What Is Viscose? A China Clothing Manufacturer’s Guide for Fashion Brands

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

22 minute read

What Is Viscose? A China Clothing Manufacturer’s Guide for Fashion Brands

What is viscose is the question sourcing and design teams ask when choosing fibers for next season. As a China Clothing Manufacturer with outerwear expertise, Eton translates fiber science and mill reality into production-ready guidance for US and EU fashion brands: how viscose is made, how it performs, what sustainability signals matter, and how to specify it for garments and linings.

Viscose sits inside the rayon family—regenerated cellulose from wood pulp—offering graceful drape and a soft hand. It also brings trade-offs: wet strength, shrinkage, and wrinkle behavior that must be managed through finishing, blending, and QA. This guide maps the process, compares viscose to modal, lyocell, cotton, and polyester, and provides OEM workflows, lab tests, and compliance frameworks for reliable manufacturing in China and Bangladesh.

Viscose is a man‑made cellulosic fiber (rayon) regenerated from wood‑pulp cellulose through a chemical process. It delivers soft handfeel, breathability, and elegant drape, yet can wrinkle and shrink without proper finishing and QA. Sustainable outcomes depend on pulp sourcing and mill chemical controls [CITE: Encyclopedic overview of viscose chemistry and production].

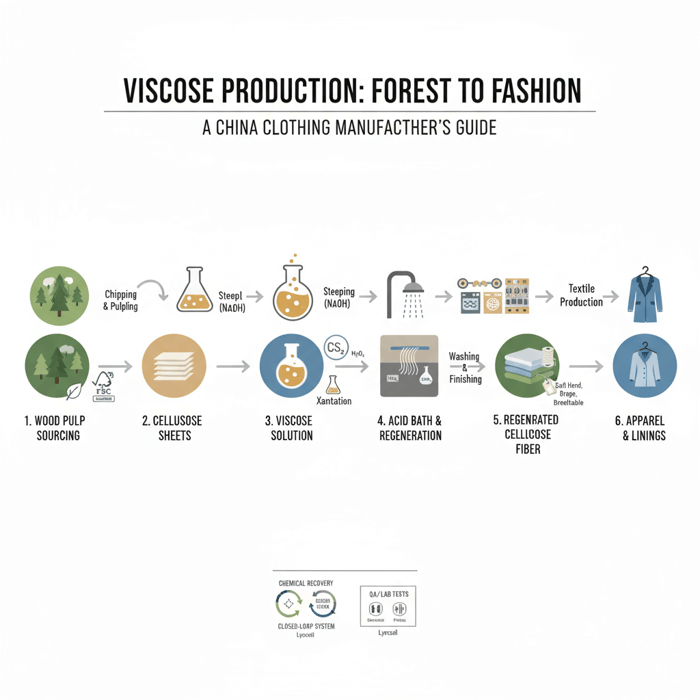

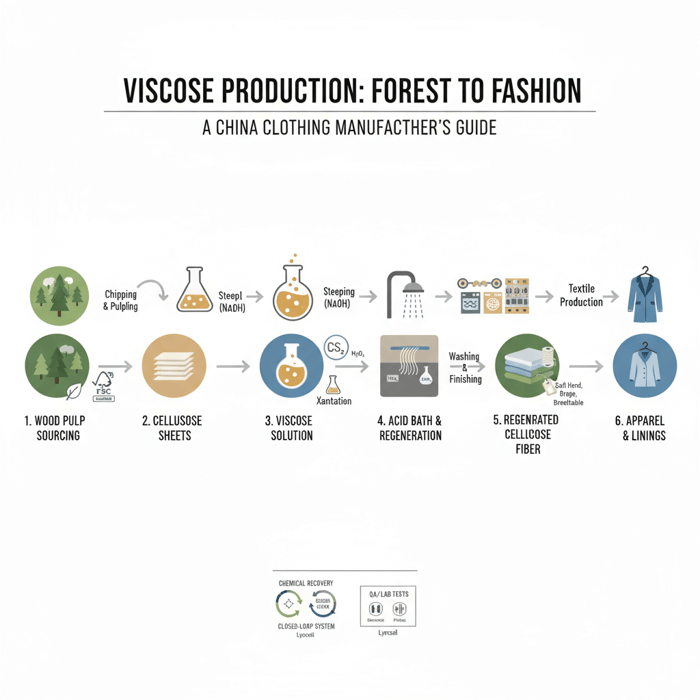

What Is Viscose? Composition, Process, and Types

Viscose is regenerated cellulose derived from wood pulp. Mills convert purified cellulose into a viscose solution using alkali treatment and xanthation (carbon disulfide), then extrude it through spinnerets into an acid bath, where cellulose regenerates as fiber. Viscose is part of the rayon family with variants such as modal (high‑wet‑modulus) and lyocell (solvent‑spun with NMMO) [CITE: Authoritative encyclopedic rayon/viscose entry].

Core production steps (plain language)

- Wood to pulp: sustainably managed forests are chipped and pulped into purified cellulose sheets or fluff [CITE: FSC/industry pulp overview].

- Steeping: pulp is steeped in sodium hydroxide (NaOH), forming alkali cellulose; this stage opens the cellulose structure [MENTION: Lenzing technical notes; Textile Exchange MMCF briefs].

- Aging and xanthation: controlled aging reduces polymer chain length; carbon disulfide (CS₂) reacts to form cellulose xanthate [CITE: Chemical safety profile for CS₂].

- Dissolving: cellulose xanthate dissolves in dilute NaOH to create viscose “dope,” which is filtered and de-aerated [MENTION: ZDHC MMCF v2.0 process guidance].

- Spinning: the dope is extruded through spinnerets into an acid bath (often sulfuric acid), regenerating cellulose as continuous filament or staple fiber.

- Washing and finishing: fibers are washed to remove residual chemicals, then cut (staple), crimped, and finished for spinning or filament use.

Terminology varies by market. “Viscose” and “rayon” are used interchangeably in many regions; “viscose rayon” typically denotes the classic CS₂‑based process, distinct from lyocell’s NMMO solvent system [CITE: Regional naming conventions for rayon/viscose].

Cellulose and solvent systems explained

Cellulose is the structural polymer in plant cell walls. The viscose route dissolves cellulose via a derivative (cellulose xanthate) that becomes soluble in alkaline solution. During spinning, acid triggers de‑derivatization, regenerating pure cellulose fiber. Modal upgrades the viscose approach to achieve higher wet modulus and strength through altered process controls. Lyocell dissolves cellulose directly in N‑methylmorpholine N‑oxide (NMMO) and typically operates in a closed‑loop system with high solvent recovery [CITE: Process comparison of viscose, modal, and lyocell; [MENTION: TENCEL lyocell technical briefs]].

Viscose, modal, and lyocell — practical differences

- Standard viscose: excellent drape and dye uptake; lower wet strength; more shrinkage risk without preshrink and finishing; cost-efficient.

- Modal (HWM): higher wet strength and dimensional stability; softer yet more resilient hand; premium over standard viscose [CITE: Britannica rayon subtype properties].

- Lyocell: higher wet strength and improved fibrillation control with proper finishing; solvent system supports strong sustainability claims; typically highest cost among MMCF options [MENTION: Higg MSI; Lenzing ECOVERO/TENCEL].

Fabric constructions for apparel

Viscose appears in light wovens (challis, lawn), twills and satins (common for linings), and jerseys with elastane for dresses. Blends alter behavior: polyester blends boost wrinkle resistance and seam strength; cotton blends retain breathability and familiar hand; nylon or elastane improves recovery and sleeve glide in linings. Construction and finishing matter as much as fiber choice when setting handfeel, drape, and care requirements [CITE: Fabric construction and finishing reference for MMCF].

[INTERNAL LINK: Our foundational MMCF guide for apparel — pillar overview]

Viscose Properties, Pros & Cons for Apparel

Viscose delivers soft handfeel, breathability, and graceful drape. Brands must plan for wrinkle behavior, shrinkage potential, and lower wet strength. Performance can be tuned via preshrink processes, finishing (resin, enzyme, anti‑static), and blend strategies. The following properties map to typical apparel outcomes [CITE: Rayon property overview; [MENTION: Lenzing technical documentation]].

- Pros: elegant drape; breathable comfort; vivid dye uptake; versatile constructions; comfortable hand.

- Cons: wrinkle‑prone without finishing; wet strength limits; shrinkage risk; seam slippage on smooth constructions; pilling risk with suboptimal yarn and finishing.

| Property | Viscose (standard) | Modal (HWM) | Lyocell |

|---|---|---|---|

| Handfeel | Soft, fluid | Soft, resilient | Smooth with crisp drape |

| Wet strength | Lower | Higher | Higher |

| Wrinkle behavior | Moderate–High | Moderate | Moderate |

| Shrinkage risk | Moderate | Lower | Lower |

| Sustainability signals | Variable; mill controls critical | Often improved process controls | Closed‑loop solvent, strong claims |

Managing shrinkage and wrinkles

Set preshrink standards and relaxation protocols early. For wovens, target ≤3% shrinkage in warp/weft based on care method (e.g., gentle machine wash); for linings, specify dimensional stability in dry cleaning processes when relevant. Combine heat‑set or mechanical relaxation with resin finishes to reduce wrinkling. Add care labels that align with actual finishing and lab outcomes (gentle cycle, cool iron, hang dry or dry clean if construction demands). Eton mandates fabric relaxation before cutting and monitors shrinkage across pilot and bulk runs [INTERNAL LINK: Lab Testing & QA Checklist for apparel].

Blends and finishes for durability

Polyester/viscose blends offer improved crease resistance, abrasion performance, and sleeve glide. Cotton/viscose blends balance breathability with drape, while nylon or elastane adds recovery and comfort. Consider anti‑static finishes for linings, enzyme finishes for handfeel, and controlled resin levels to avoid boardiness. Seam slippage risk rises in smooth satins: specify seam strength and stitch density standards alongside fabric finishing [CITE: ISO/AATCC seam slippage guidance].

Outerwear linings: practical use cases

Viscose twill or satin linings deliver premium handfeel and breathability inside jackets and parkas. For sleeves, prioritize glide (filament content or finish) to reduce drag. Define seam strength targets (e.g., minimum 6N at 6mm seam allowance, method per ISO 13936) and monitor slippage during pilot runs. Where moisture exposure is expected, consider polyester/viscose blends and anti‑static finishing to keep movement smooth in multi‑layer systems [MENTION: Outerwear lining case studies; [CITE: Standard seam slippage testing protocols]].

Viscose vs Modal vs Lyocell vs Cotton vs Polyester — How to Choose

Use criteria across drape, wet performance, shrinkage, care, sustainability, and cost. Modal and lyocell bring higher wet strength and stability; cotton offers breathability and broad consumer familiarity; polyester boosts durability and crease resistance with a fossil‑based profile. Align the fiber decision to end‑use, finishing, and compliance goals [CITE: Textile Exchange market report on MMCF; [MENTION: Higg MSI impact comparison]].

| Fiber | Drape | Wet strength | Wrinkle | Shrinkage | Sustainability signals | Indicative cost band* |

|---|---|---|---|---|---|---|

| Viscose | Excellent | Lower | Moderate–High | Moderate | Variable; mill controls critical | Mid |

| Modal | Excellent | Higher | Moderate | Lower | Process improvements common | Mid–High |

| Lyocell | Very good | Higher | Moderate | Lower | Closed‑loop solvent; strong claims | High |

| Cotton | Good | Good | Moderate | Moderate | Sourcing‑dependent; organic options | Mid |

| Polyester | Good | High | Low | Low | Fossil‑derived; recycling pathways | Low–Mid |

*Actual ranges depend on spec, mill, and certification status [CITE: Market pricing overview for MMCF and blends].

- MMCF share of global fiber supply ≈ 7% — 2023 (Source: [CITE: Textile Exchange PFM Report 2023/2024])

- ZDHC MMCF v2.0 sets emission benchmarks for viscose chemicals — 2023 (Source: [CITE: ZDHC MMCF Guidelines v2.0])

- Higg MSI shows impact ranges vary by fiber and process — 2023 (Source: [CITE: SAC Higg MSI 2023])

Criteria overview

Drape matters for dresses and relaxed silhouettes; wet strength influences durability and care outcomes; shrinkage and wrinkle behavior shape consumer experience and returns; sustainability signals affect brand positioning and retailer acceptance. Cost bands reflect base fiber plus finishing and certification premiums. Assign weights by program goals (e.g., Drape 25%, Wet Strength 20%, Sustainability 20%, Care/Shrinkage 15%, Cost 20) and track trade‑offs [INTERNAL LINK: Fiber selection framework for design teams].

Decision framework, applied

For a flowing dress program with machine‑wash care, modal or lyocell provide stability, with viscose blends viable if preshrink standards hold. For outerwear linings, viscose twill/satin blends with polyester help sleeve glide and crease resistance. For value programs, standard viscose excels on drape and dye uptake; align finishing and lab tests to meet shrinkage and seam strength targets. For sustainability claims, choose FSC pulp and mills aligned with CanopyStyle; consider ECOVERO or TENCEL for traceability [MENTION: Canopy Hot Button; [CITE: ECOVERO technical and certification notes]].

Data, Costs & Sourcing Trends in China & Bangladesh

China and Bangladesh offer capacity and finishing diversity for viscose and blends. Certified lines (e.g., ECOVERO) command premiums and may carry longer queues. Lead times hinge on mill queue, finishing complexity, and seasonality. Align early booking with compliance requirements and seasonal calendars [CITE: Regional sourcing trend report for MMCF].

- Certified MMCF availability expanding — 2023–2024 (Source: [CITE: Textile Exchange PFM Report])

- Tier‑2 adoption of ZDHC MMCF controls increasing — 2023 (Source: [CITE: ZDHC MMCF v2.0 uptake commentary])

Indicative cost and lead‑time ranges

- Standard viscose lining satins/twills: mid price bands; indicative $1.80–$3.50 per meter in China; Bangladesh similar with variability by finish and MOQ [CITE: Regional fabric price benchmarks].

- Certified viscose (e.g., ECOVERO) premiums: +10–25% over standard; traceability documentation included [CITE: Mill pricing notes for certified MMCF].

- Lead times: greige + finishing 25–45 days; fabric booking buffers recommended; garment bulk 35–75 days depending on style complexity and QA gates.

- MOQs: 500–2,000 meters per color for many mills; lower MOQs possible with surcharge or stock service [CITE: MOQ norms for MMCF fabrics].

Sourcing risk filters

- Certification and pulp sourcing: prioritize FSC and CanopyStyle‑aligned mills; request Hot Button indicators and lot‑level chain‑of‑custody [CITE: FSC chain‑of‑custody guidance; [MENTION: CanopyStyle program]].

- Chemical controls: verify ZDHC MMCF conformance and CS₂ management; request emissions data or third‑party audit summaries [CITE: ZDHC MMCF Guidelines v2.0; [MENTION: NIOSH CS₂ hazard profile]].

- QA track record: review shrinkage, seam slippage, and colorfastness performance from past programs; run pilot for new constructions.

- Capacity and seasonality: assess mill queue, holiday calendars, and finishing line utilization; secure buffers for certified runs.

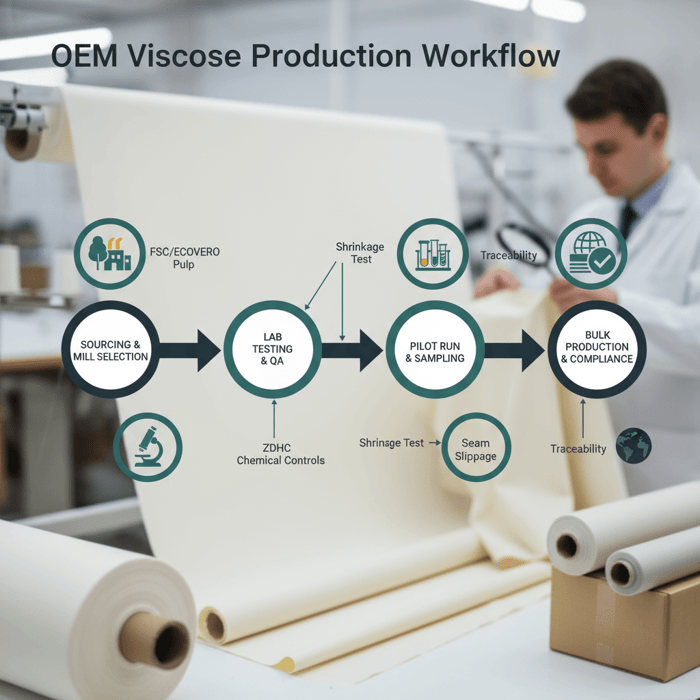

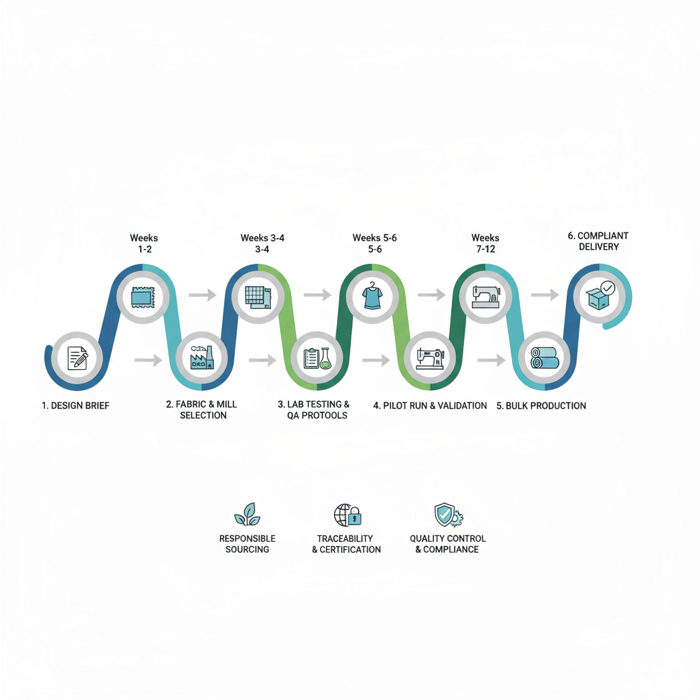

How to Design & Manufacture with Viscose (Step‑by‑Step)

Move from concept to bulk with a defined workflow: fabric selection and finishing, lab tests, pattern allowances, pilot, and in‑line QA. Control shrinkage and wet performance through preshrink/relaxation and finishing choices. Document care labels based on test outcomes and retailer requirements in the US and EU [CITE: AATCC/ISO testing standards index].

- Define end‑use and fabric spec: drape, strength targets, blend ratios, finishes. Output: tech pack inputs and BOM within 1–2 weeks.

- Greige selection and finishing plan: select mill line, confirm preshrink, resin/anti‑static options. Output: lab dip/handfeel swatches in 1–2 weeks.

- Lab tests: shrinkage, colorfastness, seam slippage, pilling, abrasion, care label validation. Output: test report in about 1 week [CITE: ISO 6330/5077, AATCC 61/8, ISO 13936, ISO 12945].

- Pattern adjustments and relaxation: apply fabric relaxation protocol; adjust tolerances; confirm shrinkage targets (e.g., ≤3%). Output: PP sample in 1 week.

- Pilot run and wear tests: small lot build; check glide, wrinkles, shrinkage; tune finishing. Output: pilot review in 2 weeks.

- Bulk production with in‑line QA: 4–8 weeks depending on complexity; daily checks for seam strength, shade, and dimensional stability.

Preparation: specs, BOM, and tech pack

List GSM, weave/knit, yarn type (staple vs filament), blend ratio, and finishes (anti‑static, resin). Define test methods: ISO 6330/5077 for dimensional change, ISO 13936 seam slippage, AATCC 8/116 crocking, AATCC 61 colorfastness to laundering, ISO 12945 pilling. Add target thresholds and care label statements based on fabric construction and end‑use [INTERNAL LINK: Care Labeling Standards for fashion brands].

Execution steps: sampling to pilot

Relax fabric rolls prior to cutting (e.g., 24–48 hours under controlled RH/temperature). Confirm shrinkage profiles with the intended wash/care. For linings, test sleeve glide with garment shell to validate movement and static behavior. Run tone and shade checks per lot to limit batch variability. Pilot with representative sizes and seam allowances to surface slippage issues before bulk [MENTION: OEM pilot case notes from Eton production teams].

Quality assurance: labs and in‑line controls

Combine lab testing with shop‑floor checkpoints: measure shrinkage after wash, monitor seam slippage in satin/twill constructions, assess pilling on abrasion rigs, and validate colorfastness to washing/rubbing. QA teams track shade bands and finishing consistency per lot. Document results and corrective actions for retailer compliance audits (US/EU). Eton applies viscose‑specific QA and traceability at lot level for global clients [INTERNAL LINK: Eton QA methodology and case files].

Sustainability, Risks & Compliance for Viscose

Sustainable viscose hinges on pulp sourcing and chemical controls. Brands should align mills with CanopyStyle and FSC and verify ZDHC MMCF v2.0 adoption. Carbon disulfide (CS₂) exposure presents health and environmental risks when unmanaged; request data and controls. Build traceability and RSLs suitable for US and EU retail programs [CITE: NIOSH CS₂ hazard profile; [MENTION: CanopyStyle and FSC program documentation]].

- Pros: renewable cellulose; strong drape and comfort; certification pathways like FSC and ECOVERO with traceability.

- Cons: deforestation risk without controls; chemical emissions concerns; performance variability across mills and finishing lines.

Risk matrix and mitigations

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Unverified pulp sourcing | Medium | High | Select FSC/CanopyStyle mills; request Hot Button evidence and chain‑of‑custody [CITE: FSC CoC guidance]. |

| CS₂ emission/worker exposure | Variable | High | Prefer mills aligned with ZDHC MMCF v2.0; request audit summaries, emission controls, and recovery rates [CITE: ZDHC MMCF v2.0; [MENTION: NIOSH CS₂ profile]]. |

| Shrinkage variability | High | Medium | Preshrink standards, relaxation protocols, and lab testing prior to bulk. |

| Certified line lead times | Medium | Medium | Early bookings; seasonal buffers; multi‑mill contingency plans [CITE: MMCF supply trend commentary]. |

Regulatory notes for US & EU apparel

US and EU buyers expect traceability and documentation: FSC or equivalent pulp certifications, CanopyStyle alignment evidence, and ZDHC MMCF‑related chemical management. Map internal RSLs to retailer lists; document care labels per AATCC/ISO tests. Track EU regulatory developments around corporate sustainability due diligence and deforestation‑related measures; align MMCF sourcing with forest protection commitments [CITE: EU CSRD/CS3D policy summary; [MENTION: Retailer RSL programs]].

Product/Service Integration: Clothing Manufacturing OEM Service

Eton’s Clothing Manufacturing OEM Service brings viscose and viscose‑blend programs from concept to compliant bulk. We coordinate mill selection (FSC/ECOVERO options), preshrink and finishing, lab testing, seam and glide controls for linings, and documentation for US/EU retailers. The workflow reduces shrinkage risk, stabilizes sizing, and supports on‑time delivery in China and Bangladesh.

| Need | OEM feature | Outcome |

|---|---|---|

| Certified viscose sourcing | FSC/ECOVERO‑aligned mill network | Traceable materials with documentation [CITE: ECOVERO technical info]. |

| Shrinkage control | Preshrink/relaxation + lab tests | Stable sizing and fewer returns. |

| Outerwear lining performance | Lining spec optimization + sleeve‑glide checks | Smoother wear and better durability. |

| Compliance & RSL | ZDHC MMCF‑aligned vendor audits; RSL management | Documented chemical safety for US/EU retail programs [CITE: ZDHC MMCF v2.0]. |

| Lead‑time reliability | Production planning + buffers | On‑time bulk with seasonal risk controls. |

Use case: Viscose twill lining for jackets

For a jacket program, specify viscose/polyster twill at 65/35 with anti‑static and resin finishes. Target sleeve glide validation with shell fabric, seam strength per ISO 13936, and dimensional stability with dry‑clean care. Pilot confirms glide and slippage at stress points (elbow, armhole). Bulk tracks shade and finishing consistency per lot [MENTION: OEM lining pilot with European retailer].

Use case: Viscose‑blend dresses with shrinkage control

For dresses, select viscose/modal jersey with elastane for recovery. Set shrinkage ≤3% under gentle machine wash; validate colorfastness to laundering and rubbing per AATCC 61/8. Apply heat‑set and relaxation protocols. Care label: gentle cycle, cold wash, line dry, cool iron. Pilot in two fabric finishes to confirm handfeel and shrinkage; choose the finish with lower residual shrinkage and better pilling scores [CITE: ISO 12945 pilling method reference].

Learn how Eton’s Clothing Manufacturing OEM Service supports viscose programs at scale: Clothing Manufacturing OEM Service.

Care, Quality Testing & Performance Standards

Care labeling should follow lab outcomes. For standard viscose, gentle machine wash or dry clean depending on construction and finishing; line dry; cool iron. Preshrunk fabrics and resin finishes reduce wrinkles; enzyme finishes refine handfeel. Define shrinkage tolerance, seam slippage, colorfastness, and pilling thresholds before PP approval [CITE: AATCC/ISO care labeling and testing references].

- Shrinkage tolerance: ≤3% warp/weft under specified care; document preshrink method and relaxation time.

- Colorfastness: AATCC 61 (laundering), AATCC 8/116 (crocking); set grade targets for shade performance.

- Seam slippage: ISO 13936 at defined seam widths; raise seam allowance or adjust stitch parameters if risk appears.

- Pilling and abrasion: ISO 12945 (Martindale); confirm finishing reduces fibrillation where needed.

Care labeling guidance

Align icons and text with the test protocol used and retailer rules in the US and EU. Avoid default “dry clean only” without cause; if finishing and seam strength allow gentle wash, label accordingly to reduce care burden. Add ironing guidance (low heat, steam) and dry options (line dry) reflecting shrinkage outcomes [INTERNAL LINK: Care Labeling Standards — ISO/AATCC].

Lab testing protocols

Build a test plan by end‑use: dresses and blouses favor shrinkage, colorfastness, and pilling checks; outerwear linings add seam slippage and sleeve‑glide evaluations. For EU retail, document method numbers and grades; for US, include AATCC equivalents. Retain lab reports and batch records for audits [CITE: Retail audit expectations for apparel QA].

Packaging and transport considerations

Use polybag and carton specs that limit compression and creasing for viscose garments; specify fold method and insert cards. For bulk transport through humid seasons, consider desiccants and humidity controls. Record storage conditions near DCs to reduce wrinkle issues on arrival.

Conclusion & Next Steps

Viscose offers drape and comfort with attention to process, finishing, and QA. Build decisions on fiber comparisons, preshrink standards, and mill compliance. Use the workflows here to move from spec to pilot to bulk with fewer risks and better consumer experience. Partner with an experienced China Clothing Manufacturer to stitch fiber choice to market success.

- Weeks 1–2: Define fabric spec and tech pack; pick mills and finishing paths.

- Weeks 3–4: Run lab tests; finalize thresholds and care labels.

- Weeks 5–6: Pilot run; validate glide, shrinkage, and shade.

- Weeks 7–12: Bulk with in‑line QA; document traceability and compliance.

[INTERNAL LINK: MMCF Guide for Apparel — pillar resource]

[INTERNAL LINK: Lab Testing & QA Checklist — tools for teams]

[INTERNAL LINK: Care Labeling Standards — ISO/AATCC references]

Explore our OEM workflow and book a program slot: Clothing Manufacturing OEM Service.

Author: Avery Chen, Senior Textile Engineer (12+ years in MMCF and outerwear production) [INTERNAL LINK: Avery Chen — bio page].

Reviewer: Lin Zhang, Compliance & QA Manager (ZDHC MMCF implementation lead) [INTERNAL LINK: Lin Zhang — compliance profile].

Methodology: Synthesized current MMCF guidance, encyclopedic references, and Eton factory workflows; mapped to US/EU apparel standards and retailer expectations.

Limitations: Cost, lead‑time, and performance ranges vary by mill, finish, and spec; always verify with current vendor data. Regulations evolve; confirm applicability to product categories and markets.

Disclosure: Eton Garment Limited provides OEM services and maintains certified mill partnerships.

Last Updated: 2025‑10‑28.

- Wikipedia — Viscose (2024). https://en.wikipedia.org/wiki/Viscose

- Britannica — Rayon (2024). https://www.britannica.com/topic/rayon

- Textile Exchange — Preferred Fiber & Materials Market Report (2023/2024). https://textileexchange.org

- Sustainable Apparel Coalition — Higg MSI (2023). https://msi.higg.org

- Lenzing — ECOVERO Technical & Sustainability Info (2024). https://www.lenzing.com/ecovero

- Forest Stewardship Council — FSC Guidance (2023–2024). https://fsc.org

- ZDHC — Man‑Made Cellulosic Fibres Guidelines v2.0 (2023). https://zdhc.org

- MasterClass — Viscose Fabric Guide (2024). https://www.masterclass.com

- Good On You — Viscose Sustainability Explainer (2024). https://goodonyou.eco

- Wikipedia — Rayon (2024). https://en.wikipedia.org/wiki/Rayon

- Sewport — Viscose/Rayon Fabric Guide (2024). https://sewport.com/fabrics-directory/viscose-fabric

- US CDC/NIOSH — Carbon Disulfide (CS₂) Hazard Profile (2023). https://www.cdc.gov/niosh/topics/carbondisulfide

What Is Viscose? Composition, Process, and Types

Viscose is regenerated cellulose from wood pulp. Mills turn purified cellulose into a viscose solution using alkali and carbon disulfide chemistry, then extrude it into an acid bath to reform cellulose as fiber. It falls under the rayon umbrella, alongside modal (high‑wet‑modulus) and lyocell (NMMO solvent‑spun) [CITE: Rayon classification and process overview].

Core production steps (plain language)

- Pulping: certified forests to cellulose pulp sheets or fluff.

- Steeping: NaOH creates alkali cellulose for improved processability.

- Aging + xanthation: CS₂ reacts to form cellulose xanthate.

- Dissolving: viscose “dope” is filtered and de‑aerated.

- Spinning: acid bath regenerates cellulose into filament or staple.

- Washing/finishing: removes residues; sets fiber behavior.

Cellulose and solvent systems explained

Viscose uses a derivatization route with cellulose xanthate; modal improves wet strength through process controls; lyocell dissolves cellulose in NMMO, typically recovering solvent in a closed loop [MENTION: Lenzing; Textile Exchange].

Viscose, modal, and lyocell — practical differences

- Viscose: fluid drape, vivid dyes, lower wet strength without tuned finishing.

- Modal: higher wet performance, softer yet more stable.

- Lyocell: strong wet strength, controlled fibrillation, premium cost profile.

Fabric constructions for apparel

Wovens (challis, twill, satin) and jerseys are common. Polyester blends raise crease resistance and seam strength; cotton blends keep breathability; elastane adds recovery.

Viscose Properties, Pros & Cons for Apparel

Expect a soft hand, breathable comfort, and graceful drape. Plan for wrinkles and shrinkage. Use preshrink and finishing, and choose blends tailored to end‑use [CITE: Rayon property references].

- Pros: drape, dye uptake, comfort, versatility.

- Cons: wrinkle behavior, shrinkage risk, seam slippage in satins, wet strength limitations.

| Property | Viscose | Modal | Lyocell |

|---|---|---|---|

| Handfeel | Soft, fluid | Soft, resilient | Smooth, crisp |

| Wet strength | Lower | Higher | Higher |

| Wrinkles | Moderate–High | Moderate | Moderate |

| Shrinkage | Moderate | Lower | Lower |

| Sustainability | Mill‑dependent | Improved controls common | Closed‑loop solvent |

Managing shrinkage and wrinkles

Codify preshrink and relaxation; apply controlled resin finishes; write care labels that reflect test results.

Blends and finishes for durability

Use polyester blends for crease resistance and seam performance; cotton blends for breathability; anti‑static for linings; enzyme for handfeel.

Outerwear linings: practical use cases

Viscose twill or satin linings add comfort and breathability. Validate sleeve glide and seam strength with defined test methods.

Viscose vs Modal vs Lyocell vs Cotton vs Polyester — How to Choose

Balance drape, wet performance, shrinkage, care, sustainability claims, and cost. Modal and lyocell improve wet strength and stability; cotton offers breathability; polyester boosts crease resistance [MENTION: Higg MSI, Textile Exchange].

Criteria overview

Assign weights to drape, wet strength, sustainability, care/shrinkage, and cost. Score options by end‑use needs.

Decision framework, applied

Flowing dresses: modal/lyocell or viscose blends with preshrink. Outerwear linings: viscose/polyester with anti‑static. Sustainability claims: FSC pulp, CanopyStyle alignment, ECOVERO/TENCEL traceability.

Data, Costs & Sourcing Trends in China & Bangladesh

Capacity is strong; certified lines add premiums and queue time. Plan buffers and document compliance.

Indicative cost and lead‑time ranges

Viscose linings often sit in mid price bands; certified viscose carries premiums; lead times vary by finish and queue.

Sourcing risk filters

Check certifications, chemical controls (ZDHC MMCF), QA record, and seasonality.

How to Design & Manufacture with Viscose (Step‑by‑Step)

Run a disciplined workflow: spec, finishing, lab tests, pilot, bulk. Track shrinkage, seam strength, colorfastness, and glide.

Preparation: specs, BOM, and tech pack

List GSM, construction, blend, finishes, and test methods with thresholds and care labels.

Execution steps: sampling to pilot

Relax fabric, evaluate shrinkage, confirm glide, and check shades; pilot before bulk.

Quality assurance: labs and in‑line controls

Combine lab and shop‑floor checks; document per lot for retailer audits.

Sustainability, Risks & Compliance for Viscose

Align mills with FSC/CanopyStyle; verify ZDHC MMCF adoption; request CS₂ controls; integrate RSLs and traceability.

Risk matrix and mitigations

Mitigate sourcing, emissions, shrinkage, and lead‑time risks through supplier selection, audits, preshrink standards, and buffers.

Regulatory notes for US & EU apparel

Provide traceability and chemical documentation; monitor EU sustainability frameworks; maintain lab records.

Product/Service Integration: Clothing Manufacturing OEM Service

Eton’s OEM service manages certified sourcing, preshrink, finishing, QA, and compliance; it stabilizes sizing and timelines.

Use case: Viscose twill lining for jackets

Specify blends and finishes for glide; test seam strength and dimensional stability; monitor shades.

Use case: Viscose‑blend dresses with shrinkage control

Select blends with elastane; validate shrinkage and colorfastness; choose the finish with better pilling performance.

Care, Quality Testing & Performance Standards

Set shrinkage limits; test colorfastness, seam slippage, and pilling; write care labels from test outcomes.

Care labeling guidance

Use icons and text aligned to test results and retailer rules.

Lab testing protocols

Tailor test plans to end‑use and market; retain documentation for audits.

Packaging and transport considerations

Limit creasing with appropriate folds and inserts; manage humidity for long transit routes.

Conclusion & Next Steps

Viscose rewards disciplined sourcing and QA. Apply the frameworks here and partner with experienced OEM teams to hit quality, compliance, and timelines.

FAQs

Related Articles

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »