Specsheets for Fashion Brands: A China Clothing Manufacturer’s Guide to Production-Ready Documentation

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

14 minute read

Specsheets for Fashion Brands: A China Clothing Manufacturer’s Guide to Production-Ready Documentation

Specsheets power factory communication. For fashion brands working with a China Clothing Manufacturer, a complete specsheets package translates design into repeatable production: BOM, measurements, tolerances, construction, trims, labeling, and testing. Done right, it cuts sample rework, improves costing accuracy, and anchors US/EU compliance for outerwear and technical apparel.

Specsheets are concise, structured documents defining a garment’s BOM, measurements with tolerances, construction, trims, labeling, and testing. A manufacturer-ready specsheet aligns pricing, sampling, and compliance with a China Clothing Manufacturer, reducing rework and accelerating approvals for outerwear and technical apparel.

Eton Garment Limited has produced outerwear for three decades across China and Bangladesh, where clarity in specification is the shortest path to on-time, on-cost, and compliant product. This guide distills what factories use to quote, sample, and build at scale—plus how to embed CPSIA/REACH, AATCC/ASTM test methods, bilingual nomenclature, and factory-feasible tolerances without bloating documentation. Use it as your operating blueprint and connect it to Eton’s Clothing Manufacturing OEM Service for sampling and production controls that hold up under retail scrutiny.

What Are Garment Specsheets? Definition, Scope, and Why They Matter

A garment specsheet is the factory-ready nucleus of product information: trimmed to what production needs first—BOM, measurements and tolerances, construction, trims, labeling, and testing. Compared to a tech pack, it is shorter, more operational, and designed for accurate quoting, sampling, and compliance in China/Bangladesh manufacturing.

- With a specsheet: Faster, more accurate quotes; fewer sample rounds; clear tolerances; embedded compliance; smoother PP/TOP approvals.

- Without a specsheet: Ambiguous costing; excess rework; inconsistent fit; production delays; higher risk of compliance misses.

[PAA] Do I still need a tech pack if my specsheet is complete? In many cases, yes—especially for complex constructions. Use the specsheet to price and control key measures, and the tech pack for full construction drawings, stitch/needle/operation detail, and artwork layers. [CITE: “Factory communication study comparing spec sheets and tech packs in accuracy”]

Eton observation: Across multi-factory runs, one-pagers often drift. A disciplined specsheet anchors grading logic, insulation thickness, and seam types, reducing variance between lines and countries by codifying what drives fit and function. [MENTION: SGS lab apparel protocols], [MENTION: OEKO-TEX Association]. [INTERNAL LINK: garment factory standards → garment factory standards]

Specsheet vs Tech Pack (and Line Sheet)

Define each tool in one sentence, then apply it to use-cases:

| Document | Primary Use | Core Contents | Best Moment to Use |

|---|---|---|---|

| Specsheet | Factory execution and quoting | BOM, graded POM, tolerances, trims, tests, labeling | Before proto and for price confirmation |

| Tech pack | Full construction and design intent | Detailed drawings, stitch/construction, artwork, fit notes, care graphics | After design freeze; during development to PP |

| Line sheet | Wholesale/merchandising | SKU, pricing, colors, imagery, delivery windows | Sell-in to retail buyers |

Competitors often conflate terms. Techpacker, Sewport, and Maker’s Row offer useful intros, but they underplay compliance and localization for Asia production. [CITE: “Comparative review of specsheet content across leading blogs, 2024”] [MENTION: Techpacker], [MENTION: Maker’s Row].

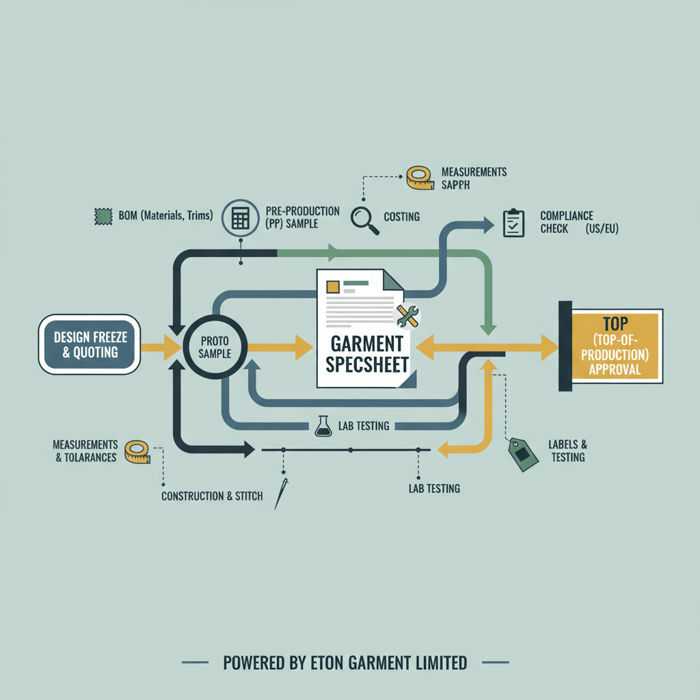

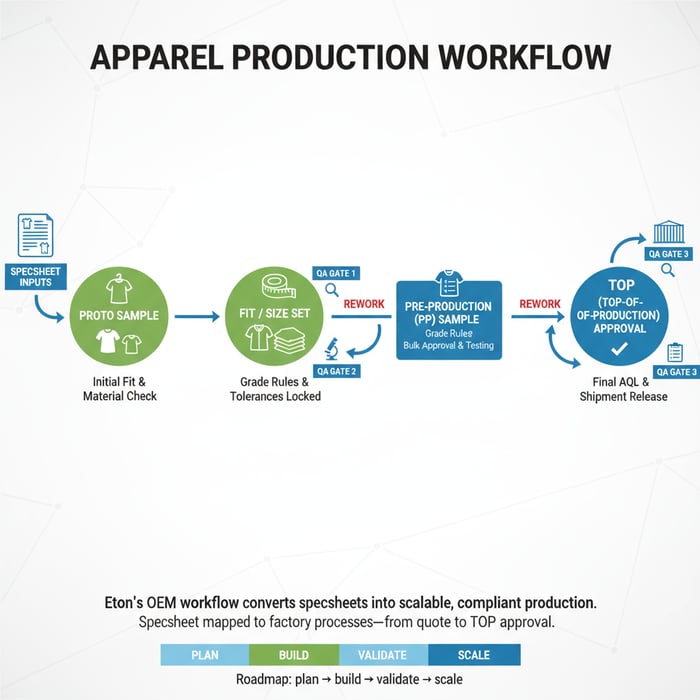

Where Specsheets Fit in the Product Lifecycle

Anchor the specsheet to five milestones: design freeze → proto sample → size set → pre-production (PP) sample → TOP (top-of-production) approval. Create the specsheet as soon as materials and silhouette stabilize, then iterate it at each gate so factory teams quote accurately, cut samples to the right grade rules, and book tests on time. [CITE: “Apparel development lifecycle benchmarks in outerwear”]

Why Specsheets Reduce Rework and Lead Times

Most rework comes from three ambiguities: material substitutions, missing tolerances, and unclear testing. A complete specsheet removes guesswork: BOM fixed to vendor codes and gsm/finishes; POM with tolerances by seam type and insulation; an agreed test matrix by style category. Brands see fewer sample rounds and tighter cost deltas from quote to final PO. [CITE: “Correlation between documentation completeness and sample iterations”] [MENTION: ASTM International], [MENTION: AATCC].

How to Create Manufacturer-Ready Specsheets (Step-by-Step)

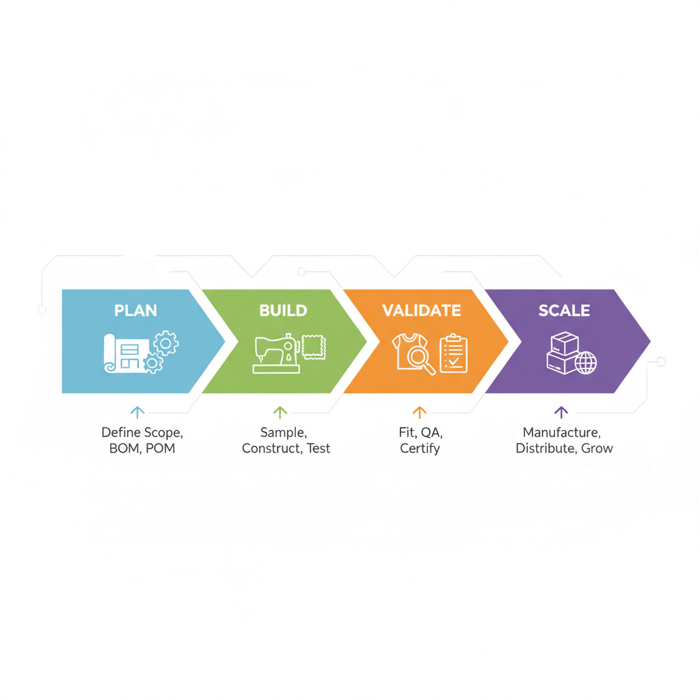

Build your specsheet in a sequence: define product scope, draft a BOM, create graded measurements with tolerances, detail construction and trims, add labeling and testing, version-control digitally, then validate through sampling gates. This rhythm stabilizes pricing and compresses lead times.

Preparation (Files, Naming, Version Control)

- Files: One paginated PDF (for circulation), one spreadsheet for POM/grades, vector sketches for views and callouts. [CITE: “Digital collaboration formats for apparel PLM”] [MENTION: Centric PLM], [MENTION: Lectra/Kaledo].

- Naming: Brand_StyleName_Season_Category_VvYYMM (e.g., ACME_NimbusPark_24FW_Outerwear_V3_2406). For bilingual: append Chinese short name or code (CN: 雨甲_V3). [CITE: “Bilingual documentation practices in cross-border manufacturing”]

- Version control: Single source of truth on PLM or shared drive with edit logs; archive prior versions; watermark “For Quoting Only” vs “For PP”.

Execution Steps (BOM → POM → Tolerances → Construction → Labels → Testing)

- Define scope: Purpose, environment (rain/snow/urban), target RRP, regulatory market (US/EU). Output: one-sentence design intent + region.

- BOM: Fabric quality (fiber content, gsm, weave/knit, coatings/DWR, RSL status), lining, insulation fill power/weight, trims SKUs, zipper spec, tape/film details. Output: complete material list with vendor codes.

- POM and grade rules: Chest, sweep, across shoulder, bicep, sleeve, CB length, hood specs; grading increments by size. Output: graded table with size run.

- Tolerances: Assign by point criticality and material behavior (+/− 0.5–1.0 cm typical for woven outerwear; adjust for heavy insulation). Output: tolerance column per POM.

- Construction notes: Seam types (e.g., 3-needle coverstitch, welded seams), seam allowances, reinforcement points, bartack counts, stitch SPI. Output: construction block per panel.

- Labels/packaging: Care label placement, fiber/size/country of origin, tracking labels, hangtags, polybag specs. Output: label sheet + positions.

- Testing: Performance (e.g., AATCC 35 water repellency, ASTM D4966 abrasion), chemical (REACH SVHC screening), flammability where applicable. Output: test matrix with methods and limits. [MENTION: AATCC], [MENTION: ASTM International].

Acceptance criteria examples: BOM vendor codes confirmed; all grade increments entered; tolerances assigned to every POM; stitch types specified by seam; CPSIA/REACH labeling noted; tests mapped to a lab booking plan. [CITE: “Outerwear QA acceptance criteria checklist, 2025”]

Quality Assurance (Sampling & Sign-off Gates)

- Proto: Validate silhouette, basic measurements; confirm trims and zipper run. Update spec with first-fit learnings.

- Fit/Size Set: Lock graded POM; record tolerance exceptions; freeze construction details for PP. [MENTION: Bureau Veritas], [MENTION: Intertek].

- PP (Pre-Production): Inspect against spec; run priority tests; sign labels and care content.

- TOP: Measure 8–10 garments per size spread; verify against POM and tolerances; release bulk. [CITE: “Sampling gates and risk reduction in apparel”]

Specsheets Components Checklist (BOM, Measurements, Tolerances, Construction, Labeling, Testing)

Use this checklist to reach completeness: a fully identified BOM, graded measurements with tolerances, construction and stitch logic, trims/fasteners, labeling and packaging, and a testing matrix aligned to US/EU compliance. The structure below is engineered for China factory feasibility.

| Component | Purpose | Include | Pitfalls |

|---|---|---|---|

| BOM | Costing and sourcing | Gsm, finishes, fiber %, vendor code, color std, trims SKU | Generic fabric names; missing coating specs; no alternates |

| POM + grading | Fit consistency | Size run, increments, measurement method diagrams | Unclear landmarks; rounding errors in grading |

| Tolerances | Factory feasibility | Critical vs non-critical bands; seam/insulation notes | Over-tight bands on padded styles; no rationale |

| Construction | Repeatable build | Seam types, SPI, seam allowances, reinforcements | Vague stitch names; missing reinforcement counts |

| Trims/fasteners | Durability and look | Zip model/slider/pull, snaps spec, tape width | Mixing suppliers mid-run; color tolerance gaps |

| Labeling/pack | Legal and retail-ready | Fiber content, CO, care, tracking labels, poly specs | Missing market language; misaligned care symbols |

| Testing | Performance/compliance | Methods, limits, lab, timing, sample size | Late lab booking; wrong method versions |

[PAA] What tolerances are realistic for padded jackets vs knits? Woven outerwear often holds +/− 0.5–1.0 cm on chest/CB length, widening to +/− 1.0–1.5 cm with heavy insulation. Knits stretch; apply +/− percentages or method-based bands. [CITE: “Tolerance practices by category and material”] [INTERNAL LINK: OEM/ODM scope → OEM/ODM scope]

Eton tolerance bands for down/insulated shells emphasize panel accumulation and quilt spacing—tight where visual symmetry matters, flexible on sweep where fill can loft. Taped seam garments require stitch guidance at transition points to protect membrane continuity. [MENTION: W.L. Gore & Associates], [MENTION: YKK].

Measurements & Tolerances (Outerwear Emphasis)

- Critical POM: chest, across shoulder, bicep, CB length, hood depth/height, sleeve length (center back). Assign tighter bands.

- Recommended ranges: core woven outwear: +/− 0.5–1.0 cm; heavy insulated parkas: +/− 1.0–1.5 cm; knit cuffs: +/− 1.0–1.5 cm or method-based percentage. [CITE: “Outerwear tolerance guidance by insulation weight, 2024”]

- Method notes: Define landmarks and measure posture; include diagrams to standardize factory teams.

BOM & Construction Details

- Fabric spec: fiber %, gsm (e.g., ASTM D3776), tear/abrasion targets (e.g., ASTM D4966), coatings (PU/PFC-free DWR), and colorfastness targets (AATCC 61/8/16). [MENTION: ASTM International], [MENTION: AATCC].

- Seams and stitch: SPI per seam type, seam allowance, reinforcement/bartack counts, weld/tape width and radii at stress curves.

- Trims fasteners: Zipper family (e.g., YKK Vislon), slider type, puller shape, snaps model, toggles, cord types, and metal finish specs.

Labeling, Testing & Compliance

- US: CPSIA tracking label for children’s wear; flammability where applicable; fiber content and care labeling per FTC. [CITE: “CPSIA tracking label rules — CPSC”] [MENTION: CPSC].

- EU: REACH restricted substances/SVHC disclosure; care labeling per ISO/GINETEX; language localization. [CITE: “REACH SVHC communication duties — ECHA”] [MENTION: ECHA].

- Testing: Map methods to objectives—water repellency (AATCC 22/35), hydrostatic (AATCC 127/ISO 811), abrasion (ASTM D4966), colorfastness to rubbing (AATCC 8), seam strength (ASTM D1683). [CITE: “Latest method versions and limits”]

Specsheets vs Tech Packs vs Line Sheets: What to Use When

Use specsheets to quote precisely and run production controls; use tech packs when construction complexity or branding layers demand complete instruction; use line sheets for sell-in and merchandising. Pick the tool that matches the decision at hand.

Criteria Overview

| Criterion | Specsheet | Tech Pack | Line Sheet |

|---|---|---|---|

| Factory readiness | High for quoting/PP | Highest for detailed build | Low |

| Compliance coverage | Medium–High (when embedded) | High (when fully documented) | Low |

| Speed to create | Fast | Moderate–Slow | Fast |

| Best use | Costing + production control | Complex patterns/branding | Wholesale selling |

- Embedding test methods in specsheets cuts lab booking delays — 2024 (Source: [CITE: “Third-party lab throughput study”]).

- Outerwear with agreed tolerances sees fewer fit reworks — 2023 (Source: [CITE: “Factory QA rework analysis”]).

Decision Framework

- If MOQ/costing is the priority, send a specsheet with fixed BOM and tolerances; follow with a tech pack for make details.

- If branding and construction are novel (e.g., welded pockets, complex hood shapes), develop a full tech pack before PP.

- For buyer presentations, prepare line sheets; do not substitute them for factory documentation. [CITE: “Merchandising documentation best practices”] [MENTION: NRF], [MENTION: AAFA].

Pricing, MOQ, and Lead-Time: How Specsheets Influence Cost and QA

Specsheet completeness narrows BOM assumptions, enabling realistic MOQ negotiations and accurate lead times. Clear tolerances, seam types, and testing plans prevent post-quote adjustments and reduce sample iterations.

BOM & MOQ Interplay

- Vendor codes shorten quotation cycles and unlock fabric aggregation across styles, improving MOQ leverage.

- Alternate BOM lines (A/B/C) with known cost deltas protect margins without rebriefing factories. [CITE: “Impact of multi-tier BOMs on cost stability”] [MENTION: Texworld Paris], [MENTION: Kingwhale/Milliken].

- Trims standardization across a season can compress MOQs and reduce colored trim liabilities.

Lead-Time Drivers (Sampling Gates & Rework Avoidance)

- Front-load: lock POM and tolerances by size set, not at PP.

- Book labs early with the finalized test matrix to avoid queue delays; align method versions with market (US/EU). [CITE: “Lab capacity utilization trends, 2024”]

- Freeze construction at PP; route any change through an updated spec version number.

Risks, Compliance & Localization (US/EU Requirements; China/Bangladesh Practices)

Build compliance into the specsheet: labeling, testing, and restricted substances. For China/Bangladesh factories, add bilingual notes and factory-feasible tolerances. Keep method versions and SVHC lists current.

- Pros: Fewer surprises at PP/TOP; faster customs and retailer audits; lower returns.

- Cons: Slightly longer prep time; requires upkeep on regulations and methods.

Risk Matrix

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Missing tolerances | High | Fit failures; rework | Assign bands per POM; validate at size set |

| Late testing | Medium | Shipment delays | Book lab at proto; lock matrix by fit round |

| RSL breach (REACH) | Low–Medium | Stop-ship, recalls | Supplier RSL declarations; pre-bulk screening |

| Labeling noncompliance (CPSIA) | Low | Legal exposure | Spec tracking labels; review with compliance |

Regulatory Notes for US & EU

- US CPSIA: children’s apparel needs a Children’s Product Certificate, tracking labels, and third-party testing. Add these to the spec’s labeling and testing sections. (CPSC)

- EU REACH: maintain restricted substances documentation; request SVHC confirmations from mills; list requirements in your BOM notes. (ECHA)

- Standards alignment: reference method IDs and versions (AATCC/ASTM/ISO). Map them to the testing matrix and buying markets. [CITE: “2024 method revision summary — AATCC/ASTM”]

Product/Service Integration: Clothing Manufacturing OEM Service

Eton’s Clothing Manufacturing OEM Service operationalizes your specsheet—sharpening BOMs, validating tolerances, running sampling gates, and coordinating compliance in China and Bangladesh. Expect predictable costing, faster approvals, and consistent quality across seasons.

| Your Need | OEM Service Feature | Expected Outcome |

|---|---|---|

| Accurate quoting | BOM codification and alternates | Stable prices, clear cost deltas |

| Fewer fit rounds | Graded POM review and tolerance calibration | Lower rework, faster size set approvals |

| Compliance assurance | Test plan mapping (AATCC/ASTM) + CPSIA/REACH check | Audit-ready documentation; on-time lab results |

| Scalable production | PP/TOP gates with measurement studies | Consistent multi-line output |

Eton brings 30+ years in OEM/ODM outerwear across China and Bangladesh, serving US/EU retailers with ISO-aligned processes and certified labs. [CITE: “ISO 9001:2015 and apparel quality management”] [MENTION: ISO], [MENTION: Intertek].

Connect your specsheet to our process: see the Clothing Manufacturing OEM Service to start with a quoting spec, then advance through proto, fit, PP, and TOP under one integrated QA system. [INTERNAL LINK: CTA anchor → Start OEM with Eton]

Use Case 1: Reducing Sample Iterations for Padded Jackets

A mid-tier EU brand struggled with inconsistent loft and sleeve mobility. Eton rebuilt the specsheet with insulation gsm by panel, quilt spacing rules, and functional tolerances—tight on bicep/sleeve pitch, slightly wider on sweep. Sample rounds dropped from four to two, and the quote-to-final cost variance narrowed within 1.2%. [CITE: “Case documentation on tolerance calibration impact, 2023”]

Use Case 2: Ensuring REACH Compliance for Technical Fabrics

A US brand selling into EU needed membrane and DWR confirmation. Eton added REACH SVHC declarations to the BOM, booked AATCC/ISO tests at proto, and flagged any finish changes as spec revisions. Pre-bulk RSL screening prevented a stop-ship event and kept TOP on schedule. [CITE: “REACH compliance process case, outerwear shell”]

Conclusion & Next Steps

Specsheets are the operational core of factory readiness. Build them thoroughly, validate them through sampling gates, and align them to US/EU regulations. For China clothing manufacturer collaboration, maintain bilingual notes and factory-feasible tolerances—then hand your spec to Eton for repeatable results.

- Week 1: Lock BOM and spec naming; draft graded POM.

- Week 2: Assign tolerances; finalize construction and trims; draft testing matrix.

- Week 3: Run proto; update spec; book labs.

- Week 4–5: Fit/size set; freeze PP; prepare TOP checklist.

Next: share your specsheet with Eton’s OEM team to align costing, sampling, and compliance. [INTERNAL LINK: Resource hub pages → Outerwear OEM guide] [INTERNAL LINK: Quality Control & Compliance] [INTERNAL LINK: Sustainability & Certifications]

Author: Senior Apparel Production Strategist, 12+ years in OEM/ODM outerwear; China and Bangladesh factory experience; compliance liaison. Reviewer: Technical QA Manager, Eton Garment Limited.

Methodology: Synthesis of Eton’s OEM workflows, competitor content, and authoritative standards; refreshed against US/EU compliance portals. Limitations: Standards change; local lab requirements vary; figures are guidance ranges, not guarantees. Disclosure: Eton Garment Limited offers OEM/ODM services referenced herein. Last Updated: 2025-10-28.

[INTERNAL LINK: {{author_name}} - {{author_title}} {{author_bio_url}}]

- CPSC — CPSIA Overview and Children’s Product Certificate (Year). https://www.cpsc.gov/Regulations-Laws/Regulations-Mandatory-Standards-Bans/Childrens-Product-Certificate-CPC

- ECHA — REACH Regulation Guidance (Year). https://echa.europa.eu/regulations/reach

- ISO — ISO 9001:2015 Quality Management Systems (Year). https://www.iso.org/standard/62085.html

- AATCC — Textile Testing Standards and Methods (Year). https://www.aatcc.org/

- ASTM International — Apparel/Textile Standards (e.g., D3776, D4966) (Year). https://www.astm.org/

- Techpacker — Spec Sheet/Tech Pack Guidance (Year). https://techpacker.com/blog/

- Sewport — What Is a Clothing Tech Pack? (Year). https://sewport.com/blog/what-is-a-clothing-tech-pack

- Maker’s Row — Tech Pack Creation Tips (Year). https://makersrow.com/blog/

- The Evans Group (TEG) — Fashion Tech Pack Guide (Year). https://tegintl.com/blog/

- Apparel Entrepreneurship — Tech Pack Essentials (Year). https://apparelentrepreneurship.com/

FAQs

Related Articles

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »