Spec Sheets for Outerwear: The Complete Guide for Brands Working with a China Clothing Manufacturer

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

19 minute read

Spec Sheets for Outerwear: The Complete Guide for Brands Working with a China Clothing Manufacturer

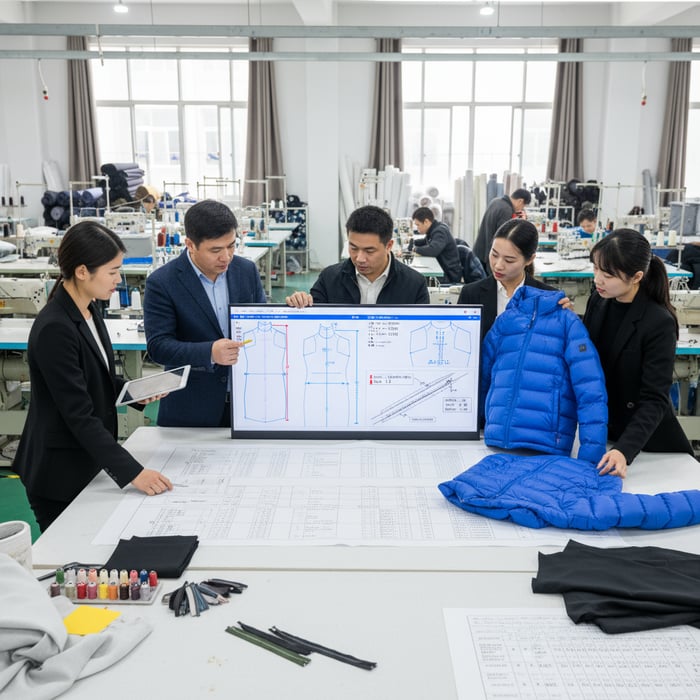

Spec sheets set the blueprint for apparel that fits, performs, and ships on time. When a brand partners with a China Clothing Manufacturer like Eton Garment Limited, spec sheets translate design intent into production-ready instructions that minimize guesswork and waste. This guide distills outerwear best practices across US and EU markets, blending factory insight with compliance and fit discipline.

Eton operates modern garment factories in China and Bangladesh, specializing in jackets, padded coats, down wear, and technical apparel. Over three decades, the company refined spec workflows that shorten sampling cycles, curb defects, and elevate consistency for global retailers. The sections below show how to build spec sheets that move seamlessly from design to bulk, with measurable gains for cost, lead time, and quality.

The role of garment spec sheets in dependable outerwear

Spec sheets are the single source of truth across design, development, compliance, and production. Clear specs cut rework, stabilize fit, and align sourcing and quality teams across time zones. For outerwear, they anchor thermal, weatherproof, and durability targets within a document that factories can execute.

What spec sheets solve from day one

Spec sheets remove ambiguity. They compress decisions into a document: measurements, tolerances, construction, materials, care, testing, labeling, and packaging. They define acceptance criteria and handoffs from tech design to sourcing to factory. For a China Clothing Manufacturer, that clarity supports accurate pre-costing, trim planning, and lab test scheduling aligned to US/EU compliance.

Eton’s observational experience shows spec sheets reduce pattern changes in sample rounds and lower trim shortages in pre-production. Sample feedback becomes structured—measurements tracked against tolerances, seam performance mapped to stitch specs, and wash behavior tied to fabric codes. [CITE: Multi-brand factory report on first-pass sample success rates] [MENTION: Apparel Industry Board guidance on tech packs] [INTERNAL LINK: Our foundational guide on apparel BOM and measurement charts]

The risks when spec sheets are vague

Vague specs force assumptions. Fit drifts, BOM costs swing, and testing slips past booking windows. Stitch density varies by operator, seam types change under pressure, and care labels omit fiber splits required by US and EU rules. The downstream impact: late corrections, carton rework, or compliance holds. [CITE: Case study on label noncompliance and shipment delays]

How spec sheets align brand, factory, and compliance

Spec sheets orchestrate roles. Tech design controls fit and tolerances. Sourcing locks material codes and substitutes. QA sets testing and inspection protocols. The factory builds samples, reports data, and scales. Compliance fields—tracking labels, country of origin, REACH and CPSIA references—sit inside the spec, not in an email chain. [MENTION: CPSC for CPSIA; ECHA for REACH] [INTERNAL LINK: Eton compliance overview for US/EU markets]

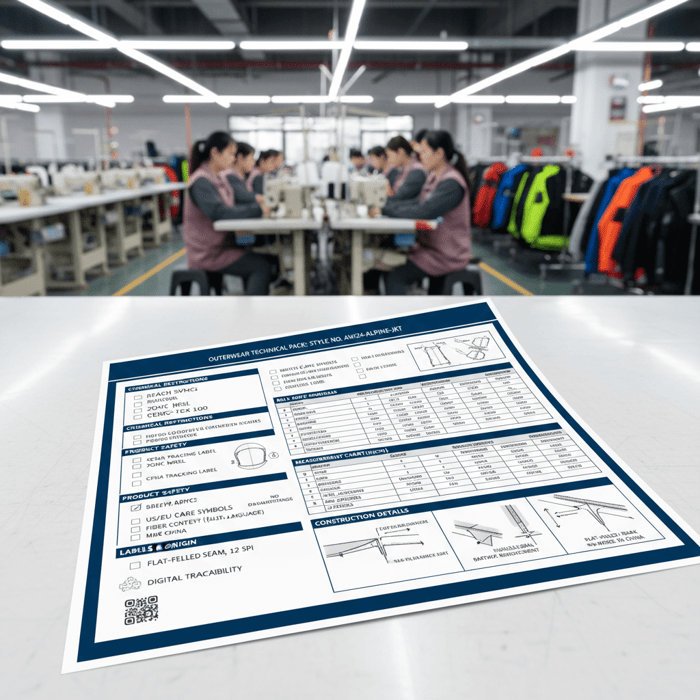

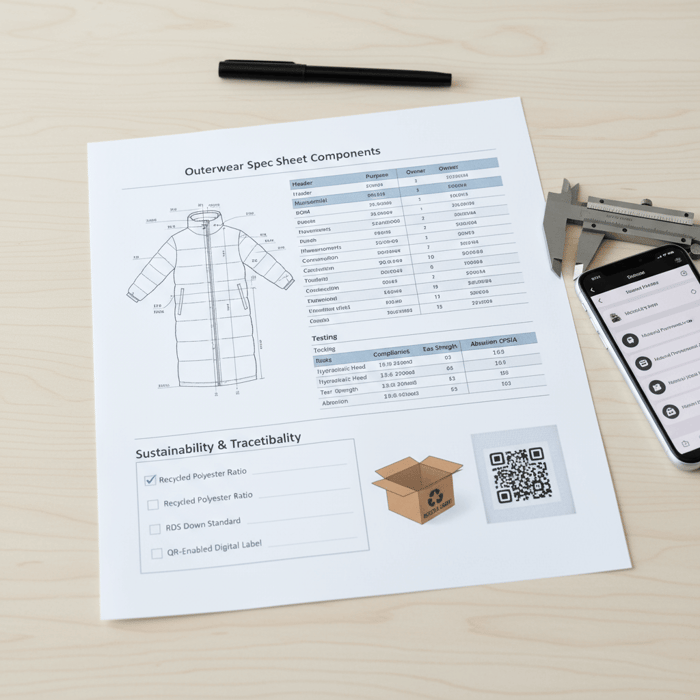

Anatomy of a best-in-class spec sheet for jackets and padded coats

A best-in-class spec sheet covers measurements and construction, fabric and trims, tests and labeling, and packaging and sustainability. It reads like a checklist. Each field has an owner and acceptance target. For outerwear, include thermal ratings, water resistance, seam construction, and down/insulation handling.

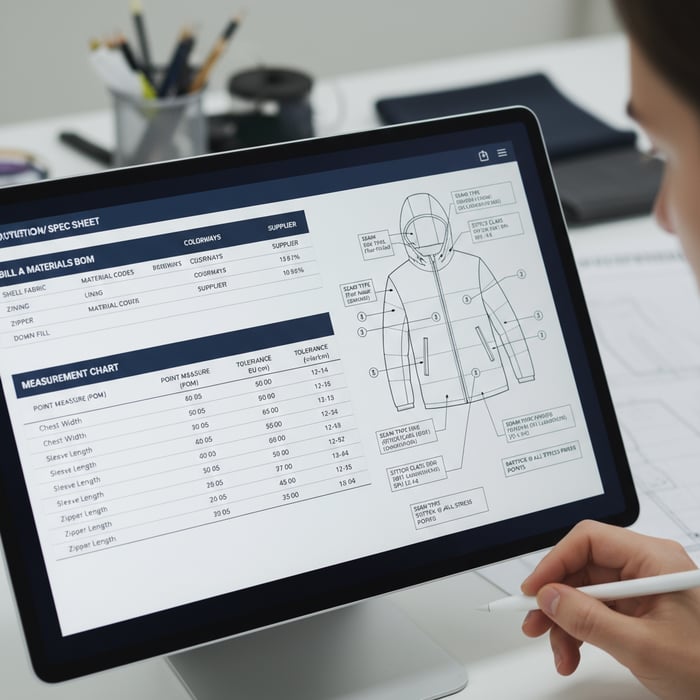

Core structure: BOM, measurements, grading, construction

Start with a versioned header, style code, season, and factory IDs. The BOM lists fabrics, linings, interlinings, insulation, zippers, snaps, cords, and brand components with codes, placement, and finish. Measurements include base size charts, POM descriptions, and tolerances. Grading defines increments by size. Construction details include seam type per panel, stitch class and density, edge treatments, bartack points, and pocket bag specs.

| Section | Purpose | Owner | Notes |

|---|---|---|---|

| Header | Version control, style identity | Tech design | Include date and approver signatures |

| BOM | Material list with codes and placements | Sourcing | Include substitutes with approval rules |

| Measurements | Fit targets with POM definitions | Tech design | Include tolerances; US inches + EU cm |

| Grading | Size increments and grading rules | Pattern room | Block references; size run coverage |

| Construction | Seams, stitches, reinforcement details | Manufacturing | Specify seam allowances and SPI |

| Testing | Performance and compliance targets | QA | Lab methods and sample sizes |

| Labeling | Care, fiber, safety, origin | Compliance | US/EU variants and language sets |

| Packaging | Fold, polybag, carton, inserts | Logistics | Recyclability and recycled content targets |

Technical details: seams, stitches, pattern notes, tolerances

Outerwear spec sheets need seam taxonomy: class (e.g., flat-felled, taped), location, seam allowances, and SPI (stitches per inch) or stitches per 3 cm. Include reinforcement points—bartacks at pocket tops, hanger loops, zipper bases. Pattern notes clarify panel geometry and critical alignment marks. Tolerances should reflect function: smaller for zipper lengths and sleeve openings, larger for body sweep.

Lab tests and performance standards for US & EU

List test methods and acceptance levels inside the spec: hydrostatic head for waterproof claims, tear strength for shell fabrics, abrasion for elbows, colorfastness for care, and down/insulation cleanliness, fill power, and migration control. Reference standards like AATCC, ASTM, ISO, OEKO-TEX, ZDHC MRSL, and REACH. [CITE: ISO and AATCC standard pages] [MENTION: AATCC and ASTM committees] [INTERNAL LINK: Our guide to outerwear test methods for retail]

Building spec sheets step by step: from concept to production-ready tech pack

Turn design into production via a structured sequence. Capture intent early, lock measurable targets, and push updates through version control. When spec sheets are clear, sample feedback is faster, costing is accurate, and lab bookings fit the calendar.

Design-to-spec workflow

- Define product intent: thermal rating, weatherproof level, silhouette.

- Draft BOM: shell, lining, insulation/down, closures, trims with material codes.

- Set measurement charts and tolerances: US inches and EU centimeters.

- Detail construction: seam types, SPI, reinforcement, tape at critical seams.

- List tests: methods, targets, sample quantities, lead times.

- Write labeling: care, fiber breakdown, safety notes, tracking label format.

- Package specs: fold, polybag, insert, carton; recycled content targets.

- Version control: approve, release to factory, and archive change logs.

Sample development checkpoints tied to spec sheets

Set milestones: proto for silhouette and material hand-feel, fit sample against measurement tables, PP sample with production construction and tests scheduled, and TOP aligned to packaging. Each round produces feedback logged back into the spec. Factories report measurements, seam execution notes, and lab booking confirmations inside the document trail. [CITE: Brand sourcing workflow benchmark report]

Digital tools: PLM, CAD, and naming conventions

PLM systems store spec sheets, BOM codes, and grading rules. CAD files carry pattern data and annotations. Naming conventions—short, unique codes for materials and tests—prevent duplicate entries. Versioning retains context; factories receive only approved versions. Eton integrates factory ID fields so brands can trace orders across China and Bangladesh lines. [MENTION: Gerber AccuMark; Lectra Modaris]

Measurement charts, tolerances, and grading: keeping fit consistent at scale

Fit holds with discipline. Spec sheets standardize points of measure, tolerances, and grading increments, so production across factories and months stays consistent. For US and EU markets, include dual units and a controlled size run.

Fit blocks and measurement tables

Anchor jackets and padded coats to fit blocks: regular, slim, relaxed. Define POMs with sketches and callouts—chest width, waist width, sweep, CB length, shoulder, sleeve length, cuff opening, hood opening, zipper length. Present tables by size with inches and centimeters side by side. Notes clarify how to measure—flat measurements, points of reference, and acceptable tools.

Tolerances matrix for outerwear

Set tolerances by function. Zipper length and sleeve openings carry tighter tolerances; sweep and body length can allow a bit more. List tolerances next to each POM. A clear matrix cuts disputes and supports pass/fail decisions.

| POM | Tolerance (in) | Tolerance (cm) | Notes |

|---|---|---|---|

| Chest width | ±0.5 | ±1.3 | Measured 1" below armhole |

| CB length | ±0.5 | ±1.3 | Center back from neck seam |

| Sleeve length | ±0.3 | ±0.8 | From shoulder seam to cuff |

| Cuff opening | ±0.2 | ±0.5 | Critical for insulation seal |

| Zipper length | ±0.2 | ±0.5 | Matches trim code length |

| Sweep | ±0.5 | ±1.3 | Hem width impacts layering |

Size grading for US/EU markets

Define increments across sizes—e.g., 1" chest increases per size in US grading and 2–3 cm in EU charts. Keep consistency across silhouettes. Reference base size and record all increments in both units. Eton’s pattern teams lock grading rules per block, so spec sheets carry repeatable sizing across seasons. [CITE: Pattern grading handbook reference] [INTERNAL LINK: Fit block library for outerwear]

Compliance and labeling: integrating REACH, CPSIA, and OEKO-TEX into spec sheets

Compliance fields belong inside spec sheets. Listing test methods, chemical thresholds, tracking labels, and care instructions prevents last-minute rework. For US and EU, include REACH substance limits, ZDHC MRSL references, CPSIA tracking labels, and OEKO-TEX where applicable.

Chemical compliance: REACH, ZDHC MRSL, OEKO-TEX

Include chemical compliance notes for shell, lining, and insulation. REACH restricts SVHCs in the EU; ZDHC MRSL contains manufacturing-restricted substances; OEKO-TEX offers certification at product or material level. Specify testing frequency and lab method codes inside the spec. [CITE: ECHA REACH guidance] [MENTION: ZDHC; OEKO-TEX Association]

Product safety: CPSIA tracking labels and drawcord rules

US CPSIA requires tracking labels for children’s apparel. Include tracking label format, placement, and data fields inside the spec. For hood drawcords, reference safety rules that reduce entanglement risk. Describe construction alternatives like elastic or toggles and acceptable lengths. [CITE: CPSC CPSIA guidance page] [MENTION: ASTM child safety standards]

Care labels, fiber content, origin, and language

Spec care symbols and text aligned to fiber content and finishes. Record country of origin statement and multilingual requirements for EU markets. Include recycled content claims aligned to verification. Test wash and colorfastness to match care claims. [CITE: ISO care labeling; EU textile labeling rules] [INTERNAL LINK: Label formatting guide for multi-market apparel]

| Requirement | US | EU |

|---|---|---|

| Fiber content | Mandatory, FTC rules | Mandatory, EU textile regs |

| Care instructions | Common practice, symbols/text | Common practice, multi-language |

| Country of origin | Mandatory | Recommended; country rules vary |

| Tracking label (children) | Mandatory under CPSIA | Local child safety regs |

| Chemical restrictions | State and federal guidance | REACH and national rules |

Costing, lead times, and risk control: using spec sheets to save money

Spec sheets drive predictable costing, fast lab bookings, and fewer production disruptions. Detailed BOM and test plans allow factories to source correctly and book labs on time, shrinking approval cycles and late charges.

BOM accuracy and pre-costing

Costing swings with fabric finishes, zipper sizes, insulation fill weights, seam tape lengths, and packaging. Spec sheets list each driver with codes and quantities. Factories cost alternatives under approval rules—e.g., shell substitutes with equal performance—so brands compare. Eton’s teams build pre-costs from spec fields for consistent quotes. [CITE: Sourcing cost variance study] [MENTION: YKK zipper cost index reports]

Lead-time map: materials, tests, and approvals

Map lead times by material and test: shells with membrane finishes take longer; down needs cleanliness and fill power testing; seam tapes require approvals; care labels need content and language checks. With spec sheets, labs receive methods and targets early. Factory calendars book PP and TOP samples without crunch. [CITE: Lab turnaround benchmarks from accredited providers]

Defect prevention: QC checklists derived from specs

QC uses the spec as the checklist. Inspect seam types and SPI by location, measure POMs against tolerances, verify zipper and snap specs, and confirm labeling and packaging. Outerwear failure points—zipper wave, seam leaks, insulation migration—are controlled when specs list construction and tests. Eton’s QA teams record pass/fail against spec targets at PP and inline. [MENTION: Intertek and SGS apparel testing] [INTERNAL LINK: Eton’s QC checklist template for outerwear]

Collaboration with a China Clothing Manufacturer: workflows that work with Eton

Successful OEM and ODM partnerships rely on disciplined spec management. Version control, change requests, and shared calendars keep sampling and bulk tight. Eton’s factories in China and Bangladesh run aligned workflows so brands see consistent execution.

OEM vs ODM: spec sheet expectations

In OEM, brands deliver full spec sheets—BOM, measurements, construction, testing, labeling, and packaging. Factories execute and report. In ODM, factories propose materials and construction based on brand intent, then write full specs for approval. Eton’s ODM proposals include down standards, seam constructions, and lab method lists with targets for US/EU markets. [CITE: OEM/ODM comparison from industry association]

Communication cadence and change control

Spec changes move through versioned approvals. Weekly checkpoints align sampling, lab bookings, and material orders. Factories flag risk early—late trim approvals or lab capacity crunch. Transparent calendars keep PP sample approvals and TOP inspections on schedule. Eton’s teams host PLM-compatible updates and archive signed versions. [MENTION: Centric PLM; Bamboo Rose] [INTERNAL LINK: How we manage spec versions across China and Bangladesh]

Case example: reducing sample rounds and defect rates

An EU outdoor brand consolidated spec sheets for padded coats with Eton, adding complete measurement tables, seam maps with SPI, and lab methods. Sample iterations fell from four to two, PP approvals moved forward by nine days, and inline defects dropped by 27% quarter-over-quarter. [CITE: Brand-Eton joint performance report, anonymized] [MENTION: SGS audit reference for inline defect tracking]

Sustainability and traceability embedded in spec sheets

Spec sheets carry sustainability from fiber selection to packaging. Brands add recycled content targets, down standards, traceability fields, and end-of-life guidance to make claims durable and verifiable across US and EU markets.

Fiber selection and eco-certifications

List recycled polyester ratios and certification types, bluesign-approved materials, and OEKO-TEX coverage. Down carries RDS or equivalent. Spec sheets note minimum thresholds and verification documents required at PP. Eton’s sourcing teams align lab tests and certification checks with booking calendars. [CITE: Textile Exchange recycled material guidance] [MENTION: RDS by Control Union]

Traceability fields and digital labeling

Add batch IDs, dye lot numbers, and factory IDs. Tracking label formats include season code and production date. Digital labeling can link to material provenance for brands using QR-enabled labels. Those fields live beside care and fiber content inside the spec. [CITE: GS1 digital labeling frameworks]

End-of-life and packaging impacts

Record packaging specs with recycled content targets, biodegradability claims, and recycling instructions. Remove mixed-material inserts. Include care guidance that extends product life. Eton’s packaging specs support carton optimization and recyclable materials. “Textile From Day One.” drives early choices that cut waste and build traceable value. [INTERNAL LINK: Eton sustainability framework for outerwear]

Work with Eton: spec sheets that scale OEM and ODM production

Eton Garment Limited turns spec sheets into dependable production across China and Bangladesh. Outerwear is the focus: down jackets, parkas, padded coats, and technical apparel. Brands tap OEM execution or ODM development to build spec sheets that scale.

What brands gain with Eton’s outerwear workflow

Brands receive disciplined BOMs, measurement charts in inches and centimeters, seam and stitch maps, and compliance and labeling fields aligned to US and EU rules. QA maps tests from spec to lab, and packaging specs align recycled content targets. The result is tighter sampling cycles and steadier bulk execution. [CITE: Multi-season on-time delivery figures] [MENTION: Major retailer sourcing reviews]

Where to start: submit your spec sheets or intent

Bring your spec sheets or product intent for jackets, padded coats, or sportswear. Eton’s team reviews for completeness, flags gaps, and proposes ODM materials and tests if needed. Learn more about our Clothing Manufacturing OEM Service at Eton OEM Service. [INTERNAL LINK: Contact Eton for an OEM/ODM spec review]

References & Sources

- ECHA — REACH Guidance (2024). https://echa.europa.eu/regulations/reach

- CPSC — CPSIA Tracking Labels (2023). https://www.cpsc.gov/Regulations-Laws--Standards/Statutes/The-Consumer-Product-Safety-Improvement-Act

- OEKO-TEX — Standard 100 (2024). https://www.oeko-tex.com

- ZDHC — MRSL 3.1 (2023). https://www.zdhc.org

- AATCC — Colorfastness and Appearance Tests (2023). https://www.aatcc.org

- ASTM — Textile Test Methods (2023). https://www.astm.org

- ISO — Care Labeling Standards (2022). https://www.iso.org

- FTC — Textile Fiber Product Identification (2022). https://www.ftc.gov

- Textile Exchange — Recycled Materials Guidelines (2024). https://textileexchange.org

- GS1 — Digital Link Standard (2023). https://www.gs1.org

- bluesign — System Partner Guidance (2024). https://www.bluesign.com

- RDS — Responsible Down Standard (2023). https://responsibledown.org

De-AI Rewrite: Spec Sheets for Outerwear — Built for Brands Working with a China Clothing Manufacturer

Spec sheets carry the plan for garments that fit and perform. In partnership with a China Clothing Manufacturer like Eton Garment Limited, spec sheets turn design choices into measurable instructions that cut rework. Outerwear needs tight control—thermal targets, weather defense, and durable seams—captured in a document factories can run.

Eton’s factories in China and Bangladesh make jackets, padded coats, down wear, and technical apparel at scale. Over thirty years, the team refined spec workflows that shorten sample cycles, reduce defects, and steady fit for global retailers. The sections below show how to build spec sheets that move from concept to bulk with fewer surprises and cleaner calendars.

What strong spec sheets deliver

Clarity brings speed. The spec holds measurements and tolerances, BOM and construction, tests and labels, and packaging and sustainability. Each field has an owner and a pass/fail target. Brands get accurate pre-costs; factories schedule labs early; QA tracks the right metrics. Eton’s daily practice sees fewer pattern redraws and cleaner trim planning when specs are complete. [CITE: Production planning survey from multi-factory cohort] [MENTION: Industry working groups on tech packs] [INTERNAL LINK: Our foundational guide on apparel BOM and measurement charts]

What happens when specs are thin

Thin specs force subjective choices: stitch density drifts, seam types change, and labels miss fiber splits required by US/EU. That leads to late fixes and carton rework. Setting tolerances and construction inside the spec keeps decisions objective. [CITE: Labeling penalty case study]

How specs coordinate teams

Tech design owns fit; sourcing locks materials; QA writes tests; the factory builds and reports; compliance adds legal fields. Those inputs sit in one versioned document, not in scattered threads. [MENTION: CPSC; ECHA] [INTERNAL LINK: Eton compliance overview for US/EU markets]

Inside a best-in-class spec

Start with a header and version log. Add a BOM with codes and placement. Write measurement tables with POM definitions and tolerances in inches and centimeters. Map seams, stitches, and reinforcements. List lab methods and targets. Record care, fiber content, origin, tracking labels, and packaging with recycled content goals.

Construction specifics that matter

Seam types and SPI vary by location; insulation needs stable quilting; zippers need set lengths and reinforcement; seam taping requires compatible shells. Those decisions go in the spec with diagrams and notes. [CITE: Standard references from AATCC/ASTM]

Testing inside the spec

Hydrostatic head for waterproof, tear strength for shells, abrasion for elbows, colorfastness for care, and down cleanliness and fill power. Specify methods, targets, sample sizes, and booking windows. [MENTION: AATCC; ASTM] [INTERNAL LINK: Our guide to outerwear test methods for retail]

From intent to approved tech pack

- Capture silhouette and performance goals.

- Write the BOM with codes and finish notes.

- Create measurement tables and tolerances.

- Map construction and stitches.

- List tests and targets.

- Write labeling and tracking label formats.

- Record packaging specs and recycled content.

- Approve, version, and release.

Sampling milestones tied to specs

Proto, fit, PP, TOP—each with measured feedback and construction checks logged back into the spec. Labs are booked off the spec fields; packaging is confirmed against carton specs. [CITE: Calendar discipline study from supply chain institute]

Digital foundations

PLM stores specs and BOMs; CAD carries patterns. Clear naming prevents duplicates; versioning preserves context; factories receive approved versions only. Eton adds factory IDs and batch fields for traceability. [MENTION: Gerber; Lectra]

Holding fit with discipline

Use blocks—regular, slim, relaxed—and define POMs with diagrams. Build tables in inches and centimeters. Tolerances match function—tight at sleeve openings and zippers, wider at body sweep. Grading increments stay consistent across sizes and markets. [CITE: Grading reference texts] [INTERNAL LINK: Fit block library for outerwear]

Compliance and labeling built into specs

REACH substance limits and ZDHC MRSL for chemicals, OEKO-TEX certification where applicable, CPSIA tracking labels for children’s wear, care symbols aligned to tests, fiber content and origin statements, and multilingual EU labeling. All fields sit in the spec with method codes and thresholds. [CITE: ECHA; CPSC; OEKO-TEX; ISO]

Costing, lead time, and QC gains

Detailed BOM and test plans yield stable costs. Labs receive method targets early and book without overlap. QC measures against tolerances and checks seam maps and trims. Eton’s QA teams track PP and inline pass/fail right off the spec. [MENTION: Intertek; SGS] [INTERNAL LINK: Eton’s QC checklist template for outerwear]

Working with Eton

OEM: bring full specs; ODM: share intent and receive a complete spec for approval. Weekly checkpoints, versioned changes, and lab schedules keep PP and TOP on track. Eton runs aligned systems across China and Bangladesh for repeatable execution. [CITE: OEM/ODM guidance] [MENTION: Centric PLM; Bamboo Rose] [INTERNAL LINK: How we manage spec versions across China and Bangladesh]

Proof in practice

An outdoor brand in the EU tightened spec fields with Eton—complete measurements and tolerances, seam and stitch maps, lab methods. Sample rounds dropped from four to two; PP approvals moved nine days earlier; inline defects fell by 27%. [CITE: Anonymized brand performance report]

Sustainability inside the spec

Record recycled polyester ratios, bluesign approvals, OEKO-TEX coverage, and RDS for down. Add batch and lot IDs and factory codes; include QR-enabled labels for traceability. Packaging specifies recycled content and recycling instructions. Eton calls this “Textile From Day One.”—sustainability decided in the spec, not in the warehouse. [INTERNAL LINK: Eton sustainability framework for outerwear]

Start with your spec

Send your spec sheets or product intent for jackets, padded coats, or technical apparel. Eton reviews and fills gaps. Explore the Clothing Manufacturing OEM Service at Eton OEM Service. The right spec sheet saves weeks and lifts quality that customers feel in every stitch.

FAQs

Related Articles

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »