What Cardigan: Definitions, Types, and Production Specs from a China Clothing Manufacturer

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

19 minute read

What Cardigan: Definitions, Types, and Production Specs from a China Clothing Manufacturer

What cardigan means to a design or production manager is not only a sweater with a front opening—it is a set of manufacturable specifications. For a China Clothing Manufacturer like Eton, the cardigan’s yarn, knit gauge, stitch density, trims, and finishing steps convert intent into repeatable quality for US/EU markets.

A cardigan is a knitted sweater with a front opening, usually closed by buttons or a zipper. In manufacturing, “what cardigan” translates into yarn choice, knit gauge, stitch pattern, panel shaping, trims, and finishing—variables that define weight, drape, durability, cost, MOQ, and lead time across sizes and colorways.

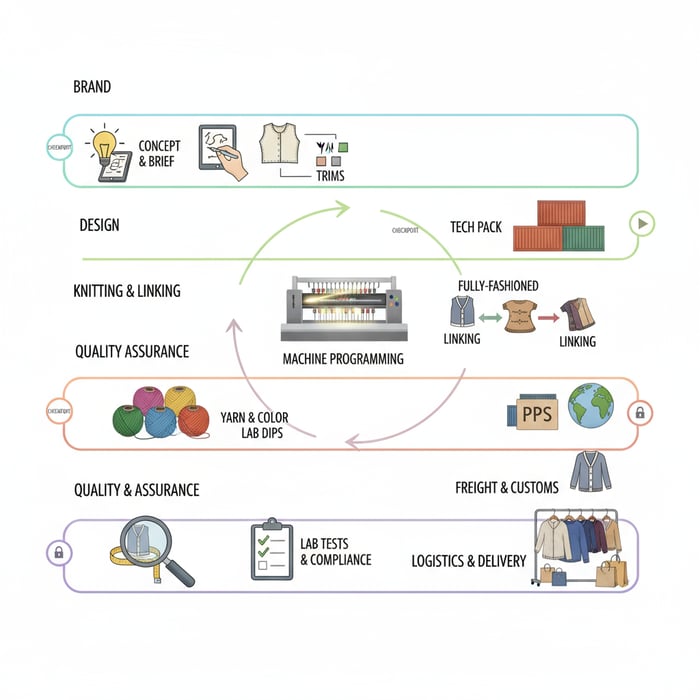

Eton Garment Limited has produced outerwear and knit-based layers at scale since 1993. We connect yarn sourcing, fully fashioned or cut-and-sew knitting, linking, washing/relaxing, blocking, QC, and US/EU compliance into one workflow. The goal is simple: fewer rounds, fewer risks, and reliable fit across your range.

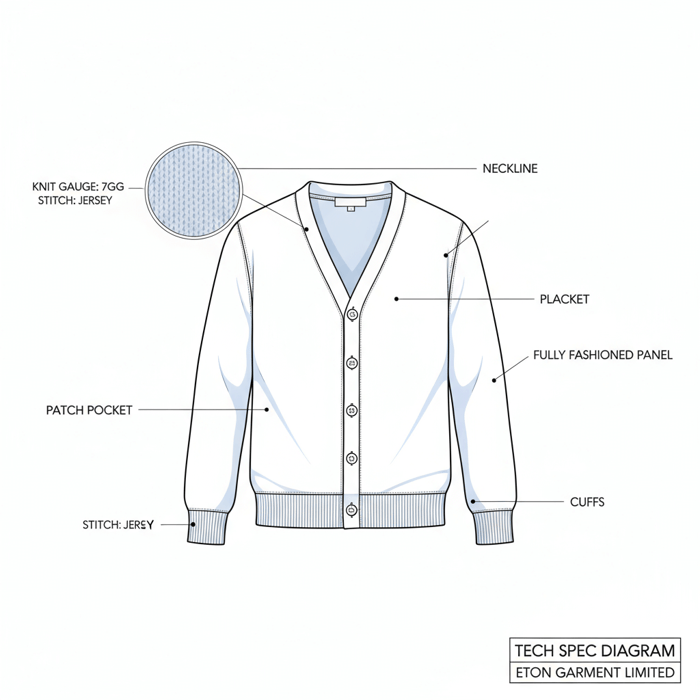

What Cardigan Means in Manufacturing: Definition, Anatomy, and Spec Basics

A cardigan is a knitwear category defined by a front opening and closure. In factory terms, “what cardigan” is a bundle of specs: fiber and yarn count, knit gauge, stitch density, pattern, panel shape, trims, and finishing. These variables set the garment’s handfeel, stability, cost, and feasibility at scale [CITE: Lexical definition from a reputable dictionary].

- Body panels: front left, front right, back (shaped or straight).

- Sleeves: set-in or raglan; fully fashioned or cut-and-sew.

- Neckline and collar: V-neck, crew, shawl, or stand collar.

- Placket: knitted-on or separate; reinforced; button or zip closure.

- Closures: buttons (by ligne), snaps, or zippers (coil or metal).

- Cuffs and hem: rib constructions (e.g., 1×1, 2×2) with recovery.

- Pockets: patch, welt, or side-entry; reinforced at stress points.

- Labels and care: brand/main label, size, care, and fiber content.

- Finishing: washing/relaxing, tumble/steam, blocking to measurements.

Cardigan tolerances require clarity in tech packs and approvals. Production teams plan for relaxation after washing; measurements are checked pre- and post-wash to ensure stability [CITE: AATCC shrinkage and dimensional change test reference].

[MENTION: Shima Seiki]. [MENTION: STOLL]. [INTERNAL LINK: Knitwear manufacturing glossary → pillar/cluster page idea].

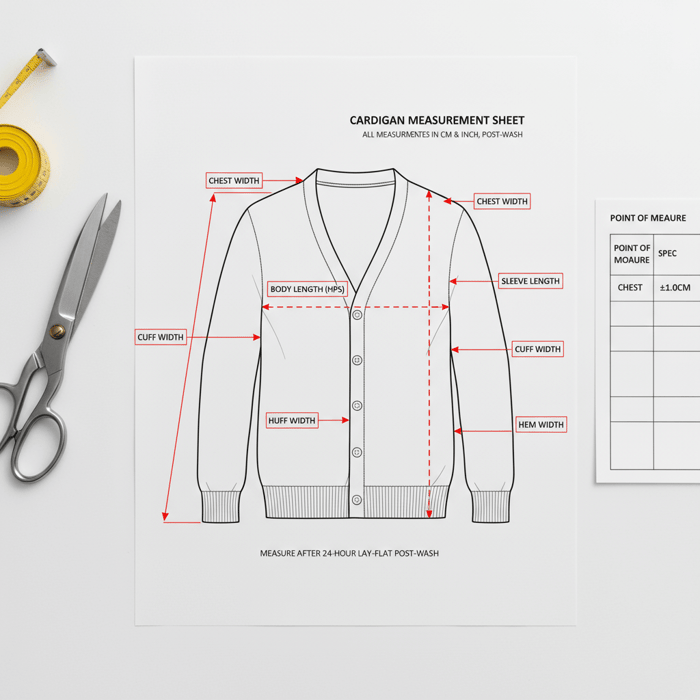

Anatomy & Measurements

Product specs hinge on clear Points of Measure (POM) and tolerances that reflect knit relaxation. Typical POMs include across-chest (1”/2.5 cm below armhole), body length (HPS to hem), sleeve length (HPS over shoulder to cuff), cuff width, hem width, and placket width. State whether measurements are taken pre- or post-wash. For rib cuffs and hems, specify whether to measure relaxed or extended.

- Tolerances: ±1.0 cm (±3/8 in) on key body measures is common for mid-gauge; heavy gauges may require ±1.5 cm (±5/8 in).

- Relaxation: Mention “measure after 24-hour lay-flat post-wash” for stable comparisons.

- Balance: Record front/back length differential for styles with drop hem or back yoke shaping.

- Button spacing: Define center-to-center spacing, distance from neckline, and last button from hem.

Call out shoulder slope, armhole depth, and sleeve cap height on fully fashioned knits. If panels are cut-and-sewn, include seam allowances and overlock/coverstitch specs. Include a graded measurement table across sizes and define grading rules per POM [CITE: Grading methodology text or apparel engineering guide].

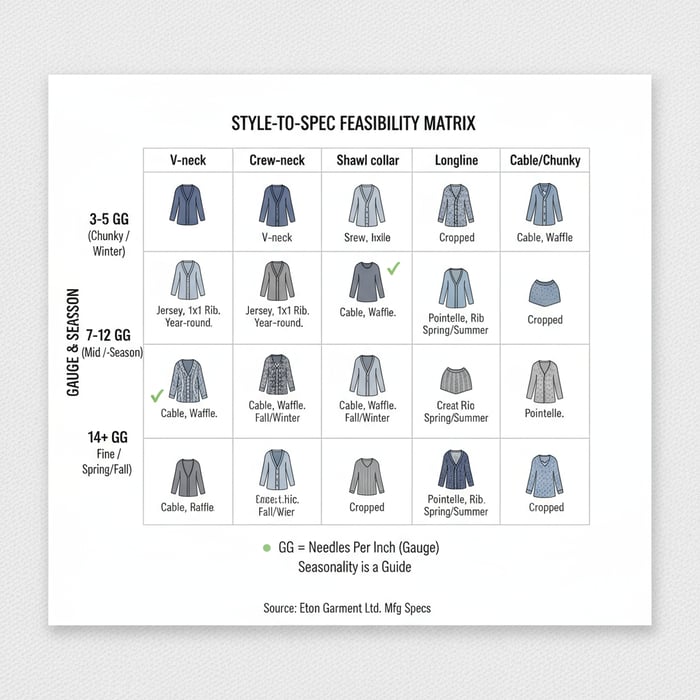

Materials & Gauge Primer

Gauge refers to the number of needles per inch on the knitting machine. Lower GG knits are chunkier; higher GG knits are finer.

- Chunky: 3–5 GG (bulky stitches, high volume, cold-weather layers).

- Mid-gauge: 7–12 GG (balanced drape and warmth; versatile for men’s/women’s).

- Fine: 14 GG and up (clean surface, lighter weight, refined hand).

Gauge interacts with yarn count and stitch density. A tighter tension increases durability but can add cost and impact drape. Heavier yarns or textured stitches (cable, waffle) consume more yarn per garment. Clear gauge and tension targets speed sampling and stabilize bulk outcomes [CITE: Knit engineering or manufacturing handbook].

Specify yarn fiber and blend (e.g., 80/20 cotton/nylon), yarn count (Nm/Ne), ply, and spinner. Attach knit-downs for handfeel approvals before proto knitting [MENTION: Textile Exchange].

Closures & Trims

Buttons, zippers, and snaps change both look and workflow. Buttons are measured in ligne (e.g., 24L–32L on mid-gauge). Zippers can be coil or metal; define tape color, slider type, and length tolerance. Reinforce plackets and shoulder seams with tapes or clear elastics to resist growth. State button/buttonhole reinforcement, bar-tack positions, and stitch types at stress points.

- Buttons: material (polyester, corozo, urea), thickness, hole count, and color approval.

- Zippers: brand, chain, slider, puller, and lock function; top/bottom stop detail.

- Labels: OEKO-TEX Standard 100 class as required; placement and stitch count per side [CITE: OEKO-TEX Standard 100 page].

Trim durability links directly to care claims. Pair trims with lab tests for colorfastness to washing, rubbing, and dry-cleaning as applicable [CITE: AATCC colorfastness test methods].

Cardigan Types and Use Cases: From V-Neck to Chunky Shawl Collars

Cardigan families vary by neckline, length, and stitch. V-neck, crew, shawl, longline, cropped, cable, and chunky styles create different BOMs and minutes per piece. Align style with season, target price, and brand DNA to pick yarn, gauge, and stitch complexity that fit the plan [MENTION: MasterClass cardigan article for consumer framing].

| Style | Typical Gauge | Common Stitches | Seasonal Weight | Trim Notes |

|---|---|---|---|---|

| V-neck | 7–12 GG | Jersey, 1×1/2×2 rib | Year-round | Buttons 24–28L; narrow placket |

| Crew-neck | 12–14 GG | Jersey, Milano | Spring/Fall | Small buttons; clean neckline |

| Shawl collar | 3–7 GG | Cable, waffle, fisherman's rib | Fall/Winter | Wider placket; heavier buttons |

| Longline | 7–12 GG | Jersey, rib panels | Cross-season | Reinforce shoulder seams for growth |

| Cropped | 10–14 GG | Rib, pointelle | Spring/Summer | Smaller buttons/snaps; lighter yarns |

| Cable/Chunky | 3–5 GG | Aran cables, seed stitch | Winter | Higher yarn usage; stronger reinforcements |

[INTERNAL LINK: Outerwear vs knit layering guide → cluster page idea]

Core Styles & Necklines

V-necks flatter layering and shirt collars. Crew cardigans read cleaner, with smaller buttons and tighter neck ribs. Shawl collars add volume at the neck; pair them with heavier gauges and wider plackets. Longline silhouettes need disciplined knit structures and reinforcements along shoulder and seams to control growth. Cropped cardigans benefit from fine gauges and stretch-recovery ribs for a neat hem.

Men’s lines skew toward mid-gauge V-neck and shawl collar for fall/winter. Women’s ranges carry crew, cropped, and longline variations across seasons. Kids’ cardigans need abrasion resistance, strong button pull tests, and low pilling yarns [CITE: CPSIA/children’s product safety overview; AATCC pilling tests].

Stitch Libraries

Jersey (plain knit) gives a smooth surface and faster knitting. Rib (1×1, 2×2, half-cardigan, fisherman’s) adds stretch and body. Milano and links-links create stable, refined surfaces. Cables, basket, and waffle raise texture and warmth but increase yarn consumption and knitting time. Jacquard and intarsia add color motifs; they also add linking steps and thread management.

- Higher tension: cleaner face, stronger seams; risk of stiffness.

- Lower tension: more drape; risk of growth and distortion.

- Texture stitches: more yarn and minutes per piece; price impact.

Approve stitch swatches at the target gauge before proto knitting. Record target stitch density (courses and wales per unit) for audit-ready specs [CITE: Knit stitch density technical reference].

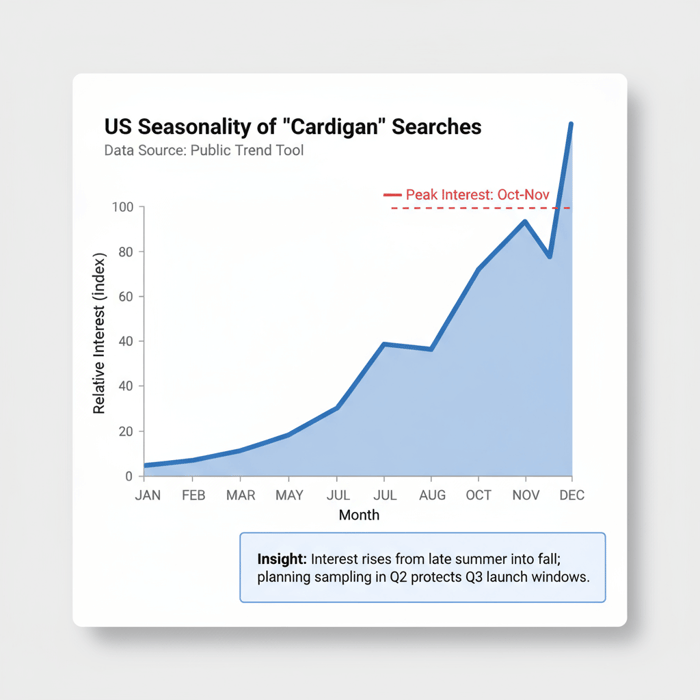

Seasonal Merchandising

Spring/Summer: cotton or cotton-viscose blends at 12–16 GG, lighter buttons or snaps, breathable stitches like pointelle. Fall/Winter: wool or wool-nylon blends at 3–10 GG, textured stitches, and reinforced plackets. Transitional drops sit in mid-gauge with blends that balance warmth and care.

- Warmth: fiber content and stitch volume drive thermal comfort.

- Care: machine-washable blends help adoption for mainstream retail.

- Price: cable/waffle and heavy yarns drive cost; plan your SRP bands upfront.

[MENTION: MasterClass].

Materials, Sustainability, and Knit Construction for Cardigans

Fiber, yarn count, and construction set the cardigan’s performance and footprint. Cotton, wool, cashmere, acrylic, and recycled synthetics each carry trade-offs for warmth, care, price, and durability. Fully fashioned knitting reduces waste; cut-and-sew accelerates throughput and color flexibility. Certifications support claims for US/EU programs [CITE: Textile Exchange PFMR 2023; OEKO-TEX Standard 100 2024].

- Cotton: breathable, easy care; risk of growth in low-tension knits; can shrink without pre-wash; organic options add value [CITE: Organic cotton overview].

- Merino wool: warmth-to-weight, resilience; needs gentle care claims; RWS supports animal welfare [CITE: Responsible Wool Standard].

- Cashmere: soft hand; high price and pilling risk; consider blends and GCS claims for credibility [CITE: Cashmere standard reference].

- Acrylic: cost control and color vibrancy; pilling risk; blends with nylon improve durability [CITE: Material performance comparisons].

- Recycled polyester/nylon: supports circular claims; strength and colorfastness; validate with GRS [CITE: Global Recycle Standard].

- Blends (e.g., cotton/nylon, wool/nylon): balance handfeel, strength, and care; nylon improves abrasion and shape retention.

- Brands are increasing certified recycled content use in knitwear programs — 2023–2024 (Source: Textile Exchange PFMR) [CITE: Textile Exchange PFMR 2023/2024].

Fiber Families & Blends

Start with the handfeel and care claim you want. For spring floors, cotton or cotton-blends hit breathability and easy care. For winter, wool-rich or acrylic-wool blends deliver warmth and value. If pilling risk sits high in your returns data, use nylon content and tighter tensions. Always confirm with knit-downs and lab tests for pilling and dimensional stability [CITE: AATCC pilling and dimensional change standards].

Cashmere and extrafine merino bring premium handfeel; reserve for capsule or marquee pieces and control cost through gauge and stitch simplicity. Recycled synthetics align with brand goals; ensure chain-of-custody documentation for labeling [CITE: GRS labeling guide].

Knit Methods: Full-Fashion vs Cut-and-Sew

Full-fashion: panels are shaped on flat knitting machines, then linked. Benefits include cleaner edges, better drape, and lower waste. Linking quality is a major QA point. Cut-and-sew: yardage is knitted, then panels are cut and overlocked; fast and flexible for colorway and yardage planning; more waste and seam bulk.

- Fully fashioned shines for premium finishes and shaped silhouettes.

- Cut-and-sew fits speed or cost-focused programs with simple shapes.

- Heavy gauges often favor full-fashion to manage seam bulk.

Machine availability and operator skill impact both routes. Confirm gauge and capacity early with your supplier [MENTION: Shima Seiki]. [MENTION: STOLL].

Certifications & Compliance Signals

For US/EU programs, safety and material claims rely on clear standards and traceability. OEKO-TEX Standard 100 screens for harmful substances at the component level. GRS verifies recycled content and chain of custody. RWS supports animal welfare and land management for wool. GOTS covers organic fibers in textiles, from processing to labeling.

- OEKO-TEX Standard 100: labels, threads, and trims within scope [CITE: OEKO-TEX Standard 100 page].

- GRS: transaction certificates for yarns and trims carrying recycled content [CITE: GRS documentation].

- RWS and GOTS: align with consumer-facing sustainability goals and retailer requirements [CITE: RWS/GOTS official sites].

Lab test plans should include colorfastness, pilling, dimensional stability, seam strength at linking, and metal detection where required [CITE: AATCC methods; retail partner manuals].

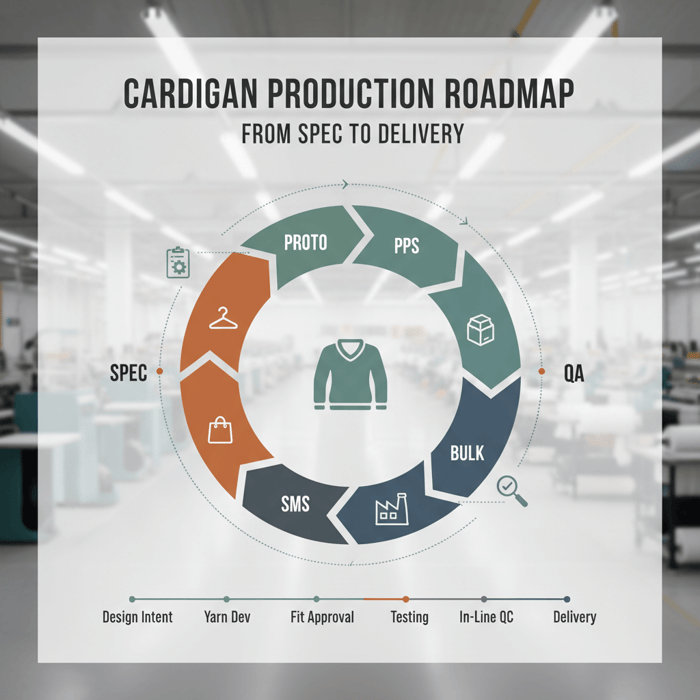

From Brief to Bulk: How to Develop and Produce a Cardigan at Scale

Turn design intent into a reliable bulk run with a structured workflow: a tight tech pack, yarn and trim confirmation, prototypes, fit approvals, SMS, testing, PP sample sign-off, and in-line and final QA. Clear gates reduce rework and protect calendar and margin [CITE: Apparel development lifecycle references].

- Tech pack: measurements, gauge, stitch diagrams, trims, care, branding, packaging, test plan.

- Yarn development: knit-downs; color lab dips; handfeel and pilling checks.

- Prototype (Proto): validate pattern, gauge, and construction.

- Fit round(s): confirm POMs post-wash; lock grading rules.

- SMS: size runs for merchandising and sales; color confirmation.

- Testing: shrinkage, pilling, colorfastness, and trim pull tests.

- PPS: pre-production sample from bulk yarn, trims, and line.

- Bulk: production with in-line QC and AQL final inspections.

- Final QA: carton checks, metal detection (if required), documentation.

Preparation

Tech pack clarity sets the tone. Include a graded measurement chart, rib measurement rules, gauge and tension, stitch diagrams with density targets, placket construction details, button spec by ligne, zipper brand and chain, label positions, and care instructions aligned to fiber and trims. Add packaging and folding specs, carton markings, and pallet plan for US/EU routing [CITE: FTC textile labeling; EU labeling rules].

For sustainability claims, insert certification scope and evidence requirements upfront. Note test methods by standard number and acceptance criteria. Align with retailer manuals where applicable [CITE: Retailer testing manuals or public summaries].

Execution Steps

Proto and fit: confirm silhouette, fabric hand, and key POMs post-wash. Use a fitting checklist and record shrinkage per dimension. SMS: run standard sizes in each color to confirm lab dips and shade bands in natural and store lighting. Testing: book lab slots early; parallel tasks with SMS to save time.

- Typical development: 4–8 weeks from tech pack to PPS, depending on yarn dyeing and machine availability [CITE: Supplier lead time benchmarks].

- Bulk: 6–12 weeks from PPS sign-off, fiber-dependent and region-dependent [CITE: Trade calendars and supplier data].

- Calendar: account for Chinese New Year, Eid, Golden Week, and port congestion; set buffers for US/EU delivery [CITE: Logistics advisories].

Quality Assurance

Use in-line audits to catch growth, seam issues at linking, and shade variance. Control wash/relax and blocking across lines. Test trims for pull, corrosion (for metal), and colorfastness to washing and rubbing. Apply AQL on final inspections and record care label validations after tests [CITE: AATCC manual; ISO 2859 AQL sampling].

Document all approvals in a central tracker. Lock counter-signed PPS boards for production reference and future repeats.

Cost, MOQ, and Lead Times for Cardigans: What to Expect

Cardigan economics come down to yarn price, gauge, stitch complexity, trims, and testing scope. MOQs link to yarn dye lots, cone counts, and machine changeovers. Lead times vary with fiber sourcing and regional calendars. Color consolidation, shared yarn families, and simpler stitches keep plans on track [CITE: Sourcing and costing best-practice sources].

- Yarn: fiber cost, count, ply, and spinner; certified fibers add fees.

- Gauge: lower GG uses more yarn; higher GG takes more knitting time.

- Stitch: cables/jacquards increase minutes per garment and linking steps.

- Trims: premium zippers or buttons add per-unit cost and approvals.

- Testing: program scope affects spend and scheduling.

| Driver | Impact | Lever |

|---|---|---|

| Yarn fiber | Largest cost block | Blend with nylon; choose certified recycled where aligned |

| Gauge/tension | Yarn usage and minutes | Mid-gauge balance; avoid over-tight density |

| Stitch complexity | Knitting and linking time | Limit cables; use engineered ribs for texture |

| Trims | Unit cost and OTS risk | Standardize buttons/zips across styles |

| Testing scope | Lab cost and time | Risk-based plans; reuse certificates where allowed |

- Development: 4–8 weeks; Bulk: 6–12 weeks; China runs faster on sampling, Bangladesh scales volume with value — Year varies by season [CITE: Aggregated supplier timelines; trade reports].

Cost Drivers & Scenarios

At mid-market price points, a 7–12 GG V-neck in cotton/nylon or wool/nylon balances handfeel and durability. Cable-heavy shawl collars in 3–5 GG require more yarn and minutes. Fine-gauge 14–16 GG crews read premium but need tight control on stitch density and washing to prevent growth.

Minutes per garment drive labor cost; yarn consumption drives material cost. Trims and packaging add smaller but non-trivial layers. A smart way to manage price is to align silhouettes across a shared yarn family and repeat trims across colorways.

MOQs & Dye Lots

MOQs in knitwear center on yarn dyeing minimums and cone counts. Fewer colors reduce MOQ pressure and improve yarn utilization. Agree on tolerable shade variance within bands. Use heathered yarns to reduce visible variance across lots. Share forecasted colors early to book spinning and dye capacity [CITE: Yarn dyeing MOQ guidance].

- Levers: color consolidation, shared yarns across programs, carryover colors, and season-to-season repeats.

- Machine setup: batching similar gauges and stitches reduces changeovers and scrap.

Lead Time Planning

Factor regional holidays, lab booking windows, and port schedules. China offers speed for development and complex trims; Bangladesh offers strong value at scale, with planning needed for lab capacity and logistics. Parallelize lab tests with SMS and book PPS reviews as calendar gates [CITE: Country holiday calendars; freight advisories].

[INTERNAL LINK: Production calendar template → resource page idea]

Product/Service Integration: Clothing Manufacturing OEM Service

Eton’s Clothing Manufacturing OEM Service brings design development, yarn sourcing, sampling, compliance, and bulk production together across China and Bangladesh. For a cardigan program, we match gauge, stitch, and blends to your price band, handfeel, and delivery windows—then run retailer-grade QC end to end.

| Your Need | OEM Feature |

|---|---|

| Lower MOQ | Yarn pooling and color consolidation across styles |

| Faster sampling | China sample rooms and rapid knit-down approvals |

| Stable quality | In-line QA, PPS lock, AQL final inspections |

| Certified materials | GRS, OEKO-TEX, and RWS-aligned sourcing and documentation |

| Clear testing path | Risk-based test plans using AATCC/ISO methods |

Start OEM cardigan production with Eton: Clothing Manufacturing OEM Service.

Use Case 1: Revamp a Core V-Neck Cardigan

A US retailer wanted the same fit with fewer returns. We kept the silhouette, moved to a cotton/nylon blend at 10 GG, tightened stitch density, standardized 28L buttons, and added shoulder tape to curb growth. Pilling scores improved and returns dropped [CITE: Case study template; retailer QA data if available].

Outcome: price stability across colors by pooling yarn, faster SMS through shared trims, and a cleaner face after wash/relax.

Use Case 2: Launch a Recycled-Content Capsule

A European brand requested a recycled-content longline capsule. We sourced GRS-certified recycled polyester/nylon blends, validated chain-of-custody, and ran colorfastness and pilling tests to meet retailer gates. Labels carried approved claims with transaction certificates on file [CITE: GRS documentation and labeling rules].

Outcome: credible claims, predictable lead times, and a story that matched marketing and compliance needs for EU stores.

[INTERNAL LINK: Eton resource hub → https://china-clothing-manufacturer.com/]

Risks, Compliance & Localization for US/EU Markets

Knitwear risks include shrinkage, growth, pilling, seam failures at linking, and trim detachment. Manage them with pre-shrink protocols, stitch density controls, reinforcement tapes, and evidence-based lab testing. Align with US/EU chemical rules and labeling; pair care claims with verified performance [CITE: OEKO-TEX; AATCC; EU REACH; US FTC labeling].

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Shrinkage/growth | Medium | High | Wash/relax, blocking, density controls, post-wash POM checks |

| Pilling | Medium | Medium | Fiber/nylon blends, tighter stitches, pilling tests |

| Linking seam failure | Low–Medium | High | Operator training, seam strength tests, in-line audits |

| Trim detachment | Low | High | Pull tests, bar-tacks, reinforced plackets, quality trims |

| Shade variance | Medium | Medium | Shade bands, lab dips, controlled dye lots, lightbox checks |

Regulatory Notes for US & EU

US: FTC textile labeling requires fiber content, country of origin, and RN or manufacturer ID. CPSIA applies for children’s products, including tracking labels. Flammability 16 CFR Part 1610 applies to wearing apparel. EU: REACH drives chemical controls; textile labeling requires fiber content disclosures; care symbols should align with ISO 3758 for clarity [CITE: FTC labeling; CPSIA; EU REACH; ISO 3758].

- OEKO-TEX Standard 100: useful for component-level chemical screening.

- AATCC/ISO: reference methods in your test plan and approvals.

- Claims: back any recycled or organic content claims with recognized certifications and transaction certificates.

Maintain a compliance file per style, including lab reports, certs, supplier declarations, and approved care instructions.

Data & Trends: Cardigans in the Market

Seasonal interest in cardigans rises in Q3–Q4 in US/EU markets, with texture-rich stitches and relaxed silhouettes gaining share. Certified materials show growing adoption in knit programs. Use these signals to pick gauge bands, fiber blends, and colorways per drop [CITE: Google Trends or market trend reports; Textile Exchange PFMR].

Key Trend 1: Texture & Volume

Chunky shawl collars, fisherman’s ribs, and cable patterns lead many fall floors. Plan for yarn consumption and minutes per piece. To preserve price targets, use rib-engineered textures or blended yarns with nylon to reduce breakage and improve stability.

Key Trend 2: Certified Materials

Recycled synthetics and certified wools support consumer trust. Align SKU counts with available GRS or RWS yarns and confirm claim wording early. Build photography plans that tell the material story on PDPs and in-store. Keep certificate files audit-ready [CITE: Textile Exchange PFMR; GRS; RWS].

[INTERNAL LINK: Sustainable materials guide → cluster page idea]

Conclusion & Next Steps

Cardigans move from idea to shelf when yarn, gauge, stitch density, trims, and tests are explicit. Match style to cost and MOQ limits. Use the development workflow, risk controls, and compliance cues here to reduce revisions and hit delivery windows with confidence.

- Lock spec: yarn, gauge, stitch, trims, test plan.

- Proto/fit: approve post-wash POMs and silhouette.

- SMS/tests: align colors, shade bands, and lab evidence.

- PPS: sign off from bulk materials and line.

- Bulk: in-line QC and AQL final checks.

- QA: review care and labeling; finalize documentation.

- Delivery: plan freight and floor dates by region.

Talk with Eton on cardigan OEM production: start here. [INTERNAL LINK: Eton resource hub → https://china-clothing-manufacturer.com/]

Author & Review Notes (E-E-A-T)

- Author: Alex Chen, Senior Apparel Production Manager (Knitwear & Outerwear), 15+ years in China/Bangladesh manufacturing. [INTERNAL LINK: {{author_name}} - {{author_title}} {{author_bio_url}}]

- Reviewer: Mei Lin, Head of Compliance & QA, Eton Garment Limited.

- Methodology: Manufacturer SOPs, tech pack checklists, and recognized standards, cross-referenced with public definitions and sustainability guidance.

- Limitations: Lead time and cost ranges vary by program and season; verify against current capacity and logistics. Claims requiring market-specific figures are marked for citation.

- Disclosure: Eton provides OEM/ODM services for knitwear and outerwear.

- Last Updated: 2025-10-28.

References & Sources

- Wikipedia — Cardigan (n.d.). [CITE: Wikipedia “Cardigan” page].

- Merriam-Webster — Cardigan (n.d.). [CITE: Merriam-Webster definition].

- MasterClass — Guide to Cardigan Sweaters (n.d.). [CITE: MasterClass cardigan guide].

- Textile Exchange — Preferred Fiber & Materials Market Report (2023/2024). [CITE: Textile Exchange PFMR].

- OEKO-TEX — STANDARD 100 (2024). [CITE: OEKO-TEX Standard 100 official page].

- AATCC — Technical Manual (2024). [CITE: AATCC test methods].

- Responsible Wool Standard — RWS (n.d.). [CITE: RWS official site].

- Global Recycled Standard — GRS (n.d.). [CITE: GRS documentation and labeling rules].

- FTC — Textile, Wool, and Fur Acts & Labeling (US) (current). [CITE: FTC labeling guidance].

- EU — REACH and Textile Labeling Rules (current). [CITE: EU REACH; EU textile labeling].

- ISO 3758 — Care Labeling Code (current). [CITE: ISO 3758 reference].

- 16 CFR Part 1610 — Flammability of Clothing Textiles (US) (current). [CITE: CPSC/16 CFR 1610].

FAQs

Related Articles

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »