Types of Men Undergarments: Manufacturing Guide with a China Clothing Manufacturer

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

19 minute read

Types of Men Undergarments: Manufacturing Guide with a China Clothing Manufacturer

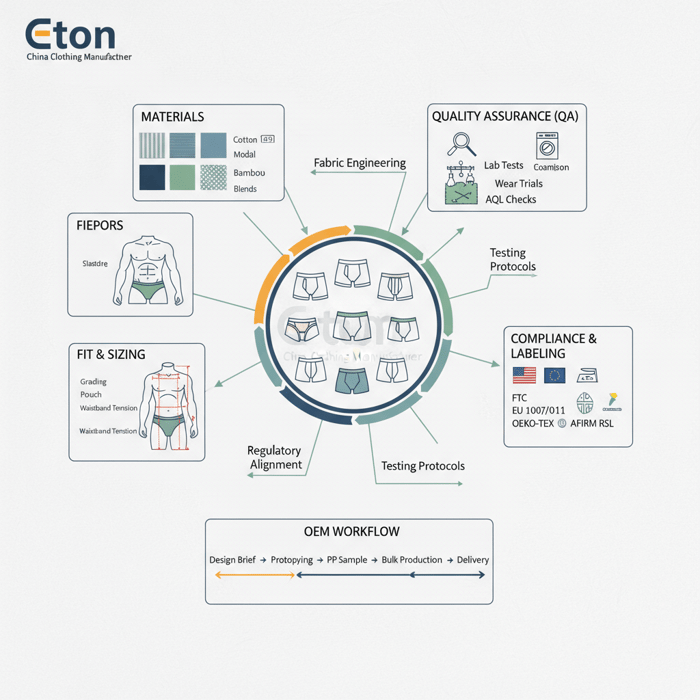

Types of men undergarments define the comfort baseline for every wardrobe, and they intersect directly with a China Clothing Manufacturer on materials, compliance, cost, and speed to market. This manufacturing guide aligns taxonomy with fabric engineering, fit systems, QA/testing, US/EU labeling, and OEM execution—built on Eton’s three decades of production experience serving global brands.

Men’s undergarments include briefs, boxers, boxer briefs, trunks, jockstraps, compression shorts, long johns/thermals, and undershirts/vests. Each type serves distinct support, coverage, and climate needs. Align type, fabric, waistband, and seams with US/EU compliance and an experienced China Clothing Manufacturer to secure comfort, durability, cost control, and scalable production.

Men’s Undergarment Types and Use-Cases

Brands benefit from a clear taxonomy: briefs, boxers, boxer briefs, trunks, jockstraps, compression shorts, long johns/thermals, and undershirts/vests. Support, coverage, ride-up risk, and activity intent drive product mapping. Use this comparison to plan assortments and guide technical specs, trims, and QA protocols from concept to bulk.

| Type | Support | Coverage | Ride-Up Risk | Best Use-Case |

|---|---|---|---|---|

| Briefs | High | Minimal (no leg) | Low | Everyday; tailored trousers |

| Boxers | Low | High (loose leg) | Medium–High | Lounge; breathability priority |

| Boxer Briefs | Medium–High | Mid-thigh | Medium | Everyday; light sport |

| Trunks | Medium | Shorter leg than boxer briefs | Medium | Everyday; under slim pants |

| Jockstraps | Very high (front only) | Minimal rear coverage | Low | Sport-specific support |

| Compression Shorts | High (graded) | Mid to long thigh | Low | Training; running; sport base |

| Long Johns/Thermals | Medium | Full leg | Low | Cold weather base layer |

| Undershirts/Vests | n/a | Torso—tank/crew/v-neck | n/a | Layering; sweat management |

Garment factory network — capabilities overview.

Core Bottoms: Briefs, Boxers, Boxer Briefs, Trunks

Briefs prioritize support with minimal fabric and low ride-up, making them ideal under suits and slim trousers. Boxers trade support for airflow; woven boxers add shape retention in the seat but ride up under movement. Boxer briefs combine a supportive pouch and leg coverage; they help reduce inner-thigh friction during commutes or desk days. Trunks offer a shorter leg than boxer briefs, preferred under skinny jeans or tailored shorts where hem lines must disappear.

Production notes: Use 1x1 or 2x2 rib or single-jersey with 5–8% elastane for briefs and boxer briefs to secure recovery. A 35–40 mm brushed-back jacquard waistband reduces dig-in. Flatlock or narrow coverstitch minimizes seam bulk against the thigh. Consider bonded labels to prevent itch and comply with care labeling in US/EU. Pouch shaping is achieved with two- or three-piece panels; add a comfort gusset at the inseam to protect against chafe in all-day wear. [MENTION: AATCC testing methods for seams] [CITE: “Best practices for waistband comfort — a recent apparel ergonomics study”]

Performance Types: Jockstraps, Compression Shorts

Jockstraps deliver targeted front support with elasticized back straps for ventilation and freedom of movement. Compression shorts apply graded pressure to reduce muscle oscillation and manage moisture, pairing nylon or polyester with elastane. Map compression levels carefully: 10–15 mmHg for light training, 15–20 mmHg for medium-intensity sessions. Place seams out of abrasion zones and use flatlock with soft thread to keep interior friction low.

Production notes: Choose filament yarns with moisture-wicking finishes tested for wicking and drying time. Validate stretch and recovery using ISO 20932 and ASTM D4964. For waistband construction, lock stitch plus silicone print on the interior can prevent slippage during movement. Incorporate mesh at high-heat zones (medial thigh, upper rear waist). Add odor-control finishes while meeting AFIRM RSL requirements. [CITE: ISO 20932 for stretch and recovery] [CITE: AFIRM RSL latest revision for chemical limits] [MENTION: Under Armour’s and Nike’s approaches to moisture systems]

Thermal & Tops: Long Johns/Thermals, Undershirts/Vests

Long johns function as winter base layers, often in brushed back interlock or waffle/thermal knits that trap warm air. For undershirts, silhouettes range from tank to crew and v-neck; modal/cotton blends soften handfeel under dress shirts, while lightweight polyester blends wick for long days. Tag placement, seam bulk, and underarm ventilation drive comfort under structured outerwear.

Production notes: Consider grams per square meter (GSM) bands: 140–170 GSM for undershirts; 180–220 GSM for thermals depending on climate. Brushed-back knits increase thermal retention but can pill without proper fiber selection. Use binding or self-fabric collars to maintain a low profile beneath shirts. Align care labeling with EU 1007/2011 and US FTC rules. [CITE: EU 1007/2011 labeling guidance] [CITE: FTC Textile Fiber Products Identification Act guidance] [MENTION: Uniqlo Heattech and Patagonia Capilene as market references]

Materials & Fabric Engineering for Men’s Undergarments

Cotton, modal, bamboo viscose, and synthetic blends (polyester/nylon with elastane) define handfeel, breathability, moisture management, durability, and cost. Select by use-case and price tier, and design within RSL and third-party certification frameworks. Elastane percentages, knit structure, and finish chemistry shape fit stability and wash-down performance.

| Material | Handfeel | Moisture Control | Breathability | Durability | Typical Cost Tier | Sustainability Notes |

|---|---|---|---|---|---|---|

| Cotton (combed/ring-spun) | Familiar, soft | Absorbent; slower dry | High | Good, watch pilling | $ | BCI/organic options [CITE: BCI overview] |

| Modal (rayon) | Silky, drapey | High absorbency | High | Moderate; blends help | $$ | PEF/LCA vary by mill [CITE: Lenzing modal data] |

| Bamboo Viscose | Soft, cool touch | Good; needs blend | High | Moderate; watch laundering | $$ | Process-dependent impacts [CITE: Bamboo viscose process review] |

| Polyester (microfiber) | Slick, lightweight | Excellent wicking | Medium–High | High abrasion resistance | $–$$ | Recycled options (rPET) [CITE: rPET recycling context] |

| Nylon (micro/6,6) | Soft, strong | Wicks; dries fast | Medium–High | Very high | $$ | High strength; blends well |

| Elastane (5–12%) | Stretch enhancer | n/a | n/a | Improves recovery | $ add-on | Heat sensitivity care [CITE: Elastane care note] |

- Stretch recovery target: ≥90% after 30 cycles (ISO 20932) [CITE: ISO 20932 standard]

- Wicking benchmark: 3.0–5.0 mm/10 min (AATCC 197) [CITE: AATCC 197 test method]

- Pilling target: Grade 3–4 after 5 cycles (ASTM D4970) [CITE: ASTM D4970 standard]

Natural Fibers: Cotton, Modal, Bamboo

Cotton offers familiarity and breathability; combed, ring-spun yarns reduce short fibers for fewer pills. For softness and color depth, many brands blend cotton with modal. Modal brings sleek drape and a cool hand but benefits from polyester or nylon for strength. Bamboo viscose feels cool and soft, though process chemistry and laundering can affect durability; blending helps.

Elastane at 5–7% balances comfort and recovery for briefs and boxer briefs. For trunks that face ride-up, lean toward 7–9% elastane and adjust leg opening circumference in grading. Pre-launder shrinkage should meet ≤3% in both directions to reduce returns. [MENTION: Lenzing’s guidance on modal performance] [CITE: Shrinkage control in knit fabrics]

Synthetics & Blends: Polyester, Nylon, Elastane

Microfiber polyester wicks and dries fast; appropriate for high-sweat activities. Nylon provides superior strength and abrasion resistance with a softer hand; common in premium boxer briefs and compression shorts. Add 7–12% elastane for graded compression shorts; control heat exposure during finishing to prevent spandex degradation.

Odor control: choose finishes that meet OEKO-TEX Standard 100 Class II for skin contact and pass AFIRM RSL thresholds. Confirm colorfastness to perspiration and washing, especially for dark microfibers. [CITE: OEKO-TEX Standard 100 overview] [CITE: AFIRM RSL latest list] [MENTION: Polygiene as a known odor control brand]

Construction & Finishes: Knits, Seams, Waistbands

Common knit structures: single-jersey for lightness; interlock for stability; rib for stretch. Flatlock seams reduce bulk in inner thighs; narrow coverstitch keeps hems secure. Bonded seams deliver a smooth feel but require controlled heat and are less tolerant of repeated high-heat laundering. Use 35–40 mm waistbands for adult men’s sizes; brush the underside or add backer for comfort.

Waistband selection influences margin and handfeel. Yarn-dyed jacquard offers brand identity; knitted-in logos can avoid stiff prints. If applying silicone grippers for sport, confirm skin-sensitivity testing and wash-down stability. [CITE: Contact dermatitis guidance from a dermatology source] [MENTION: ISO 105 colorfastness series for testing]

Fit, Sizing & Ergonomics in Men’s Undergarments

Pattern grading, waistband tension, leg length, pouch geometry, and seam placement define comfort and return rates. Build fit from validated base blocks for US/EU. Then stress-test ride-up behavior, recovery after wash cycles, and waistband fatigue through a defined trial protocol.

- Lock base measurements: waist, high-hip, thigh, rise, leg opening.

- Set grading rules by size range; capture elastic extension ratios per size.

- Prototype in target fabrics; evaluate on-body under daily movements.

- Run wash/wear cycles; log shrinkage and recovery data.

- Refine pouch and leg opening curves; confirm waistband pressure bands.

- Approve PP sample; create QC fit card and tolerance sheet for bulk.

- Pouch options: Contoured pouches improve support; single-panel pouches simplify sewing but reduce shaping.

- Fly options: Horizontal fly speeds access; vertical fly is familiar; no-fly improves support and line.

- Waistband constructions: Fold-over elastic reduces bulk; jacquard offers branding; laminated bands look sleek but require careful laundering.

- Leg lengths: Trunks are discreet under slim pants; longer legs cut chafe but need anti-ride hems.

Sizing Standards & Grading for US & EU

Map alpha sizes (S–XXL) to waist ranges in inches and centimeters for US/EU packaging. Keep grading linear at 2–3 inches per size step for waist, and apply proportional grading to rise and leg openings. Document tolerances: waist ±0.5 in (±1.3 cm), leg opening ±0.25 in (±0.6 cm), inseam ±0.25 in, waistband height ±2 mm.

Waistband tension testing: target 8–12 N at standard extension for comfort; avoid excessive relaxation after 15 wash cycles. Include a shrinkage target of ≤3%. [CITE: ASTM D1777 for thickness and related knit parameters] [MENTION: ASTM or ISO methods for elastic testing]

Ergonomics: Pouch, Fly, Seams, Leg Length

Pouch shaping reduces pressure points and improves airflow. Two-piece pouches offer moderate contour; three-piece designs allow more volume. Avoid center-front seam where sensitivity is high; offset seams or use shaped darts. For flys, reinforce edges to prevent deformation over time. For trunks and boxer briefs, add a slight differential at the back thigh to reduce upward creep during hip flexion.

Seam strategy: flatlock for inner thigh; overlock + coverstitch for speed on side seams; bartack stress points at fly and hem. Hem options: 2-needle coverstitch, self-band, or bonded edge with controlled modulus. [CITE: AATCC 135 home laundering method] [MENTION: Coats thread recommendations for stretch seams]

QA Fit Testing: Try-On Protocols & Wear Trials

Set a multi-size wear test over 10–14 days with a minimum of 15–20 testers across the US/EU size distribution. Capture riding, waistband fatigue, moisture hot spots, and post-wash changes. Use structured forms and require identical laundering cycles for comparability. Assign pass/fail gates with numeric thresholds.

Minimum checks: waistband tensile after 5/10/15 washes, shrinkage on length/width, seam strength at crotch, colorfastness to perspiration, odor after 8 hours of wear (subjective panel). [CITE: AATCC 15 colorfastness to perspiration] [CITE: ISO 13934 seam strength testing] [INTERNAL LINK: Create a “Tech Pack for Undergarments” page and link from “structured forms”]

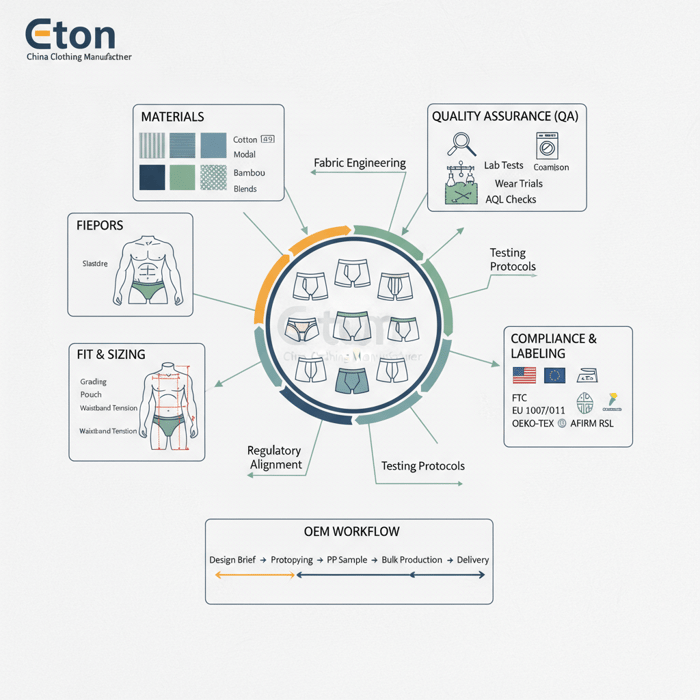

Use-Cases & Performance Variants (Everyday, Athletic, Thermal)

Match fabric and features to use-case: everyday comfort prioritizes handfeel and ventilation; athletic versions emphasize wicking, support, and anti-chafe mapping; thermal layers balance warmth with breathability under outerwear. Validate choices with lab tests and wear trials aligned to target climates.

- Everyday: modal/cotton blend jersey, 5–7% elastane, soft brushed waistband.

- Athletic: nylon/elastane with mesh mapping, flatlock seams, silicone grip.

- Thermal: brushed interlock or waffle knit, midweight GSM, low-bulk seams.

Everyday Comfort Assortments

Build a core run of boxer briefs and trunks for modern wardrobes. Modal-cotton at 160–180 GSM with 5–7% elastane provides softness with form retention. For briefs, a supportive pouch and minimal leg reduce ride-up at desks. Offer three neutral colors and two seasonal colors for re-buys and freshness.

Use garment-dyed or piece-dyed approaches based on MOQ and palette. Apply bonded labels or soft heat seals to avoid itch. [CITE: Consumer preference data on modal adoption] [MENTION: Target and Marks & Spencer as range architecture references]

Athletic Performance Assortments

For training, select nylon 6,6 microfibers for strength and elastic recovery. Add mesh zones at inner thigh and lower back; validate airflow via air permeability tests. Choose 7–9% elastane for boxer briefs; 10–12% for compression shorts. Test wicking and drying; aim for sub-30-minute dry times at room conditions.

Include flatlock seams and silicone grip at the hem to prevent ride-up. Offer reflective branding for runners and a secure pocket for keys in compression styles. [CITE: AATCC 197 and AATCC 199 for moisture management] [MENTION: ASICS and New Balance for sport baselayer cues]

Thermal Base Layers

For cold climates, interlock or waffle with brushed back increases warmth-to-weight. Pair long johns with undershirts that fit clean under dress shirts or outerwear. Keep seams low profile at shoulders to avoid rubbing under backpack straps. Validate thermal retention with comparative wear tests across temperature bands.

Offer natural fibers for office wearers who value breathability and synthetics for outdoor users seeking faster dry times. [CITE: CLO value estimation sources] [MENTION: ISO 11092 “skin model” for thermal and moisture resistance]

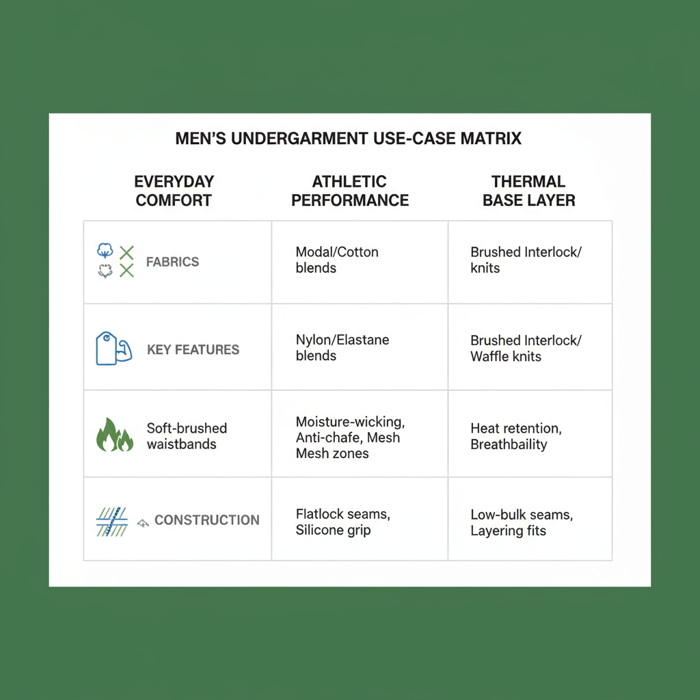

Manufacturing & Cost Breakdown for Men’s Undergarments

Translate designs into production with a clear tech pack, BOM, stitch plan, and testing. Plan MOQs and lead times with China/Bangladesh factories, then model cost drivers: fabric yield, waistband type, elastane content, seam complexity, packing, and compliance testing. Use PP approvals and AQL inspections to lock consistency.

| Component | Expected Cost Impact | Notes |

|---|---|---|

| Main fabric | High | GSM and blend drive yield; microfibers and branded fibers price higher. |

| Waistband | Medium | Jacquard with brushed back adds comfort and cost vs. plain elastic. |

| Elastane content | Low–Medium | Higher % boosts recovery; watch heat sensitivity during finishing. |

| Seams/stitching | Low–Medium | Flatlock costs more than overlock; fewer operations reduce SAM. |

| Labels & trims | Low | Heat-transfer labels enhance comfort; OEKO-TEX inks preferred. |

| Packaging | Low–Medium | Recyclable poly or paper box; QR code for care; retail ready packs. |

| Testing & compliance | Low | OEKO-TEX, RSL screening, and label verification reduce risk. |

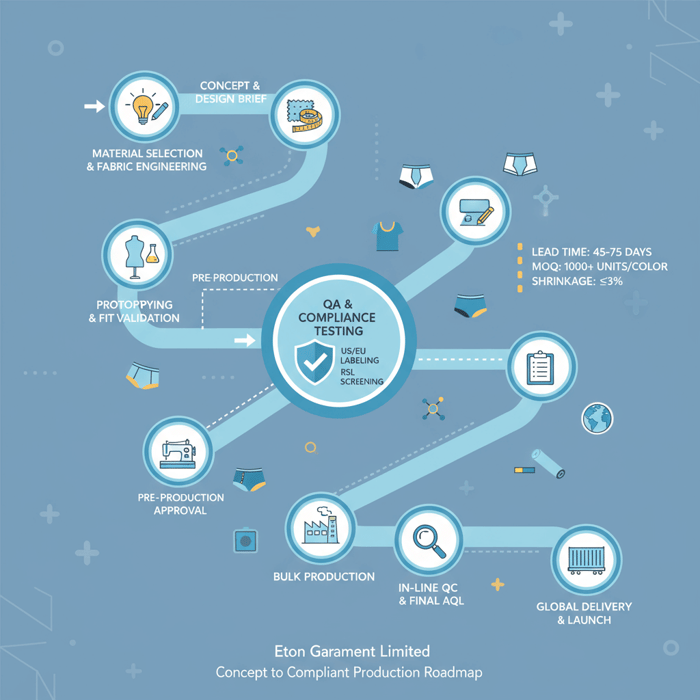

- Design brief and range plan.

- Tech pack with graded specs, BOM, stitch map, test plan.

- Proto samples; fit/wear tests and revisions.

- Pre-production (PP) sample approval.

- Bulk production with in-line QC and AQL final.

- Shipment with compliance documents and test reports.

- Proto: 1–2 weeks; Revisions: 1–2 weeks per round [CITE: Typical OEM sampling timelines]

- Bulk lead time: 45–75 days post-PP, fabric dependent [CITE: Apparel lead time benchmarks]

- MOQs: 1,000–3,000 units per color/style; elastic jacquard may require 3,000+ yards [CITE: China/Bangladesh MOQ norms]

Tech Pack Essentials & BOM

Include graded measurement chart, tolerance sheet, stitch types, seam allowances, waistband height and construction, pouch patterning, fly details, fabric specs (fiber %, GSM, finishes), colorways, trims, packaging specs, care symbols, and test plan. Add a measurement-on-body guide for consistent fit assessments across US/EU testers.

Provide lab test matrix: shrinkage, pilling, colorfastness (wash, sweat), stretch/recovery, seam strength, odor control durability, and restricted substance screening. [CITE: ISO and AATCC methods mapping by property] [MENTION: Intertek, SGS, or Bureau Veritas as common labs]

MOQs, Lead Times, Capacity Planning

Elastic jacquard suppliers set minimums that influence colorways. Plan grouped color drops to consolidate buys. Peak seasons (Q2 for fall deliveries, Q4 for spring) constrain capacity in China and Bangladesh; lock production slots 8–12 weeks ahead. Maintain a rolling forecast to reduce material shortages.

For value tiers, consolidate components to limit complexity. For premium ranges, allocate time for trial finishes and additional tests. [CITE: Supplier capacity planning guidance] [MENTION: Bangladesh apparel sector association resources]

QA & Testing Protocols

Deploy incoming fabric checks (GSM, shade bands), in-line seam and waistband inspections, and final AQL per size/color. Simulate consumer use with accelerated wash testing and extended wear trials. Use PP samples as QC controls and update them if fabric lots change.

Document corrective actions and implement a hold-and-release protocol tied to lab results. Keep records for US/EU compliance, including label proofs and RSL sign-offs. [CITE: AQL sampling standards] [MENTION: ISO 2859 for sampling procedures]

US & EU Market Data, Trends, and Consumer Preferences

Shoppers in the US/EU reward softness, consistent fit, and breathable fabrics. Modal and blended knits retain momentum, with inclusivity in size runs now a basic expectation. DTC and wholesale models coexist; value perception rests on comfort, longevity, and reliable sizing guidance on-pack and online.

- Modal adoption in men’s underwear grew year-over-year in US specialty retail [CITE: Recent Euromonitor or NPD report]

- Size inclusivity ranges expanded across EU key accounts by 2023–2024 [CITE: European retail trend brief]

- Consumers rate comfort higher than style for underwear purchases [CITE: A recent consumer survey]

Preference Signals & Price Tiers

Value tiers cluster around material and waistband choices. Entry lines pair cotton with printed elastics and basic seams. Mid-tier lines shift to modal blends, brushed waistbands, and more refined pouches. Premium lines add nylon microfibers, flatlock seams, odor control, and elevated packaging.

Price signals must match features: feel the waistband, read elastane %, and verify care ease. Offer mixed 3-packs for value and singles for premium. [CITE: Retail pricing benchmark within US/EU multi-brand retailers]

Inclusivity & Fit Trends

Broaden ranges with tall, athletic, and extended sizes to reduce returns and increase loyalty. Provide hem lengths for different thigh circumferences and rises for different torso lengths. Communicate measurements clearly in both inches and centimeters on PDPs and packaging.

Test fit across diverse body types and publish a fit finder. Improve satisfaction by offering pouch options and clear photos of seam placements. [CITE: Case study on returns reduction via enhanced fit guidance] [MENTION: Third-party fit tech providers]

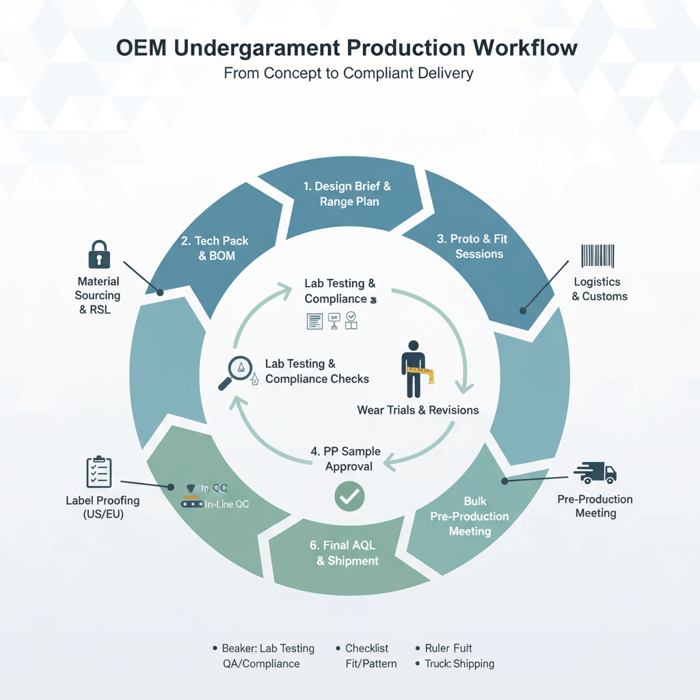

Clothing Manufacturing OEM Service (Eton): From Design to Delivery

Eton Garment Limited supports design, prototyping, compliance, and scaling across China and Bangladesh. While our heritage centers on outerwear and technical apparel, our QA rigor, pattern control, and supply networks transfer cleanly to base layers, thermals, and performance undergarments for US/EU brands.

| Brand Need | OEM Feature | Outcome |

|---|---|---|

| Fit consistency | Graded base blocks + wear testing | Lower returns; repeat buys |

| Performance validation | Lab matrix + field trials | Reliable moisture/thermal claims |

| Compliance clarity | US/EU labeling + RSL workflow | Reduced regulatory risk |

| Speed to market | Parallel sampling + material pre-booking | Shorter lead times |

| Cost control | Yield engineering + BOM rationalization | Protected margins |

Explore our Clothing Manufacturing OEM Service for capabilities, materials, and sampling windows.

Rapid Prototyping & Fit Validation

We run parallel sample streams to compress timelines: proto for design, fit for pattern, and yield for cost. A shared fit rubric reduces subjective calls, and a tracked change log maintains version control through PP. For trunks and boxer briefs, we test anti-ride hems and waistband recovery under repeated laundering.

For athletic variants, we simulate movement with treadmill and cycle sessions during wear tests and log seam friction points. [MENTION: Eton field-testing approach] [CITE: Example time savings from parallel sampling in apparel]

Compliance & Sustainability Support

We build label proofs aligned with EU 1007/2011 and US FTC rules, and we route fabrics through OEKO-TEX Standard 100 or equivalent screening where requested. Our AFIRM-aligned RSL workflow reduces chemical risk and supports retailer onboarding.

For sustainability goals, we source recycled synthetics or certified cotton, provide chain-of-custody documentation, and flag finish chemistries for review. [CITE: EU 1007/2011 official page] [CITE: FTC Textile guidance] [MENTION: OEKO-TEX Association]

Ready to brief your first style? Our Clothing Manufacturing OEM Service outlines timelines and pilot-to-bulk pathways.

Risks, Compliance & Labeling in US & EU

US FTC and EU 1007/2011 govern fiber content, care labeling, and country-of-origin statements. OEKO-TEX and AFIRM frameworks reduce chemical exposure risk. A documented RSL program, correct label content, and consistent lab testing protect brands during retailer onboarding and customs checks.

- Certification (OEKO-TEX Standard 100): external validation, consumer trust; added cost and renewal cycles.

- Process controls (AFIRM RSL implementation): embedded risk control; requires supplier training and audits.

Risk Matrix

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Waistband failure | Medium | Returns, reviews | Tensile tests; vendor audits; heat exposure controls |

| Excessive shrinkage | Medium | Poor fit post-wash | Pre-shrink; set shrinkage ≤3%; wash testing |

| RSL non-conformance | Low–Medium | Stop ship, penalties | AFIRM-aligned screening; approved chemistry list |

| Incorrect labeling | Low–Medium | Regulatory risk | Label proofing; FTC/EU checklist; internal sign-offs |

| Colorfastness issues | Medium | Staining, complaints | AATCC/ISO tests; shade band control; lot traceability |

Regulatory Notes for US & EU

US labels require: fiber content (descending order), RN or company name, country of origin, and care instructions. EU labels require standardized fiber names and percentages per 1007/2011 and multilingual care info for target markets. Children’s products require additional scrutiny for flammability and small-parts risks. [CITE: FTC label rules page] [CITE: EU 1007/2011 text]

Maintain documentation: lab reports, label proofs, factory declarations, and shipping records. Use consistent naming across packaging, linesheets, and customs documents. [MENTION: GS1 for barcode standards]

Conclusion & Next Steps

Classify the range by type and use-case, align fabrics and fit, validate with lab and wear tests, and confirm US/EU labeling. Pilot, collect feedback, then scale production with a dependable partner to control cost, quality, and timing.

- Weeks 1–2: Design brief and material shortlisting.

- Weeks 3–6: Protos, fit sessions, and revisions.

- Weeks 7–8: PP approvals and test reports.

- Weeks 9–20: Bulk production, in-line QC, and final AQL.

- Weeks 21–22: Ship and prepare retail/online launch assets.

[INTERNAL LINK: Build “Undergarment Tech Pack Checklist” and link from “Design brief”] [INTERNAL LINK: Build “US/EU Labeling Guide” and link from “labeling”] [INTERNAL LINK: Build “Sustainability & RSL” and link from “RSL program”]

E-E-A-T Notes

Author: Senior Apparel Manufacturing Strategist (10+ years in technical apparel and OEM/ODM). Reviewer: Production Manager, Eton Garment Limited. Methodology: synthesis of manufacturer workflows, lab test standards, and public regulatory frameworks. Limitations: costs, MOQs, and timelines vary by spec, season, and factory. Disclosure: Eton’s outerwear specialization informs base-layer execution; validate category details in sampling.

Last Updated: 2025-10-28. [INTERNAL LINK: Add author bio link here]

References & Sources

- [CITE: Wikipedia — Underwear (overview and taxonomy)]

- [CITE: European Commission — Textile Labelling Regulation (EU) No 1007/2011]

- [CITE: FTC — Textile Fiber Products Identification Act Guidance]

- [CITE: OEKO-TEX — Standard 100 overview and classes]

- [CITE: AFIRM Group — AFIRM RSL (latest version)]

- [CITE: ISO 20932 — Elastic fabrics — Elasticity and recovery]

- [CITE: AATCC 197/199 — Moisture management tests]

- [CITE: ASTM D4970 — Martindale pilling resistance]

- [CITE: AATCC 135 — Home laundering procedures]

- [CITE: ISO 11092 — Thermal and water-vapor resistance (skin model)]

- [CITE: ISO 105 series — Colorfastness methods]

- [CITE: Industry report — US/EU men’s underwear market trends 2023–2025]

- [CITE: Supplier capacity planning guidance, China/Bangladesh apparel sector]

- [CITE: Case study on returns reduction via size guidance]

- [CITE: Retail pricing benchmarks across specialty and mass channels]

- [MENTION: GQ — Men’s Underwear Guide; RMRS; FashionBeans; Underwear Expert; Men’s Health for editorial comparisons]

FAQs

Related Articles

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »