Wholesale Shirts for Screen Printing: A China Clothing Manufacturer’s Guide for US & EU Brands

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

4 minute read

Wholesale Shirts for Screen Printing: A China Clothing Manufacturer’s Guide for US & EU Brands

Wholesale shirts for screen printing demand consistent fabrics, stable construction, and compliance-ready sourcing from a China Clothing Manufacturer that understands US/EU requirements. This field guide from Eton translates materials, finish options, dye-migration defenses, testing methods, MOQs, and lead times into a repeatable plan that protects print quality and brand reputation at scale.

Wholesale shirts for screen printing are blanks built for ink adhesion, clean detail, and low shrinkage. Favor combed ring-spun cotton or cationic-treated blends, verify weight (GSM/oz), and control finishes. Validate with AATCC/ISO tests and confirm REACH/CPSIA documentation. For scale, an OEM partner in China/Bangladesh standardizes specs, color/size depth, and replenishment.

Eton Garment Limited has engineered outerwear and knits for three decades, supplying US/EU brands that need repeatable print results across seasons. This guide gives a practical path: what “print-ready” actually means, how cotton, blends, and finishes influence adhesion and color, how to pick specs for your artwork and customer segment, and how to align MOQs, lead times, and compliance. It also shows where OEM manufacturing beats off-the-shelf blanks: consistent fabric lots, color continuity, cationic dye workflows for darks and polys, and lab-anchored tolerances that cut reprints. You’ll find a decision framework, simple risk matrices, and a transparent look at testing and documentation. If you run graphic programs or merch drops in the US or EU, this blueprint helps you move faster with fewer surprises—and a cleaner print.

What Makes Wholesale Shirts for Screen Printing ‘Print-Ready’

Print-ready means fiber, construction, finish, and tolerances align with your ink system and curing window, especially on darks and polyester. Stable weight, controlled shrink/skew, and anti-bleed strategies reduce remakes. Confirm with adhesion/wash tests before scaling, and lock the package in a spec that production can repeat lot after lot.

Fiber & Finish

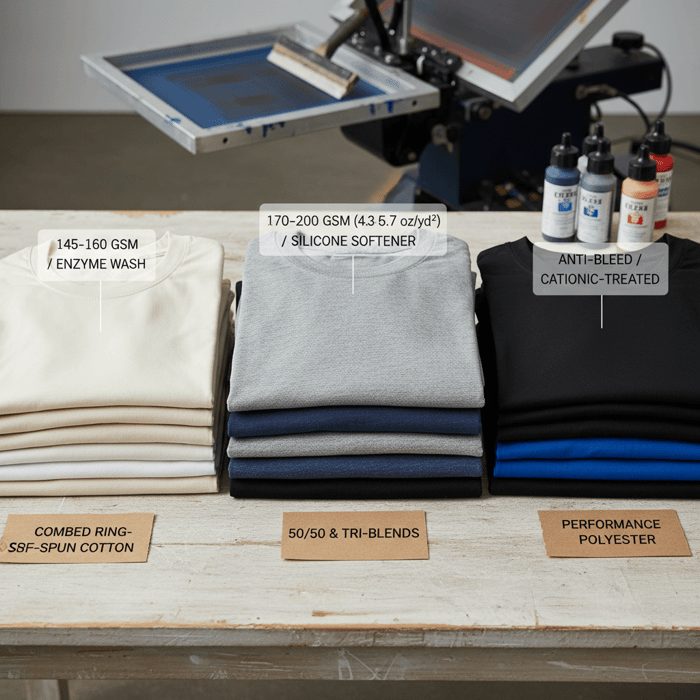

Start with fiber choice. Combed ring-spun cotton offers a cleaner surface and consistent yarn diameter, which supports crisp detail and smooth ink laydown. Open-end cotton is economical but hairier; it prints acceptably with heavier inks or larger graphics. For blends, polyester adds strength, wrinkle resistance, and drape, but unmanaged disperse dyes can migrate into ink on dark garments during cure. Cationic-treated polyester (or cationic dye processes) reduces migration and can pair with lower-cure, low-bleed inks—crucial for multilayer designs.

- Combed ring-spun cotton: smooth face, strong adhesion, soft hand.

- Open-end cotton: budget-friendly; plan for coarser face and slightly higher ink deposit.

- 50/50 and tri-blends: better drape; manage lower cure temps and potential migration on darks.

- Performance polyester: prioritize anti-bleed strategies (cationic dyes, blocker bases, low-cure inks).

Finishes matter. Enzyme washes reduce surface fuzz and pilling, improving detail and perceived brightness. Silicone softeners enhance hand feel but can reduce surface energy; some ink systems will need an underbase flash or a blocker to maintain adhesion. Pre-shrunk and compacted knits reduce shrinkage and skew after wash, protecting registration. Always test your ink on finished garments, not just greige fabric, because finishing chemistry changes the surface. [MENTION: Avient Specialty Inks (Wilflex) guidance on low-bleed systems] [CITE: Technical bulletin on silicone softeners and ink adhesion from a recognized ink supplier]

Construction, Weight & Stability

Construction sets your baseline for print alignment and hand feel. Side-seamed tees hold body shape and reduce torso twist, improving alignment on multi-color prints and centered chest hits. Tubular knits save cost and can work well for simple graphics, but expect greater variability in width and skew after wash.

- Weight guidance (dual units): 145–160 gsm (4.3–4.7 oz/yd²) hits a soft, retail feel with strong detail; 170–200 gsm (5.0–5.9 oz/yd²) adds body for heavier inks or bolder graphics.

- Knit stability: target low residual shrinkage through compacting; specify skew tolerance to protect alignment.

- Neck``

FAQs

Related Articles

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »