Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

20 minute read

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

Custom clothing embroidery gives fashion brands a durable, premium mark that holds up in retail and real-world wear. When executed with an experienced China Clothing Manufacturer, embroidery scales cleanly across jackets, parkas, caps, and technical apparel. This guide translates factory methods into brand-ready decisions—file prep, stitch count, digitizing, MOQs, timelines, QA, and US/EU compliance—so teams can brief, cost, sample, and deliver with confidence.

Eton Garment Limited brings 30 years of outerwear OEM/ODM experience—from design and fabric sourcing to production and compliance—so logos and badges stitch out consistently at retail-grade quality. You’ll find practical ranges for stitch density, backing/stabilizers, thread choice, needle selection, and testing, plus an OEM workflow that reduces rework and compresses cycle time. The goal: a clean, repeatable path for embroidered collections in the US and EU, supported by sustainable materials and traceable documentation.

Custom clothing embroidery is the process of stitching digitized artwork onto garments with industrial machines. Success for fashion brands hinges on clean files, accurate digitizing, stitch density, backing, and thread choice—aligned with OEM QA, MOQs, lead times, and US/EU compliance. A proven China Clothing Manufacturer delivers repeatable quality at scale.

What Is Custom Clothing Embroidery? Fundamentals Brands Must Know

Embroidery stitches digitized artwork directly into fabric. Cost, quality, and durability are shaped by stitch count, density, thread type, needle, backing/stabilizers, hooping, and placement. Outerwear adds complexity—laminated shells, down-proof constructions, stretch panels—so machine settings and digitizing rules must reflect fabric behavior and retail-level QA.

Core variables for consistent outcomes:

- Artwork and digitizing: convert vector art into stitch paths (DST/EMB), specify underlay, pull compensation, and trims.

- Stitch count and density: total stitches drive time and cost; density influences coverage, hand feel, and puckering risk.

- Thread: polyester for wash/crock fastness; rayon for sheen; select Oeko-Tex Standard 100 options where possible.

- Needles: size and point type by fabric—sharp for wovens, ballpoint for knits, microtex for fine technical shells.

- Backing/stabilizers: cutaway, tearaway, water-soluble/film; match backing to fabric stretch and transparency.

- Hooping and tension: frame stability and machine tension reduce skew, nesting, and fabric distortion.

- Placement: seam proximity, panel curvature, and baffle construction influence stitch integrity.

Mini glossary:

- Satin stitch: long, smooth columns that produce crisp edges on letters and narrow shapes.

- Fill stitch (tatami): patterned coverage for large areas; can add texture and reduce stitch volume if tuned well.

- Running stitch: single-pass linework for fine detail, outlines, or underlay tracks.

- 3D puff: foam-backed raised embroidery—common on caps; requires specific digitizing and cleanup passes.

- Applique: fabric pieces stitched onto the garment to reduce stitch count for large graphics.

- Chenille: looped/pile embroidery, often on varsity styles; best applied on stable substrates.

PAA micro-answer: Higher stitch count does not automatically mean better quality. Quality hinges on the right density, underlay strategy, thread choice, and fabric-specific needle/backing selection. Over-dense designs increase puckering and stiffness—especially on lightweight shells and stretch panels.

[MENTION: Tajima and Barudan multi-head machines in apparel production] [MENTION: Madeira and Gunold thread systems for retail-grade colorfastness] [INTERNAL LINK: Embroidery 101 for Apparel OEMs — foundational pillar] [CITE: Technical embroidery textbooks or machine OEM guides for stitch density best practices]

Stitch Count, Density, and Coverage

Digitizing determines stitch count and the density that drives coverage and hand feel. Satin stitches deliver clean edges on letters and narrow shapes; fill stitches handle larger areas with patterned coverage. Target density is influenced by thread weight and fabric behavior. Many outerwear logos run satin densities near 0.35–0.45 mm spacing and fill densities tuned to balance coverage with fabric movement. On laminated shells or down-proof fabrics, reduce density and increase underlay to spread load and minimize puckering. For small text, increase pull compensation and prefer satin columns over tiny fills.

Cost scales with count: more stitches mean longer machine time. Brand teams can trim count by rationalizing letter shapes, simplifying gradients, and using applique for large fields. Coverage should feel substantial but not board-stiff; test on production fabric to confirm hand feel and drape. Add buffers: small digitizing tweaks can swing stitch count by 10–20% and materially change both cost and tension behavior. [CITE: Machine runtime benchmarks by embroidery OEMs] [MENTION: Wilcom digitizing software guidance on density and underlay] [INTERNAL LINK: Outerwear embroidery best practices — tuning density to fabric]

Threads, Needles, and Backing/Stabilizers

Thread selection affects wash and colorfastness. Polyester (commonly 40 wt) handles laundering, UV exposure, and abrasion better than rayon; rayon carries a premium sheen for dress styles. For US/EU retail, source Oeko-Tex Standard 100-certified thread and backing when feasible. Needle sizes typically range 70/10–90/14: use sharp points for wovens and microtex needles on fine technical shells; switch to ballpoint for knits to prevent fabric damage. Match needle to thread weight to avoid shredding or oversized holes.

Backing controls stability. Tearaway suits stable wovens; cutaway supports knits and high-stretch panels; water-soluble films stabilize delicate or coated surfaces without residual bulk. On down-proof and laminated shells, prefer low-profile films or carefully placed cutaway that won’t telegraph through the face. Pair backing with hooping and machine tension to prevent nesting and outline skew. [CITE: OEKO-TEX Standard 100 documentation for inputs] [MENTION: AATCC guidance on colorfastness and crocking] [INTERNAL LINK: Sustainability/compliance pillar — certified materials]

Embroidery Methods: Flat, 3D Puff, Applique, Chenille

Flat embroidery suits most logos across jackets, fleeces, caps, and knits. 3D puff uses foam to lift satin columns; it delivers dimensional marks on caps and select outerwear panels but needs cleanup passes and careful hooping. Applique reduces stitches for large varsity-style graphics; it improves drape and cuts runtime. Chenille brings a textured, pile look—run it on stable substrates or backed panels to avoid distortion. Select method by garment behavior: for water-repellent shells and down-proof fabrics, flat embroidery with tuned density often wins for durability and seam integrity. [CITE: Brand case studies comparing 3D puff vs. flat on caps] [MENTION: Stahls' guidelines on applique/foam materials] [INTERNAL LINK: Technique selection matrix — cluster article]

Custom Clothing Embroidery Techniques & Applications for Fashion Brands

Match method to garment for aesthetics and durability. Flat embroidery excels on softshells and shells; 3D puff is strong on caps; applique fits larger varsity graphics; chenille adds texture on stable bases. Outerwear needs special attention to seam migration, puckering, and down-proof integrity, so digitizing, needle choice, and backing must be garment-specific.

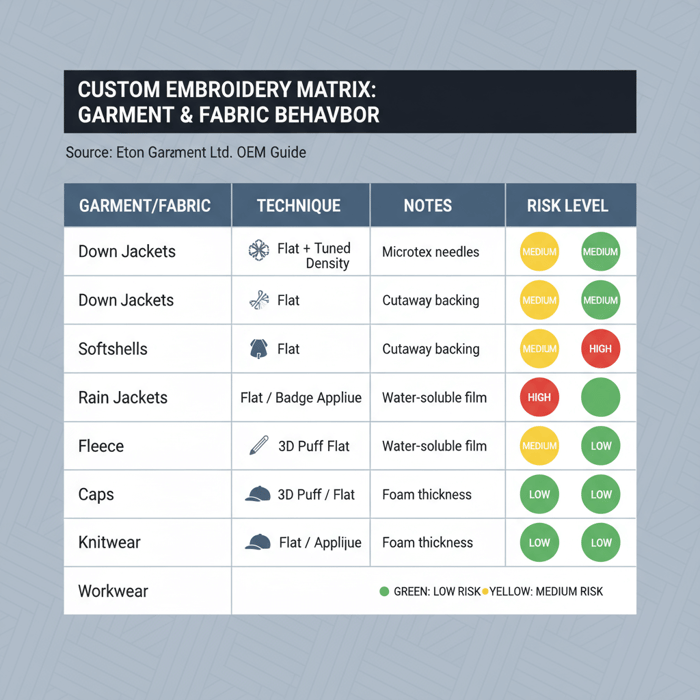

| Garment/Fabric | Recommended Technique | Notes | Risk Level | Care Tips |

|---|---|---|---|---|

| Down jackets (down-proof shell) | Flat embroidery with tuned density | Use microtex needles; reduce density; avoid baffles; consider applique on backed panels | Medium | Test for leakage/puckering; gentle wash; verify seam integrity |

| Softshells (stretch, DWR) | Flat embroidery | Ballpoint needle; cutaway backing; lower tension; avoid seam crossings | Medium | Avoid high heat; check DWR retention; wash test |

| Rain jackets (laminated) | Flat embroidery or badge applique | Lower density; water-soluble film; test for delamination and wicking | High | Line dry; verify hydrostatic/water ingress after embroidery |

| Fleece | Flat embroidery | Use cutaway backing; underlay to tame pile; satin for crisp edges | Low | De-pill care; colorfastness check |

| Caps (6-panel) | 3D puff or flat embroidery | Panel curvature; foam thickness 2–4 mm; cleanup passes | Low–Medium | Spot clean; shape retention |

| Knitwear | Flat embroidery | Ballpoint needle; cutaway backing; limit density on stretch ribs | Medium | Lay flat dry; tension check |

| Workwear (heavy wovens) | Flat embroidery or applique | Sharp needle; tearaway backing; durable thread; larger placements | Low | High-temp wash test; abrasion check |

Outerwear & Technical Apparel

Outerwear fabrics behave under the needle. Down-proof shells require fine needles and moderated densities to preserve the membrane and prevent leakage. Laminates can pucker or channel water; lower tension, water-soluble film, and test placements away from seams reduce risk. Stretch softshells need ballpoint needles, cutaway backing, and tuned underlay to stabilize stitch paths. Always sample on production fabric and monitor stitch balance, seam migration, and face distortion. [CITE: ISO/AATCC wash test references for laminated shells] [MENTION: YKK knowledgebase on seam integrity near hardware] [INTERNAL LINK: Outerwear quality standards — stabilization methods]

Caps, Knitwear, and Workwear

Caps benefit from 3D puff with 2–4 mm foam; digitize removal passes to cut clean edges. Panel curvature changes alignment—brace hooping and use center marks. Knitwear stretches; ballpoint needles reduce fiber damage, and cutaway backings keep marks readable. Workwear favors durable, larger marks with polyester thread and balanced density on heavier wovens; applique improves large graphics and quick runtimes. [CITE: Foam specification sheets for 3D puff] [MENTION: Headwear OEM guides on panel curvature] [INTERNAL LINK: Technique-specific digitizing templates]

Branding Placement for Readability

Placement and size drive legibility. Common ranges: left chest logos 40–70 mm width; sleeve badges 20–40 mm height; back yoke 80–120 mm width; cap front 45–75 mm width. Respect baffles and seams—avoid stitch paths across high-stress or curved panels. Use alignment references (center/front yoke notch) and verify tilt on curved surfaces. In tech packs, specify exact dimensions, Pantone-to-thread mapping, and placement from reference points. [CITE: Brand retail guidelines on logo visibility] [MENTION: Pantone system and thread brand charts] [INTERNAL LINK: Embroidery tech pack checklist]

Custom Clothing Embroidery Costs, MOQs & Lead Times (OEM Reality)

Embroidery cost is driven by base setup + stitch count + placement + run size + fabric difficulty. MOQs vary by factory and machine allocation (often 200–600+ units per style/color), and timelines run digitizing (2–4 days), sampling (7–14 days), PP approval, then bulk (30–60+ days). Compliance and testing can add time; plan buffers for re-runs.

| Stitch Count | Common Use | Placement Examples | OEM Notes |

|---|---|---|---|

| ≤5k | Small chest marks, sleeve badges | Caps front, left chest | Fast runtime; minimal backing; good for multi-color logos |

| 5–10k | Medium logos with fills | Left chest, back yoke | Balance fill density with fabric; moderate runtime |

| 10–20k | Large badges/graphic locks | Chest-centered, back panel | Consider applique to cut stitches and improve drape |

| 20k+ | Oversized varsity graphics | Backs/front panels | Use applique; monitor stiffness; test hooping stability |

- Embroidery pros: premium look/feel; durable; high perceived value; strong on uniforms/workwear.

- Embroidery cons: heavier hand on lightweight shells; higher unit runtime; limited gradients.

- Heat transfer pros: crisp detail; lower runtime; works on complex art.

- Heat transfer cons: potential film edge, lower abrasion resistance, risk on DWR/laminates.

- Screen print pros: fast for large areas; color layering options.

- Screen print cons: may crack/peel over time; limited on water-repellent shells.

- Digitizing turnaround: 2–4 business days [CITE: Embroidery service SLAs from leading digitizers]

- Lab colorfastness testing: 5–10 business days [CITE: Accredited textile lab SLAs, 2023–2025]

- Retail PP sample hit rate (first pass): 70–85% when artwork and fabric are aligned [CITE: OEM sample program internal metrics or industry reports]

Cost Drivers and How to Optimize

Design levers reduce stitch count and runtime without sacrificing brand presence:

- Simplify fills: switch large fills to applique; keep satin edges for crisp outlines.

- Rationalize colors: fewer thread changes reduce stops and trims.

- Tune density: relieve over-dense sections to reduce puckering and stiffness.

- Scale wisely: test 5–10% size reductions; legibility often holds while cuts lower count.

- Placement efficiency: avoid multi-hoop positions; consolidate marks per panel.

- Batch planning: group colorways and logos to minimize thread swaps and setup time.

[CITE: Runtime models from multi-head machine vendors] [MENTION: Tajima TFMX series and Barudan benchmarks] [INTERNAL LINK: Get a costed sample — Eton garment factory]

MOQs and Capacity Planning

OEM MOQs reflect setup, line balancing, and multi-head allocation. Expect 200–600+ units per style/color for embroidery placements, driven by machine park and delivery windows. Eton allocates multi-heads to batch colorways, reduce changeovers, and stage PP approvals per panel placement. Larger graphics and complex logos require more runtime—plan headcount and shifts accordingly. If multiple placements per garment are needed (e.g., chest + sleeve + back), factor compounded runtime and capacity impacts into delivery schedules. [CITE: Apparel factory capacity planning whitepapers] [MENTION: Lean line balancing case studies in garment production] [INTERNAL LINK: Clothing Manufacturing OEM Service capacity overview]

Timelines: Digitizing → Sample → PP → Bulk

Typical sequence:

- Digitizing: 2–4 days with DST/EMB outputs; confirm underlay and compensation for fabric.

- Prototype sample: 7–14 days on production fabric; review density, tension, and puckering.

- PP sample: 5–10 days post-adjustments; lock size, placement, thread colors, and backing.

- Bulk production: 30–60+ days depending on volume, placements, and line allocation.

- Compliance/testing: add 5–10 days as required for US/EU labeling and material tests.

Build buffers for art changes, brand feedback, and fabric behavior. Align compliance and care labeling early to avoid hold-ups. [CITE: Brand retail calendars and development cycles, 2024–2025] [MENTION: AAFA calendars for seasonal development] [INTERNAL LINK: Development timeline template]

How to Prepare Artwork & Tech Packs for Custom Clothing Embroidery

Supply clean vector artwork, specify size by placement, map Pantone to thread colors, and call out density/underlay preferences in the tech pack. Request stitched samples on production fabric—never approve from printouts alone. Lock digitizing files (DST/EMB) after PP approval for repeatable bulk.

- Send vector files (AI/EPS/SVG) + Pantone selections + placement dimensions.

- Receive digitized DST/EMB with stitch count and density/underlay notes.

- Approve stitched samples on production fabric; annotate tension, coverage, and legibility.

- Finalize PP: confirm thread brand/color codes, backing, needle size, and machine notes.

- Proceed to bulk with locked files and signed-off QA checklist.

[CITE: Digitizing best practice guides by leading software vendors] [MENTION: Wilcom/Embird documentation] [INTERNAL LINK: Embroidery tech pack checklist — downloadable]

File Prep & Digitizing Specs

Preferred formats: vector (AI/EPS/SVG) for art handoff; DST/EMB for machine execution. Include size by placement (e.g., 55 mm left chest), min line thickness of ~1.2–1.5 mm for legibility, and minimum text height of ~4–5 mm for uppercase sans-serif. Request underlay strategy (e.g., edge-run + zigzag for satin), pull compensation on narrow columns, and trim logic. Provide Pantone references mapped to thread brand codes; state thread chemistry (polyester vs. rayon). [CITE: Manufacturer digitizing specifications and retail labelling guides] [MENTION: Pantone-to-thread charts from Madeira/Gunold] [INTERNAL LINK: Artwork handoff SOP]

Tech Pack Requirements

Include:

- Placement artwork and scaled dimensions with reference points (from center front, side seam, yoke notch).

- Thread brand/model, color codes, and chemistry; backup substitutions if out of stock.

- Backing/stabilizer type and gram weight; special notes for down-proof/laminated shells.

- Needle size and point type; machine tension targets and hooping notes.

- Care label updates; US/EU compliance references and traceability documentation.

Note constraints: small text, complex gradients, over-dense fills. Provide alternative art for risky placements (e.g., sleeve over seams). [CITE: Retail tech pack standards in apparel] [MENTION: AATCC labeling practices] [INTERNAL LINK: Tech pack template — outerwear]

Sample Approval Protocol

Approve samples on production fabric and final shell color. Review:

- Stitch density and tension balance: no nesting, clean outlines, consistent coverage.

- Puckering and distortion: especially on lightweight/laminated shells and stretch panels.

- Color accuracy: Pantone-to-thread mapping under daylight and store lighting.

- Placement and alignment: use reference points; check curvature and seam proximity.

- Care outcomes: wash/crock tests, abrasion checks, and label readability.

Log adjustments and lock digitizing files after PP approval. [CITE: AQL sampling and PP protocols] [MENTION: ISO 2859-1 AQL schemes in apparel] [INTERNAL LINK: PP sample sign-off checklist]

Choosing a China Clothing Manufacturer for Custom Clothing Embroidery (with Eton’s OEM Service)

Evaluate machine capability, digitizing speed, PP sample hit rates, compliance, and outerwear expertise. Eton integrates design, digitizing, sampling, and bulk embroidery across China and Bangladesh with rigorous QA and US/EU compliance support, delivering repeatable quality and on-time shipments.

| Brand Need | Eton OEM Feature | Expected Outcome |

|---|---|---|

| Embroidery on down-proof shells | Microtex needles + tuned density + film backing | Clean stitch-out with minimal puckering/leakage |

| 3D puff caps at scale | Puff digitizing passes + foam spec + panel bracing | Sharp raised logos across multi-head runs |

| Retail-grade compliance | Oeko-Tex inputs, REACH/CPSIA alignment, AAFA RSL | Documented, market-ready shipments for US/EU |

| Aggressive timelines | Integrated workflow; line balancing on multi-heads | Faster PP approvals and dependable delivery windows |

| Transparent costing | Stitch-count cost modeling and placement planning | Budget clarity with stitch-saving options |

Vendor Evaluation Criteria & Red Flags

Look for multi-head capacity, sample speed, digitizing quality, and outerwear experience. Confirm Oeko-Tex input options, REACH/CPSIA understanding, and AAFA RSL tracking. Red flags: no stitched PP on production fabric, vague density/needle notes, poor Pantone-to-thread mapping, and missing test reports. Inspect inline QA controls and AQL levels. [CITE: WRAP/BSCI/SEDEX social compliance frameworks] [MENTION: ECHA REACH guidance and CPSC CPSIA references] [INTERNAL LINK: Vendor evaluation checklist]

Eton Workflow: Design → Digitize → Sample → QA → Bulk

Eton’s Clothing Manufacturing OEM Service connects design briefs to digitizing and sampling, then PP approval and bulk. Teams lock stitch densities, thread colors, backing types, and machine notes early. QA checkpoints run at inline, PP, and final inspection with AQL standards, plus lab tests for wash/colorfastness as needed. The result: fewer reworks, predictable timelines, and consistent retail outcomes across China and Bangladesh. Clothing Manufacturing OEM Service

[CITE: Case examples on outerwear embroidery throughput] [MENTION: Liverpool F.C., Forever 21, and Jeep Apparel partnerships acknowledged in Eton’s portfolio] [INTERNAL LINK: Author bio — Alex Chen, Technical Development Lead]

Quality, Testing & Durability Standards for Embroidery

Control stitch density, tension, backing type, and thread quality. Validate with wash, colorfastness, and abrasion testing—especially for technical fabrics. Align care labeling to garment construction. Build inline checks for needle damage, puckering, thread breaks, and registration drift, and confirm at PP and final inspection.

- Inline inspection: stitch balance, tension, no nesting; placement alignment; thread trims and cleanup.

- PP approval: stitched on production fabric; confirm color, legibility, puckering; finalize digitizing files.

- Final AQL: lot-level checks; care label accuracy; documentation bundle (reports, DoC).

| Test | Standard/Reference | What to Check |

|---|---|---|

| Colorfastness to washing | AATCC 61 or ISO 105-C06 | Shade change, staining on adjacent fabrics |

| Colorfastness to rubbing | AATCC 8 or ISO 105-X12 | Dry/wet crocking, thread integrity |

| Colorfastness to perspiration | AATCC 15 or ISO 105-E04 | Discoloration under acidic/alkaline sweat |

| Lightfastness | AATCC 16.3 or ISO 105-B02 | Fade under UV exposure |

| Wash performance | ISO 6330 | Puckering, stitch retention, label legibility |

Inline, PP, and Final Inspection Controls

Inline: sample pulls per batch, tension checks, thread path oversight, hooping consistency. PP: confirm final digitizing, density, thread codes, and backing. Final: AQL per ISO 2859-1 with embroidery-specific checkpoints—placement accuracy, seam integrity near marks, color and label checks. Log defects (pucker, skew, trim residue) and corrective actions. [CITE: ISO 2859-1 AQL sampling] [MENTION: Supplier QA manuals in apparel] [INTERNAL LINK: Embroidery inspection checklist]

Garment Care & Labeling Considerations

Align care symbols to fabric and decoration. Advise low-heat drying for laminated shells and cap foam, and limit harsh detergents for optimal color retention. Confirm label content per market (fiber content, RN/CN/CA numbers, origin, care symbols) and maintain traceability through batch logs. [CITE: Care labeling standards and regional requirements] [MENTION: GINETEX care symbols reference] [INTERNAL LINK: Care label localization guide]

Risks, Compliance & Localization (US/EU Focus)

Align inputs and labeling to REACH (EU), CPSIA (US), and OEKO-TEX. Follow the AAFA RSL for restricted substances. Localize care labels, warnings, and documentation; keep traceability for audits. Regulations evolve—verify current editions before production.

Risk Matrix

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Puckering on lightweight shells | Medium | High | Lower density; film backing; tension tuning; sample on production fabric |

| Color bleed/crock | Low–Medium | Medium | Polyester thread; lab test; avoid aggressive detergents |

| Needle damage | Low–Medium | High | Correct needle type/size; hooping discipline; inline checks |

| Restricted substances | Low | High | AAFA RSL onboarding; Oeko-Tex inputs; supplier declarations |

| Documentation gaps | Medium | Medium–High | Maintain DoC, test reports, and batch traceability; audit-ready files |

Regulatory Notes for US & EU

- REACH (EU): check restricted substances and labeling; maintain supplier declarations. ECHA (REACH)

- CPSIA (US): children’s apparel thresholds and testing; tracking labels where required. CPSC (CPSIA)

- OEKO-TEX Standard 100: verify threads/backings meet harmful-substance thresholds. OEKO-TEX Standard 100

- AAFA RSL: align inputs with the latest restricted substances list. AAFA RSL

- Social compliance: WRAP/BSCI/SEDEX certifications for ethical manufacturing. WRAP

Disclaimer: Regulations change. Confirm current editions and any country-specific requirements before production. [CITE: EU and US national updates 2023–2025] [MENTION: National market surveillance agencies] [INTERNAL LINK: Sustainability/compliance pillar — documentation map]

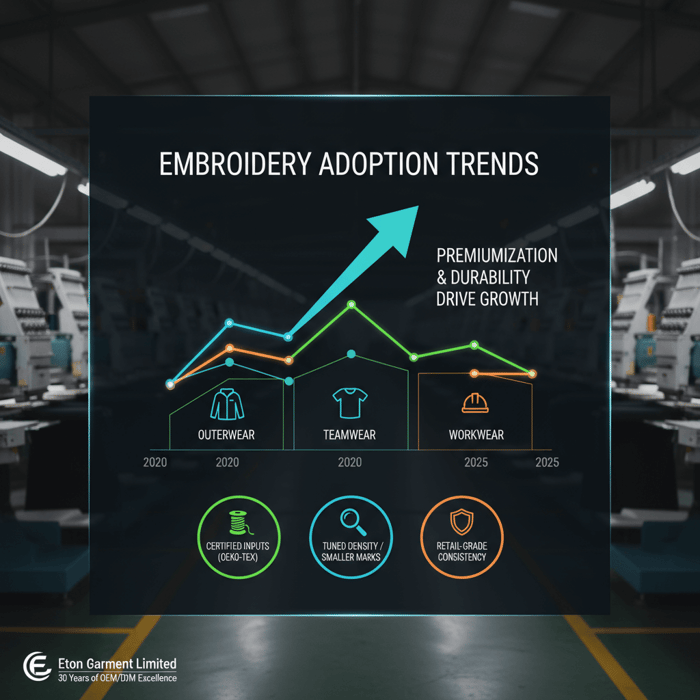

Data & Trends: Embroidery Demand in US & EU

Embroidery remains resilient in teamwear, outerwear, and workwear. Premiumization favors durable, elevated marks; compliance pushes certified inputs; uniforms continue to demand retail-grade consistency. Brands optimize designs for stitch savings while maintaining presence, and they plan faster cycles with integrated OEM workflows.

- Uniforms/workwear maintain high embroidery adoption in US/EU retail [CITE: Industry association reports, 2023–2025]

- Brands favor certified materials in decorated apparel for compliance [CITE: OEKO-TEX trend brief, 2024]

- Outerwear marks trend toward tuned density and smaller sizes for cleaner hand feel [CITE: Retail buyer interviews or trade publications]

Key Trend 1: Premiumization in Outerwear

Outerwear buyers prioritize quality signals—clean stitching, stable placement, and consistent color mapping. Smaller, well-digitized chest marks replace oversized graphics, reducing stiffness and runtime. Brands cite repeatable quality and timely PP approvals as differentiators for seasonal drops. [CITE: Trade show buyer feedback summaries] [MENTION: EuroShop/Outdoor Retailer insights] [INTERNAL LINK: Outerwear embroidery best practices — density tuning]

Key Trend 2: Compliance-Driven Material Choices

Retail teams specify Oeko-Tex threads/backings and audit traceability. AAFA RSL alignment and REACH/CPSIA documentation become standard in vendor packs. Sustainability targets push longer-wear products with durable decorations—good embroidery extends garment lifecycles and lowers returns. [CITE: Sustainability reports from apparel councils] [MENTION: Textile Exchange material guidance] [INTERNAL LINK: Sustainability/compliance pillar]

Conclusion & Next Steps

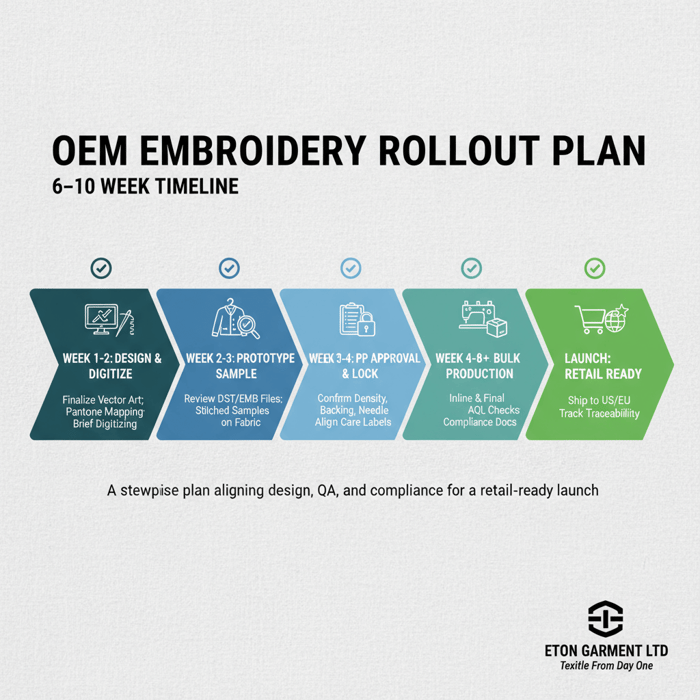

Embroidery success comes from matching technique to garment, tuning stitch-density mechanics, and partnering with a compliance-ready OEM. Lock artwork and digitizing, approve PP samples on production fabric, and plan capacity across multi-heads with documented QA to hit retail windows for US/EU launches.

- Week 1–2: Finalize vector art and Pantone-to-thread mapping; brief digitizing with fabric notes.

- Week 2–3: Review DST/EMB files; request stitched prototypes on production fabric.

- Week 3–4: PP sample approval; lock density, backing, and needle specs; align care labels.

- Week 4–8+: Bulk production; inline and final AQL checks; compliance documentation bundle.

Ready to run an embroidery sample with OEM-grade QA? Start with Eton’s Clothing Manufacturing OEM Service and ship retail-ready outerwear, caps, and workwear on time. Textile From Day One.

- ECHA — REACH Regulation overview and guidance (2024–2025). https://echa.europa.eu/regulations/reach

- CPSC — CPSIA guidance and test requirements (2024–2025). https://www.cpsc.gov/Regulations-Laws--Standards/Statutes/The-Consumer-Product-Safety-Improvement-Act

- OEKO-TEX — Standard 100 (2024–2025). https://www.oeko-tex.com/en/our-standards/oeko-tex-standard-100

- AAFA — Restricted Substances List (latest edition). https://www.aafaglobal.org/

- WRAP — Social compliance. https://wrapcompliance.org/

- [CITE: Industry digitizing best practices — Wilcom/Embird documentation]

- [CITE: AATCC standards — 8, 15, 16.3, 61; ISO standards — 105-C06, 105-X12, 105-E04, 105-B02, 6330]

- [CITE: ISO 2859-1 — AQL sampling for apparel]

- [CITE: Multi-head embroidery OEM runtime benchmarks — Tajima/Barudan publications]

- [CITE: Textile Exchange — sustainability guidance (2023–2025)]

- [CITE: Trade publications/trade show reports — EuroShop, Outdoor Retailer]

- [CITE: Accredited textile lab SLAs — colorfastness testing timelines]

[INTERNAL LINK: Clothing Manufacturing OEM Service — https://china-clothing-manufacturer.com/garment-factory/] [INTERNAL LINK: Embroidery tech pack checklist — lead magnet] [INTERNAL LINK: Outerwear quality standards — pillar page] [INTERNAL LINK: Sustainability and compliance in apparel — pillar page]

[MENTION: Tajima, Barudan, Madeira, Gunold, AATCC, ISO, ECHA, CPSC, OEKO-TEX, AAFA] [CITE: Add machine park photos and PP sample macro shots to strengthen E-E-A-T]

FAQs

Related Articles

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Choosing a Sportswear Company: A US/EU Buyer’s Playbook with a Trusted China Clothing Manufacturer

10 minute read

October 28th, 2025

Choosing a Sportswear Company: A US/EU Buyer’s Playbook with a Trusted China Clothing Manufacturer... more »