The american made list vs. overseas manufacturing: a China Clothing Manufacturer’s practical guide for fashion brands

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

9 minute read

The american made list vs. overseas manufacturing: a China Clothing Manufacturer’s practical guide for fashion brands

american made list searches often start with consumer directories but quickly become sourcing decisions—especially for US/EU teams benchmarking domestic options against a China Clothing Manufacturer with proven OEM/ODM capacity. This practical guide shows how to verify U.S.-origin claims, compare costs and lead times, and choose the right path for each apparel category.

An american made list is any directory or shortlist of U.S.-made products, brands, or factories. For apparel, confirm claims against the FTC’s “all or virtually all” standard with a documented BoM and production records. Use a decision matrix to compare U.S., nearshore, and offshore options on cost, MOQ, lead time, capability, and compliance risk—then act with a pilot run.

What “American Made” really means for apparel (FTC labeling and claims)

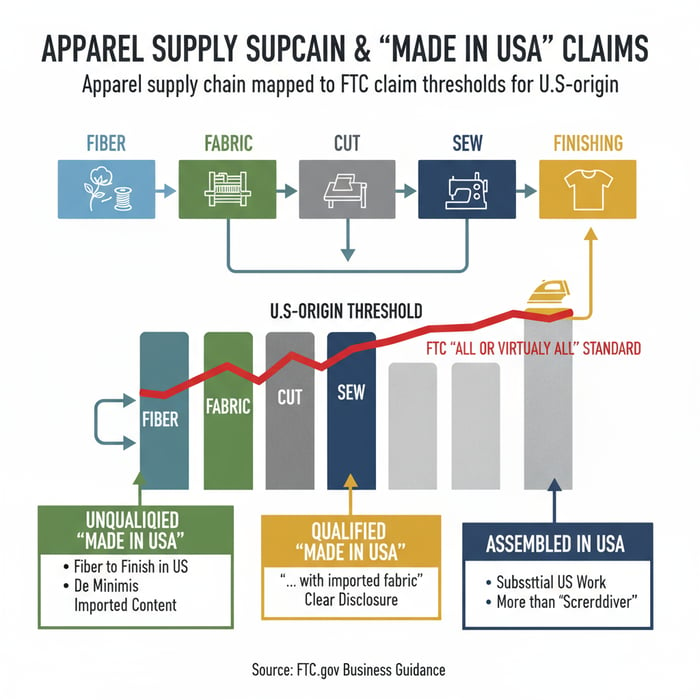

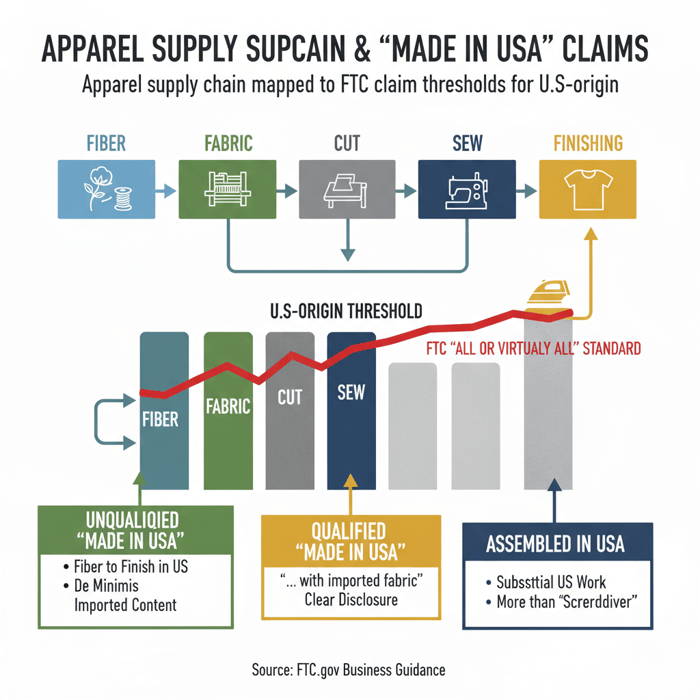

“Made in USA” means the product is “all or virtually all” made in the United States. Apparel teams must substantiate any origin claim with documented evidence and avoid misleading disclosures. Understanding unqualified versus qualified claims, and how “assembled in USA” differs, protects brands from penalties and preserves trust. [CITE: FTC Made in USA Labeling Rule—official business guidance page]

[MENTION: Federal Trade Commission], [MENTION: U.S. Customs and Border Protection]

Claim types and how they apply in apparel

- Unqualified “Made in USA”: All or virtually all of the product’s significant parts and processing are of U.S. origin. For apparel, this typically covers fabric formation, cutting, sewing, and finishing in the U.S., with de minimis imported content only. [CITE: FTC business guidance—definitions and examples]

- Qualified “Made in USA” (e.g., “Made in USA with imported fabric”): Allows limited imported inputs but requires clear, prominent qualification. Useful when fabrics, down fill, or specialized trims are sourced abroad. [CITE: FTC guidance on qualified claims]

- “Assembled in USA”: Substantial assembly in the U.S. from domestic and imported parts that is more than a “screwdriver” operation. For apparel, cutting and sewing may qualify, but claims must reflect the extent of U.S. work. [CITE: FTC assembled claims examples]

- Country-of-origin disclosures in e-commerce PDPs: Align PDP copy, hangtags, and care labels with the same documented origin basis; avoid mixing marketing slogans with origin claims. [CITE: FTC deceptive marketing enforcement page]

Apparel-specific nuance: imported down fill, seam tape, waterproof zippers, and branded trims often carry significant value. Overreliance on imported high-value components can undermine an unqualified claim. When in doubt, either qualify the claim or remove it. [CITE: FTC enforcement case summary with apparel examples]

Substantiation: the documents you need on file

- Bill of Materials (BoM): Source country per material, percentage of garment cost, and supplier IDs.

- Production records: Cutting tickets, sewing line reports, finishing logs, and time/date stamps for U.S. facilities.

- Supplier attestations: Signed origin statements for fabrics, trims, down fill, seam tapes, zippers, and packaging.

- Logistics proofs: Domestic freight documents, inbound material records, and any import entry forms for inputs. [CITE: CBP 19 CFR Part 134—country-of-origin marking rules]

- Audit notes: Internal or third-party audit checklists, photos, and interviews confirming U.S. processing.

Keep a single “origin dossier” for each style and season, and refresh it when suppliers or inputs change. For edge cases, consult counsel. (COO & Labeling Guide for Apparel Brands—pillar page)

How to build and verify your american made list for apparel

Turn discovery into diligence. Start with a broad american made list, screen for category fit, and verify claims before sampling. Use a gated process—screen, verify, sample, pilot, and audit—to de-risk your PDP claims and protect against misleading origin statements. [CITE: FTC business guidance—substantiation expectations]

- Discovery: Pull candidates from USA Love List, The Good Trade, trade groups, and referrals. Tag by category (outerwear, basics, denim) and technical needs (seam taping, down handling, DWR). [CITE: Directory references—USA Love List; The Good Trade apparel list]

- Screening: Send an RFI focused on capacity, machinery (taping, quilting), and compliance history. Request anonymized case examples and lab test summaries. [MENTION: Outdoor Industry Association] [CITE: Example RFI templates from industry groups]

- Verification: Request BoMs, origin attestations, and production records for two similar styles. Confirm the claim type (unqualified, qualified, assembled) and approve language. [CITE: FTC MUSA business guidance—qualified claims]

- Sampling: Run fit/construction samples; if applicable, lab-test seam strength, hydrostatic head, and breathability. [MENTION: AATCC; ASTM standards for textiles] [CITE: AATCC/ASTM test method references]

- Pilot run: Place a limited PO to validate lead time, on-time delivery, and QC stability across sizes and colors.

- Ongoing audits: Refresh supplier documentation each season and after any material change; conduct surprise checks where feasible. [CITE: Brand compliance program case study]

Supplier discovery channels for US-made apparel

- Directories: USA Love List and The Good Trade are useful starting points for an american made list of consumer-facing brands, but they rarely provide capacity or compliance detail. [CITE: Directory pages]

- Trade associations: American Apparel & Footwear Association (AAFA), National Council of Textile Organizations (NCTO) can point to mills and factories with relevant capabilities. [CITE: AAFA/NCTO member directories]

- Referrals: Veteran pattern makers, fabric mills, and trims suppliers often know which domestic lines currently run outerwear successfully.

- Local clusters: Look for clusters in Los Angeles, New York/New Jersey, and the Carolinas for cut-and-sew and select knitting/weaving providers. [CITE: Regional manufacturing reports]

Verification dossier: template and red flags

Build a one-pager for each supplier/style: claim type, documents received, audit date, and allowable PDP language.

- Green flags: Dated production records, traceable BoM with cost percentages, consistent claim language across quotes and samples.

- Red flags: “Assembled in USA” phrasing used interchangeably with “Made in USA,” missing source countries on trims, or reluctance to share production logs. [CITE: FTC enforcement case—misleading U.S.-origin claims]

Add a second reviewer from compliance for any unqualified claim. (Outerwear technical development checklist—cluster page)

american made list vs overseas manufacturing: make the right choice for each product

Use criteria scoring—cost, MOQ, lead time, technical complexity, and compliance risk—to decide if a U.S.-made path fits. Basics and premium small runs often suit domestic lines; complex technical outerwear typically favors overseas partners where taping, down processing, and specialized trims are routine. [CITE: Comparative cost studies for apparel sourcing—recent industry report]

| Criterion | United States | Mexico/EU (Nearshore) | China/Bangladesh |

|---|---|---|---|

| Unit Cost (outerwear) | 2–3 | 3 | 4–5 |

| MOQ Flexibility | 4 | 3–4 | 3–4 |

| Lead Time (concept-to-bulk) | 3 | 3–4 | 4–5 |

| Technical Capability (taping/down) | 2–3 | 3–4 | 5 |

| Compliance Documentation | 4–5 | 4 | 4–5 |

| Scalability | 3 | 4 | 5 |

- United States—Pros: smaller MOQs, easier oversight, origin story. Cons: higher labor costs, limited technical outerwear capacity, trims sourcing bottlenecks. [CITE: Domestic manufacturing cost benchmark—recent report]

- Mexico/EU—Pros: time-zone alignment, moderate costs, good craftsmanship. Cons: variable technical capability, fabric/trims may still be imported.

- China/Bangladesh—Pros: deep technical skill, full trims ecosystem, scale. Cons: longer logistics legs, import duties, and need for rigorous QC gates.

Criteria overview: what to weigh and how to score

- Cost and landed margin: Include fabric, trims, labor SAMs, duties, freight, and testing. [CITE: HTS duty references and freight index—recent 12–24 months]

- MOQ range: Evaluate fabric/trim minimums, not just cut-and-sew. Seam tape and down fill have their own MOQs. [CITE: Technical trims supplier documentation]

- Capability: Taping lines, quilting, down handling rooms, lamination partners, and bonded seam expertise affect yield and defect rates. [MENTION: Bemis; YKK]

- Speed: Calendar capacity, holidays, lab lead times, and fabric dyeing/finishing throughput impact “concept-to-ship.”

- Compliance risk: Claim substantiation, facility certifications, and brand policy fit (e.g., chemical RSL/MRSL). [MENTION: ZDHC; OEKO-TEX]

Decision framework: scenarios (basics vs technical outerwear)

- Premium basics capsule (tees, fleece, simple jackets): U.S. feasible for small runs and short cycles; qualify claims if fabric is imported. Nearshore adds capacity with moderate costs. [CITE: Case study of U.S.-made basics—brand article]

- Complex outerwear (taped seams, down, WP/BR): Overseas often wins on capability, cost, and trims ecosystem. Keep claim language neutral and focus on performance storytelling and sustainability credentials. [CITE: Performance outerwear sourcing analysis]

Costs, MOQs, and lead times—US vs China/Bangladesh for outerwear

Outerwear is labor- and equipment-intensive. U.S. unit costs run higher, MOQs can be modest at factory level but constrained by fabric/trim minimums, and capacity varies widely. China/Bangladesh offer established taping, quilting, and down ecosystems with predictable sampling-to-bulk timelines. Validate assumptions with a pilot PO. [CITE: Comparative outerwear cost study—2023–2025]

| Metric | United States | China | Bangladesh |

|---|---|---|---|

| Factory MOQ (pcs/style) | 100–500 | 300–1,000 | 500–1,500 |

| Fabric MOQ (yds per color) | 1,000–3,000 | 1,000–3,000 | 1,000–3,000 |

| Seam tape MOQ (yards) | 5,000–10,000 | 5,000–10,000 | 5,000–10,000 |

| Down fill batch (kg/spec) | Varies; often imported | Standardized lots | Standardized lots |

| Dev → PP sample (weeks) | 3–6 | 2–4 | 3–5 |

| Bulk production (weeks) | 6–10 | 6–9 | 7–10 |

| Transit (door-to-door) | Domestic 1–2 weeks | Ocean 4–6 weeks; Air 5–10 days | Ocean 5–7 weeks; Air 5–10 days |

[CITE: Fabric and trims supplier MOQ sheets—2024]; [CITE: Freight time benchmarks—transpacific/transatlantic indices]

Common bottlenecks: waterproof zipper lead times, seam tape color matching, DWR finishing windows, and seasonal lab queues. Build room for retests and color approvals.

Clothing Manufacturing OEM Service

Data & trends shaping “American Made” decisions in 2024–2025

Reshoring momentum continues, but apparel outcomes depend on category, wage differentials, and local capability. Consumer interest in origin claims remains high, paired with rising scrutiny of misleading labels. Treat data as directional and validate for your category and tier. [CITE: Reshoring Initiative annual report—2024]

- FTC enforcement updates on “Made in USA” claims—2023–2024 actions highlighted (Source: FTC business guidance) [CITE: FTC enforcement press releases]

- Reshoring/FDI announcements continue into 2024; apparel lags heavy industry (Source: Reshoring Initiative) [CITE: Reshoring Initiative 2024 Data Report]

- Consumers reward transparent origin and sustainability narratives (Source: reputable consumer survey, 2024) [CITE: Consumer insights report]

FAQs

Related Articles

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »