T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

16 minute read

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

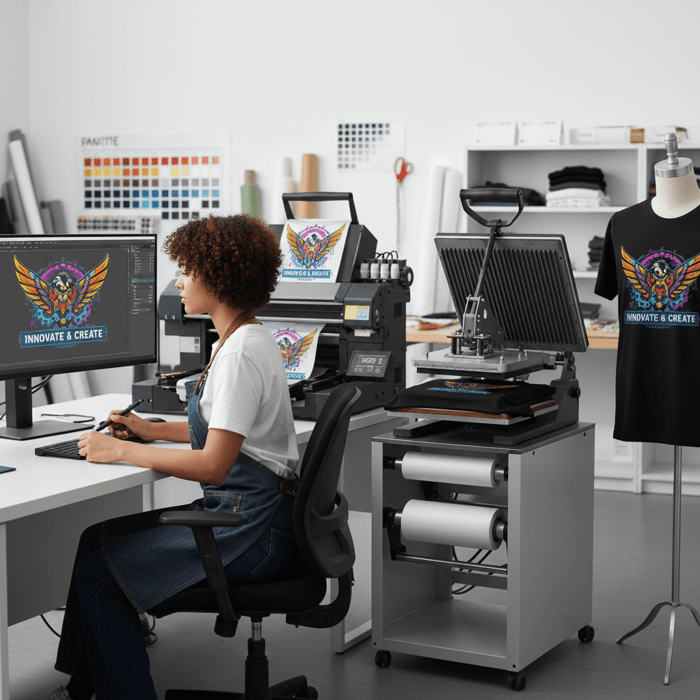

A t shirt decal maker helps brand teams turn graphics into pressable or printable files for T-shirts—fast. For US and EU fashion brands, the right workflow is the one that aligns creative speed with production reality, compliance, and repeatable quality. As a China Clothing Manufacturer, Eton converts early prototypes into factory-ready, compliant apparel.

A t shirt decal maker is a design tool and workflow that outputs cuttable or printable files (SVG/PNG/PDF) for HTV, DTF, DTG, or screen printing. For brands moving from tests to volume, pair rapid design with factory-grade QA, tech packs, and compliance, often via a China Clothing Manufacturer partner.

What is a t shirt decal maker? Definitions, files, and common methods

A t shirt decal maker is any software, online tool, or hardware ecosystem that produces graphics ready for T-shirt decoration. Outputs typically include SVG for cutting and PNG/PDF for printing; the workflow feeds HTV, DTF, DTG, or screen printing. For brands, the decal maker choice should align with durability, scale, and compliance.

In practice, “decal” often describes a graphic applied via heat and pressure onto fabric. A “transfer” is the carrier (film or paper) used to move the printed or cut graphic to the garment. Many teams start with consumer tools—[MENTION: Canva], [MENTION: Adobe Express], [MENTION: Cricut], or [MENTION: Heat Transfer Warehouse] materials—and later switch to production-ready formats as volumes rise.

File types and where they fit

- SVG: Vector paths for hobby cutters and pro plotters; ideal for HTV and single-color layering.

- PNG: Transparent raster files for DTF/DTG; ensure adequate resolution and clean edges.

- PDF: Used for screen print separations and complex vector layouts; lock fonts and embeds.

For accurate color and longevity, keep Pantone references in the artwork and record stitch/print placements in a tech pack. Vector files scale cleanly; raster requires planned resolution for expected print size. Include bleed and safe areas when exporting for DTF and screen workflows. [CITE: Color management guidance from a recognized print standards body]

Where decal maker tools slot into production

Decal makers serve as prototyping accelerators—ideal for capsule drops, pre-buy meetings, and small-batch testing. As design stabilizes, files graduate into brand-standard assets with documented color targets, ink types, and fabric tests. This integration keeps creative speed while preparing for repeatable, compliant production. [INTERNAL LINK: Brand standards and tech pack starter — guide on our site]

Workflow: from design to pressed T-shirt in clear steps

A fast, repeatable workflow keeps creative momentum while improving durability and consistency. The sequence below fits HTV and DTF; for DTG and screen print, swap out method-specific steps. Tight documentation helps teams move from DIY to factory sampling without rework or color drift.

- Create artwork in your t shirt decal maker; lock fonts; convert key shapes to outlines.

- Define color: Pantone codes for solids; ICC profile for prints; record fabric base.

- Export the right file: SVG for cutting; PNG/PDF for DTF/DTG/screen (with bleed and transparency).

- Prep material: select HTV or DTF film rated for your fabric (cotton, blends, nylon).

- Cut or print: test scale, small details, and registration marks.

- Weed/trim and preheat the garment to remove moisture; lint-roll for clean adhesion.

- Press: correct temperature, pressure, dwell; peel per manufacturer instructions.

- Post-press cure/cool; perform a 24-hour wash test before approving the run.

- Document settings in the tech pack for future repeats and factory handoff.

Standardizing this path reduces failed samples and uneven hand-feel when new substrates enter the mix. Record press metrics, peel type (hot/warm/cold), and humidity to keep outcomes consistent across locations. [MENTION: Cricut’s HTV tutorials] provide baseline steps; enterprise teams will add QA checkpoints and compliance notes for US/EU retail. [CITE: AATCC or ISO wash durability test protocols]

Method comparison: HTV vs DTF vs DTG vs screen printing

HTV, DTF, DTG, and screen printing cover most T-shirt decoration needs. Each method trades off setup cost, speed, hand-feel, color fidelity, and scalability. For US/EU brands, screening and DTF often win at volume; HTV fits micro-runs; DTG excels at photo prints and on-demand.

| Method | Setup | Detail/Color | Durability | Hand-feel | Best Use |

|---|---|---|---|---|---|

| HTV | Low (cutter + press) | Solid colors, layering; limited micro detail | Good with proper press; may crack over time | Film-like; varies by brand | Prototyping, small drops, team kits |

| DTF | Medium (printer + powder/curing + press) | Fine detail; broad color on many fabrics | Strong if cured and pressed correctly | Semi-film; improving with newer films | Short-to-mid runs, multicolor logos |

| DTG | Medium-High (printer + pretreat + cure) | Excellent photo prints; white ink on dark fabrics | Good; relies on pretreat and cure quality | Soft, integrated ink feel | On-demand, artwork-heavy tees |

| Screen | High (screens, separations, inks) | Strong solids; Pantone matching; halftones | Excellent; proven over decades | Soft with plastisol hybrids; softest with water-based | Mid-to-large runs; cost-efficient at scale |

Across 2024–2025, DTF adoption has accelerated for its detail and fabric versatility, while screen remains the volume workhorse for solids and brand color fidelity. DTG holds ground for on-demand photo prints. [CITE: 2024/2025 custom T-shirt market share trends, e.g., Grand View Research] [MENTION: Printful’s production guides].

Fabric compatibility and finish quality

- Cotton: Compatible with all methods; DTG and water-based screen prints deliver soft hand.

- Blends (poly/cotton): DTF and screen (with correct inks) are stable; DTG pretreat is crucial.

- Nylon/technical: HTV and DTF require low-temp films; screen needs specialty inks.

When branding outerwear or coated fabrics, verify adhesion with low-temperature films and primers. Note migration risk on polyester; guard with blocker base or low-bleed inks. [CITE: Ink migration and low-bleed ink technical notes from an industry ink supplier] [MENTION: Wilflex/PolyOne or Nazdar technical papers].

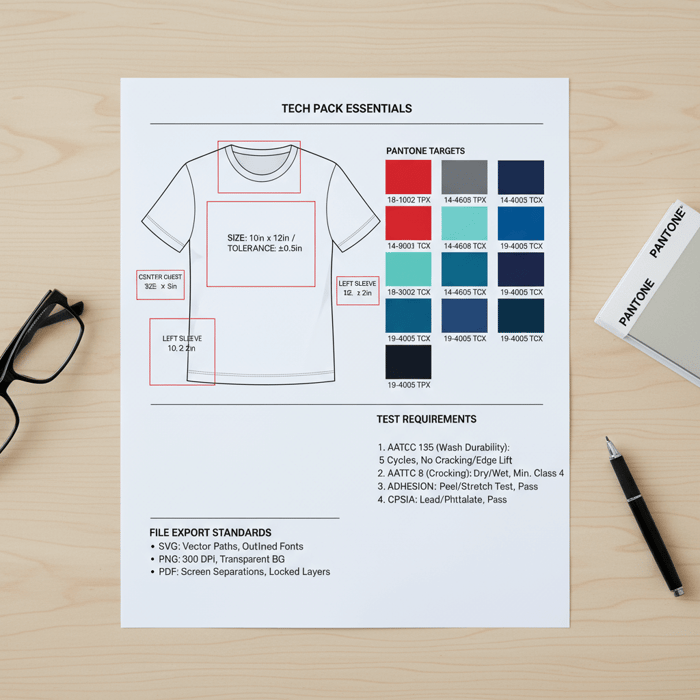

File prep and color control: SVG, PNG, PDF, Pantone, and resolution

Clean artwork accelerates approval and reduces press errors. Vector paths, Pantone targets, proper resolution, and documented placements form the backbone of production-ready decal files. Control color upstream; lock fonts; and write export rules that match your chosen method.

Artwork and export standards

- Vector (SVG/PDF): Expand strokes; outline critical shapes; remove hidden layers.

- Raster (PNG): 300 dpi at print size; export with transparency; avoid anti-aliased edges for cutters.

- Pantone/CMYK/RGB: Include Pantone codes for solids; embed ICC for raster print.

- Bleed/safe area: 2–3 mm bleed for DTF/screen; note jersey seams and rib stretch.

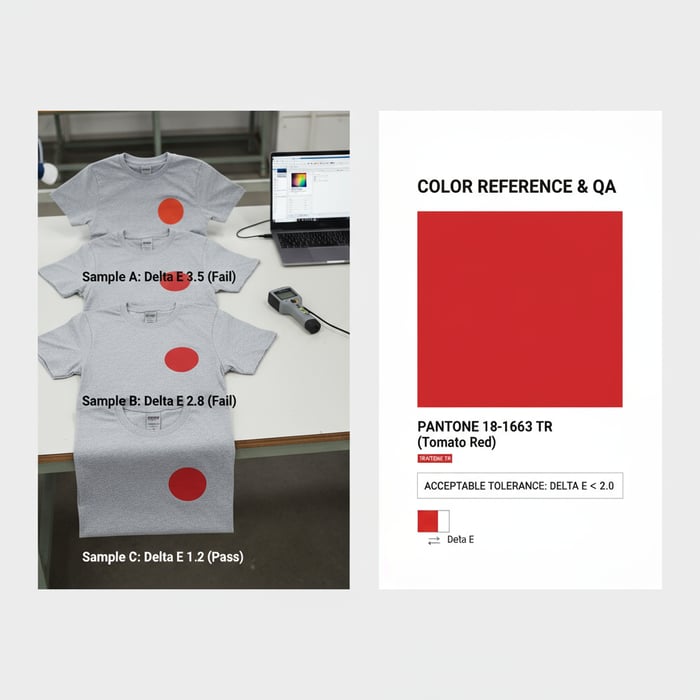

Record placements (center chest, left chest, sleeve), sizes, and tolerances. Note whether color is achieved via film, ink, or thread, and include the acceptable variance (±1–2 Delta E for color). Add annotations for peel type and press settings. [CITE: Pantone color tolerance guidance] [INTERNAL LINK: Tech pack template and BOM checklist — internal resource].

Small details: what prints sharpest

Fine lines under 0.4–0.5 mm can fail on HTV and might soften on DTF without optimized RIP settings and film. DTG can render photo-level detail; screen prints require well-built separations and mesh counts matched to ink. Validate with a micro-detail test swatch before firm orders. [CITE: Screen mesh count and halftone guidance from SGIA/PRINTING United]

Cost and ROI at 10, 100, and 1,000 units

Method choice shifts with quantity, design complexity, and fabric. Cost wins at small runs favor HTV/DTF; screen print becomes efficient beyond setup amortization; DTG suits art-heavy prints where on-demand economics matter. Use the table below as directional guidance; verify with regional suppliers.

| Qty | HTV | DTF | DTG | Screen (1–3 colors) |

|---|---|---|---|---|

| 10 | $8–$12 / €7–€11 | $7–$10 / €6–€9 | $9–$14 / €8–€13 | $12–$18 / €11–€16 |

| 100 | $5–$8 / €5–€7 | $4–$7 / €4–€6 | $6–$10 / €5–€9 | $3–$6 / €3–€5 |

| 1,000 | $3.50–$5.50 / €3–€5 | $3–$5 / €3–€4.50 | $4–$7 / €3.50–€6 | $1.80–$3.50 / €1.60–€3 |

Ranges include labor and material for decoration only—garment blank, label/pack, and freight add cost. Complex art, multiple placements, and specialty inks or films increase the unit price. Screen amortizes setup as quantity rises; DTF holds steady for multicolor designs under mid-size batches. [CITE: Vendor price sheets and market surveys, verified 2024–2025]

What drives cost

- Number of colors and placements; size of print area.

- Fabric type (cotton vs poly/nylon technical); required film or ink.

- Compliance and certification needs (OEKO-TEX, CPSIA).

- Final finishing: relabeling, polybag, pack folds, and barcodes.

Heat press settings and durability: the QA signals brands need

Press variables determine adhesion and life span for HTV and DTF. Temperature, pressure, and dwell create consistent results; peel timing matters. Document settings by fabric, verify with wash tests, and record acceptable tolerances in tech packs to avoid inconsistent outcomes across sites.

Press profiles: common baselines

- HTV: 290–320°F (145–160°C), medium-firm pressure, 10–15 seconds; peel per manufacturer.

- DTF: 300–330°F (150–165°C), firm pressure, 15–20 seconds; hot/warm/cold peel per film chemistry.

- Post-press: light second press (3–5 seconds) for edge sealing; cool on platen.

Test at the low and high ends of recommended settings. Note ambient humidity and preheat cycles for nylon or coated fabrics. Record brand-specific success profiles to support multisite consistency. [CITE: Manufacturer technical datasheets for press films, verified 2024] [MENTION: Stahls’ heat press resources]

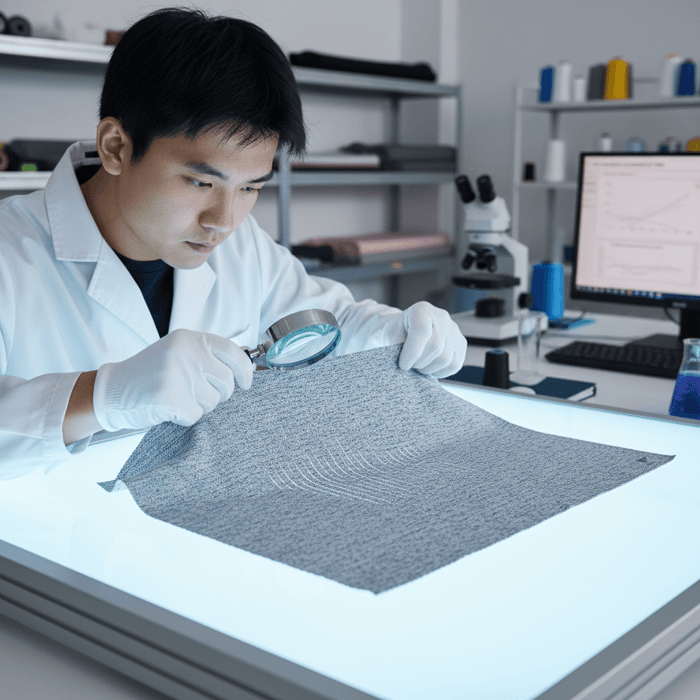

Durability checks and lab standards

- Wash durability: AATCC 61/135 or ISO equivalents—hand-feel, cracking, edge lift after cycles.

- Colorfastness: AATCC 8/61—bleed and crocking on light/dark fabrics.

- Adhesion: Peel and stretch tests on rib/jersey; needle crack checks across seams.

Pass/fail thresholds should be defined per market and product tier. High-performance fabrics require extended test batteries. Document results in QC records and attach to the tech pack. [CITE: AATCC/ISO standard references] [INTERNAL LINK: Our quality process overview — standards and QA checkpoints]

Risk and compliance: REACH, CPSIA, OEKO-TEX, and IP licensing

US and EU retail requires compliance with chemical safety and labeling laws. Embed compliance in material selection, ink chemistry, and packaging. For children’s apparel, CPSIA testing and tracking labels are mandatory. When using licensed logos, secure rights and maintain chain-of-custody documentation.

US/EU requirements

- EU REACH: SVHC limits; supplier declarations and testing where needed. [CITE: ECHA SVHC and textile guidance]

- US CPSIA: Lead and phthalate limits, tracking labels for children’s tees. [CITE: U.S. CPSC/CPSIA guidance]

- OEKO-TEX: STANDARD 100 and ECO PASSPORT for inks/films and trims. [CITE: OEKO-TEX standards]

Record chemical conformance from ink/film vendors; maintain test reports and certificates. Use restricted substance lists (RSL) and material safety data sheets (SDS) in your BOM. Train teams on IP use—licensed marks require proof of rights for production and export. [MENTION: ZDHC] [MENTION: bluesign]

QA documentation that stands up in audits

- Children’s Product Certificate (CPC) with accredited lab results (US).

- Supplier declarations and test reports aligned to REACH for EU shipments.

- SKU-level tracking labels; factory chain-of-custody logs for licensed artwork.

Retail partners will request proof on first shipments and during audits. Build compliance into your early sampling phase to avoid relabeling, reprinting, and delays. Compliance checklist for US/EU apparel — downloadable PDF

When to move from DIY/POD to factory production

Switch when volumes, consistency, and compliance outweigh hobby workflows. POD bridges early demand; factory sampling locks spec, color, and QA at scale. Watch for cost per unit stabilizing above screen’s curve, lead-time constraints, and multi-region distribution needs.

Signals it’s time to switch

- Orders exceed 100–300 units per SKU with repeat reorders.

- Multiple placements, Pantone matching, and brand QA standards are mandatory.

- US/EU compliance documents are required by retailers.

At these thresholds, factories deliver lower per-unit costs, better consistency, and scalable QC. Keep POD for long-tail designs while transitioning hero SKUs to OEM with locked specifications. [MENTION: Printful’s POD model] [CITE: Retail compliance requirements summary, 2024]

Operational benefits

- Tech pack-driven repeats; reduced color drift across batches.

- Bulk purchasing of inks/films aligned to brand RSL and certificates.

- Integrated finishing: relabel, barcode, pack formats; retailer-ready cartons.

Factory partners also create audit-ready documentation, cutting launch friction for wholesale and marketplaces. [INTERNAL LINK: Factory onboarding steps — how we structure sampling and QA]

Factory Transition Playbook: turning decal files into OEM production

Translate t shirt decal maker outputs into factory-ready assets: artwork, tech packs, BOMs, test requirements, and compliance files. With these artifacts, factories can reproduce color, finish, and adhesion, across batches and plants, while meeting US/EU certification needs.

Core tech pack contents

- Artwork: master vector + raster; Pantone targets; separations as needed.

- Placements: center/left chest, sleeve, back; sizes with tolerances.

- Materials: films and inks with brand-accepted SKUs and certificates.

- Process: press temperatures, pressure, dwell, peel; DTG pretreat/cure; screen mesh and squeegee notes.

- Tests: AATCC/ISO wash, crocking, adhesion; pass criteria.

- Compliance: REACH/CPSIA docs; OEKO-TEX/ECO PASSPORT, supplier SDS.

Factories will request sample approvals and retain sealed samples as quality references. A controlled change log records any approved deviation, keeping repeats aligned. [CITE: Tech pack best practices from apparel manufacturing sources] [INTERNAL LINK: Sample approval and gold seal protocol]

Bill of Materials (BOM) and vendor alignment

- Specify exact film/ink brand and type; list substitute options with test requirements.

- Record garment blanks, thread, labels, and packaging elements.

- Assign compliance attributes to each line item.

Vendor-managed inventories reduce mispicks and substitutions. Eton’s teams build BOMs with chemistry disclosures to meet retailer RSLs and market audits. [MENTION: Major retailers’ RSL frameworks] [CITE: Typical RSL structure and verification protocols]

Sustainability signals: chemistry, substrates, and certification pathways

Sustainability affects brand credibility and market access in US/EU. Choose inks and films with transparent chemistry, aim for OEKO-TEX or equivalent certifications, and document impacts. Water-based inks on cotton improve hand-feel and environmental profiles; DTF films are improving with lower-temperature chemistries.

Materials and chemistry considerations

- Inks: Water-based and hybrid plastisols that pass brand RSLs; aim for ECO PASSPORT.

- Films: Low-temp adhesives for technical fabrics; document VOCs and restricted phthalates.

- Pretreats and primers: Evaluate SDS and downstream wash-off; track effluent handling.

Certification adds cost but reduces risk across retailers and regions. Maintain a library of approved consumables and supplier declarations to speed up onboarding. [CITE: OEKO-TEX certification criteria and program updates, 2023–2025] [MENTION: ZDHC MRSL and wastewater guidelines]

Measurable outcomes

- Lower reject rates and fewer lab failures over time.

- Faster approvals with major retailers and marketplaces.

- Clearer brand story for consumers and compliance teams.

Report sustainability wins with hard metrics—pass rates, chemical inventories, and audit outcomes—rather than marketing language. [CITE: Retail acceptance of OEKO-TEX and bluesign in listing requirements]

Eton’s Clothing Manufacturing OEM Service: scaling from decal maker prototypes to retail-ready apparel

Eton converts decal maker prototypes into consistent, testable, and compliant production. As a China Clothing Manufacturer with factory bases in China and Bangladesh, we consolidate design, materials, sampling, and QA into a single workflow for outerwear and apparel programs serving US and EU markets.

What we deliver for T-shirt graphics programs

- Design integration: We ingest SVG/PNG/PDF and build tech packs with Pantone targets.

- Material sourcing: Films and inks pre-vetted against RSLs; documented SDS; OEKO-TEX alignment.

- Lab testing: AATCC/ISO wash, crocking, and adhesion; CPC support for children’s tees.

- Production: Screen, DTF, DTG, or hybrid workflows tailored per SKU and volume.

- Finishing: Relabel, barcode, pack formats; retailer-ready cartons.

Explore our Clothing Manufacturing OEM Service at Eton Garment Limited. We help teams decide when to retain POD for long-tail SKUs and where to shift hero graphics into OEM runs for cost, consistency, and compliance. [INTERNAL LINK: Garment factory service overview — https://china-clothing-manufacturer.com/garment-factory/]

Practical examples and field notes from 30+ years of apparel production

Across outerwear and tees, we’ve seen the same bottlenecks: under-documented artwork, color drift, and inconsistent press settings. A lightweight tech pack, clear Pantone targets, and a single-page QA checklist fix most repeat issues and cut sampling cycles across regions.

Observed pitfalls and how teams avoid them

- Micro detail fails: Increase stroke weight and validate on 8–12pt test glyphs.

- Poly bleed: Use blocker base or low-bleed inks; set lower press temps.

- Color mismatch: Record Delta E tolerances and measure against sealed samples.

Garment variety adds complexity; maintain gold seals for each fabric class. For nylon shells, record low-temp films and peel timing. For heavyweight cotton, extend dwell slightly and validate wash durability. [CITE: Case study on poly dye migration controls] [MENTION: PRINTING United technical library]

From prototype to purchase order: a brand-ready path

Turn a t shirt decal maker concept into a purchase order with three gates: design lock, lab pass, and price/file approval. Each gate reduces risk, shortens rework, and builds audit-ready documentation for US/EU retail partners.

Three gates to greenlight

- Design lock: Approved artwork, Pantone targets, placements, tolerances.

- Lab pass: AATCC/ISO tests; CPC (if applicable); compliance certificates.

- Price/file approval: Confirm cost, MOQ, lead time, and final production files.

After these gates, the first shipment sets the quality baseline. Factories retain sealed samples and compliance folders for audits. Brands gain predictable repeats, fewer test failures, and stable pricing across reorders. [CITE: Retail audit preparation checklists, 2023–2025] [INTERNAL LINK: PO readiness checklist — internal resource]

References & Sources

- Grand View Research — Custom T-shirt Printing Market (2024/2025). https://www.grandviewresearch.com/industry-analysis/custom-t-shirt-printing-market [CITE: Market size, method trends]

- OEKO-TEX — STANDARD 100, ECO PASSPORT (2023–2025). https://www.oeko-tex.com/ [CITE: Certification criteria]

- ECHA — EU REACH, SVHC Guidance (2024). https://echa.europa.eu/regulations/reach [CITE: REACH compliance]

- U.S. CPSC — CPSIA Requirements (2024). https://www.cpsc.gov/Business--Manufacturing/Business-Education/Childrens-Product-Certificate-CPC/CPSIA-Requirements [CITE: CPSIA compliance]

- AATCC — Textile Test Methods (2023–2025). https://www.aatcc.org/ [CITE: Wash and colorfastness tests]

- PRINTING United Alliance (SGIA) — Technical Resources (2023–2025). https://www.printing.org/ [CITE: Screen mesh and separations]

- Pantone — Color Standards and Tolerances (2024). https://www.pantone.com/ [CITE: Delta E guidance]

- Stahls’ — Heat Press and HTV Technical Guides (2024). https://www.stahls.com/ [CITE: Press profiles]

- ZDHC — MRSL and Wastewater Guidelines (2024). https://www.zdhc.org/ [CITE: Chemical sustainability]

- bluesign — System and Approved Chemistry (2024). https://www.bluesign.com/ [CITE: Chemical management]

- Printful — Design Maker and Method Guides (2024). https://www.printful.com/design-maker [CITE: POD workflows]

- Canva — T-Shirt Maker (2025). https://www.canva.com/t-shirt-maker/ [CITE: Design tool]

- Adobe Express — T-Shirt Design (2025). https://www.adobe.com/express/create/t-shirt [CITE: Design tool]

- Heat Transfer Warehouse — HTV Guides (2024). https://www.heattransferwarehouse.com/blog/ [CITE: HTV materials]

Explore our exclusive Factory Transition Playbook to learn more.

Eton Garment Limited — Company overview

Clothing Manufacturing OEM Service — Overview

FAQs

Related Articles

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Choosing a Sportswear Company: A US/EU Buyer’s Playbook with a Trusted China Clothing Manufacturer

10 minute read

October 28th, 2025

Choosing a Sportswear Company: A US/EU Buyer’s Playbook with a Trusted China Clothing Manufacturer... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »