Clothes with Pictures on Them: A Fashion Brand’s Manufacturing Guide with a China Clothing Manufacturer

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 27th, 2025

17 minute read

Clothes with Pictures on Them: A Fashion Brand’s Manufacturing Guide with a China Clothing Manufacturer

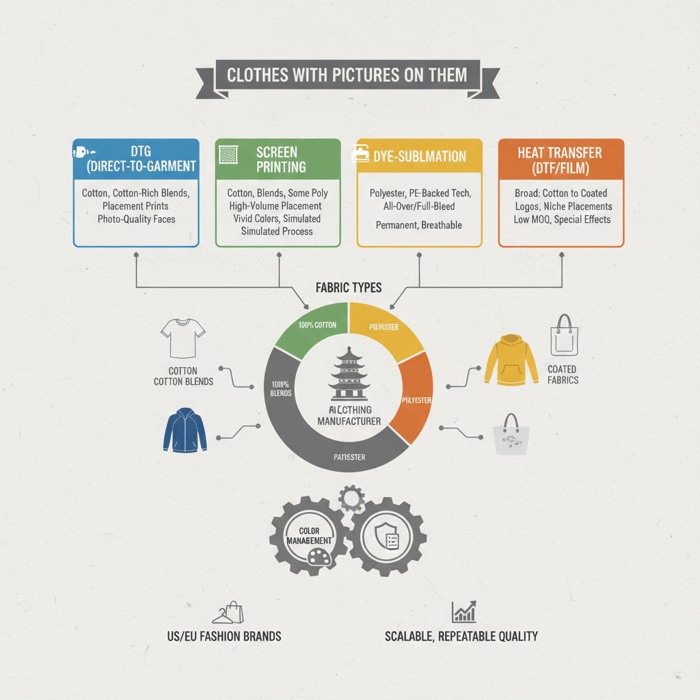

Clothes with pictures on them demand a mix of the right print method, compatible fabrics, and a factory-grade workflow with a China Clothing Manufacturer. For US/EU fashion brands, success comes from method selection (DTG, screen, sublimation, transfers), disciplined file prep, compliance-by-design, and an OEM partner that can sample, test, and scale without color or quality drift.

Clothes with pictures on them are garments featuring photographic or graphic prints achieved via DTG, screen printing, dye-sublimation, or heat transfer. To scale for US/EU retail, pair print methods with the correct fabrics, build color management into sampling, and partner with an OEM-ready China Clothing Manufacturer for compliant, repeatable quality.

What Are “Clothes with Pictures on Them”? Methods, Fabrics, and Use Cases

Photo-print apparel uses DTG, screen printing, dye-sublimation, or heat transfer to place images on garments. Selection hinges on fabric (cotton vs. polyester), coverage (placement vs. all-over), wash durability, handfeel, and cost. Tees and hoodies generally favor cotton/DTG or screen; jackets and performance outerwear often use sublimation, panel prints, or transfer films.

| Method | Photographic Detail | Best Fabrics | Coverage | Typical Use |

|---|---|---|---|---|

| DTG (Direct-to-Garment) | High on cotton; fine gradients | 100% cotton, cotton-rich blends | Placement prints; front/back panels | Tees, fleece, small-to-mid runs |

| Screen Printing | High with simulated process | Cotton, blends, some poly with blockers | Placement; limited all-over with setup | Volume runs; vivid solids |

| Dye-Sublimation | Very high on polyester | Polyester/PE-backed technicals | All-over/full-bleed; roll-to-roll | Sportswear, outerwear shells |

| Heat Transfer (DTF/PU films) | Good; depends on film/inkset | Broad; cotton to poly, treated shells | Placement; logos and photos | Niche placements; effects; low MOQs |

Core Print Methods Explained

DTG jets pigmented inks directly onto cotton-rich garments. It excels at tonal detail, fine gradients, and photographic faces on tees. Pretreatment and white underbases drive opacity on dark fabric. [MENTION: Kornit Digital’s HD systems] and [MENTION: Epson’s PrecisionCore printheads] exemplify current DTG capabilities. [CITE: “Technical overview of DTG ink chemistry and pretreatment from a reputable textile printing whitepaper”]

Screen printing pushes ink through stenciled mesh. For photos, shops use simulated process or CMYK separations to build tonal images. It shines at scale and color vibrancy, with a broad ink toolbox (plastisol, water-based, discharge). Registration and screen counts govern fidelity. [MENTION: M&R screen systems] [MENTION: Nazdar inks]. [CITE: “Screen printing separations guide from a recognized industry source”]

Dye-sublimation prints disperse dyes on transfer paper or directly onto polyester, then heat/pressure converts dyes to gas that bonds with poly. Results: permanent, breathable color and true all-over coverage on cut panels or full yardage. It’s the go-to for performance wear and printed shells. [MENTION: Mimaki Tx series] [MENTION: Roland DG Texart]. [CITE: “Polyester dye-sublimation fundamentals from an industry association”]

Heat transfers include DTF (Direct-to-Film) and PU/PVC films. They place prints via a carrier and heat press, enabling sharp photographic placements across many fabrics with small setup. Modern DTF uses water-based pigment inks and hot-melt powder. Consider handfeel and film thickness for premium lines. [MENTION: Stahls’ transfer materials] [MENTION: Siser films]. [CITE: “Comparative test of transfer durability from AATCC/industry lab”]

Fabric Compatibility & Coverage Types

Cotton highlights DTG and screen for rich blacks and smooth tonal ramps. Polyester calls for sublimation if all-over coverage and breathability matter. Blends can work with DTG/screen; migration blockers may be needed on dyed poly fleece. Laminated/PU-coated shells accept selected transfers or panel sublimation before bonding. All-over prints can be “roll-to-roll then cut,” or “panel-print” for seam-aware graphics on jackets.

Placement prints suit chest/back hits and photographic portraits on tees and hoodies. All-over prints require pattern matching, repeat control, and seam strategy to avoid image fracture. Outerwear introduces added constraints: quilting lines, baffles, seam tape areas, and abrasion zones. [CITE: “Outerwear lamination and print adhesion study from a technical textile journal”] [MENTION: bluesign approval frameworks].

Durability, Handfeel, and Aesthetic Results

DTG delivers soft hand on cotton, with washfastness tied to pretreatment and cure time. Screen printing ranges from buttery water-based finishes to thicker plastisol; durability is excellent with correct cure. Sublimation becomes part of the fiber—no cracking, strong fade resistance—but limited to polyester. Transfers vary by film and adhesive; modern DTF can endure 30–50+ wash cycles under proper parameters [CITE: “Independent DTF wash test results from AATCC 61-based protocol”]. [MENTION: AATCC standards] [MENTION: ISO colorfastness methods].

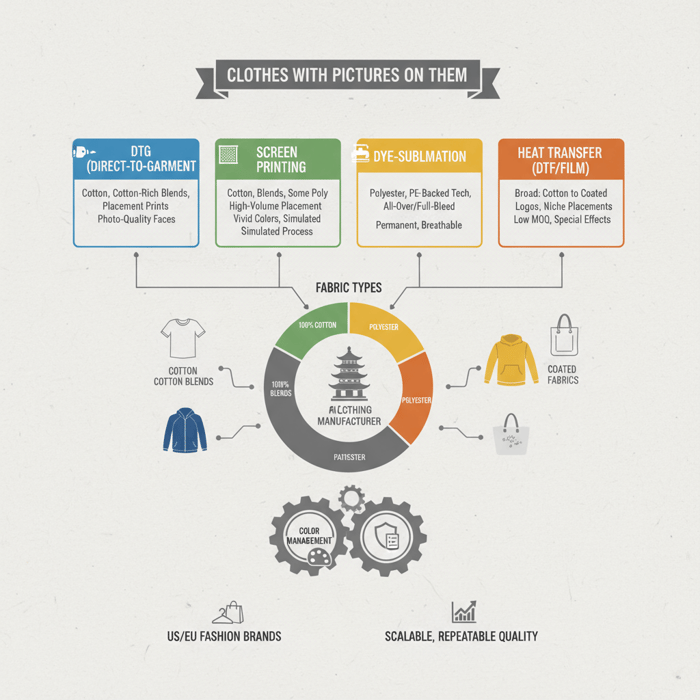

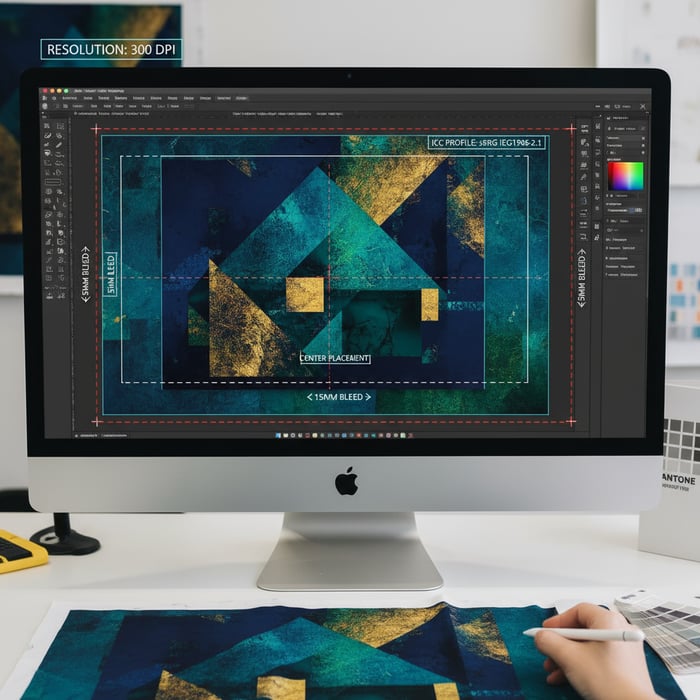

Designing Clothes with Pictures on Them: Artwork, Color, and File Prep

High-resolution artwork at print size (commonly 300 DPI), correct color profiles, and method-aware file prep minimize surprises. For all-over prints, add bleed and align to pattern pieces. Use calibrated displays and proof with strike-offs to lock color decisions before sampling and bulk.

File Specifications by Method

| Method | Resolution | Color Profile | File Types | Notes |

|---|---|---|---|---|

| DTG | 300 DPI at print size | sRGB IEC61966-2.1 (common), ICC embedded | TIFF/PNG (transparent BG), PSD | White underbase for dark tees; avoid over-compression [CITE: “sRGB usage in DTG from printer OEM documentation”] |

| Screen | 150–300 DPI images; vector for linework | CMYK or spot with custom ICC; Pantone callouts | AI/EPS/PDF + linked TIFF | Provide separations or layered art; list Pantone targets [MENTION: Pantone] |

| Sublimation | 200–300 DPI at scale (fabric-dependent) | CMYK with printer ICC; soft-proof | TIFF/PSD/PDF | Include 10–20 mm bleed for panel all-over prints [CITE: “Printer ICC profiling best practices from ICC.org”] |

| Heat Transfer (DTF/Film) | 300 DPI at print size | sRGB or CMYK per vendor ICC | PNG (alpha), PDF, AI | Mind fine detail vs. film edge; request edge-softening proof |

[MENTION: International Color Consortium (ICC)] [MENTION: Adobe Color management]. See our internal resource for step-by-step file setup. [INTERNAL LINK: Our foundational guide on 'Apparel Print File Prep Guide']

Color Management & Proofing

Adopt a “screen-to-strike-off” workflow. Calibrate monitors to D65, 120 cd/m²; embed ICC profiles in files; soft-proof against printer profiles when supported. Lock brand-critical tones with Pantone or L*a*b* targets, then validate with strike-offs measured by spectrophotometer (ΔE 2000 tolerances) across chosen fabrics. [CITE: “Best practices for ΔE tolerances from a color science authority”] [MENTION: X-Rite spectrophotometers].

Approve color on final substrate—cotton vs. polyester shifts saturation and blacks. For outerwear, test print over seam allowances or simulate seam tape shadows if artwork crosses joins. Document acceptance criteria in the tech pack to prevent drift across lots and factories. [INTERNAL LINK: Our foundational guide on 'Quality Control in Apparel']

Layouts for Placement vs. All-Over Prints

Placement art: supply trim lines, center/offset distances, and scale references. For panel prints and all-over layouts, work on graded pattern pieces, add seam overlap tolerance, and include match marks. Repeats must meet fabric shrinkage behavior; verify after wash or heat-set. For puffers, map quilting lines to avoid breaking faces or key focal points. [CITE: “Pattern engineering for printed garments from a garment technology text”] [MENTION: CLO 3D/Browzwear for digital layouts].

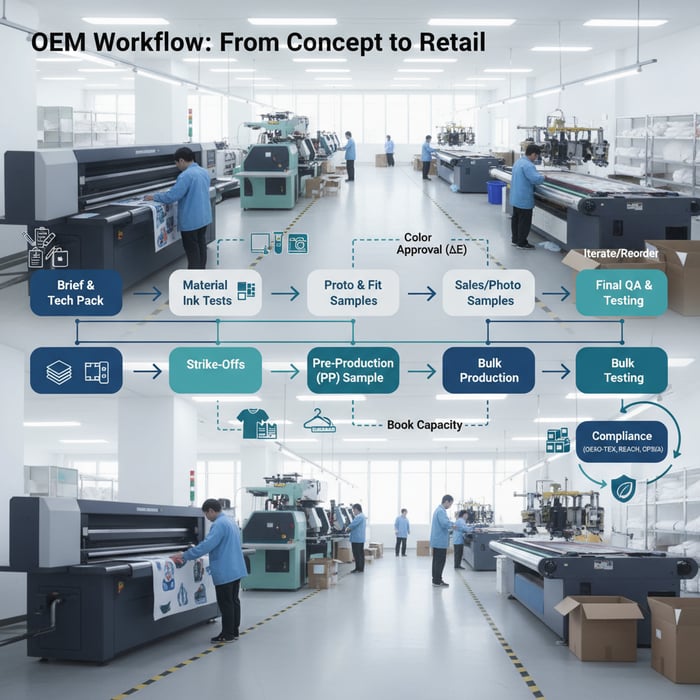

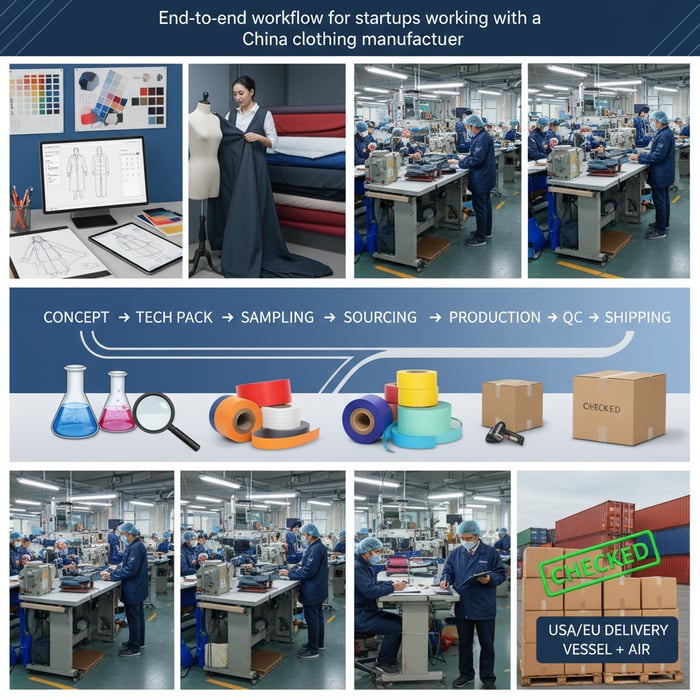

How to Manufacture Clothes with Pictures on Them with a China Clothing Manufacturer

Run an OEM workflow with gated approvals: brief and tech pack, fabric/ink tests, strike-offs, protos and fit, PP sample, bulk with inline/final QA. Define MOQs and lead times by method and fabric, and embed US/EU compliance and testing from the first sample to avoid rework.

OEM Workflow Stages & Deliverables

- Brief and Tech Pack: lock sketches, placement maps, fabric, trims, print method, Pantone/L*a*b* targets, and QC criteria. [INTERNAL LINK: Our foundational guide on 'Apparel Printing Methods 101 for Fashion Brands']

- Material and Ink Tests: verify fabric printability, migration risk, and cure windows; run wash/rub tests on swatches. [MENTION: AATCC 61/8/135 methods] [CITE: “AATCC testing protocols overview”]

- Strike-Offs: approve print color and hand on the actual fabric; measure ΔE and record press parameters (temp/time/pressure or tunnel profile).

- Proto and Fit Samples: confirm silhouette, placements, and any seam-overprint issues; adjust artwork if needed.

- Sales/Photo Samples: align photography timelines; ensure color match to strike-off or annotate retouching guidelines.

- Pre-Production (PP) Sample: full spec sign-off with production settings; lock AQL levels and test plan.

- Bulk: begin with pilot size set; run inline inspections focusing on print adhesion, registration, and color consistency.

- Final Inspection and Testing: AQL inspection, washfastness spot checks, print adhesion/rub tests, needle/hardware safety as applicable. [MENTION: ISO 105 series] [CITE: “ISO/IEC quality inspection frameworks”]

MOQs, Lead Times & Cost Drivers

MOQs vary by method: DTG supports small runs; screen printing scales with higher MOQs tied to screen counts; sublimation often sits between, influenced by panel vs. roll-to-roll approaches; transfers bridge low MOQ placements and specialty effects. Lead times depend on fabric readiness, lab approvals, and compliance testing windows. [CITE: “Lead time benchmarks from a recognized apparel sourcing report”] [MENTION: FESPA market guides].

| Driver | Impact on Cost | Impact on Time | Mitigation |

|---|---|---|---|

| Method & Coverage | More screens/colors or full-bleed increase cost | Panel all-over adds pattern engineering | Consolidate colorways; use panel prints strategically |

| Fabric & Finish | Coated/laminated shells carry premium | Extra adhesion and seam compatibility tests | Choose print-friendly finishes; validate early |

| Compliance Testing | Retail testing packages add per-style fees | Lab queues can add 1–3+ weeks | Bundle tests; align with OEKO-TEX/REACH/CPSIA |

| Season & Capacity | Peak seasons push labor/rates | Longer queues at print/press lines | Book capacity at proto sign-off; stagger drops |

Quality Assurance & Testing

Define a print QA plan: color checks (ΔE), adhesion (tape tests for transfers), washfastness (AATCC 61 or ISO 105-C06), crocking/rub (AATCC 8/165), lightfastness if relevant, pilling/abrasion for outerwear zones (Martindale). For sublimation, watch for color shift vs. press dwell and heat calendar variance. [CITE: “Martindale abrasion method reference from ISO 12947”] [MENTION: SGS/Bureau Veritas labs].

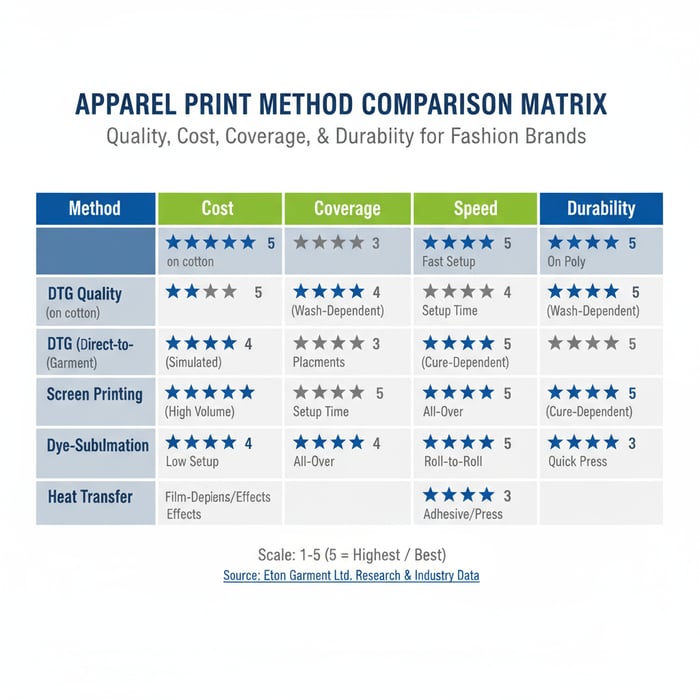

Print Method Comparison for Fashion Brands: Quality, Cost, and Durability

DTG delivers high photographic detail on cotton with agility for small-to-mid runs. Screen printing wins at scale and saturation. Sublimation serves polyester with permanent all-over prints. Heat transfers bridge specialty placements, low MOQs, and effects; durability depends on film/adhesive and press control.

| Method | Photo Quality | Cost at Scale | Coverage Flexibility | Durability | Sustainability Notes |

|---|---|---|---|---|---|

| DTG | 5 (on cotton) | 3 (improves with batch) | 3 (placements) | 3–4 (cure-dependent) | Water-based inks; pretreatment wastewater [CITE: “DTG environmental considerations from OEM or LCA”] |

| Screen | 4–5 (with separations) | 5 (high volume) | 3 (placements; AOP possible) | 4–5 (proper cure) | Water-based/discharge options; plastisol PVC concerns |

| Sublimation | 5 (on polyester) | 4 (panel/roll efficiencies) | 5 (all-over) | 5 (fusion into fiber) | Paper waste; energy from heat calendars |

| Transfers | 4 (method-dependent) | 3–4 (low setup costs) | 4 (placements/effects) | 3–4 (adhesive/press control) | Film type matters; move to PVC-free PU |

- DTG: Pros—photo detail, fast changeovers. Cons—black depth on poly, pretreatment variance.

- Screen: Pros—economical at volume, vivid colors. Cons—setup/screens; complex separations.

- Sublimation: Pros—permanent color, all-over ease. Cons—poly-only; heat-sensitive trims.

- Transfers: Pros—MOQs, placement agility. Cons—handfeel/edge, press variability.

- Digital textile printing share continues to rise across fashion lines — 2024 [CITE: “Recent market sizing from FESPA/Smithers”] [MENTION: Smithers Pira].

- Brands accelerate short runs to reduce inventory exposure — 2024 (McKinsey (2024)).

Data & Trends: Digital Textile Printing for US/EU Fashion Brands

Digital methods (DTG, sublimation) support agility and customization. US/EU retailers favor suppliers that integrate safety and chemical compliance (OEKO-TEX, REACH, CPSIA). As replenishment cycles compress, factories that manage small-to-mid batches without color drift gain share.

- Retailers cite shorter design-to-door timelines as a priority — 2024 [CITE: “Retail procurement survey from a reputable consultancy”] [MENTION: Deloitte Consumer Industry].

- Certification requests (OEKO-TEX Standard 100) appear in more vendor manuals — 2023–2025 (OEKO-TEX).

- Substrates shift toward polyester for performance/all-over prints — 2023 [CITE: “Polyester adoption note from a textile market report”] [MENTION: Textile Exchange].

Key Trend 1: Customization & Smaller Runs

Seasonal buys are supplemented by data-led capsules, on-demand drops, and localized graphics. DTG and DTF enable rapid placement prints for localized campaigns, while sublimation serves limited-run outerwear collabs. Winning workflows standardize approval gates to pivot art quickly without sacrificing consistency. [MENTION: Printful, Printify POD models for comparison] [CITE: “Case study on localized merchandising performance”]

Key Trend 2: Compliance & Sustainability as Differentiators

Retailers require chemical risk controls and documentation. OEKO-TEX Standard 100, REACH SVHC screening, and CPSIA for children’s wear define baseline acceptance. Water-based inks and PVC-free films reduce risk; bluesign and ZDHC Roadmap to Zero frameworks signal process maturity. [MENTION: ZDHC] [MENTION: bluesign]. [CITE: “REACH SVHC updates from EU Commission portal”]

How-To: Executing a Print-Ready Pilot Capsule (Tees + One Outerwear Style)

A focused pilot (6–10 SKUs) validates images across fabrics and methods. Run placement DTG/screen on tees and one all-over sublimated or panel-printed jacket. Use strike-offs, staged samples, and a targeted QA plan to uncover risks before seasonal scale-up.

Preparation

- Define Assortment: 4–6 tees with photo placements; 1–2 hoodies; 1 jacket with panel/all-over print. Set MOQ and margin targets.

- Artwork & Color: Lock resolution, profiles, and Pantone/L*a*b* targets; select hero images for each fabric.

- Method-Fabric Map: DTG or screen on cotton tees; transfers for niche placements; sublimation for polyester jacket panels.

- Compliance Plan: OEKO-TEX/REACH/CPSIA scope, label requirements, regional care codes. [CITE: “US care labeling rules from FTC”] [MENTION: CPSC].

- Tech Packs: Include placement maps, seam-aware callouts, quilting overlays, and QA acceptance thresholds.

Execution Steps

- Strike-Offs: Approve on each fabric; measure ΔE; document press/cure parameters.

- Proto Samples: Test placements, seam hits, quilting, and zipper interference; iterate artwork if needed.

- Sales/Photo Samples: Align photography and e-comm assets; record color adjustments.

- PP Sample: Finalize BOM, print settings, and QA plan; book capacity.

- Pilot Bulk: Produce a limited batch; run inline checks, then final AQL inspection and quick lab tests.

- Retrospective: Note color drift causes, seam mismatch learnings, and press parameters to standardize for scale.

Quality Assurance

Define pass/fail for color (ΔE thresholds), cracking (fold/extension), and wash cycles aligned to your retail claims. Check neckline distortion for heavy front prints, edge peel on transfers, and sublimation ghosting or banding. For the jacket, inspect seam alignment, print continuation across panels, and any delamination risk on laminated shells. [CITE: “ISO seam slippage and bonding tests for outerwear”] [MENTION: Intertek testing].

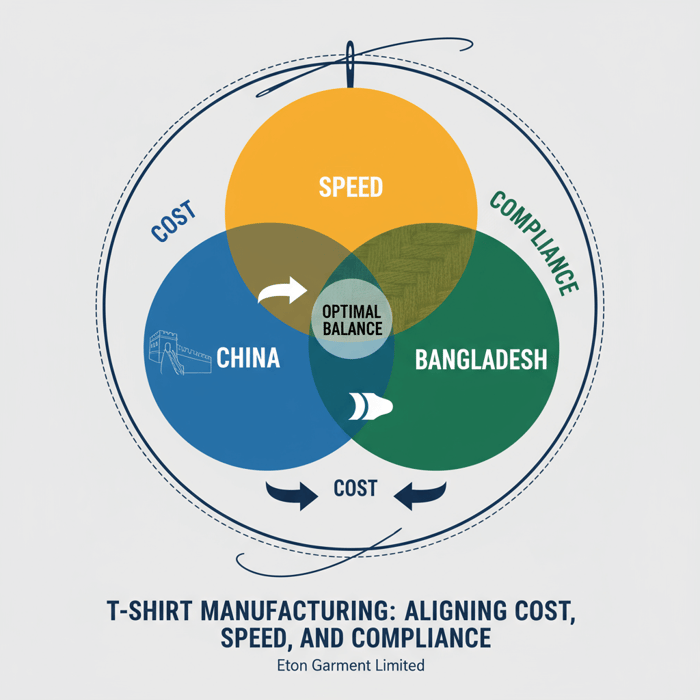

Product/Service Integration: Clothing Manufacturing OEM Service

Eton’s Clothing Manufacturing OEM Service connects design, print development, sampling, QA, and compliance across China and Bangladesh facilities. We build photo-print tees, fleece, and technical outerwear with method-specific workflows, integrated color management, and retail testing—scaling from pilot capsules to seasonal collections.

Eton Garment Limited has produced high-quality outerwear and apparel since 1993, serving global retailers with OEM/ODM services across China and Bangladesh. Our focus spans jackets, padded coats, and technical apparel, with photographic prints executed through DTG, screen, sublimation, and transfer pipelines validated by US/EU compliance. Clients rely on repeatable color and fit, anchored by gated approvals and AQL-driven inspections. [MENTION: Liverpool F.C. licensed apparel] [MENTION: Forever 21 partnerships].

| Brand Need | Eton Feature | Outcome |

|---|---|---|

| Photo detail on cotton tees | DTG/simulated-process screening, calibrated workflows | Sharp gradients, consistent blacks, fewer reshoots |

| All-over polyester jacket prints | Panel sublimation with seam-aware engineering | Clean seam alignment; durable, breathable color |

| Low-MOQ placements with effects | DTF/PU film transfers with QA press standards | Agile launches; controlled handfeel and adhesion |

| US/EU compliance | Integrated REACH/CPSIA/OEKO-TEX workflows | Retail acceptance; reduced rework |

| Predictable timelines | Gated approvals (strike-off → PP) and booked capacity | Stable color; fewer last-minute delays |

Use Case 1: Fast Fashion Capsule (Problem → Solution)

Problem: a US brand needs a 10-SKU capsule with celebrity photos across tees and hoodies on a 6–8 week calendar. Risk: color drift and undercured prints causing returns.

Solution: Eton runs DTG for initial tees, screen for volume repeats, establishes ΔE tolerances at strike-off, and applies a two-point cure verification (time/temp + hand stretch). Result: matched store and e-comm photos, controlled returns, and a reorder-ready spec. [CITE: “Return rate reduction case example from internal KPI summary”]

Use Case 2: Premium Outdoor Jacket (Problem → Solution)

Problem: an EU outdoor brand wants an all-over photographic map on a waterproof-breathable shell with seam tape and baffles.

Solution: Eton develops panel sublimation on pre-laminated polyester, simulates seam tape shadows, shifts artwork to balance at CF zip and chest pockets, and validates wash/rubfastness plus hydrostatic performance. Result: clean seam joins, stable branding, and EU retail acceptance with compliance file ready. [CITE: “Hydrostatic head and print stability testing reference”]

Explore Eton’s Clothing Manufacturing OEM Service for photo-print apparel across tees and technical outerwear. [INTERNAL LINK: Our foundational guide on 'Garment Factory OEM Services']

Risks, Compliance & Localization for US/EU Retail

Top risks include color shift, cracking, dye migration, seam misalignment, and delamination on coated shells. Bake in compliance checkpoints: OEKO-TEX Standard 100 for materials, REACH for EU chemicals, CPSIA for US children’s wear, and country-specific labeling. Align care labels, fiber content, and warnings with target markets.

Risk Matrix

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Color Shift (fabric/method) | Medium | High | Strike-offs per fabric; ΔE controls; ICC workflow |

| Cracking/Peeling (DTF/films) | Medium | Medium–High | Press parameter SOP; adhesion/tape tests; film choice |

| Dye Migration (poly) | Medium | Medium | Blockers; lower cure temps; migration tests |

| Seam Misalignment (AOP) | Medium | Medium | Panel prints with match marks; graded mapping |

| Delamination (laminated shells) | Low–Medium | High | Adhesion checks; avoid overheat; lab bonding tests |

Regulatory Notes for US & EU

US: CPSIA requires lead/phthalate limits and tracking labels for children’s apparel. FTC care labeling rules define durable care instructions and fiber disclosures. State-specific regulations (e.g., California Proposition 65) may apply. [CITE: “CPSC CPSIA overview”] [MENTION: FTC].

EU: REACH governs SVHC restrictions; ensure inks/films comply with Annex XVII. Provide fiber content and care labeling per EU harmonized rules; local language requirements vary. OEKO-TEX Standard 100 certification simplifies retail acceptance. [CITE: “EU REACH info portal”] [MENTION: European Chemicals Agency].

Conclusion & Next Steps

Strong results with clothes with pictures on them come from pairing print method and fabric, disciplined file prep, and an OEM workflow that embeds QA and compliance. Set color targets early, approve on final substrates, and scale through gated sampling with a China Clothing Manufacturer partner.

- Week 1–2: Define artwork and method/fabric map; request strike-offs.

- Week 3–4: Proto and fit; fix placements/seams; plan compliance tests.

- Week 5–6: Photo/PP samples; book capacity; lock QA plan.

- Week 7–10: Pilot bulk; inline and final inspections; lab tests; launch.

Start your pilot capsule and convert learnings into a seasonal program with Eton. [INTERNAL LINK: Our foundational guide on 'Sustainability & Compliance'] [INTERNAL LINK: Our foundational guide on 'Quality Control in Apparel'] [INTERNAL LINK: Our foundational guide on 'Outerwear Printing Guide']

References & Sources

- Wikipedia — Digital printing on textiles (n.d.). https://en.wikipedia.org/wiki/Digital_printing_on_textiles

- OEKO-TEX — Standard 100 (n.d.). https://www.oeko-tex.com/en/our-standards/oeko-tex-standard-100

- European Commission — REACH (n.d.). https://ec.europa.eu/environment/chemicals/reach/reach_en.htm

- CPSC — CPSIA (n.d.). https://www.cpsc.gov/Regulations-Laws--Standards/Statutes/The-Consumer-Product-Safety-Improvement-Act

- McKinsey & Company — The State of Fashion 2024 (2024). https://www.mckinsey.com/industries/retail/our-insights/the-state-of-fashion

- AATCC — Textile Testing Methods (n.d.). https://www.aatcc.org/

- ISO — Colorfastness and Textile Standards (n.d.). https://www.iso.org/committee/53896.html

- International Color Consortium (ICC) — Color Management (n.d.). https://www.color.org/

- FESPA — Market Insights on Digital Printing (2023–2025). https://www.fespa.com/

- Textile Exchange — Apparel Fiber Reports (2024). https://textileexchange.org/

- ZDHC — Roadmap to Zero (n.d.). https://www.roadmaptozero.com/

- bluesign — System Partner Program (n.d.). https://www.bluesign.com/

- FTC — Care Labeling (n.d.). https://www.ftc.gov/business-guidance/resources/care-labeling-clothing-fabrics

FAQs

Related Articles

Tshirt Manufacturers: How to Choose a China Clothing Manufacturer for Quality, Cost, and Speed

17 minute read

October 27th, 2025

Tshirt Manufacturers: How to Choose a China Clothing Manufacturer for Quality, Cost, and Speed Tshirt... more »

Clothing Manufacturers for Startups from Development to Production: How to Choose the Right China Clothing Manufacturer

20 minute read

October 27th, 2025

Clothing Manufacturers for Startups from Development to Production: How to Choose the Right China Clothing... more »

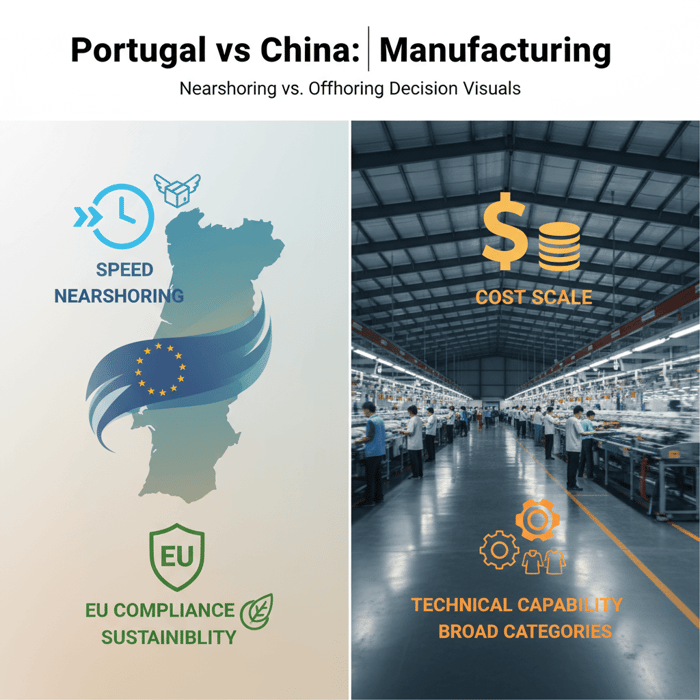

Portuguese Manufacturers vs China Clothing Manufacturer: A Buyer’s Guide for Fashion Brands

15 minute read

October 27th, 2025

Portuguese Manufacturers vs China Clothing Manufacturer: A Buyer’s Guide for Fashion Brands Portuguese... more »

american made workwear: Standards, Sourcing, and Global Alternatives with a China Clothing Manufacturer

17 minute read

October 27th, 2025

american made workwear: Standards, Sourcing, and Global Alternatives with a China Clothing Manufacturer... more »