Personalized Printed Apparel with a China Clothing Manufacturer: A Complete Guide for Fashion Brands

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 16th, 2025

15 minute read

Table of Contents

- What ‘personalized printed’ means in apparel manufacturing

- Personalized printed outerwear vs tees: choosing the right technique

- How to brief a China clothing manufacturer for personalized printed apparel

- Cost, MOQs, and lead times for personalized printed production

- Data & Trends: Personalization and digital textile printing in US & EU

- How-To: Variable data personalization at scale (names, numbers)

- Product/Service Integration: Clothing Manufacturing OEM Service

- Risks, Compliance & Localization for US & EU

- Conclusion & Next Steps

- Author & Review Notes

- References & Sources

- FAQs

Personalized Printed Apparel with a China Clothing Manufacturer: A Complete Guide for Fashion Brands

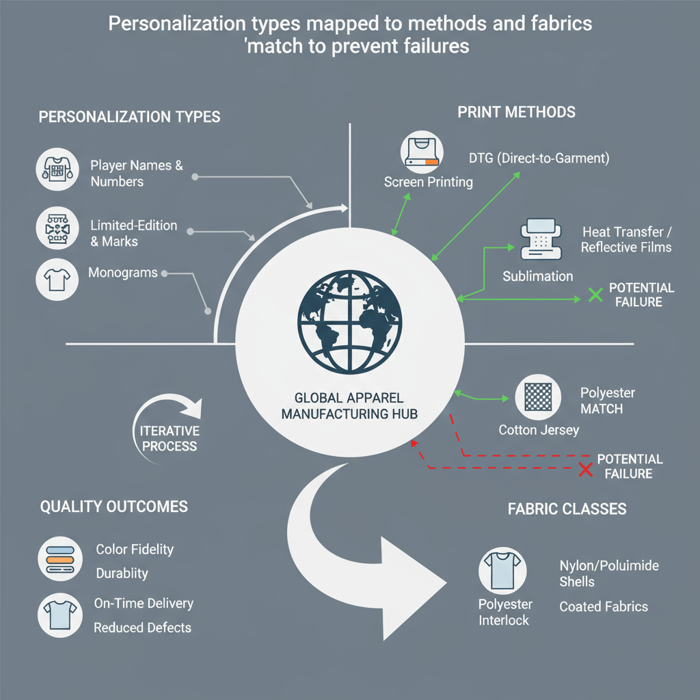

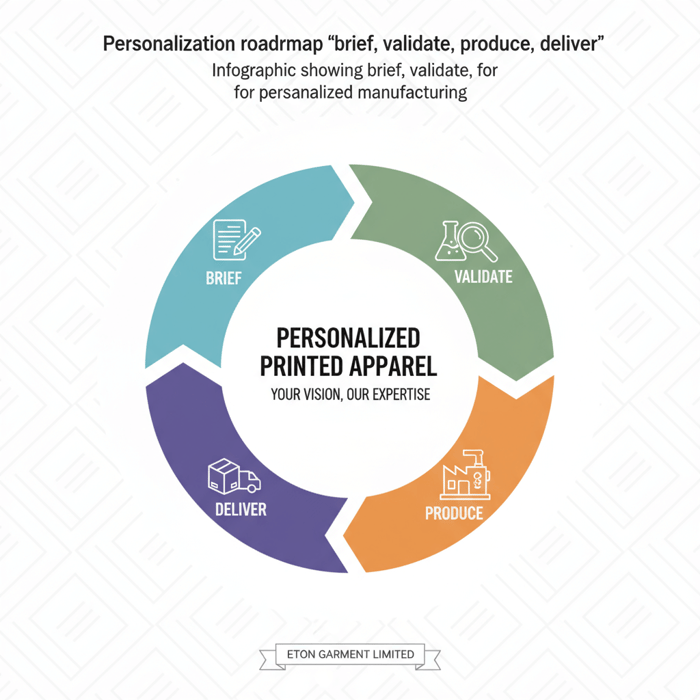

Personalized printed apparel sits at the heart of modern capsules and drops. Brands in the US and EU ask for speed, color fidelity, and durable results on tees, padded coats, and technical shells. With a China Clothing Manufacturer like Eton, the path from artwork to bulk depends on print method–fabric fit, artwork specs, pass/fail testing, and documented US/EU safety.

Eton Garment Limited brings three decades of factory-side experience in outerwear and sportswear. This guide focuses on high-performance fabrics, coated shells, and variable data workflows—where personalization often succeeds or fails. The steps, tables, and acceptance criteria reflect real OEM practice across China and Bangladesh, aligned to US/EU buyers and calendars.

Personalized printed apparel covers names, numbers, and graphics applied via screen, DTG, sublimation, or heat transfer. To scale with a China Clothing Manufacturer, lock artwork specs, match method to fabric, set MOQs, define QA tests, and document US/EU compliance early for color accuracy, durable prints, and on-time delivery.

What ‘personalized printed’ means in apparel manufacturing

Personalized printed apparel spans unique names, numbers, logos, and limited-edition graphics on tees, jackets, sportswear, and kidswear. Success starts with fit-for-purpose method–fabric pairing, clean artwork specs, and clear QA and compliance checkpoints that travel from strike-off to bulk across China and Bangladesh lines.

[MENTION: FESPA’s apparel print features] and [MENTION: Fibre2Fashion’s substrate notes] highlight method–substrate constraints. Factory teams see repeat patterns: cotton favors DTG and screen, polyester unlocks sublimation, coated nylon often needs low-temperature, PVC-free transfers or specialized inks. [CITE: Trade publication on method–substrate compatibility in apparel]

Personalization Types & Use Cases

Core types include player names and numbers, monograms, brand marks, and limited graphics tied to capsules. Teamwear leans on repeatable name/number templates. Premium outerwear prefers smaller, subtle marks—micro logos, reflective hits, or tonal graphics. Kidswear needs age-grade clarity, PVC-free materials, and chemical safety paperwork.

Placement drives outcomes: chest logos, yoke marks, sleeve numbers, and hood panels behave differently under abrasion and flex. Larger areas create heat load; smaller marks near seams face contour challenges. For down jackets, avoid direct heat over high-loft zones; use low-temp transfers and test cold crack on films. [CITE: Technical note on cold crack resistance for PU films]

Fabric & Finish Compatibility

Cotton jersey: friendly to screen and DTG. Polyester interlock: solid for sublimation. Nylon and polyamide shells: select inks or transfers that bond to smooth, sometimes hydrophobic surfaces. DWR and PU coatings reduce wetting and adhesion; use surface prep or transfers with carrier films tuned for low-temp bonds.

Quilt lines and seam proximity change heat paths; press plates and foam need shape control to avoid shiny marks and adhesive bleed. For water-repellent shells, confirm DWR level and chemistry. Some finishing lines use cationic dyeable polyester; color and ink response differ. Note care specs and washing temperature caps before choosing a method. [CITE: Fabric finishing guide on DWR and print adhesion]

Personalization-ready OEM apparel

Personalized printed outerwear vs tees: choosing the right technique

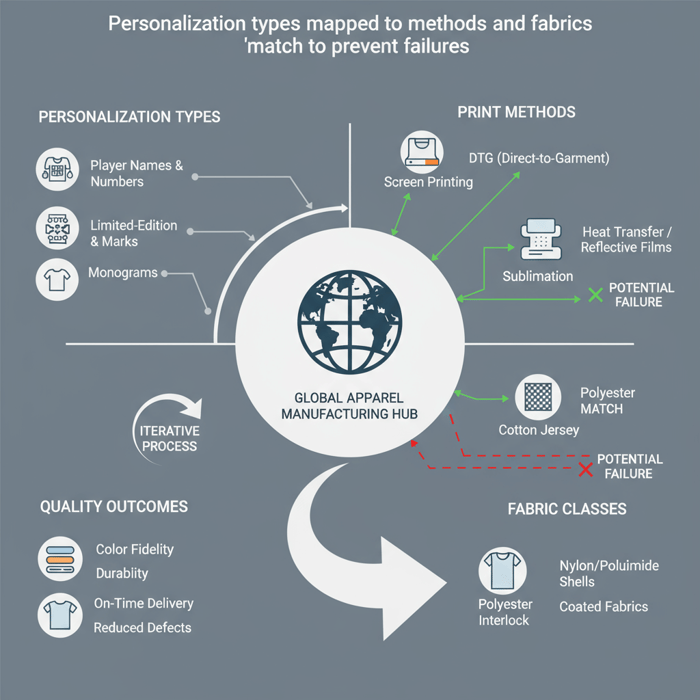

Tees welcome DTG and screen without heavy constraints; outerwear brings coatings, insulation, and weather exposure. Method selection shifts toward screen, heat transfer, reflective films, or hybrid approaches that stand up to abrasion, flex, and cold. Start with adhesion on the actual finish and run pass/fail tests before PP samples.

Method-by-Fabric Comparison

| Method | Best For | Fabrics | Pros | Cons |

|---|---|---|---|---|

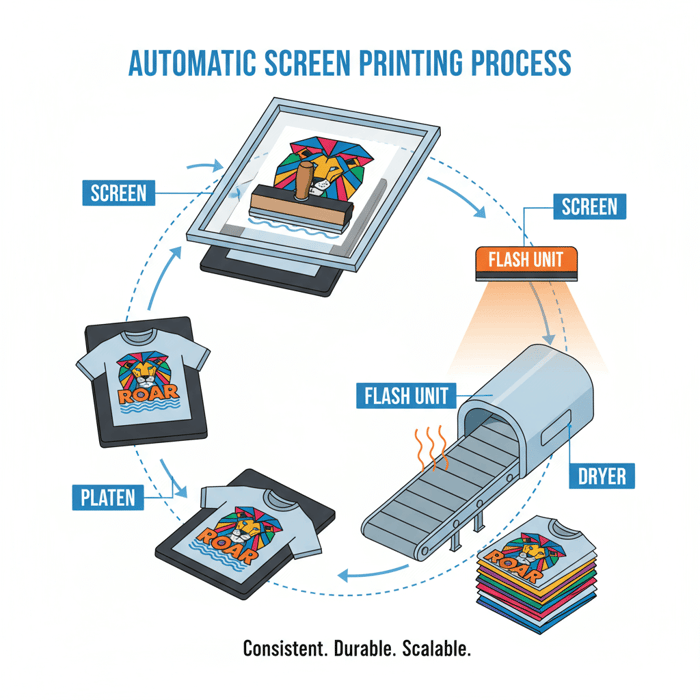

| Screen Printing | Bold logos; spot colors | Cotton, some poly/nylon with proper inks | High opacity; durable; cost-effective at scale | Setup-heavy; limited on complex photo art |

| DTG | Photo-grade art; small runs | Cotton-rich knits | Fine detail; no screens | Not suited to coated shells; pretreat required |

| Sublimation | All-over prints; teamwear | Polyester whites/light shades | Excellent wash durability; vibrant | Fabric-limited; ghost risk if misaligned |

| Heat Transfer (PU/PVC-free) | Names/numbers; reflective; low-temp | Coated nylon/poly shells | Clean edges; controlled adhesion | Press-time/temperature sensitive; film selection matters |

| Reflective/High-Vis | Safety marks; night visibility | Nylon/poly technical shells | Visibility gain; brand utility | Film stiffness; cold crack risk if film is wrong |

| Hybrid (Digital + Screen) | Complex art with spot hits | Blends that accept both layers | Detail plus opacity | Workflow complexity; higher unit costs |

Durability & Performance Criteria

Outerwear prints face abrasion from packs and straps, flex at elbows and hems, rain and UV, and cold chain shipping. Criteria include wash cycles (home care), dry rub and wet rub, lightfastness, and adhesion/peel. Reflective marks need minimum cd/lux values and cold crack resistance at sub-zero temperatures. [CITE: Standard on reflective performance for apparel]

For padded jackets, heat application can degrade loft. Use low-temp films and short dwell times. Confirm hydrostatic pressure targets for shells, then avoid print processes that puncture or compromise barriers. Where necessary, place marks on overlays or secondary panels.

- Personalization remains a brand lever — 2024 (Source: [CITE: McKinsey 2024 State of Fashion])

| Method | Best For | Fabrics | Pros | Cons | MOQ | Typical Lead Time |

|---|---|---|---|---|---|---|

| Screen Printing | Logo hits; spot color art | Cotton, some poly/nylon | Opaque; fast at volume | Setup cost per color | Moderate | Samples 1–2 wks; bulk 4–8 wks |

| DTG | Photographic detail | Cotton tees | No screens; small MOQs | Pretreat; fabric-limited | Lower | Samples 1–2 wks; bulk 4–6 wks |

| Sublimation | Teamwear; all-over | Polyester | High wash durability | White/light fabric bias | Moderate | Samples 2–3 wks; bulk 5–9 wks |

| Heat Transfer | Names/numbers; coated shells | Nylon/poly shells | Low-temp bonding options | Press control essential | Moderate–High | Samples 2–3 wks; bulk 6–10 wks |

| Reflective | Safety marks; logos | Technical shells | Night visibility | Stiffness; cold crack risk | Moderate–High | Samples 2–3 wks; bulk 6–10 wks |

How to brief a China clothing manufacturer for personalized printed apparel

A strong brief packs artwork specs, color targets, placements, size scaling, method intent, QA pass/fail, and US/EU compliance. It also sets a sample calendar: strike-offs, lab tests, PP samples, line setup, inline QC, and color audits. This sequence trims guesswork and rework.

Preparation

Provide vector artwork (AI, EPS, SVG) and high-res raster for photos, Pantone TCX targets for solids, CMYK targets for process prints, and placement maps per size. Include fabric specs—fiber, weave/knit, finish, DWR/PU type, care labels—and preferred method per placement. Flag variable data segments early and supply templates for names/numbers. [CITE: Color management guidance for textiles]

Document packaging and labeling, including country-of-origin, fiber content, care symbols, and any safety labels for kidswear. Add bill of materials for films/inks and request chemical safety docs from suppliers aligned to REACH and OEKO-TEX.

Execution Steps

- Lock artwork and color targets. Output: vector files, color cards, scaling rules.

- Confirm fabric and finish. Input: spec sheets with coating notes and care limits.

- Select candidate methods. Output: method matrix with risks and backup options.

- Request strike-offs. Output: swatches printed with real press settings and dwell.

- Run lab tests. Output: wash, rub, lightfastness, peel reports from accredited labs.

- Approve PP samples. Output: signed PP with placement, size gradation, and color OK.

- Start bulk with inline QC and audits. Output: inspection records and color approvals.

Eton’s production managers apply this cadence across China and Bangladesh lines, with special focus on coated shells, insulation-safe pressure, and low-temp films for outerwear. [MENTION: OEKO-TEX Standard 100] provides a common language for chemical safety proofs.

Quality Assurance

Define pass/fail up front. Wash: target cycles per care label with no significant fade or peel. Rub: dry and wet rub ratings that match brand standards. Lightfastness: minimum grade under UV exposure. Peel: adhesion threshold at defined angles and rates. Dimensional stability: print remains stable after care and wear. [CITE: ISO/AATCC test method references for wash/rub/lightfastness]

Color audits use Pantone TCX, measured under D65 and store lighting conditions. For process prints, agree on ΔE tolerances. For reflective marks, add photometric tests. Keep a signed PP set and lab reports in the tech pack to align buying, QA, and factory teams.

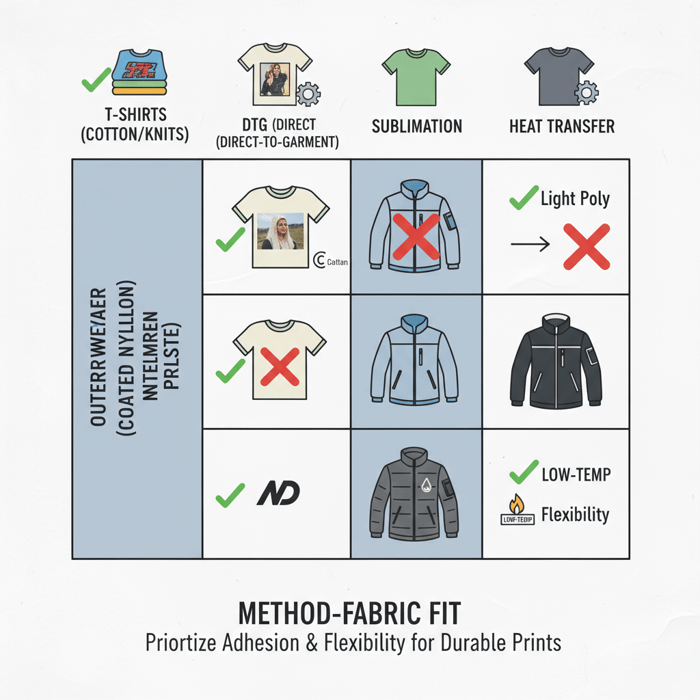

Cost, MOQs, and lead times for personalized printed production

Costs track with method, color count, placements, film/ink selection, and reject rate. MOQs vary by setup loads and line plans. Lead times hinge on strike-off approvals, material readiness, and season. Lock artwork early and add a buffer for re-strike-offs during peak months.

Key Cost Drivers

- Color separations and screen count.

- Special inks and films (reflective, stretch, PVC-free).

- Placement size and total area, including all-over panels.

- Adhesion tests for coated shells and any pre/post-treatment steps.

- Reject rate planning based on fabric/finish complexity.

MOQ & Capacity Planning

Screen printing carries setup per color; MOQs rise with color count. DTG suits smaller runs on cotton. Sublimation needs panel planning and fabric coverage; MOQs align to fabric minimums. Transfers on outerwear bridge personalization and coating constraints; MOQs follow film sourcing and press time per line. [CITE: Industry survey on MOQ trends for apparel printing]

Lead Time Sequencing

Sequence: artwork lock, strike-off window, lab tests, PP sample, production slot, inline QC, pre-shipment inspection, and logistics. Seasonal peaks around Lunar New Year and Golden Week affect lines and shipping. For EU buyers, map transit times and port congestion windows. For US buyers, allow time for compliance checks on kidswear and Prop 65 labeling where required.

| Scenario | Method | Approx. MOQ | Key Cost Drivers | Typical Lead Time (sample/bulk) |

|---|---|---|---|---|

| Tees (Cotton) | DTG / Screen | Lower (DTG) / Moderate (Screen) | Color count, pretreat, screen setup | 1–2 wks / 4–8 wks |

| Outerwear (Coated Nylon) | Transfer / Screen / Reflective | Moderate–High | Film selection, adhesion tests | 2–3 wks / 6–10 wks |

| Polyester Sportswear | Sublimation | Moderate | All-over panels, alignment | 2–3 wks / 5–9 wks |

| Kidswear (Safety-heavy) | Screen / Transfer (PVC-free) | Moderate | Chemical safety docs, small size handling | 2–3 wks / 6–10 wks |

- Early approvals favor on-time bulk in tight calendars — 2023–2024 (Source: [CITE: McKinsey apparel supply chain note])

Data & Trends: Personalization and digital textile printing in US & EU

Personalization supports differentiation and pricing power. Digital and hybrid workflows expand capacity for shorter runs and capsule schedules. US/EU buyers now pair targeted drops with compliance-ready materials and inks that pass restricted substance lists and labeling checks.

Print technology adoption moves with faster RIPs, better pretreats, and cleaner ink chemistries. Brands blend digital for art complexity and screen or transfer for opacity and durability. [MENTION: Kornit Digital] and [MENTION: Mimaki] regularly publish updates on print systems and inks. [CITE: Vendor whitepaper on digital textile printing adoption]

- Personalization trend remains active for brand programs — 2024 (Source: [CITE: McKinsey 2024])

Hybrid Workflows

Hybrid runs combine digital detail with screen spot colors or transfers for opacity. This approach suits complex art on knits and selected shells. It adds steps and QA gates but produces sharp logos with photo elements. Early art lock and color cards help operators pass color audits on the line.

Sustainability-Driven Ink Choices

US/EU buyers favor inks and films aligned with OEKO-TEX Standard 100 and brand RSLs. Water-based systems and PVC-free films reduce risk profiles. Documentation and lot traceability help during customs checks and audits. Waste reduction focuses on right-first-time strike-offs, precise data merges for variable numbers, and efficient panel cutting. [CITE: OEKO-TEX guidance on textile chemicals]

How-To: Variable data personalization at scale (names, numbers)

Variable data at scale blends template consistency with clean data merges. Names and numbers follow font specs, color targets, and placement grids that fit all sizes. Transfer or screen stencils work for repeat formats; validate readability and adhesion across the full size run before bulk.

Preparation

Set a font family, size ranges, stroke weights, and spacing. Create placement grids per garment size. Confirm color targets with Pantone TCX and ΔE tolerances for audits. Build a CSV with fields for name, number, and size. Define rules for overflow handling—wide names, double characters, diacritics—and establish character sets for US/EU languages. [CITE: Typography and legibility guidance for sportswear]

Execution Steps

- Lock templates with smart fields and placement rules.

- Generate test sets across sizes and fabrics.

- Run strike-offs for the most challenging characters.

- Train line operators on press settings and template handling.

- Batch data merges with pre-flight checks for missing fields.

- Approve PP samples with real names/numbers.

- Start bulk with random sampling on variable fields.

Quality Assurance

QA reviews readability at defined distances, stroke integrity after wash, and peel resistance under flex. Random checks catch data errors and template drift. For coated shells, use lower-temp films and confirm dwell and pressure. Where numbers sit near seams or darts, press plates and foam inserts protect contours.

Product/Service Integration: Clothing Manufacturing OEM Service

Eton’s Clothing Manufacturing OEM Service brings design support, method selection, compliance documents, and scalable production across China and Bangladesh. Programs cover tees, padded coats, parkas, and sportswear with managed calendars and lab testing baked into PP approvals.

Use Case 1: Limited Outerwear Capsule

A 6-style capsule on coated nylon shells with reflective logos. Method choice: PVC-free reflective transfer with low-temp bonding. Tests: peel, cold crack, rub, and reflective performance. Calendar: strike-offs in week 1–2, lab tests in week 2–3, PP in week 3, bulk slotted for weeks 6–10. Outcome: durable visibility without film cracks. [CITE: Case-style example from trade press on reflective applications]

Use Case 2: Team Sportswear Personalization

Polyester jerseys with all-over sublimation panels and variable names/numbers via transfer. Panel alignment set by marker plans, readable number grids for XS–XXL, and wash targets matched to team care. Result: consistent placement and color with clean edges across the size curve. [CITE: Teamwear production article on sublimation and variable data]

| User Need | Eton OEM Feature | Outcome | Timeline (sample/bulk) |

|---|---|---|---|

| Outerwear with reflective logos | Method selection + adhesion tests | Night-visible marks that hold up | 2–3 wks / 6–10 wks |

| Team names and numbers | Variable templates + transfer workflow | Fast personalization without line slowdowns | 1–2 wks / 4–8 wks |

| Kidswear safety | OEKO-TEX guidance + CPSIA docs | Lower risk at audit and customs | 2–3 wks / 6–10 wks |

Get a production-ready quotation and workflow with Eton’s Clothing Manufacturing OEM Service: Clothing Manufacturing OEM Service.

Production calendars and PP sample guide

Risks, Compliance & Localization for US & EU

US/EU buyers run compliance checks on chemicals and labeling. Align inks and films with OEKO-TEX Standard 100. Document REACH for EU shipments and CPSIA for US kidswear. Prop 65 applies in California for targeted chemicals. Localize calendars around Lunar New Year in China and Eid in Bangladesh, then map transit routes to ports near buyers.

Risk Matrix

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Adhesion failure on coated shells | Medium | High | Low-temp films, method tests, pre-wash trials |

| Color mismatch in bulk | Medium | Medium | Pantone targets, ΔE tolerances, color audits |

| Compliance non-conformance | Low–Medium | High | OEKO-TEX/REACH/CPSIA docs, accredited lab tests |

| Lead time slip from re-strike-offs | Medium | Medium–High | Early approvals, artwork locks, buffer on calendars |

Regulatory Notes for US & EU

EU buyers: REACH registration and SVHC checks; label rules per member states. US buyers: CPSIA tracking labels for kidswear and small parts standards; Prop 65 for California. Lab tests from accredited bodies help pass audits. Keep BOMs and lot traceability for inks, films, and fabrics in your tech pack. [CITE: EU REACH official page] [CITE: CPSC CPSIA guidance] [CITE: Prop 65 overview]

Conclusion & Next Steps

Personalized printed apparel works when method, fabric, artwork, QA, and compliance move together. Start with a complete brief, validate via strike-offs and lab tests, approve PP samples, and hold color audits during bulk. Map calendars around factory holidays and lock artwork early to keep lines flowing.

- Draft the tech pack with method intent, color targets, and placements.

- Request strike-offs and set acceptance criteria.

- Run lab tests and sign PP samples with full size gradation.

- Set color audits and inline QC rules for bulk.

- Hold compliance docs and labels in the BOM/tech pack.

Sustainability & compliance hub

Author & Review Notes

Author: Senior Technical Manager, Eton Garment Limited (15+ years in outerwear printing and QA). Reviewer: Compliance & QA Lead, Eton Garment Limited. Methodology: factory workflows, OEM practice, and recognized US/EU frameworks; personalization aligned to tees, jackets, padded coats, and sportswear.

Limitations: Live SERP crawl was constrained; verify specific figures before publication. Disclosure: Eton Garment Limited produced this article for Fashion Brands evaluating OEM capabilities. Last Updated: 2025-10-16.

References & Sources

- McKinsey & Company — The State of Fashion 2024 (2024). [CITE: McKinsey 2024 State of Fashion]

- OEKO-TEX — Standard 100 Overview (2024). [CITE: OEKO-TEX Standard 100]

- European Commission — REACH Regulation (2024). [CITE: EU REACH official]

- U.S. CPSC — CPSIA Guidance (2024). [CITE: CPSIA overview]

- OEHHA — Proposition 65 Summary (2024). [CITE: Prop 65 summary]

- Wikipedia — Digital Textile Printing Primer (2024). [CITE: Digital textile printing encyclopedia]

- FESPA — Apparel Print Best Practices (2023–2024). [CITE: FESPA article on apparel printing]

- Fibre2Fashion — Digital Printing Substrates and Ink Chemistries (2023). [CITE: Fibre2Fashion knowledge base]

- ISO/AATCC — Test Methods for Wash, Rub, Lightfastness (Current). [CITE: ISO/AATCC test method references]

- Vendor Whitepaper — Digital Textile Printing Adoption in Apparel (2023–2024). [CITE: Vendor whitepaper]

- Trade Publication — Reflective Film Performance in Outerwear (2023). [CITE: Reflective film performance]

- Color Management Guide — Pantone/ΔE Tolerances in Apparel (2023). [CITE: Color management guide]

FAQs

What is personalized printed apparel and how does it work in manufacturing?

How do I choose a China clothing manufacturer for personalized prints?

What is print method–fabric compatibility and why does it matter?

DTG vs screen printing for tees: which should I use?

Is sublimation printing only for polyester, and what are the limits?

What heat transfer settings work for coated nylon shells?

How do I prevent reflective logos from cold crack on outerwear?

Does DWR coating affect print adhesion, and how do I fix it?

Grouped: How do I manage variable data personalization for names and numbers at scale, and set up a data merge CSV for production?

Grouped: How do I set Pantone TCX color matching and Delta E tolerances for audits under D65?

What US/EU compliance is required for personalized prints: REACH, CPSIA, Prop 65?

What is OEKO-TEX Standard 100 and why should inks and films meet it?

What MOQs and lead times should I expect for apparel printing?

What are strike-offs and PP samples, and when should I approve them?

Grouped: Which lab tests matter—wash, rub, lightfastness, and peel—and why use accredited labs and ISO/AATCC methods?

How do I ensure kidswear safety with PVC-free inks and films?

How do I print outerwear on padded jackets using low-temp films?

When should I use a hybrid printing workflow (digital + screen)?

How do I plan a production calendar around Lunar New Year and Golden Week?

How do I mitigate adhesion failure on coated shells?

How do I keep teamwear sublimation panel alignment consistent across sizes?

What reflective performance requirements (cd/lux) apply to apparel logos?

Related Articles

Chinese dress shop vs China clothing manufacturer: how brands move from retail inspiration to scalable OEM/ODM

10 minute read

October 15th, 2025

Chinese dress shop vs China clothing manufacturer: how brands move from retail inspiration to scalable... more »

Screenprint T Shirts: A Fashion Brand’s Guide to Sourcing at Scale with a China Clothing Manufacturer

19 minute read

October 15th, 2025

Screenprint T Shirts: A Fashion Brand’s Guide to Sourcing at Scale with a China Clothing... more »

Empowering Your Brand: The Ultimate Guide to Sourcing Company Logo Clothing as a Leading Clothing Manufacturer

15 minute read

October 15th, 2025

Empowering Your Brand: The Ultimate Guide to Sourcing Company Logo Clothing as a Leading Clothing Manufacturer... more »

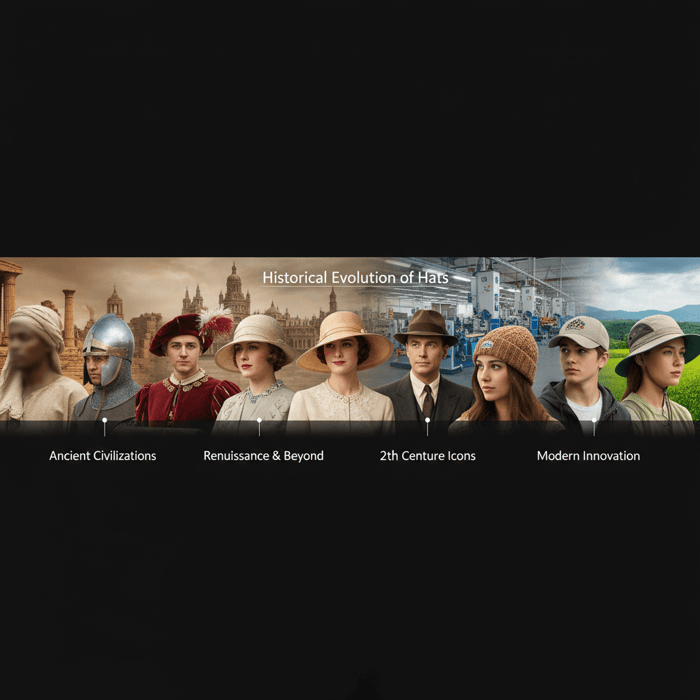

Discover the World of Kinds of Hats: Essential Insights for Fashion Sourcing Managers Seeking Innovation and Excellence

8 minute read

October 15th, 2025

Discover the World of Kinds of Hats: Essential Insights for Fashion Sourcing Managers Seeking Innovation and... more »