american made workwear: Standards, Sourcing, and Global Alternatives with a China Clothing Manufacturer

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 27th, 2025

17 minute read

american made workwear: Standards, Sourcing, and Global Alternatives with a China Clothing Manufacturer

american made workwear speaks to durability, safety, and truth-in-labeling. For brands in the US and EU, the claim intersects with FTC rules, OSHA/NFPA performance standards, price architecture, and capacity planning. The category spans heavy-duty uniforms, FR/arc flash gear, and technical outerwear. Teams weighing domestic production against a China Clothing Manufacturer face trade-offs: claim integrity, total landed cost, lead times, and scale. This playbook provides the legal definitions, the build steps, and the sourcing frameworks that keep claims honest and garments field-ready.

An unqualified “Made in USA” claim carries a high bar—“all or virtually all” of the product’s significant parts and processing must be of US origin. Imported trims and key fabric rolls can break that threshold without careful qualification. Brands need precise claim language, documented origin for every component, and a supplier roster that matches both standards and volume forecasts. Label integrity and performance testing go hand in hand.

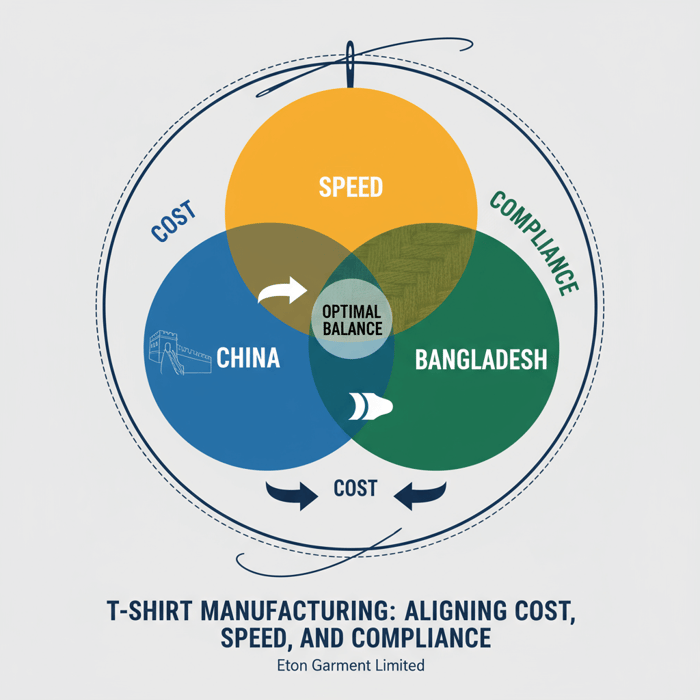

Domestic factories bring proximity and authenticity, which resonates with US buyers. Overseas partners provide scale, specialized machinery, and cost advantages, especially for insulated outerwear, seam-sealed garments, and advanced laminates. Dual-sourcing—US for limited runs and a China Clothing Manufacturer for scale—can support resilience, provided claims stay truthful. A qualified claim or split assortment strategy often solves the capacity puzzle without misleading consumers.

Eton Garment Limited has produced technical apparel since 1993, supporting global retailers with OEM and ODM services. The company’s teams have handled FR fabrics, high-tenacity nylons, and complex reinforcement layouts across China and Bangladesh. For lifestyle or industrial segments, this guide translates compliance into build-ready steps and helps brands position american made workwear honestly while planning for growth.

american made workwear qualifies for an unqualified “Made in USA” claim only when “all or virtually all” significant parts and processing are U.S.-made. If any notable part or processing is imported, use a qualified claim. Compare domestic and overseas total landed costs, standards compliance, and lead times; build dual-sourcing with accurate, transparent labels.

What “american made workwear” Legally Means (FTC Rules, Claim Types, Examples)

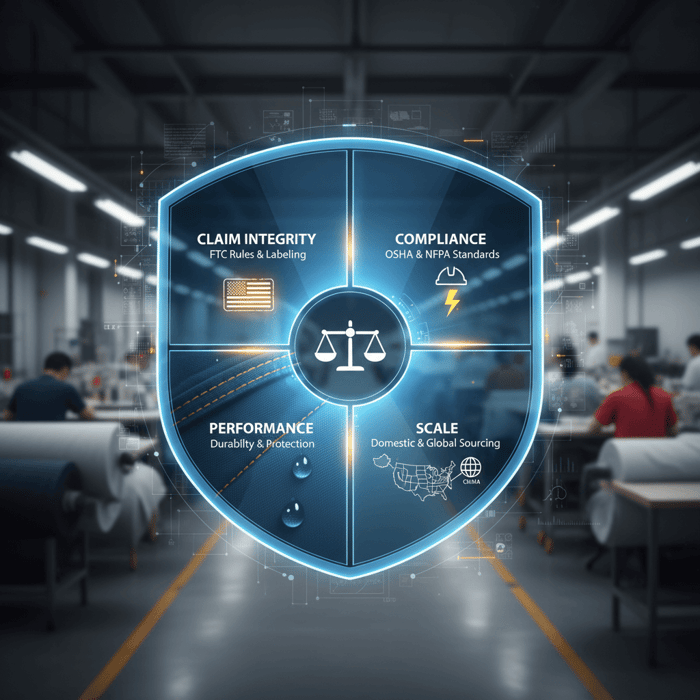

Unqualified “Made in USA” requires that all or virtually all significant parts and processing are of U.S. origin. Qualified claims, such as “Made in USA of U.S. and imported parts,” must be truthful and specific. Build an internal claim audit that checks fabric, trims, processing steps, and packaging against FTC guidance. [CITE: FTC compliance guide official page]

[MENTION: Federal Trade Commission], [MENTION: U.S. Customs and Border Protection]

[INTERNAL LINK: Our foundational guide on FTC-compliant labeling for apparel]

- Unqualified “Made in USA” — All or virtually all significant parts and processing are U.S.-origin; minimal foreign content. [CITE: FTC definition of unqualified claims]

- Qualified “Made in USA of U.S. and imported parts” — Some components or processing imported; qualifier must be clear and not misleading.

- “Assembled in USA” — Final assembly occurs in the U.S.; principal assembly steps are substantial; imported parts permitted with truthful disclosure.

| Claim Type | Requirements | Example Language | Risk Level |

|---|---|---|---|

| Made in USA (Unqualified) | All or virtually all significant parts and processing are U.S.-origin; negligible foreign content | “Made in USA” on label and product page | High if any notable imported fabric, key trims, or primary processing exists |

| Made in USA (Qualified) | Truthful qualifier describing imported parts/processing; avoid broad or vague phrasing | “Made in USA of U.S. and imported parts” or “Made in USA – fabric imported” | Moderate if qualifier is precise and substantiated |

| Assembled in USA | Substantial assembly in U.S.; principal assembly steps occur domestically; disclose imported parts | “Assembled in USA with globally sourced materials” | Moderate; verify that assembly steps are substantial, not minor |

| Designed in USA | Concept/design in U.S.; does not indicate origin of parts or processing | “Designed in USA” (avoid implying domestic manufacturing) | Low if used alongside accurate origin claims |

[CITE: FTC enforcement cases demonstrating mislabeling consequences]

PAA micro-question: Can a brand claim “Made in USA” if buttons or zippers are imported? A single imported trim can be acceptable only if it is de minimis. Significant imported components or processing typically require a qualified claim. Document the trim’s cost share, functional role, and origin. [CITE: FTC de minimis principle explanation]

Unqualified vs Qualified Claims (What’s Allowed)

Unqualified claims suit products with U.S.-woven fabric, U.S.-made trims, and U.S. cutting/sewing/finishing. Qualified claims fit where fabric is imported, or key trims come from overseas, yet cutting and sewing occur in the U.S. Be concrete: name the imported component and avoid hedging language. Document BOM cost shares and processing steps, including dyeing, laminating, quilting, seam sealing, and packaging. [CITE: FTC guidance on qualified claims language]

Practical templates align to FTC expectations:

- FR pant with imported zippers: “Made in USA – trims imported (YKK zipper from Japan).”

- Arc flash jacket with EU fabric: “Made in USA of imported FR fabric, assembled and tested domestically.”

- Lifestyle chore coat: “Assembled in USA with globally sourced materials; patterning, cutting, and finishing in North Carolina.”

[MENTION: YKK], [MENTION: National Institute of Standards and Technology]

Assembled in USA vs Final Processing (Truthful Boundaries)

“Assembled in USA” requires substantial assembly steps—multiple operations that transform components into a finished garment. Simple activities like attaching a label or performing minor finishing do not qualify. Trace the principal steps: grading, cutting, stitch assembly, attaching pockets and reinforcements, setting zippers/snaps, bar-tacking stress points, laundering/pressing, packaging. If substantial steps occur in the U.S., and parts are imported, “Assembled in USA” can fit with a clear qualifier. [CITE: FTC test for substantial assembly steps]

Create an internal audit worksheet with checkpoints, photos, and timestamps. Align marketing copy to the audit’s scope. Brands should schedule legal review prior to first PO. [INTERNAL LINK: Compliance and labeling checklist]

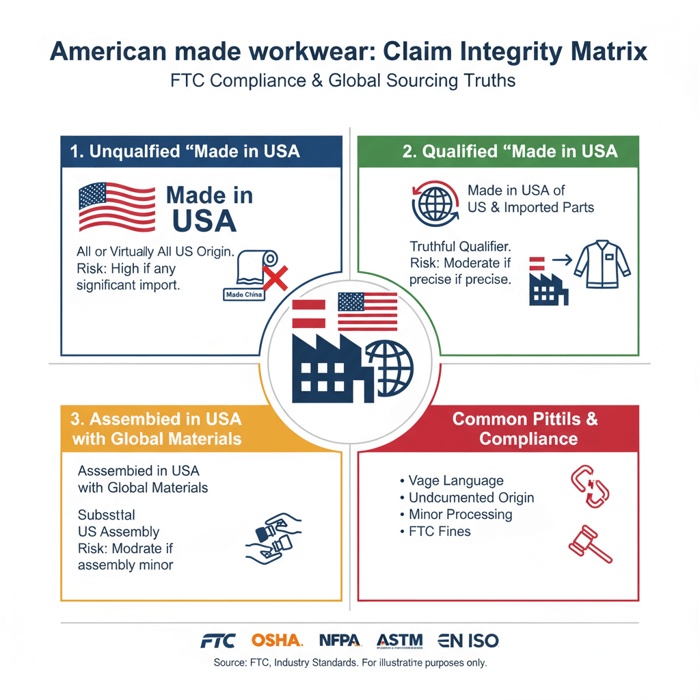

american made workwear vs Overseas Production: Cost, Lead Times, Quality, Scale

Domestic production offers proximity and claim integrity. Overseas partners enable scale, specialized machinery, and lower unit costs. Decide by total landed cost, MOQs, lead times, and required standards. Build a dual-sourcing fallback to reduce exposure to capacity shocks and material shortages. [CITE: Supply-chain resilience reports 2024–2025]

[MENTION: McKinsey & Company], [MENTION: Reshoring Initiative]

- Reshoring announcements remained high in 2024; capacity growth uneven across categories (Source: [CITE: Reshoring Initiative 2024 report]).

- Brands prioritize resilience and nearshoring for speed; capital stays tight in discretionary categories (Source: [CITE: McKinsey State of Fashion 2025]).

| Criteria | Domestic (U.S.) | Overseas (e.g., China Clothing Manufacturer) |

|---|---|---|

| Unit Cost (USD) | Higher; labor and overhead premium | Lower; labor and scale efficiencies |

| MOQs | Lower to medium; flexibility for capsules | Medium to high; efficient at scale |

| Lead Times | Shorter for sampling; medium for production | Longer lead + transit; faster at scale once ramped |

| Specialized Capability | Strong in niches; capacity varies by region | Strong in technical outerwear, seam sealing, quilting |

| Compliance & Testing | Easy lab proximity; clear FTC alignment | Requires rigorous spec packs and documentation |

| Claim Integrity | Supports unqualified “Made in USA” where BOM/process allow | Supports qualified claims; improves price architecture |

| Scale & Consistency | Limited capacity in peaks; local agility | High scale; consistency via strict QA systems |

| Total Landed Cost | No overseas freight/duties; domestic overhead | Add freight, duties, tariffs; lower base unit cost |

For US contracts requiring FR/arc flash, the decision hinges on standards compliance and predictable timelines. For EU lifestyle capsules, price points and assortment breadth often favor dual-sourcing with qualified claims. [CITE: Case summaries on dual-sourcing in apparel]

Criteria Overview (Cost, MOQ, Lead Time, Compliance)

Build the business case around unit economics, MOQs aligned to sell-in, sampling and PPS schedules, and lab test cadence. Domestic can shave weeks off sampling. Overseas can deliver consistent fabric lots and advanced process control. Model total landed cost: materials, labor, consumables, testing, packaging, freight, duties, tariffs, and returns allowances. [CITE: Apparel TCO framework – authoritative source]

Compliance adds cost—FR finishing, arc flash tests, hi-vis certification, and AQL inspections. A clear spec pack offsets rework risk. [INTERNAL LINK: Spec pack template for workwear]

Decision Framework (Scoring Your Brand Priorities)

Score each model against weights: claim integrity (US-only label ambition), standards (FR/NFPA scope), price band, assortment breadth, timelines, and scale. Assign 1–5 scores and compute weighted totals. Keep a fallback path: US pilot for story, overseas scale for margin, with truthful claim segmentation. [CITE: Sourcing decision rubrics – apparel operations research]

Example weighting:

- Claim integrity: 25%

- Standards compliance: 20%

- Price architecture: 20%

- Timelines: 15%

- Scale: 20%

[INTERNAL LINK: Manufacturing workflows for technical outerwear]

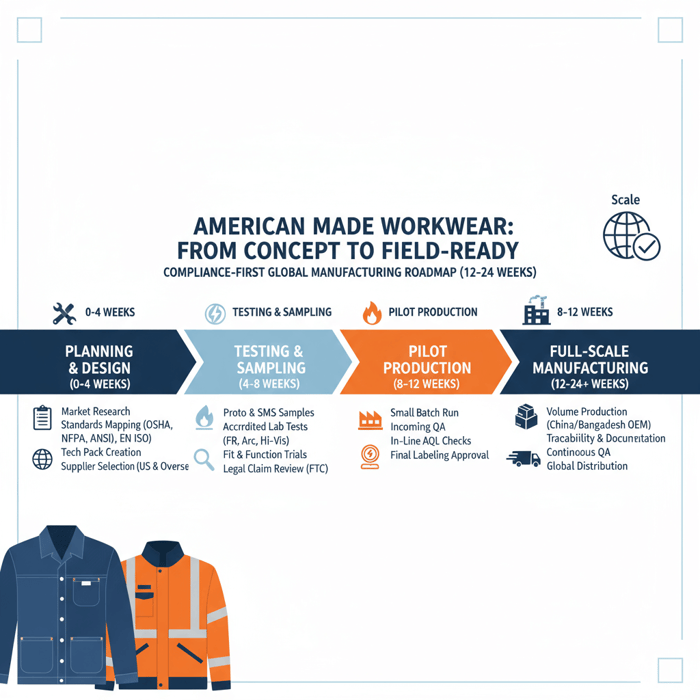

How to Build an american made workwear Line (Step-by-Step)

Define job risks, map standards, write a spec pack, and select suppliers for domestic or dual-source production. Validate claim language early. Test to FR/arc flash/hi-vis standards, run AQL inspections, and pilot before scale. Keep origin documentation for every component to protect label integrity. [CITE: OSHA PPE obligations], [CITE: NFPA 70E 2024]

[MENTION: ASTM International], [MENTION: ANSI/ISEA]

- Define wearer tasks and risk categories.

- Map standards and tests from OSHA/NFPA/ASTM/EN ISO.

- Build a spec pack: materials, construction, reinforcements, tolerances, test plan.

- Set claim strategy with legal review: unqualified, qualified, assembled.

- Select suppliers; align capacity, lead times, and lab support.

- Develop samples; run fit and function trials.

- Test at accredited labs; lock results in PLM.

- Pilot production; perform incoming and in-line QA with AQL.

- Confirm labeling, packaging, and documentation.

- Scale production; maintain traceability and claims audit.

Preparation (Tech Pack, Materials, Claims)

Capture fabric specs: fiber content, weight (gsm), weave, FR treatment or inherent FR, abrasion ratings, tear strength, seam slippage, water resistance, and breathability. Define reinforcements at elbows, knees, and stress points; set bar-tack counts and seam types (e.g., flat-felled, triple-needle). Write trims: zippers, snaps, reflective tapes, labels. Draft claim language and align BOM origin, including thread and interfacing. [CITE: ASTM F1506 for arc-rated clothing]

[INTERNAL LINK: Material testing and certification library]

Execution Steps (Sampling → Testing → Pilot → Scale)

Sampling: produce proto and SMS sets. Fit on target size range; validate reach, kneel, lift, and crouch motions. Testing: FR, arc flash (ATPV/Ebt), hi-vis (color fastness and retroreflectivity), abrasion (Martindale/Taber), and seam strength. Pilot: small batch with full QA—incoming fabric inspection, in-line needle control, final AQL 2.5 or 4.0 based on risk. Scale: lock patterns, approve PPS, freeze materials and trims for consistency. [CITE: Accredited lab directories for textile testing]

[MENTION: SGS], [MENTION: Intertek]

Quality Assurance (AQL, FR/Arc Tests, Traceability)

Set AQL levels by garment type and risk exposure. Track fabric rolls and shade lots with roll IDs. Record lab reports with test methods and dates. Archive photos of assembly steps, bar-tack counts, and seam construction. Maintain a claims file with BOM origin certificates, supplier affidavits, and assembly logs. This documentation supports FTC truthfulness and retailer audits. [CITE: Retail audit requirements for origin and performance claims]

[INTERNAL LINK: Supplier audit checklist for workwear]

Workwear Standards & Materials (OSHA/NFPA/ASTM; Fabric Selection)

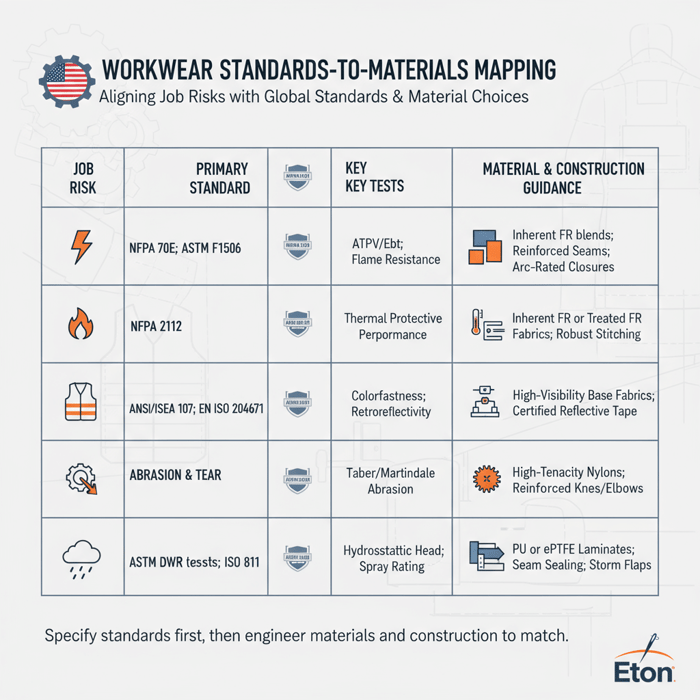

Match job risks to standards and engineer materials accordingly. FR and arc flash garments follow NFPA 70E categories and often reference ASTM F1506. Hi-vis follows ANSI/ISEA 107 or EN ISO 20471. Specify fabric and construction, and confirm performance through accredited lab testing. [CITE: NFPA 70E 2024], [CITE: ANSI/ISEA 107], [CITE: EN ISO 20471]

| Job Risk | Primary Standard | Key Tests | Material & Construction Guidance |

|---|---|---|---|

| Arc Flash | NFPA 70E; ASTM F1506 | ATPV/Ebt; flame resistance; heat transfer | Inherent FR blends; reinforced seams; arc-rated closures; label ATPV |

| Flash Fire | NFPA 2112 | Thermal protective performance; heat resistance | Inherent FR or treated FR fabrics; durable FR treatments; robust stitching |

| Hi-Vis | ANSI/ISEA 107; EN ISO 20471 | Colorfastness; retroreflectivity; luminance | High-visibility base fabrics; certified reflective tape; secure placement |

| Abrasion & Tear | ASTM D3884; ASTM D2261 | Taber/Martindale abrasion; tear strength | High-tenacity nylons; reinforced knees/elbows; bar-tacks at stress points |

| Weather Protection | ASTM DWR tests; ISO 811 | Hydrostatic head; spray rating | PU or ePTFE laminates; seam sealing; storm flaps; clean finishing |

FR & Arc Flash Basics (NFPA 70E Categories)

NFPA 70E defines risk categories based on incident energy. Garments carry arc ratings (ATPV or Ebt) suitable for the task. Typical attributes: inherent FR fabrics, secure closures, protective plackets, and clear labels with arc rating. Pair garments with appropriate PPE ensembles for the full system, including gloves and face shields. [CITE: NFPA 70E arc rating guidance]

Design for consistent protection: controlled stitch types, robust thread, minimal melt-prone components, and tested trims. [INTERNAL LINK: Arc flash apparel development notes]

Hi-Vis & Abrasion Resistance (ASTM/EN ISO)

Hi-vis standards align garment class with minimum areas of background, retroreflective, and combined-performance materials. Specify tape width and placement that meets class rules. For abrasion, choose fabric weights and weaves tied to duty cycles; reinforce knees and elbows; select hard-wearing trims. Run colorfastness and retroreflectivity tests after laundering cycles. [CITE: ANSI/ISEA 107 tape placement requirements], [CITE: EN ISO 20471 class definitions]

[MENTION: bluesign], [MENTION: OEKO-TEX]

Market Data & Trends for american made workwear (US & EU)

Consumers value authenticity and resilience across workwear. Domestic stories command loyalty in US markets, while EU buyers balance value and safety marks. Reshoring announcements continue, yet many brands choose dual-sourcing to match capacity and price points. Segment by industrial contracts vs lifestyle workwear to align claim language and standards. [CITE: State of Fashion 2025], [CITE: Reshoring Initiative 2024]

- Industrial buyers prioritize uptime and compliance, accepting premium pricing for validated gear (Source: [CITE: Industrial PPE procurement study]).

- Lifestyle workwear shows premiumization trends tied to origin and durability claims (Source: [CITE: Consumer behavior report 2024]).

Key Trend 1: Reshoring vs Dual-Sourcing

US capacity grows unevenly across fabric mills, cut-and-sew, and finishing. Domestic pilots support brand storytelling. Overseas scale keeps margin targets intact. Dual-sourcing spreads risk across regions and balances speed with volume. Accurate claim segmentation maintains trust: unqualified for US-only builds, qualified for global mixes. [CITE: Case studies on dual-sourcing in apparel]

[INTERNAL LINK: Sourcing resilience playbook for apparel]

Key Trend 2: Premiumization & Authenticity Claims

Consumers trade up for longer wear, safety credentials, and transparent origin. Clear FTC-compliant language earns repeat purchase. Documented testing and recognized certifications (e.g., bluesign/OEKO-TEX for chemical safety) support a credible story. Lifestyle capsules gain traction with honesty about materials and assembly. [CITE: Premiumization trend data 2024–2025]

[MENTION: Retail Industry Leaders Association], [MENTION: National Retail Federation]

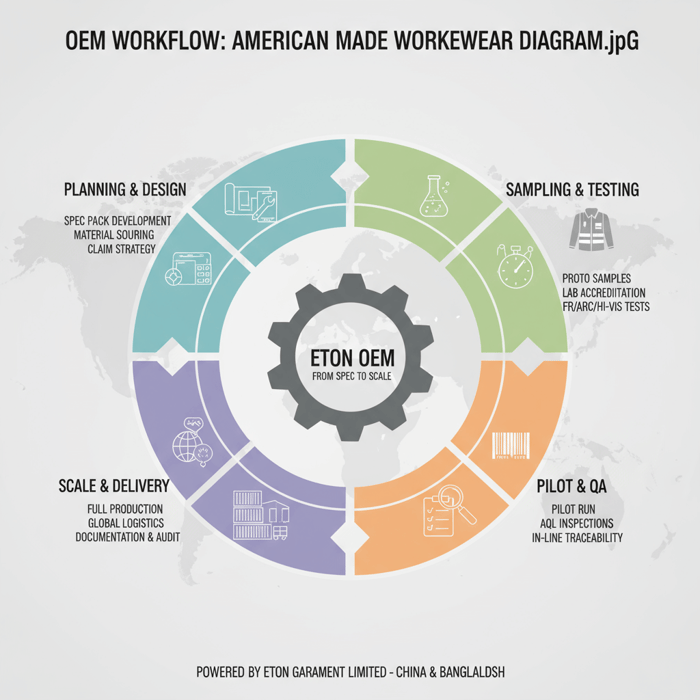

Product/Service Integration: Clothing Manufacturing OEM Service (Eton)

Eton’s Clothing Manufacturing OEM Service supports technical outerwear and durable workwear with pattern development, lab testing, and scalable production in China and Bangladesh. Use Eton for capacity and technical capability while maintaining truthful origin claims for US and EU markets. [CITE: Independent audits on OEM quality and consistency]

[INTERNAL LINK: Technical outerwear capabilities overview]

| Brand Need | OEM Feature | Outcome |

|---|---|---|

| FR/Arc flash jackets | Material handling for FR fabrics; reinforced seam construction; lab testing plan | Validated performance; repeatable quality at scale |

| Insulated parkas | Quilting lines, insulation control; thermal performance testing | Warmth consistency; balanced weight and durability |

| Hi-vis capsules | Certified reflective tape sourcing; correct placement; colorfastness tests | Class compliance; durable visibility after laundering |

| Heavy-duty lifestyle workwear | High-tenacity nylon/canvas selection; bar-tack reinforcement; abrasion testing | Long wear life; fewer returns |

Eton’s teams have managed seam sealing on laminated shells, triple-needle constructions, and stress-point reinforcement maps. Production bases in China and Bangladesh use AQL-driven checkpoints and roll traceability, supported by accredited lab partners. Claim language stays accurate by documenting component origins and processing steps. [CITE: QA performance benchmarks across OEM partners]

Typical timelines:

- Design & proto: 3–5 weeks

- PPS & lab tests: 3–4 weeks

- Pilot production: 4–6 weeks

- Scale ramp: 6–10 weeks

Request a structured scope with testing, AQL, and traceability commitments. Align origin claims with BOM details. For assortment breadth or tight margins, combine domestic pilots with Eton’s scale under a qualified claim. [CITE: Retail timeline norms for outerwear and workwear]

See Clothing Manufacturing OEM Service at https://china-clothing-manufacturer.com/garment-factory/.

Use Case 1: Industrial Outerwear (Problem → Solution)

Problem: A utility brand needs arc-rated jackets with consistent ATPV, abrasion resistance, and storm protection, delivered across multiple regions. Solution: Eton’s technical team sets fabric specs with inherent FR, designs reinforced seam maps, validates arc tests at accredited labs, and controls seam sealing for weatherproofing. AQL 2.5 gates prevent variation. Claim integrity: qualified origin when fabric is imported and assembly occurs overseas. [CITE: Electrical PPE program requirements]

[MENTION: NFPA], [MENTION: OSHA]

Use Case 2: Lifestyle Workwear Capsule (Problem → Solution)

Problem: A US lifestyle label wants american made workwear storytelling but needs price points below premium. Solution: Domestic pilot run for hero pieces labeled unqualified or “Assembled in USA” based on BOM; Eton scales accessory items and off-season capsules with accurate qualified claims. The brand preserves authenticity while meeting margin and delivery windows. [CITE: Case studies on capsule strategies]

[INTERNAL LINK: Brand storytelling and origin claim segmentation]

Risks, Compliance & Localization (US & EU)

Mitigate labeling risk by aligning FTC claim types to BOM and process documentation. US safety references include OSHA PPE rules and NFPA standards. EU equivalents include EN ISO frameworks for hi-vis and protective clothing. Keep a clear claims file, lab reports, and supplier affidavits. Use qualified language when any significant component or processing is imported. [CITE: FTC Made in USA rule], [CITE: EN ISO protective clothing directory]

- Pros: Clear claim integrity; consumer trust; smoother audits; fewer returns linked to performance gaps.

- Cons: Higher unit costs domestically; longer transit for overseas; added compliance admin for dual-sourcing.

Risk Matrix

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Mislabeling FTC claim | Medium | High | Claims audit; legal review; qualified language |

| FR/Arc test failure | Low–Medium | High | Accredited lab tests; material controls; PPS gates |

| Supply disruption | Medium | Medium–High | Dual-sourcing; safety stock; alternate trims |

| Color/reflectivity drift | Medium | Medium | Lot control; laundering tests; certified tapes |

| Returns due to durability | Medium | Medium | Abrasion tests; reinforcement specs; AQL |

Regulatory Notes for US & EU

US: Follow FTC labeling rules for origin claims and OSHA/NFPA for safety. EU: Use EN ISO standards for hi-vis and protective garments; origin claims follow national consumer law and EU guidance on misleading origin statements. Keep documentation in English and local languages as needed for audits. [CITE: EU guidance on origin claims], [CITE: EN ISO 20471 and ISO 11612]

[MENTION: European Committee for Standardization], [MENTION: U.S. Department of Labor]

Conclusion & Next Steps

Set a claim strategy aligned to BOM and process, define standards, and choose a sourcing model: domestic, dual-source, or overseas. Validate performance through accredited labs and lock QA. Document origins for transparency. For technical capacity and scale, partner with Eton’s OEM service and keep labels honest across US and EU markets. [CITE: Retail compliance checklists]

- Choose claim language: unqualified, qualified, or assembled.

- Map risk and standards to each garment.

- Write the spec pack and test plan.

- Select suppliers; confirm capacity and lab support.

- Run samples and PPS; perform tests.

- Pilot with AQL; confirm labels and documentation.

- Scale with traceability and claim audits.

[INTERNAL LINK: Get a production quote – intake form]

Author: Eton Garment Limited Editorial Team (Outerwear & Technical Apparel), 15+ years combined OEM/ODM experience.

Reviewer: Senior Technical Manager, Eton (Quality & Compliance).

Methodology: Standards and regulations reviewed; internal production experience; external sources cited; competitive scan via zero-shot research.

Limitations: Not legal advice; FTC and regional regulations change; validate MOQs/costs with current suppliers.

Disclosure: Eton provides OEM/ODM services; content informs while offering a solution pathway.

Last Updated: 2025-10-27.

- Federal Trade Commission — Complying with the Made in USA Labeling Rule (2024). https://www.ftc.gov/business-guidance/resources/complying-made-usa-standard

- McKinsey & Company — The State of Fashion 2024/2025 (2025). https://www.mckinsey.com/

- Reshoring Initiative — 2024 Data Report (2024). https://reshorenow.org/

- OSHA — 29 CFR 1910 PPE Requirements (Current). https://www.osha.gov/

- NFPA — NFPA 70E Standard for Electrical Safety in the Workplace (2024). https://www.nfpa.org/

- ANSI/ISEA — High-Visibility Safety Apparel and Accessories (Current). https://www.safetyequipment.org/

- EN ISO 20471 — High-visibility clothing (Current). https://standards.iteh.ai/catalog/standards/cen/...

- ASTM International — F1506 Standard (Current). https://www.astm.org/f1506-22.html

- OEKO-TEX — Standard programs (Current). https://www.oeko-tex.com/

- bluesign — System and criteria (Current). https://www.bluesign.com/

FAQs

Related Articles

Tshirt Manufacturers: How to Choose a China Clothing Manufacturer for Quality, Cost, and Speed

17 minute read

October 27th, 2025

Tshirt Manufacturers: How to Choose a China Clothing Manufacturer for Quality, Cost, and Speed Tshirt... more »

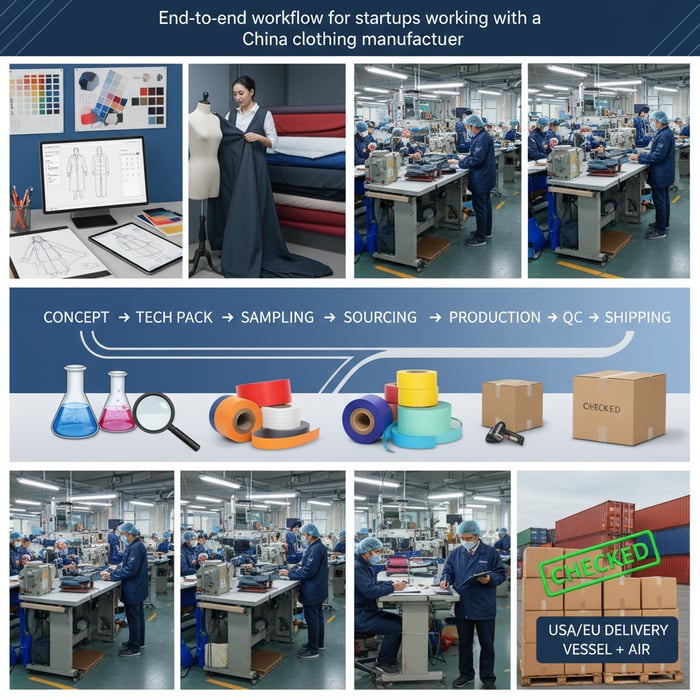

Clothing Manufacturers for Startups from Development to Production: How to Choose the Right China Clothing Manufacturer

20 minute read

October 27th, 2025

Clothing Manufacturers for Startups from Development to Production: How to Choose the Right China Clothing... more »

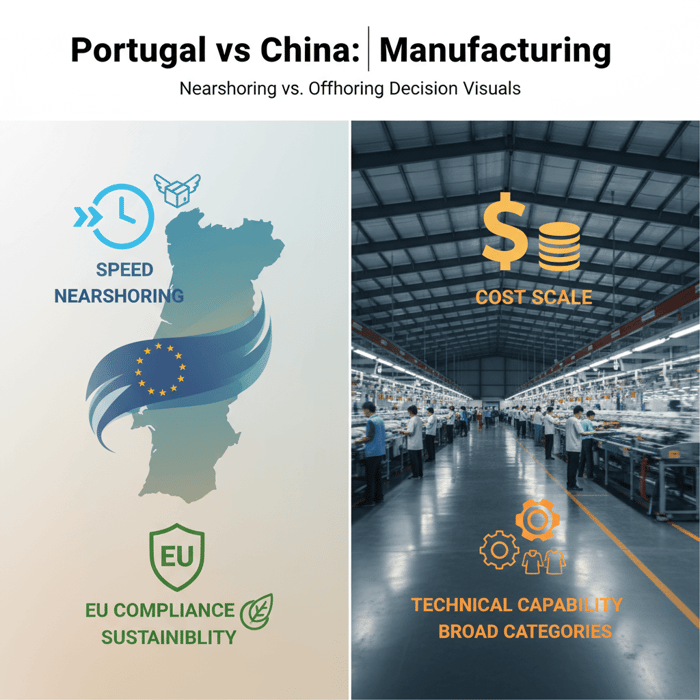

Portuguese Manufacturers vs China Clothing Manufacturer: A Buyer’s Guide for Fashion Brands

15 minute read

October 27th, 2025

Portuguese Manufacturers vs China Clothing Manufacturer: A Buyer’s Guide for Fashion Brands Portuguese... more »

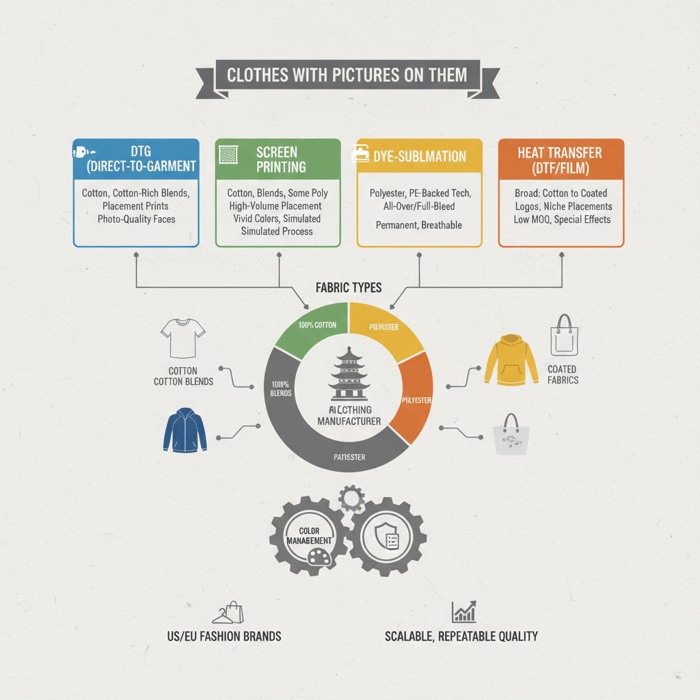

Clothes with Pictures on Them: A Fashion Brand’s Manufacturing Guide with a China Clothing Manufacturer

17 minute read

October 27th, 2025

Clothes with Pictures on Them: A Fashion Brand’s Manufacturing Guide with a China Clothing Manufacturer... more »