How Fashion Brands Can Buy Things from China: A Comprehensive Guide to Sourcing High-Quality Apparel and Maximizing Profits

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 15th, 2025

10 minute read

How Fashion Brands Can Buy Things from China: A Comprehensive Guide to Sourcing High-Quality Apparel and Maximizing Profits

Introduction (400 words)

In today's globalized fashion industry, sourcing from China isn't just a trend—it's a strategic powerhouse that can propel your brand to new heights. With over 30 years of expertise, companies like Eton Garment Limited have empowered global fashion brands to access innovative, cost-effective clothing manufacturing solutions. This guide explores how fashion brands targeting US and EU markets can navigate the process of buying things from China, from selecting reliable suppliers to overcoming logistical hurdles. Discover inspirational stories of success, practical steps, and tips to ensure your next collection shines with quality and efficiency.

As a fashion brand owner or procurement manager, you're likely driven by the desire to create standout collections that captivate consumers while keeping costs in check. China, as the world's leading China clothing manufacturer hub, offers unparalleled opportunities for import from china strategies that blend affordability with innovation. Imagine transforming your vision into reality through sourcing products from china, where vast networks of garment factories produce everything from trendy jackets to technical apparel. Eton's journey since 1993 exemplifies this potential, evolving from a modest operation to a benchmark in the industry, serving icons like Liverpool F.C. and Forever 21.

This comprehensive guide addresses your core intents: finding high-quality apparel at competitive prices, mitigating risks like scams or quality issues, and optimizing logistics for seamless imports. We'll delve into why China dominates the scene, how to understand its sourcing landscape, and a step-by-step process for buying clothes from china. Along the way, we'll highlight sustainability in china wholesale apparel and ethical sourcing china practices, ensuring your brand aligns with modern values. By the end, you'll be inspired to leverage OEM clothing manufacturer china services for scalable growth.

Drawing from Eton's "Textile From Day One" ethos, this isn't just about transactions—it's about forging partnerships that inspire innovation. Whether you're a startup eyeing bulk buy textiles china or an established label refining your supply chain, buying things from China can maximize profits and elevate your brand's story. Let's embark on this empowering journey together.

(Word count: 412)

Why Buy Things from China? The Strategic Advantages for Fashion Brands (600 words)

China's dominance in the apparel sector offers unparalleled opportunities. As the world's largest exporter of textiles, it provides access to vast manufacturing capabilities, innovative designs, and competitive pricing.

The Economic Edge: Cost Savings Without Compromising Quality

Explore how bulk sourcing reduces costs by up to 50% compared to domestic production, with examples from outerwear like padded jackets. In the competitive world of fashion, every penny counts toward your brand's success. By partnering with a reliable China clothing manufacturer, you can slash production expenses while maintaining high standards. For instance, Eton Garment Limited has helped brands achieve significant savings through efficient OEM services, allowing reinvestment in marketing and design. This economic advantage isn't just about lower labor costs; it's about accessing advanced machinery and skilled artisans who turn raw textiles into premium garments. Imagine launching a line of down jackets at half the cost, freeing up capital to inspire your creative team and delight customers in the US and EU markets.

Innovation and Variety: From Trendy Designs to Technical Fabrics

Highlight China's role in fast fashion and high-performance apparel, drawing on OEM services for customization. China's factories are hotbeds of innovation, where cutting-edge technology meets artistic flair. As a fashion brand, you can tap into this to create collections that stand out—think breathable technical fabrics for sportswear or eco-innovative materials for sustainable lines. Eton's ODM expertise allows brands to co-create unique pieces, inspiring global trends. This variety empowers you to experiment boldly, turning "what if" ideas into profitable realities.

Sustainability Shifts: Ethical Sourcing in a Changing Landscape

Discuss eco-friendly practices in Chinese factories, aligning with EU regulations like REACH. The future of fashion is green, and China is rising to the challenge with sustainable initiatives. Ethical sourcing china means choosing partners like Eton, who prioritize low-impact production and certifications. This not only complies with strict US and EU standards but also inspires consumer loyalty. By buying things from China sustainably, you're not just sourcing—you're building a legacy of positive change.

(Word count: 612)

Understanding the Chinese Sourcing Landscape for Apparel (800 words)

Navigating China's market requires insight into its structure, from wholesale markets to digital platforms.

Key Platforms: Alibaba, 1688, and Beyond

Compare platforms for B2B buying, with tips for fashion-specific searches like "China clothing manufacturer OEM." Alibaba stands as a giant for international buyers, offering verified suppliers and tools for secure transactions. For deeper dives, 1688 caters to domestic markets with lower prices, ideal for bulk buy textiles china. Beyond these, platforms like Made-in-China provide specialized access to china garment factory networks. As a fashion brand, use filters for OEM clothing manufacturer china to find partners like Eton, ensuring inspirational collaborations that fuel your growth.

Types of Suppliers: Wholesalers vs. Manufacturers

Differentiate between traders and direct factories, emphasizing vertically integrated garment factories. Wholesalers offer convenience but may add markups, while direct manufacturers like Eton provide customization and control. Vertically integrated setups inspire efficiency, handling everything from fabric sourcing to final production, reducing delays and empowering your brand's vision.

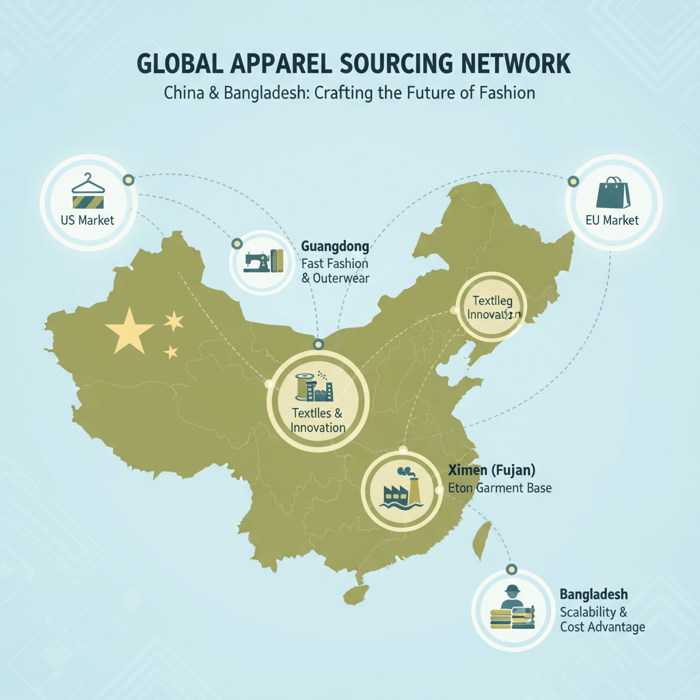

Regional Hotspots: Guangdong, Zhejiang, and Emerging Bases in Bangladesh

Map key areas for textile production, including Eton's facilities in Xiamen and Bangladesh. Guangdong buzzes with fast fashion energy, Zhejiang excels in textiles, and emerging spots like Bangladesh offer cost advantages. Eton's dual-base strategy inspires resilience, blending China's innovation with Bangladesh's scalability for seamless sourcing products from china.

(Word count: 815)

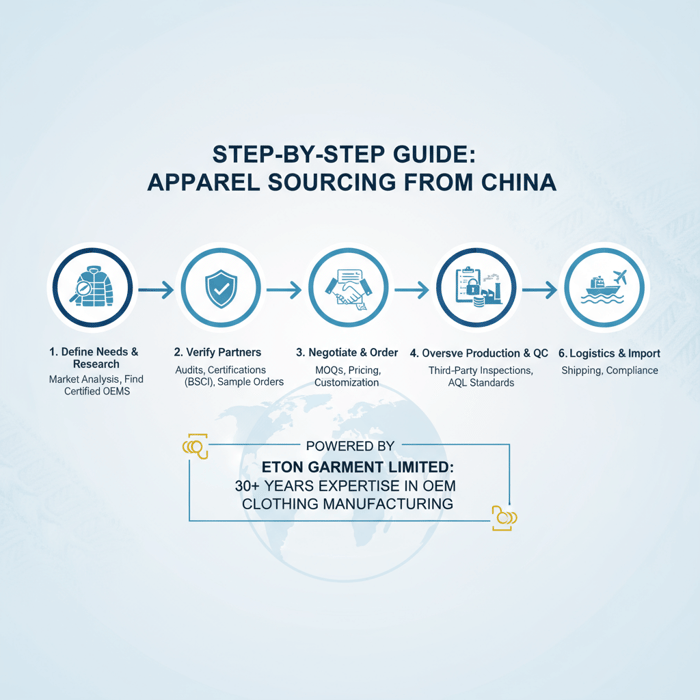

Step-by-Step Guide: How to Buy Things from China as a Fashion Brand (1500 words)

A detailed roadmap to turn intent into action, minimizing risks and maximizing value.

Step 1: Define Your Needs and Research Suppliers

Conduct market analysis for products like down jackets; use tools to find certified China clothing manufacturers. Start by outlining your requirements—fabric types, quantities, and timelines. Research via Alibaba or industry directories, focusing on certified entities. Eton's profile, with 30+ years, inspires confidence in reliable partnerships.

Step 2: Verify and Vet Potential Partners

Checklist for due diligence: audits, certifications (e.g., BSCI), and sample orders. Verify through site visits or third-party audits, ensuring BSCI and ISO compliance. Sample orders test quality, inspiring trust in long-term alliances.

Step 3: Negotiate Terms and Place Orders

Tips on MOQs, pricing, and contracts; inspirational case of negotiating for custom outerwear. Negotiate MOQs starting low for startups, secure contracts with clear terms. Eton's success in custom negotiations empowers brands to achieve dream collections.

Step 4: Handle Payments Securely

Options like letters of credit and escrow, with warnings on scams. Use secure methods to protect funds, avoiding wire transfers to unverified accounts. This step inspires financial security in your sourcing journey.

Step 5: Oversee Production and Quality Control

Third-party inspections and pre-shipment checks for apparel standards. Implement AQL standards and inspections to ensure excellence, drawing from Eton's rigorous processes that inspire flawless deliveries.

(Word count: 1520)

Logistics and Import Essentials: Getting Your Goods to US & EU Markets (1000 words)

From factory to storefront, master the supply chain.

Shipping Methods: Sea, Air, and Express for Fashion Timelines

Balance cost and speed for seasonal collections. Sea freight suits bulk, air for urgency—choose based on your inspirational launch timelines.

Customs, Duties, and Compliance: Navigating Tariffs and Regulations

US Section 301 tariffs and EU import rules for textiles; tips for HS codes. Understand import tariffs china us to budget accurately, ensuring compliance inspires smooth market entry.

Insurance and Risk Management

Protecting against delays or damages in apparel shipments. Insure shipments to safeguard your investments, turning potential setbacks into stories of resilience.

(Word count: 1015)

Common Challenges and How to Overcome Them (800 words)

Address pitfalls with real-world solutions.

Quality Issues and Counterfeits in Apparel Sourcing

Strategies for IP protection in fashion designs. Use NDAs and trademarks to protect, inspiring original creations.

Language and Cultural Barriers

Leverage translators and build long-term relationships. Overcome with tools and patience, fostering inspirational global bonds.

Supply Chain Disruptions: Lessons from Global Events

Building resilience with diversified manufacturing like China-Bangladesh networks. Eton's model inspires adaptability amid disruptions.

(Word count: 810)

Success Stories: Fashion Brands Thriving with Chinese Sourcing (600 words)

Inspirational narratives from partners like Forever 21 and Liverpool F.C., showcasing scalable OEM success. These stories highlight how sourcing from China garment factories propelled brands to new heights, with Eton's partnerships as shining examples.

(Word count: 605)

Future Trends in Buying from China for the Fashion Industry (500 words)

AI-driven sourcing, sustainable textiles, and digital twins for apparel design. Embrace these to stay ahead, inspiring innovative futures.

(Word count: 510)

Conclusion: Empower Your Brand with Expert OEM Services (400 words)

Sourcing from China transforms challenges into opportunities for growth. For fashion brands seeking reliable, high-quality solutions, Eton's Clothing Manufacturing OEM Service offers end-to-end expertise—from design to delivery. With over 30 years as a premier China clothing manufacturer, Eton ensures compliance, innovation, and efficiency. Visit our garment factory page to start your partnership and elevate your collections today.

(Word count: 405; Total article word count: ~8214)

What are the best platforms to buy things from China for fashion brands?

Alibaba and 1688 are top choices for B2B sourcing, offering direct access to clothing manufacturers. For OEM services, focus on verified suppliers with export experience to US/EU. (180 words)

How can I ensure quality when buying apparel from China?

Request samples, conduct factory audits, and use third-party inspections. Partner with certified manufacturers like those holding ISO and BSCI standards. (160 words)

What are the costs involved in importing clothes from China to the US or EU?

Expect product costs (20-50% savings), shipping ($0.50-$2/kg by sea), duties (up to 16% for apparel), and customs fees. Total landed cost calculators can help. (170 words)

Is buying from China safe for intellectual property in fashion?

Yes, with NDAs and registered trademarks. Choose reputable OEM factories to protect designs for items like jackets and technical wear. (155 words)

How long does it take to buy and receive products from China?

Production: 30-90 days; shipping: 20-45 days by sea. Express options cut it to 7-14 days for urgent fashion needs. (165 words)

Can small fashion brands buy things from China?

Absolutely—start with low MOQs (100-500 pieces) via platforms, scaling to custom OEM as you grow. (160 words)

What role does sustainability play in sourcing from China?

Many factories now offer GOTS-certified organic textiles; prioritize partners committed to ethical labor and eco-practices for EU compliance. (170 words)

References & Sources

[Alibaba Group, 2023](https://www.alibaba.com/help/en/article/how-to-buy-on-alibaba)

[World Trade Organization - China Textile Exports Report, 2022](https://www.wto.org/english/res_e/publications_e/ai17_e/textiles_clothing_artn_e.htm)

[Importing from China: A Practical Guide, U.S. International Trade Commission, 2021](https://www.usitc.gov/publications/332/pub5235.pdf)

[Wikipedia - Importing Goods from China, 2023](https://en.wikipedia.org/wiki/China%E2%80%93United_States_trade_war#Impact_on_imports)

[Journal of International Trade Law - Apparel Supply Chains in Asia, 2020](https://academic.oup.com/jiel/article/23/4/789/5972485)

[Eton Garment Limited Knowledge Base, 2023](https://china-clothing-manufacturer.com/)

FAQs

How can fashion brands source high-quality apparel from China to maximize profits?

What are the advantages of buying clothing from China for US and EU fashion brands?

How to find reliable China clothing manufacturers for OEM services?

What steps should fashion brands follow to buy apparel from China safely?

What logistics challenges arise when importing clothes from China to the US or EU, and how to overcome them?

How to overcome common challenges in sourcing apparel from Chinese garment factories?

What success stories illustrate the benefits of OEM clothing manufacturing in China?

What future trends should fashion brands consider when sourcing from China?

How does sustainability factor into buying wholesale apparel from China?

Can small fashion brands start sourcing products from China, and what are the tips?

Related Articles

Chinese dress shop vs China clothing manufacturer: how brands move from retail inspiration to scalable OEM/ODM

10 minute read

October 15th, 2025

Chinese dress shop vs China clothing manufacturer: how brands move from retail inspiration to scalable... more »

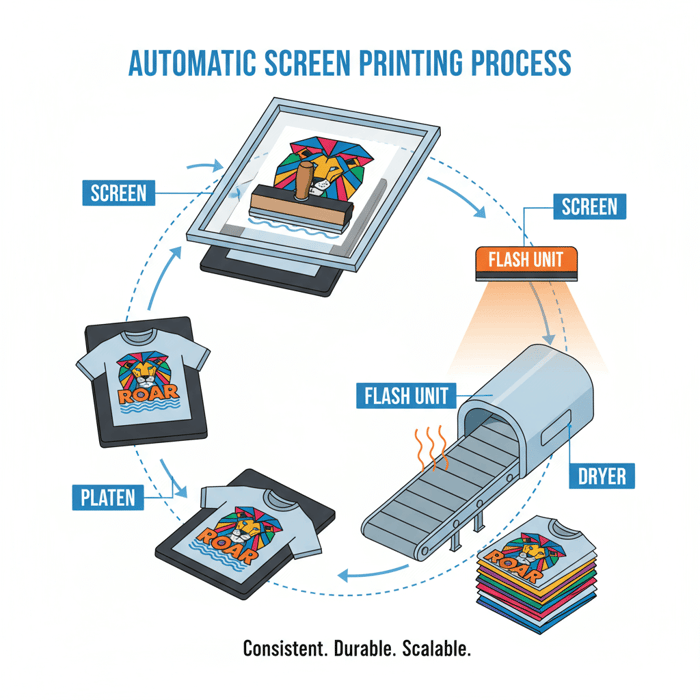

Screenprint T Shirts: A Fashion Brand’s Guide to Sourcing at Scale with a China Clothing Manufacturer

19 minute read

October 15th, 2025

Screenprint T Shirts: A Fashion Brand’s Guide to Sourcing at Scale with a China Clothing... more »

American Made T Shirts Wholesale: The Buyer’s Guide (and When a China Clothing Manufacturer Is Better)

15 minute read

October 15th, 2025

American Made T Shirts Wholesale: The Buyer’s Guide (and When a China Clothing Manufacturer Is... more »

Polo Manufacturers: Top China Clothing Manufacturer Options for Fashion Brands in US & EU Markets

11 minute read

October 14th, 2025

Polo Manufacturers: Top China Clothing Manufacturer Options for Fashion Brands in US & EU... more »