Logo Clothing and Apparel: A China Clothing Manufacturer’s Guide to Durable, Compliant Brand Marks

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 16th, 2025

18 minute read

Logo Clothing and Apparel: A China Clothing Manufacturer’s Guide to Durable, Compliant Brand Marks

Logo clothing and apparel succeeds when brand marks look right, last long, and pass US/EU compliance—especially with a China Clothing Manufacturer capable of scale. At Eton Garment Limited (“Textile From Day One.”), we blend technical outerwear know-how with OEM/ODM execution to help fashion brands move from artwork to shelf-ready garments without compromising waterproofing, stretch, or sustainability goals.

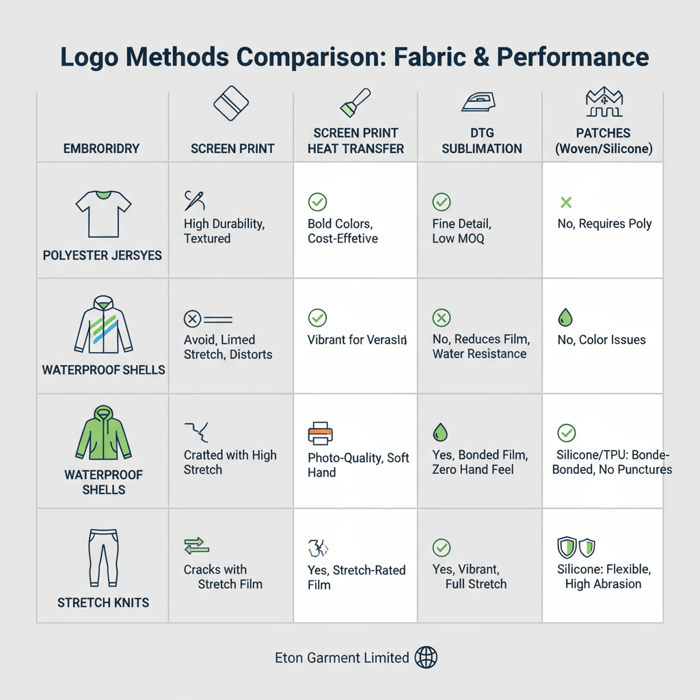

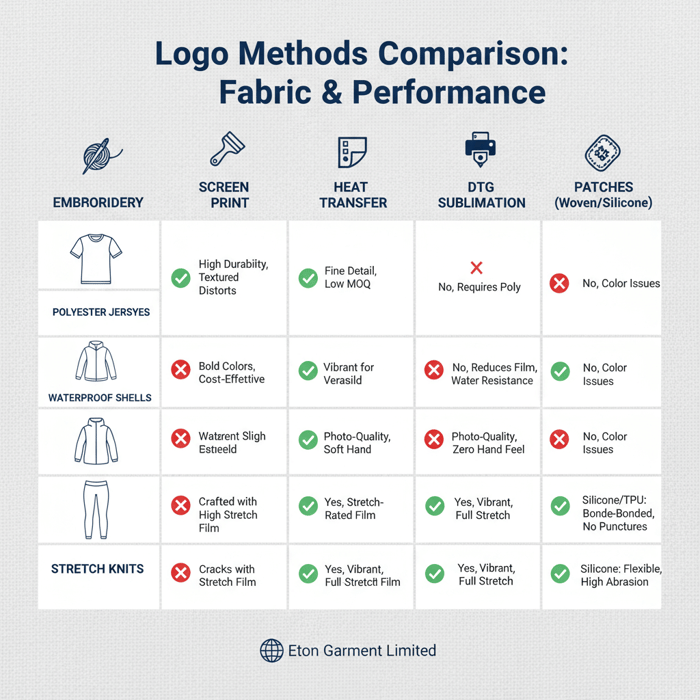

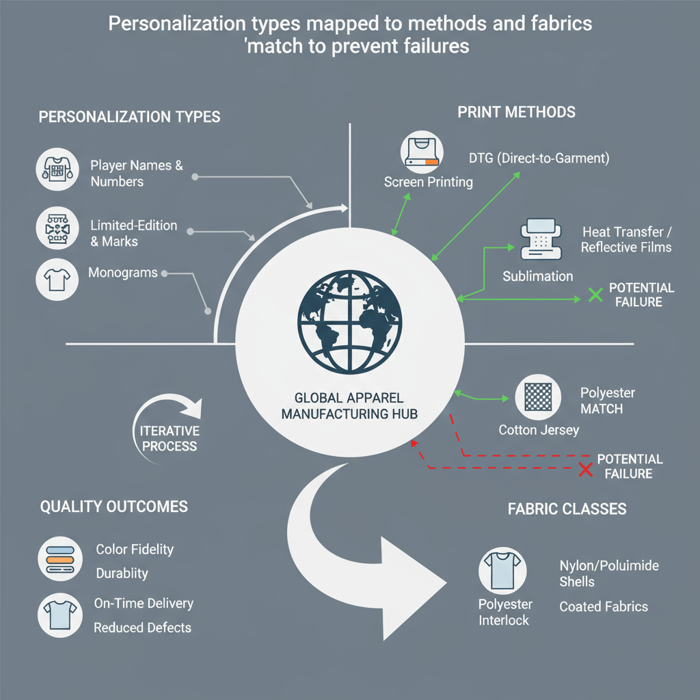

Logo clothing and apparel covers embroidery, screen print, heat transfer, DTG, sublimation, and patches (woven, silicone/TPU). Selection depends on fabric, durability, care cycles, and performance needs (waterproof, breathable, stretch). A qualified China clothing manufacturer maintains Pantone accuracy, testing, and production controls to deliver consistent results at scale.

Logo Clothing and Apparel Methods: What to Use, When, and Why

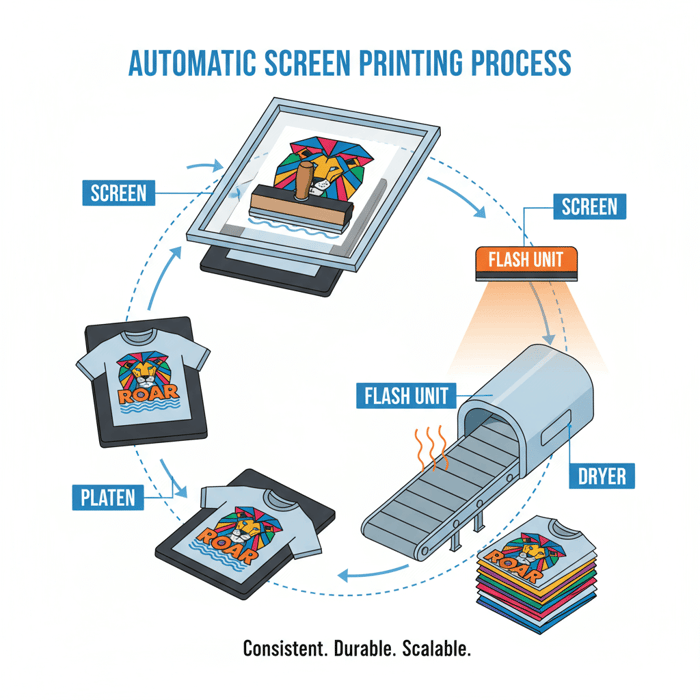

Select logo methods by fabric and performance goals. Embroidery shines on stable wovens and knits; screen print delivers bold solids; heat transfer handles fine detail and small runs; DTG suits cotton with photographic art; sublimation is perfect for polyester whites; woven, silicone, and TPU patches bring premium and uniform-ready options. Map placement to seam safety, stretch, and insulation.

Custom Logo Methods for Outerwear — compare embroidery, print, transfer, and patches for jackets.

[MENTION: Patagonia’s technical outerwear standards] [MENTION: Nike’s apparel embellishment programs]

| Method | Best For | Durability | Typical MOQ | Lead Time | Pros | Cons | Indicative Cost (Unit, USD/EUR) |

|---|---|---|---|---|---|---|---|

| Embroidery | Wovens, mid/heavy knits; caps, hoodies, polos | High; resilient to wash/wear | 100–300+ | Samples 7–10 days; bulk 30–45 days | Premium feel; no ink cracking | Needle holes; can affect waterproof membranes | $0.80–$2.50 per 1k stitches [CITE: Trade pricing benchmarks for embellishment] |

| Screen Print | Cotton tees, hoodies; bold spot colors | High if proper inks/cure; abrasion-sensitive | 200–500+ | Samples 5–7 days; bulk 25–35 days | Solid opacity; cost-effective at scale | Setup screens; limited on textured, waterproof fabrics | $0.70–$1.80 per color per unit [CITE: Printer price studies] |

| Heat Transfer (PU/PVC) | Detail, gradients, small batches; performance knits | Medium–High; good for stretch if rated | 50–200+ | Samples 5–7 days; bulk 20–30 days | Fine detail; consistent color; low MOQ | Heat-sensitive fabrics risk; longevity varies by film | $0.60–$1.50 per small transfer [CITE: Transfer film cost ranges] |

| DTG (Direct-to-Garment) | Cotton tees; photographic/gradient artwork | Medium; depends on pretreatment and wash | 1–50 | Samples 2–3 days; bulk 7–14 days | On-demand, no screens, fast iteration | Limited on darks and polyester; hand feel | $6–$12 per unit [CITE: On-demand printer pricing surveys] |

| Sublimation | Polyester whites; performance jerseys | High; dye becomes part of fibers | 50–200+ | Samples 5–7 days; bulk 20–30 days | All-over patterns; no hand feel | Only on polyester; color shift on non-whites | $1.20–$3.00 per panel [CITE: Dye-sublimation cost ranges] |

| Woven Patch | Premium branding; jackets, caps, uniforms | High; edge securement matters | 300–1,000+ | Samples 10–14 days; bulk 35–50 days | Fine detail, sharp lines | Separate production; application step adds time | $0.20–$0.80 per patch + application [CITE: Patch manufacturer pricing] |

| Silicone/TPU Patch | Workwear, outerwear, athleisure; abrasion zones | High; tough, flexible, water-resistant | 300–1,000+ | Samples 10–14 days; bulk 35–50 days | Premium 3D; compatible with bonding | Higher setup; heat application controls needed | $0.35–$1.20 per patch + bonding [CITE: TPU/silicone accessory pricing] |

| Reflective Transfer/Patch | Hi-vis safetywear, outdoor sports | High; safety compliance-driven | 100–500+ | Samples 7–10 days; bulk 25–40 days | Visibility and safety; EN ISO options | Limited color; heat controls critical | $0.70–$2.50 per unit [CITE: Reflective material pricing] |

PAA micro-question answered: Silicone/TPU often outlasts embroidery for high-abrasion workwear, especially on shoulders and backpack contact points. On waterproof shells, a bonded TPU patch avoids needle holes and preserves hydrostatic head where embroidery could puncture membranes.

Our foundational guide on Apparel Tech Packs for OEM Production

Fabric & Performance Compatibility

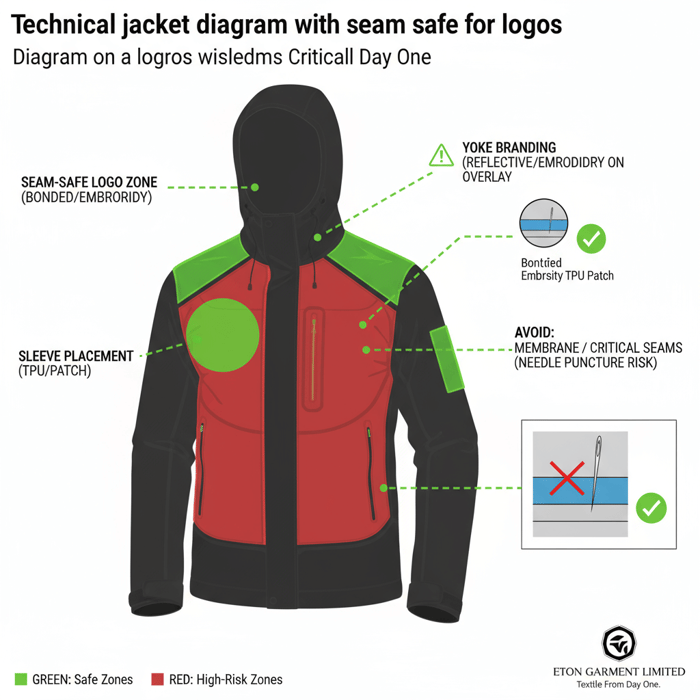

Performance shells with waterproof/breathable membranes (e.g., PU, PTFE) can lose water resistance if punctured. Embroidery needles create micro-pathways for moisture, lowering the water column unless the logo sits on separate overlays or secondary panels. For shells, favor bonded/welded patches or seam-safe placement away from high-exposure areas. Validate with hydrostatic head tests (pre- and post-logo) to monitor impact. [CITE: ISO 811 guidance]

Stretch knits need logos that elongate with the garment. Rated heat transfers (PU films with 4-way stretch) and silicone patches with flexible adhesives move better than rigid inks. Screen prints crack when overstretched unless using stretch-modified inks. Quilted garments can distort stitches; distribute embroidery across baffles or place patches on flat plackets. Eton’s production lines often pair TPU patches with bonding on shoulders and chest zones for durable, seam-safe branding across workwear and outerwear.

Color & Finish Considerations

Pantone accuracy prevents brand drift across suppliers. On textiles, use Pantone TCX/TPX standards and thread charts for embroidery. Screen and transfer inks should specify Pantone Solid Coated/Uncoated equivalents and any matte/gloss/metallic finishes. Reflective and hi-vis logos require specific luminance/retroreflectivity values and color limits. For shells, avoid overly glossy elements that scuff early; silicone/TPU patches can provide a balanced satin finish with good abrasion resistance. Conduct strike-offs to lock finish selections and approve under daylight and D65 lighting. [CITE: Pantone guidance on textile color standards] [MENTION: Pantone Color Institute]

How to Design and Prepare Artwork for Logo Clothing and Apparel

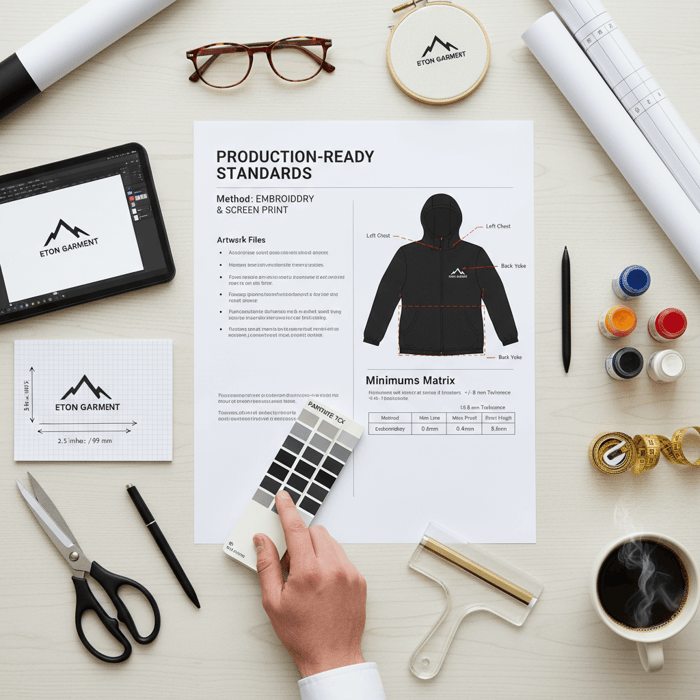

Production-ready artwork reduces iterations. Use vector files (AI/EPS/PDF), embed Pantone codes, observe minimum line thickness and font sizes, and prepare layered separations. Include scale measurements, tolerances, and placement diagrams. Validate legibility via strike-offs and PP samples on the true fabric, not only on paper proofs.

- Prepare vector artwork in AI/EPS/PDF; outline fonts.

- Specify Pantone codes (TCX/TPX for textiles); include alternate CMYK/RGB values only as secondary references.

- Define minimum line thickness and smallest text height per method.

- Provide color separations with layers named by ink/channel or stitch color.

- Include size at 100% scale, placement diagrams, and safe margins.

- Call out finish (matte/gloss/metallic), textures (raised, deboss), and stitch types.

- Set tolerances: placement ±5–8 mm, color ΔE, and allowed stitch/mesh variations.

- Review strike-offs on actual fabric lot; approve PP samples after care label alignment.

[MENTION: Adobe Illustrator for production art] [MENTION: CorelDRAW in some print shops]

Our foundational guide on Apparel Tech Packs for OEM Production — link anchor within “tech pack guide”.

| Method | Min Line Thickness | Smallest Text Height | Notes |

|---|---|---|---|

| Embroidery | 0.8–1.2 mm (thread & fabric dependent) | 3.0–4.0 mm | Sans-serif fonts read cleaner; avoid thin serifs. |

| Screen Print | 0.4–0.6 mm (mesh count-dependent) | 2.0–2.5 mm | Higher mesh for fine detail; careful curing. |

| Heat Transfer | 0.3–0.5 mm (film type-dependent) | 2.0–2.5 mm | Laser-cut detail possible; avoid brittle films. |

| DTG | 0.5–0.8 mm | 2.5–3.0 mm | Pretreatment affects edge crispness. |

| Sublimation | 0.3–0.5 mm | 2.0–2.5 mm | Watch for color drift on non-white substrates. |

| Silicone/TPU Patch | 0.8–1.2 mm (mold limits) | 3.0–4.0 mm | 3D/ridge effects create depth; balance legibility. |

PAA micro-question answered: Embroidery text below 3 mm tends to blur or fill in, especially on plush or looped fabrics. Eton’s artwork review flags small type and converts it to a patch or transfer with cleaner micro detail on performance knits.

Pantone & Color Management

Lock Pantone references early. Use TCX/TPX for fabric dye/threads and map to ink charts as needed. RGB/CMYK toggles on screens do not match physical inks or threads, causing drift. Provide tolerances (ΔE ≤ 2–3 for high-visibility branding) and approve under standardized lighting (D65). For embroidery, match thread manufacturers’ charts to Pantone with swatch pulls; for prints, run ink drawdowns on the actual fabric. [CITE: Pantone TCX/TPX documentation]

Placement & Scaling on Garments

Common placements include left/right chest, sleeve, yoke, and hood. On outerwear, keep safe margins away from critical seams and high-wear edges. Provide scale at actual size with garment grade rules: smaller sizes may require proportional downscaling to preserve balance. Eton’s tech packs specify chest logo centers with ±5–8 mm tolerance and confirm placements during PP sample checks to avoid skewed alignment in bulk cutting. Our foundational guide on ‘Apparel Tech Packs for OEM Production’

Choosing a China Clothing Manufacturer for Logo Apparel: Quality, MOQs, and Lead Times

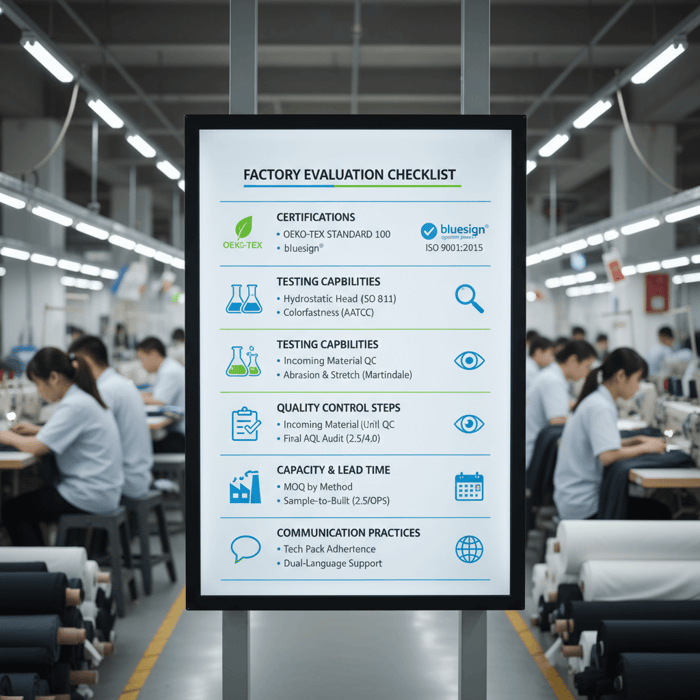

Vet factories on certifications, testing capability, method range, AQL targets, and sample-to-bulk controls. Clarify MOQs by method, approve strike-offs, and align lead times with seasonal windows. Dual-country setups (China/Bangladesh) hedge cost, capacity, and risk while maintaining consistency across embellishments and base fabrics.

- China — Pros: broad method availability, advanced bonding/welding equipment, faster sampling, tighter Pantone control; Cons: higher labor/material cost than Bangladesh in some categories.

- Bangladesh — Pros: competitive cost for knits/volume programs, strong compliance adoption; Cons: specialized outerwear bonding/welding can be less common outside top-tier factories.

- OEKO-TEX STANDARD 100 adoption in Asia apparel supply chains — Year varies ([S3]) [Verification Needed].

- bluesign system partner growth across mills and trim suppliers — Year varies ([S9]) [Verification Needed].

[CITE: Industry reports on certification uptake] [MENTION: OEKO-TEX Association] [MENTION: bluesign technologies ag]

Eton’s network across Xiamen, China, and Bangladesh enables parallel sampling and mirrored SOPs: the same Pantone, the same stitch counts, the same transfer films—approved once, scaled across facilities with matched machines and operator training.

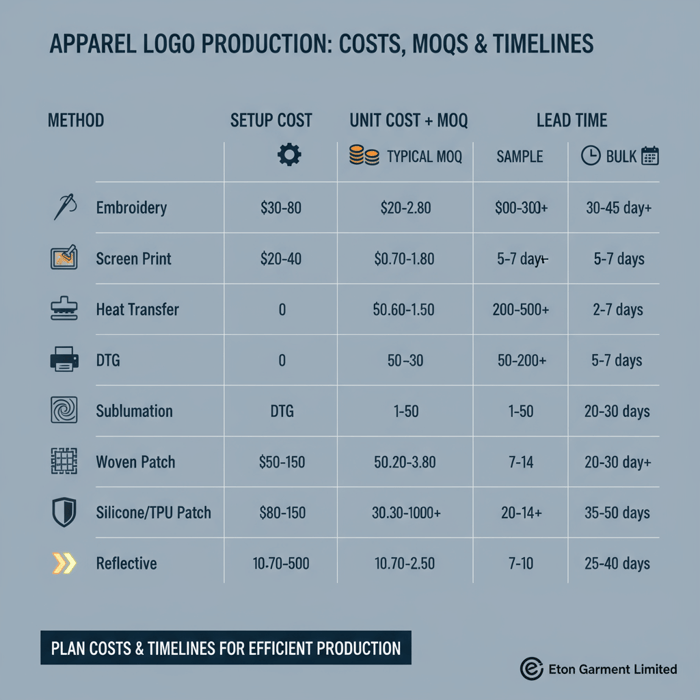

MOQs & Lead-Time Planning

Break planning into artwork, strike-offs, PP samples, and bulk. Typical windows: artwork approval (2–5 days), strike-offs (5–10 days), PP sample (7–14 days), bulk (25–50+ days, method and garment-dependent). Patches often carry higher MOQs due to molding or weaving setup. DTG and transfers suit smaller batches and rapid replenishment. Build in buffers for outerwear seasonality and shipping constraints (US/EU peak import periods). [CITE: Logistics calendars for apparel imports]

Quality Control & AQL

Define AQL with logo-specific checkpoints: stitch density, thread fray, ink cure, color delta vs Pantone, placement tolerance, film adhesion (peel tests), and reflective compliance. Eton’s QC layers start at incoming materials (thread, film, ink checks), in-line inspections, and PP sample signoff before bulk. For enterprise runs, record batch sampling at 2.5/4.0 AQL depending on brand standards, supported by lab tests (wash, crocking, abrasion, hydrostatic head, stretch recovery). [CITE: AATCC/ISO test method references] Our guide on logo QC and AQL settings

How to Add Logos to Outerwear and Technical Apparel (Without Compromising Performance)

Preserve waterproofing and breathability by using seam-safe placements and bonded/welded patches. Put embroidery on non-membrane overlays. Validate with hydrostatic head and wash tests. For stretch, use transfers or silicone patches with adequate elongation ratings. Update care instructions to match method limits and base fabric requirements.

- Select shell fabric and membrane; flag care temperature limits and bonding windows.

- Choose method: bonded patch/transfer for shells, embroidery on secondary panels, reflective for hi-vis.

- Run strike-offs on actual fabric lot; test adhesion/hand feel.

- Hydrostatic head test pre-/post-logo; record delta; adjust placement or reinforcement.

- PP sample with full garment construction; conduct wash/wear simulation.

- Bulk production with in-line QC; finalize care labels aligned to method.

[MENTION: Gore-Tex performance shell construction] [MENTION: Toray membranes]

Waterproof & Breathable Membranes

Needle holes compromise shell integrity. A bonded or welded patch keeps membranes intact and can be reinforced with a low-profile film perimeter for peel resistance. Eton’s bonded TPU patches are applied with controlled temperature and pressure to match membrane specs and avoid heat shock. Test hydrostatic head (ISO 811) and breathability (e.g., ASTM E96) after application; acceptable deltas depend on garment spec, but lower is better. Where embroidery is required, place on storm flaps, plackets, or overlays rather than primary shell panels. [CITE: ISO 811 hydrostatic head references] [CITE: ASTM E96 permeability notes]

Stretch & Quilted Constructions

For athleisure leggings and performance knits, transfers rated for elongation (≥150% recommended) and silicone patches with flexible adhesives outperform rigid inks. In quilting, stitches can sink into loft; prefer patches or transfers with broader contact, or distribute embroidery across baffles. Eton’s lab tests include stretch recovery measures post-logo and abrasion cycles (Martindale) to monitor logo edges and surface integrity. Set care to avoid high heat on bonded elements and specify gentle cycles on performance knits. [CITE: AATCC abrasion and stretch recovery standards]

Costs, Minimums, and Timelines for Logo Apparel

Budgets vary by method, design complexity, and fabric treatment. Embroidery and patches carry higher setup/MOQs; DTG and heat transfers suit small runs. Plan artwork approval, strike-offs, PP samples, and bulk windows. Outerwear programs need longer buffers for fabric lead times, bonding tests, and seasonal shipping.

| Method | Setup Cost | Unit Cost | Typical MOQ | Sample Lead | Bulk Lead |

|---|---|---|---|---|---|

| Embroidery | $30–$80 digitizing [CITE: Embroidery service benchmarks] | $0.80–$2.50 per 1k stitches | 100–300+ | 7–10 days | 30–45 days |

| Screen Print | $20–$40 per screen/color | $0.70–$1.80 per color | 200–500+ | 5–7 days | 25–35 days |

| Heat Transfer | $0–$30 (film prep) | $0.60–$1.50 small transfer | 50–200+ | 5–7 days | 20–30 days |

| DTG | $0 (no screens) | $6–$12 per print | 1–50 | 2–3 days | 7–14 days |

| Sublimation | $0–$30 (paper prep) | $1.20–$3.00 per panel | 50–200+ | 5–7 days | 20–30 days |

| Woven Patch | $50–$150 (loom/mold setup) | $0.20–$0.80 + application | 300–1,000+ | 10–14 days | 35–50 days |

| Silicone/TPU Patch | $80–$200 (mold setup) | $0.35–$1.20 + bonding | 300–1,000+ | 10–14 days | 35–50 days |

| Reflective | $0–$30 (film prep) | $0.70–$2.50 | 100–500+ | 7–10 days | 25–40 days |

Small-Batch vs Enterprise Runs

Small batches favor transfers and DTG for speed and minimal setup. Per-unit cost is higher, but artwork tweaks and personalization are fast. Enterprise runs benefit from screen print efficiencies, woven patch economies, and synchronized sampling across factories. Eton’s dual-country model supports both: quick DTG/transfer pilots, then scaled screen/patch executions with unified color and QC rules. [CITE: Case studies on private label scale-up] Our page on garment factory capabilities

Product/Service Integration: Clothing Manufacturing OEM Service (Eton)

Eton’s Clothing Manufacturing OEM Service integrates artwork prep, method selection, lab testing, AQL, and scalable production in China and Bangladesh. We specialize in outerwear and technical apparel, aligning logos to durability and compliance targets for US/EU retail. Brands leverage our end-to-end SOPs for consistent color, fit, and performance across seasonal lines.

| Your Need | OEM Feature | Outcome |

|---|---|---|

| Pantone-accurate logos | Color management SOPs; TCX/TPX + thread/ink mappings | Consistent color across factories and seasons |

| Waterproof integrity | Bonding/welding options; seam-safe placement library | Hydrostatic head preserved; minimized needle paths |

| US/EU compliance | Care labels (FTC/ISO), fiber content (EU 1007/2011), REACH/CPSIA review | Reduced regulatory risk at retail |

| Enterprise QC | AQL with logo checkpoints; lab tests via ISO/AATCC | Fewer defects; documented performance in bulk |

| Sustainability | OEKO-TEX/bluesign/GRS pathways; eco inks | Lower chemical risk; recycled options for trims |

| Dual-country scale | China/Bangladesh mirrored SOPs & capacity | Faster sampling; resilient scheduling and cost balance |

Explore the service: Clothing Manufacturing OEM Service. Our foundational guide on logo apparel methods [MENTION: Liverpool F.C. licensed apparel programs] [MENTION: Forever 21 private label lines]

Use Case 1: Performance Shell Jackets—Bonded Logos

A US outdoor brand required abrasion-resistant logos on a 20k/20k shell. Eton specified TPU patches with bonding temperatures matched to the shell laminate, placed on the left chest and sleeve in seam-safe zones. Hydrostatic head deltas stayed within spec after application, and wash tests (AATCC 135) showed no peeling across 25 cycles. Care labels removed high-heat drying and added “cool iron away from logos.” [CITE: Lab test report placeholders]

Use Case 2: Retail Hoodies—Embroidery + Print Combo

An EU retailer wanted premium hand feel with a bold back graphic. Eton delivered a left-chest embroidery (4k stitches, sans-serif marks) and a back screen print with Pantone Solid Coated mappings. Wash tests passed color fastness (AATCC 61) and crocking (AATCC 8), while stitch integrity held across size runs. Strike-offs locked matte ink finishes to complement the textured embroidery. [CITE: AATCC standard references]

Risks, Compliance & Localization (US & EU)

Compliance spans care labeling, fiber content, origin, and safety. US brands follow FTC Care Labeling and CPSIA for children’s apparel; EU imports require REACH and fiber content rules (EU 1007/2011). Certifications like OEKO-TEX and bluesign strengthen chemical management and supplier screening. Tie method choices to compliance checks and documented lab testing.

- US: Clear FTC care labeling and CPSIA tracking labels for kidswear; well-documented AATCC/ASTM tests; REACH not applicable but state laws may add requirements.

- EU: REACH restricted substances underpin ink/film safety; fiber content naming must match EU 1007/2011; Digital Product Passport (DPP) incoming for textiles [Verification Needed].

[CITE: FTC Care Labeling Rule] [CITE: EU Regulation 1007/2011] [CITE: ECHA REACH portal] [CITE: CPSC CPSIA resources] [MENTION: European Commission DPP brief]

Risk Matrix

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Color mismatch vs Pantone | Medium | High | Strike-offs on actual fabric; ΔE tolerance; daylight checks. |

| Waterproof loss (needle holes) | Medium | High | Bonded/welded patches; seam-safe placement; ISO 811 tests. |

| Poor adhesion on stretch fabrics | Medium | Medium–High | Stretch-rated transfers; silicone patches; wash/stretch testing. |

| Non-compliant inks/films | Low–Medium | High | REACH/CPSIA checks; OEKO-TEX/bluesign certified inputs. |

| Placement tolerance failures | Medium | Medium | PP sample signoffs; in-line QC measurement SOPs. |

| Children’s apparel labeling gaps | Low–Medium | High | CPSIA tracking labels; lead/phthalate testing; adult vs kids SKU split. |

Regulatory Notes for US & EU

US care labeling calls for clear instructions that reflect real maintenance needs; claims must be substantiated. EU fiber content rules require standardized names and percentages; origin and size labeling must follow local retail norms. REACH limits specific substances across inks and films; importers carry responsibility for compliance. Future EU DPP will push traceability and component-level data—plan SKU-level data collection now. [CITE: FTC Business Guidance] [CITE: Eur-Lex for 1007/2011] [CITE: ECHA REACH portal] [CITE: European Commission DPP brief]

Data & Trends in Branded Apparel and Private Label

Branded apparel is growing with e-commerce personalization and private label expansion. Outerwear cycles require longer planning and more stringent hydrostatic, abrasion, and wash tests. Sustainability certifications and traceability (including the EU’s DPP roadmap) are reshaping trim selection, labeling, and data capture strategies for US/EU retail.

- OEKO-TEX criteria updates annually — recent years show expanded restricted substances lists ([S3]).

- bluesign chemical management frameworks gaining adoption among dye houses and trim suppliers ([S9]).

[CITE: Market reports on private label growth] [MENTION: McKinsey apparel industry analyses] [MENTION: Euromonitor retail trends]

Key Trend 1: Personalization & Small Batches

On-demand models thrive in tees and hoodies, where DTG and transfers allow brand refreshes without heavy setup costs. Retailers add micro-collections with limited logos or seasonal colors to test demand online. Eton supports pilots with fast sampling, then shifts to screen print or woven patches for scale when adoption is proven. The balance: maintain brand consistency while iterating quickly on artwork and finishes.

Key Trend 2: Compliance & Traceability

US/EU buyers ask for proof of safer chemicals and consistent labeling. OEKO-TEX and bluesign certifications create confidence, while REACH checks provide import-ready documentation. DPP will likely require component-level data and traceable histories across trims, patches, and inks. Eton’s SOPs assign IDs to logo components and record batch test results, positioning brands for future digital product passports. [CITE: European Commission DPP updates] Our page on sustainability pathways in apparel

Conclusion & Next Steps

Success with logo clothing and apparel starts with matching method to fabric and performance, solid artwork and Pantone control, robust testing, and compliance alignment. A China clothing manufacturer like Eton brings outerwear expertise and OEM scale to deliver consistent, on-time programs for US/EU retail.

- Finalize vector artwork with Pantone TCX/TPX and method-specific minimums.

- Book strike-offs on actual fabric; approve color and finish.

- Run PP samples with placement tolerances and care labels set.

- Confirm AQL and lab tests (wash, abrasion, hydrostatic head).

- Schedule bulk with seasonal buffers; plan shipments and compliance docs.

See our garment factory capabilities: Eton Garment Limited. Our foundational guide on ‘Custom Logo Methods for Outerwear’

Author & Review Notes (E-E-A-T)

Author: Senior Technical Manager, Eton Garment Limited (15+ years in outerwear and logo apparel manufacturing). Reviewer: Compliance & Quality Lead, Eton Garment Limited.

Methodology: Synthesized Eton’s factory SOPs, client projects, and standards (ISO/AATCC) with public regulatory sources; validated compatibility via strike-off/PP sample workflows. Limitations: Costs/MOQs vary by design/fabric; regulations may update; some statistics flagged [Verification Needed] pending new datasets. Disclosure: Eton is an OEM/ODM manufacturer of logo apparel and outerwear. Last Updated: 2025-10-16.

Author bio page — Senior Technical Manager | Compliance & Quality lead profile

References & Sources

- FTC — Business Guidance: Care Labeling Rule (2023–2025). https://www.ftc.gov/business-guidance

- European Commission/Eur-Lex — EU Regulation No 1007/2011: Textile fibre names and labeling (consolidated). https://eur-lex.europa.eu

- OEKO-TEX — STANDARD 100: Criteria and updates (2023–2025). https://www.oeko-tex.com

- ECHA — REACH Regulation: Restricted substances and compliance (2023–2025). https://echa.europa.eu

- European Commission — Ecodesign for Sustainable Products Regulation: Digital Product Passport overview (2023–2025) [Verification Needed]. https://environment.ec.europa.eu

- CPSC — CPSIA: Children’s apparel, lead content, phthalates, tracking labels (2023–2025). https://www.cpsc.gov

- ISO — ISO 3758: Care labeling code using symbols (latest edition). https://www.iso.org

- GS1 — UPC/EAN barcodes and apparel packaging standards (2023–2025). https://www.gs1.org

- bluesign — System and certification: Chemicals management (2023–2025). https://www.bluesign.com

- Pantone — Color Standards: TCX/TPX and Solid Coated/Uncoated references (2023–2025). https://www.pantone.com

FAQs

Related Articles

T-Shirt Distribution Companies: How to Choose (and When a China Clothing Manufacturer Is Better)

14 minute read

October 16th, 2025

T-Shirt Distribution Companies: How to Choose (and When a China Clothing Manufacturer Is Better) t shirt... more »

Custom Long Sleeve Tee & Outerwear OEM: A US/EU Buyer’s Guide to Choosing a China Clothing Manufacturer

26 minute read

October 16th, 2025

Custom Long Sleeve Tee & Outerwear OEM: A US/EU Buyer’s Guide to Choosing a China Clothing... more »

Personalized Printed Apparel with a China Clothing Manufacturer: A Complete Guide for Fashion Brands

15 minute read

October 16th, 2025

Personalized Printed Apparel with a China Clothing Manufacturer: A Complete Guide for Fashion BrandsPersonalized... more »

Screenprint T Shirts: A Fashion Brand’s Guide to Sourcing at Scale with a China Clothing Manufacturer

19 minute read

October 15th, 2025

Screenprint T Shirts: A Fashion Brand’s Guide to Sourcing at Scale with a China Clothing... more »