line with OEM Manufacturing

- Choosing an Environment Friendly Clothing Manufacturer in China

- Sustainable Materials and Trade-offs: A Decision Framework

- Product/Service Integration: Clothing Manufacturing OEM Service (Eton)

- Risks, Compliance & Localization for US & EU

- Conclusion & Next Steps

- FAQs

Environment Friendly Clothing: A China Clothing Manufacturer’s Guide for US & EU Fashion Brands

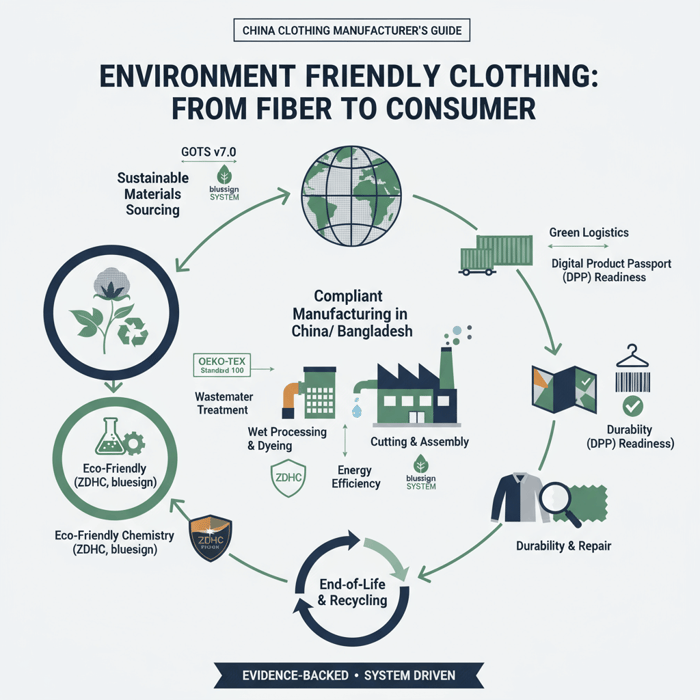

Environment friendly clothing, built with a trusted China Clothing Manufacturer, cuts impact across materials, chemicals, water, and logistics while keeping performance, cost, and lead times on track for US/EU brands. This guide clarifies standards (GOTS, OEKO-TEX, bluesign, ZDHC), breaks down outerwear trade-offs (PFC-free DWR, insulation, seam sealing), and maps a practical OEM/ODM execution plan you can audit.

Environment friendly clothing minimizes environmental harm across materials, dyes/finishes, manufacturing, packaging, and logistics while meeting performance and compliance needs. Look for credible standards (GOTS, OEKO-TEX, bluesign, ZDHC), verifiable data, and factory practices that reduce water, chemicals, and carbon—especially when partnering with a China clothing manufacturer.

Environment friendly clothing, within the China Clothing Manufacturer context, means building apparel that measurably reduces environmental impacts end to end—materials, wet processing, packaging, and logistics—while meeting US/EU performance and regulatory expectations. This article translates intent into execution: definitions and standards, material trade-offs, wastewater/chemistry controls, and a factory-vetting framework for China and Bangladesh. You’ll get a step-by-step OEM roadmap, decision tables for outerwear materials and finishes, and localization for EU Digital Product Passport readiness, PFAS trends, and green-claims compliance. Eton’s Clothing Manufacturing OEM Service integrates sustainable sourcing, technical development, bulk production, and quality control under one system—turning sustainability targets into reliable delivery at scale. Textile From Day One.

What Is Environment Friendly Clothing? Definitions, Standards, and Scope

Environment friendly clothing is apparel designed and manufactured to measurably reduce environmental impacts across the lifecycle. Verified standards and data—not slogans—anchor claims: materials, chemical inputs, water and energy intensity, packaging, logistics, durability, repair, reuse, and end-of-life options all count.

- Materials: Organic/regenerative fibers, recycled synthetics, certified cellulosics.

- Chemicals: Restricted substances lists (RSLs/MRSLs), safer chemistries, SDS documentation.

- Water/Energy: Efficient wet processing, wastewater treatment, metered energy, and cleaner power.

- Packaging: Recycled content, mono-materials for easy recycling, minimized overpack.

- Logistics: Consolidated shipments, ocean over air, route efficiency, emissions visibility.

- Durability: Longer product life through robust construction, repair access, care guidance.

- Circularity: Design for reuse, remanufacture, and material recovery with traceable claims.

[MENTION: UNEP’s systems view of the textile value chain] and [MENTION: European Commission Textiles Strategy] frame impact hotspots and interventions. To avoid greenwashing, align with chain-of-custody standards and require testable evidence at every stage. [CITE: A current policy brief explaining lifecycle scope in textiles].

Terminology and Boundaries

Eco-friendly (environment friendly) clothing focuses on measurable environmental reductions. Sustainable apparel balances environmental, social, and economic pillars over time. Ethical apparel emphasizes human rights, wages, and safe work. Circular apparel designs out waste and keeps materials in use. All intersect, but claims should match evidence and scope: a garment can be environment friendly by using ZDHC-conformant dyes and recycled fabric without covering social certifications unless stated.

Scope setting matters. Define which lifecycle stages are in play (fiber to finished goods, packaging, logistics) and which indicators will be measured (water intensity, chemical conformance, recycled content percentage). Document inclusions/exclusions upfront in briefs to keep claims accurate. [CITE: A standards handbook on scope and chain-of-custody].

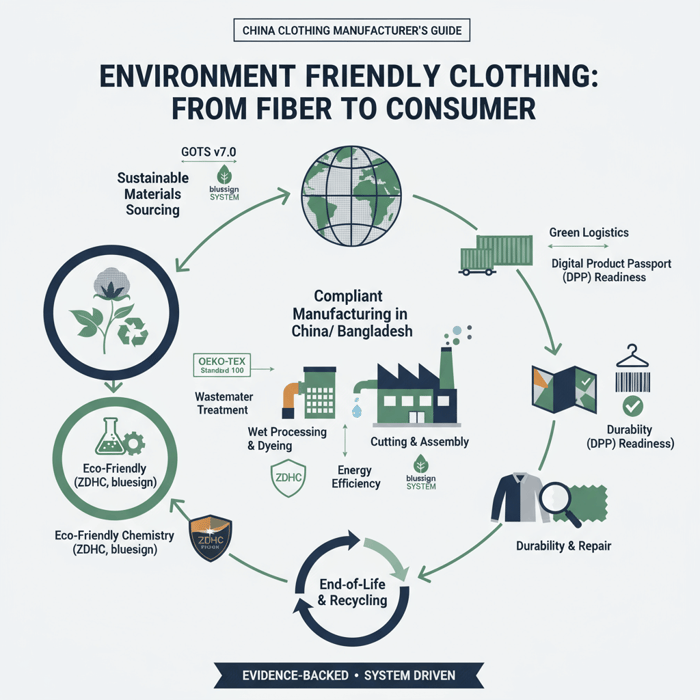

Certifications and What They Prove

Certifications vary by stage and scope. GOTS v7.0 certifies organic fiber processing with environmental and social criteria across the chain; bluesign focuses on input chemistry and resource efficiency at the mill level; OEKO-TEX Standard 100 tests finished goods for harmful substances; ZDHC’s MRSL governs input chemicals and its wastewater guidelines validate treatment performance. Chain-of-custody is crucial: a certified fiber doesn’t make the whole garment certified unless each stage maintains scope and documentation.

Ask for current scope certificates (with facility names), transaction certificates for certified shipments, and finished-goods test reports. Verify expiry dates and lab accreditation. In China and Bangladesh, align mill-level bluesign or ZDHC participation with garment factory RSL management and production records. [MENTION: OEKO-TEX updates 2024] and [MENTION: ZDHC Roadmap to Zero] provide aligned frameworks. [CITE: Official GOTS v7.0 documentation], [CITE: bluesign chemical management overview].

Materials & Lifecycle Impacts for Environment Friendly Clothing

Select materials with verified impact data and performance fit. Prioritize organic/regenerative cotton, recycled polyester/nylon (rPET/ECONYL), TENCEL Lyocell, and hemp. Align dyes and finishes with the ZDHC MRSL and adopt PFC-free water repellents where the end-use permits. Validate each claim with supplier declarations, transaction certificates, and test reports.

- Global apparel fiber mix trending toward synthetics remains above 60% — 2023 [CITE: An industry fiber mix report].

- ZDHC MRSL adoption expanded across Asia mill networks — 2024 [CITE: ZDHC annual progress update].

- OEKO-TEX added more restricted substances in 2024, tightening PFAS scrutiny — 2024 [CITE: OEKO-TEX 2024 Highlights].

- EU plans phase-ins for Digital Product Passport data exchange for textiles — 2025+ [CITE: European Commission DPP brief].

Recycled polyester can lower virgin petrochemical demand and reduce energy intensity, yet microfiber release risks persist. Pair rPET with robust fabric constructions, tighter yarn systems, and care guidance (gentle cycles, filters) to mitigate. For outerwear, consider rPET shell fabrics with PFC-free DWR and tested seam sealing compatibility. [MENTION: WRAP Textiles 2030], [MENTION: McKinsey/BoF State of Fashion]. [CITE: A peer-reviewed study on microfiber mitigation].

Priority Materials and When to Use Them

Organic cotton: Best fit for casual pieces, liners, and shells where breathability matters; watch variability in staple length and finish absorbency. Regenerative cotton: Similar to organic with soil-health benefits; seek credible farm-level verification. TENCEL Lyocell: Strong for drape and moisture management in shells and mid-layers; confirm abrasion resistance for heavy-duty use. Hemp: Durable and breathable with lower pesticide use; blend for handfeel and wrinkle moderation. Recycled polyester (rPET): Go-to for outerwear shells and insulation; specify denier/finish to balance handfeel and abrasion resistance. Recycled nylon/ECONYL: Suited to high-abrasion zones and performance shells; confirm dye uptake and finish compatibility.

Outerwear note: Pair shells with linings and interlinings that support breathability and comfort. Set hydrostatic head and air permeability targets in tech packs. Test PFC-free DWR durability with multi-wash protocols and rain-room validation. [CITE: A technical paper on DWR performance testing], [MENTION: bluesign-approved mills for outerwear].

Chemicals, Dyeing & Finishing

Align mills with the ZDHC MRSL; require SDS for all input chemicals and insist on conformance letters. Use lab dips to lock color and plan bulk controls to avoid re-dye waste. Check color fastness (wash, rub/crocking, light) and, for outerwear, validate seam-seal chemistries against PFC-free finishes. Build a finish matrix showing acceptable combinations for each shell fabric to reduce rework. In China and Bangladesh, review wastewater results against ZDHC guidelines and local permits; ask for independent lab data with recent sampling dates.

Finish reliability hinges on test cadence: pilot yardage, then SMS, then PP bulk. Capture finish lot numbers, application parameters, and oven curves. For PFC-free DWR, retest after 5 and 10 washes for spray rating and dynamic rain performance. [CITE: ZDHC wastewater guideline], [MENTION: OEKO-TEX ECO PASSPORT for chemicals].

Durability, Care, and End-of-Life

Durable garments often beat short-lived “biodegradable” options on net impact. Engineer for abrasion, seam strength, and component longevity (zippers, snaps). Provide care instructions that minimize water and energy (cold wash, line dry) and consider modular repair features (replaceable toggles, accessible linings). End-of-life: leverage mono-material shells or separable constructions to ease recycling; consider take-back or resale pathways; include material coding in care labels to aid sorting.

Document recycled-content percentages and adhesives used (some hinder recycling). Track batch IDs so material recovery partners can verify inputs. [CITE: A lifecycle assessment comparing durability vs. biodegradability], [MENTION: European Environment Agency overview].

How to Build an Environment Friendly Clothing Line with OEM Manufacturing

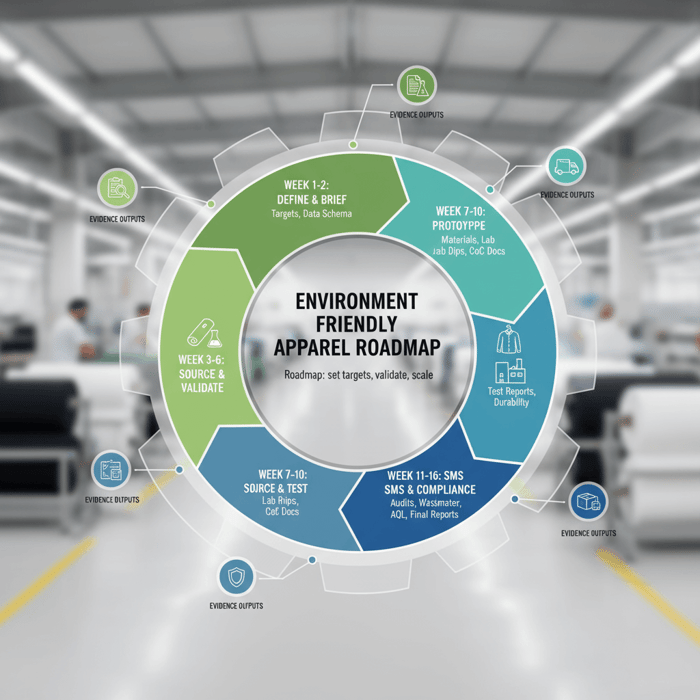

Turn intent into a production plan: set targets, lock materials and chemistries, validate via sampling and testing, and scale with monitored compliance. Use phased gates—brief, proto, SMS, PP—each with sustainability checkpoints and documentation you can audit.

- Set targets (materials %, MRSL alignment, wastewater KPIs, DPP data model) → Produce a design brief in 1–2 weeks.

- Source and validate materials → Secure lab dips, data sheets, and chain-of-custody docs in 2–4 weeks.

- Prototype and test (care, durability, performance) → Obtain third-party test reports in 2–3 weeks.

- SMS and compliance checks (Higg FEM/shared audits) → Sign declarations of conformity in 3–5 weeks.

- PP and bulk QC (AQL + wastewater tests) → Prepare shipment readiness in 4–8 weeks.

Timelines vary by season, mill capacity, and finish complexity. Lock chemistries early to avoid late-stage rework. Keep DPP data fields ready from day one. [CITE: A sourcing timeline benchmark], [MENTION: Higg FEM platform owner].

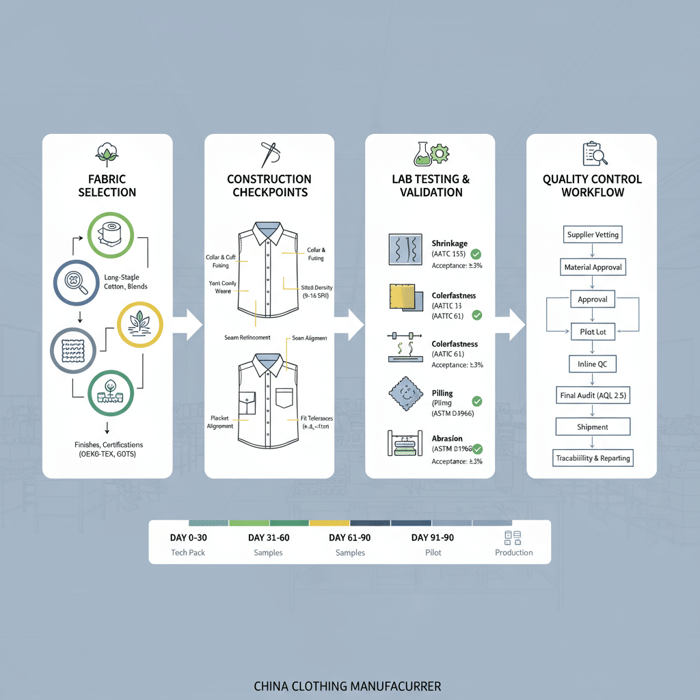

Preparation (Targets, Tech Packs, BOM)

Translate sustainability goals into measurable targets: recycled-content percentages, organic scope, MRSL alignment, wastewater parameters, energy mix, and DPP attributes. Build tech packs with material codes, expected test methods (e.g., ISO/ASTM for color fastness, hydrostatic head), and care label requirements. Populate BOMs with cert scope IDs, transaction certificates, and SDS links. Add a data schema for DPP (material composition, origin, process steps, repair guidance) to avoid retrofitting later.

For China Clothing Manufacturer partners, specify acceptable mills and finish houses, with backup options for seasonal capacity. Include routing plans for consolidated shipments. [INTERNAL LINK: Our foundational guide on sustainable tech packs], [CITE: EU DPP technical overview].

Execution Steps (Sampling to PP)

Prototype: Build size set samples and validate fit and construction. Testing: Run abrasion, seam strength, color fastness, and DWR durability. SMS: Confirm color stability and finish reproducibility across small runs; check wastewater data during the same window. PP: Approve bulk-ready samples with finish lot documentation and chain-of-custody confirmations. Record each gate with report IDs, SDS files, MRSL conformance letters, and audit references.

Evidence ties the process together: lab certificates, bluesign or ZDHC participation documents, OEKO-TEX finished-goods tests. Keep a shared tracker for timestamps and lab IDs. [MENTION: BSCI audit framework], [CITE: ISO 14001 systems guidance].

Quality Assurance (In-Line + Final)

Align AQL sampling with eco criteria: retest PFC-free water repellency after washes; check seam seals on finished garments; verify color fastness on multi-batch productions. In-line inspections capture construction deviations early; final inspections focus on performance and cosmetic consistency. Hold a corrective-action loop for finish drift or unexpected test failures.

Factory-level wastewater checks should align with ZDHC guidelines and local permits; keep results linked to production weeks and finish lines. In Bangladesh and China, confirm third-party lab credentials and randomize sampling. [CITE: An audit case study on wastewater testing cycles].

Choosing an Environment Friendly Clothing Manufacturer in China

Evaluate manufacturers on certifications, chemistry governance (ZDHC alignment), wastewater controls, energy profile, and traceability. Verify with audits, Higg FEM sharing, test reports, and production record checks—not brochures or unchecked claims.

| Criteria | Evidence Required | Red Flags |

|---|---|---|

| Certifications | Valid scope certificates (GOTS v7.0, OEKO-TEX) with facility names and expiry dates | Expired certificates, partial coverage, or mismatched facility names |

| Chemistry | ZDHC MRSL conformance letters and SDS for input chemicals | No MRSL policy, refusal to share SDS or conformance letters |

| Wastewater | Third-party lab results mapped to production weeks and finish lines | Self-declared data only; no lab credentials; infrequent testing |

| Energy/Carbon | Metered energy, KPI trends, and renewable energy certificates | No metering or energy tracking; missing baselines |

| Traceability | Batch-level chain-of-custody and declarations of conformity | Gaps post-dyeing; inconsistent lot tracking |

Certificates at the garment factory level are insufficient without upstream mill compliance. Demand fabric-mill evidence for chemistry and wastewater, and ensure scope covers each step. [MENTION: Common Objective fiber guide], [CITE: A traceability best-practice report].

Garment factory capabilities should be transparent across sites in China and Bangladesh, with aligned processes for wet finishing, audits, and data sharing. [INTERNAL LINK: Our outerwear sourcing hub].

Audit & Data-Sharing Tools (Higg FEM, BSCI, ISO 14001)

Triangulate data: combine Higg FEM facility modules with BSCI social audits and ISO 14001 environmental management systems. Check that audit scopes match the processes in question (e.g., wet processing vs. CMT-only). Request audit summary reports, corrective-action timelines, and the status of remediation. Share selected audit outcomes with retailers through established platforms.

Use shared dashboards to map audit dates, lab test IDs, wastewater sampling weeks, and finish lot records. A consistent “evidence trail” increases trust and speeds approvals. [CITE: Higg FEM methodology], [MENTION: amfori BSCI guidance].

On-Site Validation & Pilot Runs

For DWR and seam sealing, start with pilot runs to validate finish stability and process SOPs. Conduct on-site reviews of chemical stores, mixing logs, and application lines. Run small-lot yardage across different line settings to confirm reproducibility. Document oven curves and seam-seal parameters.

Once validated, scale with tighter QC and frequent finish lot sampling. Keep a playbook documenting chosen chemistries, the compatible shell fabrics, and allowable ranges. [CITE: A pilot-run case note], [MENTION: bluesign system partners in China].

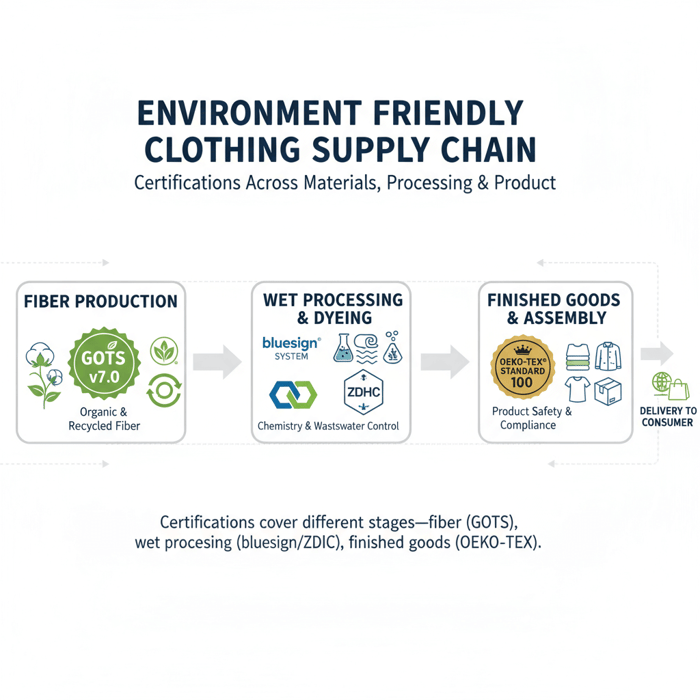

Sustainable Materials and Trade-offs: A Decision Framework

Use criteria-based scoring that weighs impact, performance, cost, and risk. Avoid absolutes—choose the best fit for each garment’s end-use, care habits, and expected lifetime. Combine recycled content with durable construction and verified chemistry.

| Material | Impact | Performance | Cost | Notes |

|---|---|---|---|---|

| Organic Cotton | Medium (lower pesticides; variable yields) | Breathable; moderate abrasion | Medium | Good for liners/shells in casual outerwear |

| TENCEL Lyocell | Low–Medium (closed-loop solvent) | Excellent drape; moisture management | Medium | Blend for abrasion; confirm finish compatibility |

| Hemp | Low (low pesticide use) | Breathable; strong; wrinkles | Medium | Blend to soften hand; durable shells |

| Recycled Polyester (rPET) | Medium–Low vs. virgin | Abrasion-resistant; DWR-friendly | Low–Medium | Manage microfiber risk; validate PFC-free DWR |

| Nylon 6/ECONYL | Medium–Low vs. virgin | High abrasion; strong shells | Medium–High | Check dye uptake; finish and seam seal |

- Recycled fiber availability improving across rPET and nylon — 2023–2024 [CITE: A global recycled fiber supply brief].

- PFAS restrictions tightening across US/EU markets — 2024–2025 [CITE: A regulatory tracker on PFAS in textiles].

- Bluesign and ZDHC participation rising among Asia mills — 2024 [CITE: bluesign/ZDHC participation stats].

Criteria Overview

Impact: pesticide use, energy intensity, water footprint, chemical toxicity profiles. Performance: abrasion resistance, hydrostatic head, air permeability, DWR durability, seam-seal compatibility. Cost: raw material pricing, finish costs, testing outlay. Risk: claim substantiation, supply volatility, regulatory exposure (PFAS, green claims), rework probability.

Weight criteria by garment function. A commuter parka needs durable PFC-free DWR and strong seam seals; a fashion bomber can bias toward drape and handfeel with moderate weather resistance. [CITE: A test method guide for outerwear], [MENTION: retailer chemistry policies in EU/US].

Decision Framework

Score each material against weighted criteria. Build a short list that meets the garment’s use case and compliance targets. Pilot chemistry combinations early to reduce rework: match shell fabric with a tested PFC-free DWR and seam tape that survives wash cycles. Track test results, finish lots, and cost impacts in one sheet linked to your BOM.

Document trade-offs openly: for a high-abrasion shell, recycled nylon might outperform TENCEL; for breathability and drape, TENCEL wins. Keep recycled-content claims tied to transaction certificates. [CITE: A chain-of-custody primer], [MENTION: WRAP durability guidance].

Product/Service Integration: Clothing Manufacturing OEM Service (Eton)

Eton’s OEM service turns sustainability goals into production reality: certified materials sourcing, ZDHC-aligned chemistry workflows, wastewater testing, and rigorous QC—engineered for outerwear performance in China and Bangladesh.

| Brand Need | Eton OEM Feature | Outcome |

|---|---|---|

| Verified eco-materials | Pre-vetted mills and chain-of-custody management | Authentic recycled/organic claims with audit-ready docs |

| PFC-free DWR in outerwear | Finish selection and durability testing protocol | DWR performance validated with wash and rain-room tests |

| DPP-ready traceability | Batch-level data capture across gates | Structured data for future EU Digital Product Passports |

| Compliance assurance | Audit triangulation and third-party test reports | Lower recall risk; faster retailer approvals |

Eton Garment Limited operates across China and Bangladesh with three decades of outerwear manufacturing, serving global partners like Liverpool F.C., Forever 21, and TFG Group. We focus on cold-weather and performance markets, where finish reliability, seam sealing, and QC decide customer trust. Start a project with our Clothing Manufacturing OEM Service.

Use Case 1: PFC-free Parka—Problem → Solution

Problem: A US retailer mandates PFAS-free finishes but requires rain performance over multiple washes. Solution: We selected a bluesign-approved PFC-free DWR compatible with a recycled polyester shell, locked seam-seal tape chemistry, and ran 0/5/10-wash spray rating tests plus rain-room trials. Bulk SOPs documented finish application and oven curves. Outcome: Pass rates above target with stable handfeel and consistent color.

Documentation included SDS, MRSL conformance letters, wastewater reports aligned to production weeks, and OEKO-TEX finished-goods tests. [CITE: A PFC-free finish durability study], [MENTION: OEKO-TEX Standard 100 testing protocols].

Use Case 2: Recycled-Content Insulated Jacket—Problem → Solution

Problem: A EU brand wants 70% recycled content in shell, lining, and insulation, with controlled microfiber risk. Solution: We sourced rPET shell and lining from ZDHC-engaged mills and recycled insulation with documented chain-of-custody. Construction optimized stitch density and fabric tightness to reduce fiber release. Outcome: Verified recycled-content percentages, stable color fastness, and abrasion performance within spec.

Evidence included transaction certificates, Higg FEM data sharing, and third-party lab tests. Care labels guided washing to limit shedding. [CITE: A microfiber release mitigation report], [MENTION: Common Objective recycled fiber insights].

Risks, Compliance & Localization for US & EU

Plan for evolving regulations: EU textiles strategy and DPP readiness, PFAS trends, green-claims substantiation, and due diligence expectations. Align claims with certification-backed evidence and maintain audited trails from mill to finished goods, including wastewater and chemistry data.

- Pros: Higher brand trust; access to retailers with stricter RSL/MRSL; lower recall and reputational risk.

- Cons: More documentation; potential cost premiums; longer development cycles for finish validation and testing.

Risk Matrix

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| PFAS non-compliance | Medium | High | Adopt PFC-free chemistries; third-party testing; SOP validation |

| Green claims disputes | Medium | High | Cert-backed evidence; chain-of-custody; audit trails |

| Wastewater violations | Low–Medium | High | Regular testing; ZDHC alignment; independent labs |

| Supply volatility | Medium | Medium | Backup mills; flexible MOQ planning; diversified routes |

Regulatory Notes for US & EU

EU: The textiles strategy pushes durability, repairability, and DPP-enabled transparency. Prepare structured data models for composition, origin, process steps, and care guidance. PFAS restrictions continue to tighten, impacting water repellents and seam-seal chemistries. Claims require robust evidence under green-claims proposals. [CITE: European Commission textiles strategy], [CITE: DPP updates].

US/UK: Retailer-specific RSLs and state-level PFAS rules vary. Align with OEKO-TEX updates and MRSL frameworks to reduce conflict across buyers. Keep counsel involved for labeling and claim substantiation. [MENTION: European Environment Agency], [CITE: A PFAS regulatory summary for apparel].

Conclusion & Next Steps

Environment friendly clothing is a system. Define targets, pick the right materials and chemistries, validate with testing, and partner with a China clothing manufacturer that can prove compliance and performance at scale with traceable data.

- Week 1–2: Define targets, brief, and DPP-ready data schema.

- Week 3–6: Source and validate materials; lock lab dips.

- Week 7–10: Build prototypes; complete test reports.

- Week 11–16: SMS, audits, wastewater checks; sign declarations.

- Week 17–24: PP approvals; bulk QC and shipment.

[INTERNAL LINK: Outerwear sustainability resource hub] to deepen each step with templates and SOPs. Eton’s team in China and Bangladesh can co-own this roadmap from design to delivery while meeting US/EU retail expectations.

Author: Senior Apparel Sustainability & Sourcing Lead (10+ years OEM/ODM outerwear experience). Reviewer: Head of Compliance, Eton Garment Limited.

Methodology: Synthesis of standards (GOTS v7.0, OEKO-TEX 2024, ZDHC), industry reports (UNEP, EU Strategy, WRAP, McKinsey/BoF), and factory process knowledge (lab dips, wastewater testing cycles, in-line AQL).

Limitations: No single material/finish suits all use cases; regulations evolve; verify legal requirements regionally. Disclosure: Eton provides OEM/ODM services; recommendations reflect operational capabilities and industry practices. Last Updated: 2025-10-14.

[INTERNAL LINK: {{author_name}} — {{author_title}} {{author_bio_url}}]

- Good On You — What is sustainable fashion? (Year). https://goodonyou.eco/what-is-sustainable-fashion/

- The Good Trade — What Is Sustainable Fashion? (Year). https://www.thegoodtrade.com/features/what-is-sustainable-fashion

- Earth.org — The Environmental Impact of Fast Fashion (Year). https://earth.org/environmental-impact-of-fast-fashion/

- Common Objective — Sustainable Fibres: A Guide (Year). https://www.commonobjective.co/article/sustainable-fibres-a-guide

- McKinsey & Company — The State of Fashion 2024 (Year). https://www.mckinsey.com/industries/retail/our-insights/state-of-fashion

- UNEP — Sustainability and Circularity in the Textile Value Chain (2023). https://www.unep.org/resources/report/sustainability-and-circularity-textile-value-chain

- European Commission — EU Strategy for Sustainable and Circular Textiles (2022–2023). https://environment.ec.europa.eu/strategy/textiles-strategy_en

- WRAP — Textiles 2030 Progress Report (2023). https://wrap.org.uk/resources/report/textiles-2030-progress-report-2023

- ZDHC — Roadmap to Zero Programme (Year). https://www.roadmaptozero.com/

- GOTS — Version 7.0 (2023). https://global-standard.org/the-standard/gots-version-7-0

- OEKO-TEX — Highlights 2024 (2024). https://www.oeko-tex.com/en/news/highlights-2024

- European Environment Agency — Textiles and the environment (Year). https://www.eea.europa.eu/topics/waste/resource-efficiency/textiles

- European Commission — Digital Product Passport (Year). https://single-market-economy.ec.europa.eu/industry/sustainability/digital-product-passport_en

FAQs

What is environment friendly clothing and how is it verified?

How do I choose a China clothing manufacturer for eco goals?

What is OEM clothing manufacturing and how does it support sustainability?

What does GOTS certification cover in apparel?

What is OEKO-TEX Standard 100 and why does it matter?

How does the bluesign system improve textile sustainability?

What is the ZDHC MRSL and how do brands implement it?

How reliable is PFC-free DWR for outerwear performance?

What should brands know about PFAS regulations for textiles in the US and EU?

What is the Digital Product Passport for textiles and what data is required?

What are the pros and cons of recycled polyester rPET in apparel?

When should I choose TENCEL Lyocell fabric for environment goals?

What is regenerative cotton and how do I verify it?

When is recycled nylon ECONYL the right choice?

What works for microfiber release mitigation in apparel?

What does wastewater testing in textile mills need to include?

How does chain-of-custody in apparel support sustainability claims?

What is a Higg FEM assessment and how should brands use it?

What does ISO 14001 mean in apparel manufacturing?

How do I get seam sealing right for outerwear with PFC-free finishes?

What is hydrostatic head testing and what targets should I set?

How do I ensure green claims compliance in fashion marketing?

Related Articles

Shirt High Quality Guide with a China Clothing Manufacturer: Build Premium Shirts that Last

15 minute read

October 14th, 2025

Shirt High Quality Guide with a China Clothing Manufacturer: Build Premium Shirts that Last Shirt high... more »

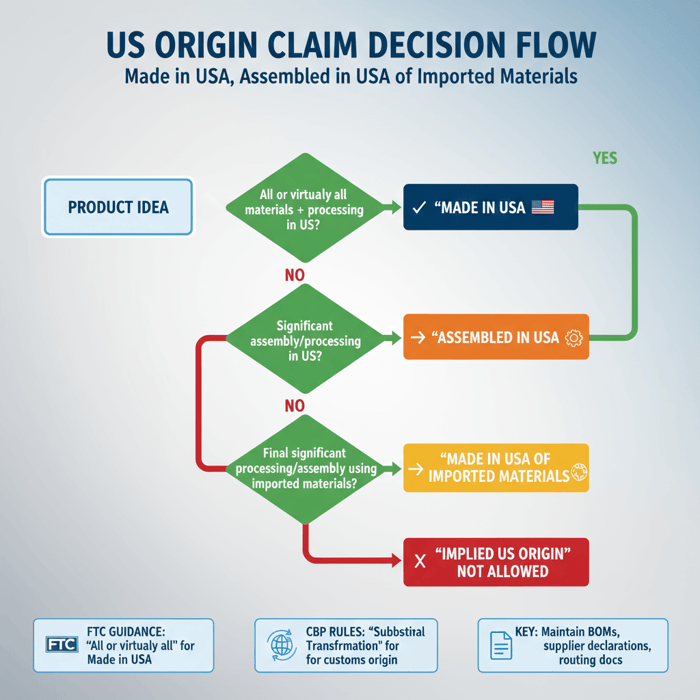

Affordable American-Made Clothing vs China Clothing Manufacturer: A Practical Sourcing Guide for Fashion Brands

12 minute read

October 14th, 2025

Affordable American-Made Clothing vs China Clothing Manufacturer: A Practical Sourcing Guide for Fashion... more »

Polo Manufacturers: Top China Clothing Manufacturer Options for Fashion Brands in US & EU Markets

11 minute read

October 14th, 2025

Polo Manufacturers: Top China Clothing Manufacturer Options for Fashion Brands in US & EU... more »

United States Apparel Sourcing Guide: Top Manufacturers and Strategies for Fashion Brands in 2024

18 minute read

October 13th, 2025

United States Apparel Sourcing Guide: Top Manufacturers and Strategies for Fashion Brands in 2024 In the... more »