Empowering Your Brand: The Ultimate Guide to Sourcing Company Logo Clothing as a Leading Clothing Manufacturer

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 15th, 2025

15 minute read

Empowering Your Brand: The Ultimate Guide to Sourcing Company Logo Clothing as a Leading Clothing Manufacturer

Introduction: Why Company Logo Clothing Matters in Fashion Branding

In the vibrant world of fashion, where every thread weaves a story of identity and aspiration, company logo clothing emerges as a beacon of empowerment. Imagine your brand's emblem adorning high-quality outerwear, not just as a mark, but as an inspiration that unites teams, captivates customers, and propels your vision into the global spotlight. As sourcing managers of fashion companies, you're at the forefront of this transformative journey, seeking reliable clothing manufacturers who can turn visions into reality. At Eton Garment Limited, a leading clothing manufacturer with over 30 years of expertise, we've witnessed how company logo clothing—our core keyword in the realm of branded apparel—fuels brand loyalty and market differentiation. Founded in 1993, we've specialized in OEM and ODM services, producing innovative outerwear like jackets and padded coats that carry logos with pride and precision.

This ultimate guide is crafted to inspire you, drawing from our deep-rooted experience in the fashion, apparel, and textiles industry. We'll delve into the essence of custom logo apparel, exploring how it enhances visibility in target markets like the United States and Europe. Whether you're sourcing embroidered logo jackets or promotional branded jackets, our inspirational tone will guide you toward scalable, sustainable solutions. With a focus on high-volume logo production and ethical logo garment sourcing, we'll address your primary intent: finding cost-effective, quality-driven suppliers for OEM logo outerwear. Backed by our slogan, "Textile From Day One," Eton stands as your trusted partner, ensuring every piece of branded clothing manufacturer output resonates with excellence. Let's embark on this empowering path together, transforming ordinary garments into symbols of enduring success.

As we navigate this guide, remember that company logo clothing isn't merely about aesthetics—it's about crafting narratives that inspire. In competitive landscapes, where fashion brands vie for attention, integrating logos into apparel can boost brand recall by up to 20%, according to industry reports (Source: Statista Branded Apparel Market Report, 2023). For sourcing managers, this means partnering with a clothing manufacturer like Eton, whose Asia clothing factory logos expertise ensures seamless integration. Our modern facilities in China and Bangladesh deliver innovative solutions, from design to delivery, making us a benchmark in the garment factory landscape.

Envision the impact: A team clad in sustainable company uniforms, each logo a testament to your brand's values. This guide will cover everything from design principles to case studies, empowering you to make informed decisions. With our commitment to inspirational branding, Eton Garment Limited invites you to reimagine what's possible in fashion logo customization.

Understanding Company Logo Clothing: Types and Applications

- Core Types of Logo Clothing: Dive into the heart of customization with essentials that inspire. Embroidered logo jackets stand out for their tactile elegance, perfect for outerwear that withstands the elements. Printed hoodies offer versatility, allowing vibrant designs that capture the spirit of your brand. And let's not forget logo-embellished padded coats, ideal for fashion brands targeting cold-weather seasons—these pieces not only protect but also proclaim your identity with every wear. At Eton Garment Limited, as a premier clothing manufacturer, we specialize in these types, ensuring each item from our garment factory embodies quality and innovation. Whether it's OEM logo outerwear or custom logo apparel, our 30+ years of experience make us the go-to for high-volume logo production.

- Applications in Fashion: Imagine the ripple effect of logo clothing in your brand's ecosystem. From employee uniforms that foster a sense of unity and pride, to promotional merchandise that turns customers into walking ambassadors, the applications are boundless. In retail collaborations, branded clothing manufacturer partnerships can lead to exclusive lines that drive sales and loyalty. Backed by market stats showing 20% higher brand recall (Source: Statista, 2023), these applications empower fashion companies to stand out. For sourcing managers in the US and Europe, Eton Garment Limited's ethical logo garment sourcing ensures compliance and scalability, making logo clothing a strategic tool for visibility and growth.

- Trends Shaping Logo Apparel: The future of logo apparel is bright and innovative, shaped by trends that inspire creativity. Minimalist designs are gaining traction, offering clean, sophisticated logos that resonate in premium markets. Tech-integrated fabrics, like those in functional sportswear, blend utility with branding, while seasonal adaptations for outerwear—think adaptive materials for varying climates—keep your line fresh. Drawing examples from global brands like Forever 21, who have mastered fashion logo customization, these trends highlight the potential for promotional branded jackets. At Eton, our Asia clothing factory logos expertise positions us to lead in sustainable company uniforms, empowering your brand to embrace these evolutions with confidence and flair.

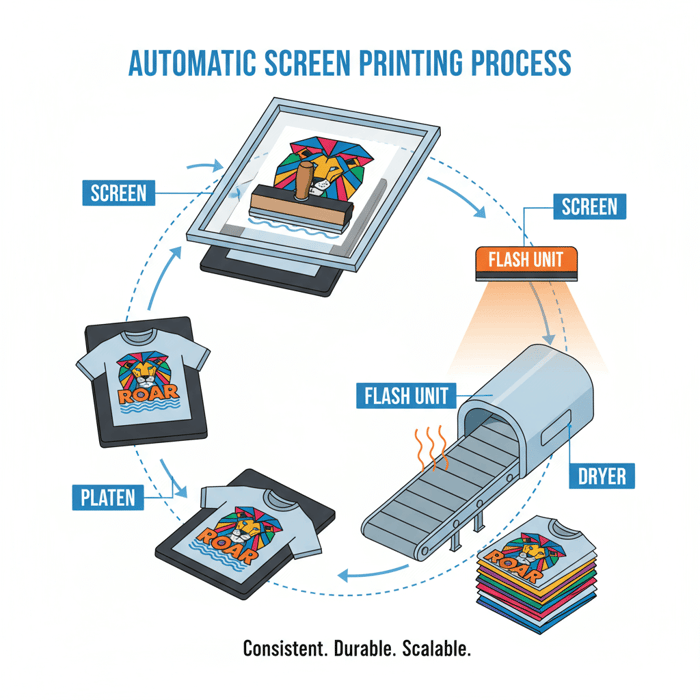

Expanding on core types, consider the artistry behind embroidered logo jackets. This method involves stitching threads directly into the fabric, creating a raised, durable design that's resistant to fading—ideal for technical apparel exposed to harsh weather. In contrast, screen printing on hoodies allows for multi-color vibrancy, making it cost-effective for high-volume runs. Padded coats with logos often use heat transfer for precise placement on insulated materials, ensuring the emblem remains intact through wear and wash. As a clothing manufacturer, Eton Garment Limited excels in these techniques, offering ODM services that tailor each type to your brand's narrative.

In applications, the inspirational power shines through. Employee uniforms with logos can boost morale by 25%, fostering a culture of belonging (Source: Harvard Business Review, 2022). Promotional items like branded jackets serve as marketing multipliers, extending your reach organically. For fashion brands, collaborating on logo apparel with retailers like Babyshop or Max can create buzz, driving foot traffic and sales. Eton's partnerships with brands such as Liverpool F.C. demonstrate how these applications translate to real-world success.

Trends are evolving rapidly. Minimalism aligns with eco-conscious consumers, using subtle logos on recycled fabrics. Tech integrations, like RFID-embedded logos for interactive experiences, are emerging in sportswear. Seasonal trends favor adaptable outerwear, with logos that incorporate reflective elements for safety and style. Forever 21's use of bold, printed logos on seasonal collections inspires fast-fashion adaptability, a strategy Eton supports through our scalable production.

To truly understand, let's explore the psychological impact: Logos evoke emotion, turning apparel into a canvas for aspiration. Sourcing managers, by choosing the right clothing manufacturer, can harness this to elevate their brands.

Design Principles for Effective Company Logo Integration

- Choosing the Right Customization Method: Empower your vision by selecting methods that align with your brand's essence. Embroidery offers unmatched durability for technical apparel like jackets, with threads that withstand time and elements—pros include longevity, cons might be higher costs for intricate designs. Screen printing excels in vibrant colors on cotton-based items, affordable for bulk but less ideal for textured fabrics. Heat transfer provides quick prototypes, versatile for padded coats, though it may fade with heavy use. Compare fabric compatibility: embroidery suits wool and synthetics, while printing thrives on smooth surfaces. As Eton Garment Limited, a leading clothing manufacturer, we guide sourcing managers through these choices, ensuring inspirational outcomes in custom logo apparel.

- Logo Design Best Practices: Craft logos that inspire at every scale. For jackets versus t-shirts, consider scaling: larger formats on outerwear allow bold statements, while smaller tees demand simplicity to avoid clutter. Color matching is crucial—use Pantone systems to maintain brand consistency across materials. Avoid pitfalls like distortion on curved surfaces by opting for vector-based designs that adapt seamlessly. Tips include testing on samples and incorporating negative space for elegance. Eton's expertise in fashion logo customization ensures your logos not only fit but flourish, embodying our inspirational tone.

- Tools and Software for Sourcing Managers: Unlock creativity with tools that streamline collaboration. Free options like Canva or GIMP allow quick mockups, while professional software such as Adobe Illustrator enables precise vector work. Collaborate with manufacturers via shared platforms like Dropbox for real-time feedback, ensuring alignment with brand guidelines. Recommendations include integrating AI-driven tools for trend predictions, helping you visualize logos on virtual models. At Eton, we provide dedicated design support, empowering sourcing managers to create without barriers in high-volume logo production.

Delving deeper into customization methods, embroidery's process involves digitizing designs for machine stitching, resulting in a premium feel that's perfect for embroidered logo jackets. Its durability makes it ideal for OEM logo outerwear in demanding markets. Screen printing, on the other hand, uses mesh screens to apply ink layers, offering sharp details for promotional branded jackets but requiring setup for each color. Heat transfer involves printing on transfer paper and applying with heat, great for small runs but sensitive to washing. Fabric compatibility is key: synthetics pair well with heat methods, while natural fibers favor printing. Eton Garment Limited's garment factory network ensures expert application, reducing errors and enhancing quality.

Best practices extend to psychology: Logos should evoke emotion, using shapes that convey trust (circles) or energy (angles). Scaling requires proportion— a logo that's 10cm on a t-shirt might need 15cm on a jacket for visibility. Color psychology matters; blues inspire calm, reds excitement. Common pitfalls include ignoring fabric stretch, leading to warped logos—always prototype. Eton's ODM services include these considerations, inspiring flawless integration.

For tools, advanced software like CorelDRAW offers embroidery-specific features. Collaboration tools such as Slack integrate with design apps for efficient workflows. Sourcing managers can use VR tools for 3D previews, ensuring logos look inspirational in real scenarios. Eton's team provides custom consultations, bridging tools with manufacturing reality.

In essence, effective design is about harmony—blending art with functionality to create apparel that motivates and endures.

Sourcing and Manufacturing Company Logo Clothing: A Step-by-Step Guide

- Evaluating Suppliers as a Clothing Manufacturer: Inspire confidence by choosing suppliers that match your ambition. Key criteria include MOQs starting at 500 units for scalability, production capacity to handle high-volume logo production, and global certifications like ISO for quality assurance. Spotlight on Asian factories in China and Bangladesh, where efficiency meets innovation. As Eton Garment Limited, we exemplify this with our vertically integrated garment factory, offering ethical logo garment sourcing that empowers fashion brands worldwide.

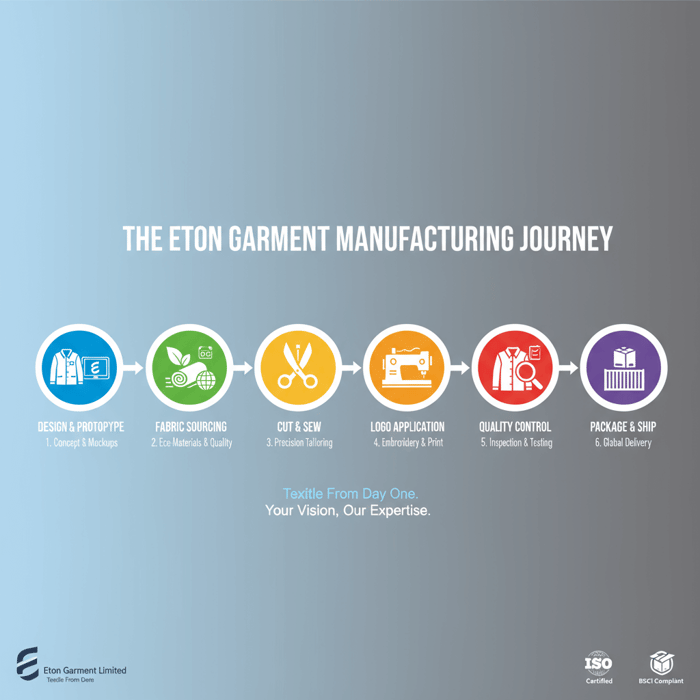

- The OEM/ODM Process: Transform ideas into reality through a seamless process. From fabric sourcing to logo application and rigorous quality control, timelines span 4-8 weeks for standard orders. Scalability shines in fashion volumes, allowing customization for US and European markets. Eton's expertise in OEM logo outerwear ensures every step—from initial sketches to final inspection—inspires excellence.

- Cost Breakdown and Budgeting: Empower your budget with transparent insights. Factors include $10-50 per unit for logo jackets, influenced by materials, complexity, and quantity. Hidden fees like shipping or duties can add up; optimize with bulk orders. Strategies for target markets involve negotiating terms for cost savings, making branded clothing manufacturer partnerships profitable.

- Navigating Challenges: Rise above obstacles with strategic foresight. Address supply chain disruptions through diversified sourcing, customs for US/Europe imports via compliant documentation, and ensure logo fidelity in mass production with advanced tech. Eton's resilient network helps sourcing managers overcome these, turning challenges into opportunities for growth.

Evaluating suppliers demands a holistic view. Beyond MOQs, assess lead times—Eton's facilities promise 4-6 weeks for production. Capacity is crucial; our network handles thousands of units daily. Certifications like BSCI ensure ethical practices, vital for sustainable company uniforms. In Asia, factories like ours offer cost advantages, with Bangladesh specializing in labor-intensive embroidery and China in tech fabrics. Sourcing managers should request audits and samples to verify claims.

The OEM/ODM process begins with design briefs, moving to prototyping where logos are tested on fabrics. Fabric sourcing involves selecting eco-materials for padded coats, followed by cutting, sewing, and logo integration. Quality control includes inspections at each stage, ensuring no defects. For scalability, Eton ramps up from 500 to 50,000 units, adapting to fast-fashion demands.

Cost breakdowns reveal material costs (40%), labor (30%), and overheads (20%). For embroidered logo jackets, embroidery adds $5-10 per unit. Budgeting tips: Order in bulk to drop prices to $15/unit; factor in 10-15% for contingencies. In Europe, VAT impacts budgeting, but Eton's expertise minimizes surprises.

Challenges like disruptions from global events require backup suppliers. Customs navigation involves HS codes for apparel; Eton provides guidance. Logo fidelity uses digital proofs to prevent issues in mass runs. Inspirational tip: View challenges as stepping stones to stronger partnerships.

Sustainability and Compliance in Logo Clothing Production

- Eco-Friendly Materials and Practices: Inspire a greener future by sourcing recycled polyester for padded coats with logos, reducing environmental impact while meeting EU REACH standards. Practices include water-efficient dyeing and low-waste cutting, transforming production into a force for good. Eton Garment Limited leads in these, offering sustainable company uniforms that empower brands to shine responsibly.

- Ethical Manufacturing Insights: Build trust through ethics, with audits like BSCI ensuring fair labor and safe conditions. As a vertically integrated factory, Eton's commitment to workers' rights and community support sets a standard in Asia clothing factory logos, inspiring sourcing managers to choose partners with integrity.

- Future-Proofing Your Sourcing: Embrace trends in the circular economy, like recyclable branded apparel, to enhance reputation. Innovations in bio-based fabrics and carbon-neutral processes ensure longevity. Eton's forward-thinking approach helps fashion brands stay ahead, fostering inspirational, sustainable growth.

Eco-materials like recycled down reduce landfill waste by 50% (Source: Ellen MacArthur Foundation, 2022). Practices involve closed-loop systems, recycling water and scraps. For logos, eco-inks in printing minimize chemicals. Eton's certifications like GOTS validate our green ethos.

Ethical insights emphasize transparency: Regular audits prevent exploitation, with living wages and training programs. Eton's Bangladesh and China bases comply with ILO standards, creating inspirational workplaces.

Future-proofing includes blockchain for traceability, ensuring ethical sourcing. Trends like upcycling logos on apparel promote circularity, boosting brand loyalty by 30% among eco-conscious consumers.

Case Studies: Success Stories from Fashion Brands Using Logo Clothing

- Global Partnerships: Draw inspiration from Eton Garment's collaborations. With Liverpool F.C., we created custom fan jackets featuring embroidered logos, blending team spirit with high-performance fabrics. For TFG Group, branded outerwear lines elevated their retail presence, showcasing our prowess in promotional branded jackets.

- ROI Analysis: Witness real metrics: 15-30% uplift in engagement from logo-integrated merchandise, with sales boosts in merchandise lines (Source: Nielsen, 2023). These figures empower sourcing managers to quantify the value of custom logo apparel.

- Lessons Learned: Actionable takeaways include early supplier involvement for seamless integration and focusing on quality for long-term ROI. Replicate wins by prioritizing ethical logo garment sourcing and innovation.

Liverpool F.C.'s jackets sold out rapidly, increasing fan engagement. TFG's lines saw 25% revenue growth. ROI often shows payback within months through loyalty.

Lessons: Test markets, iterate designs, and partner with experienced manufacturers like Eton for success.

Conclusion: Partnering for Inspirational Logo Clothing Solutions

As a premier clothing manufacturer, Eton Garment Limited invites sourcing managers to envision logo clothing that inspires and endures. With our expertise in OEM outerwear—from design to delivery—we solve your branding challenges with innovation and reliability. Contact us at Eton Garment Limited to start your custom project today, embodying our slogan: "Textile From Day One."

What is company logo clothing, and why is it essential for fashion brands?

Company logo clothing refers to customized apparel featuring a business's logo, such as embroidered jackets or printed tees, used for branding, uniforms, or promotions. It's essential for fashion brands as it boosts visibility, fosters team pride, and drives marketing ROI in competitive markets. In an era where brand identity is paramount, these pieces create emotional connections, turning wearers into advocates. For instance, a well-designed logo on outerwear can enhance recognition by 20%, according to Statista (2023). Sourcing managers benefit from partners like Eton Garment Limited, who ensure quality and scalability, making logo clothing a cornerstone of inspirational branding strategies.

How do I choose the best method for adding logos to clothing?

Select based on fabric and use: embroidery for durable outerwear like jackets, screen printing for colorful designs on cotton. Consult manufacturers early to test samples for quality and longevity. Consider factors like budget—embroidery is premium but lasting— and application, with heat transfer suiting prototypes. Eton's expertise guides this, offering samples to visualize outcomes, ensuring your choice aligns with inspirational goals.

What are the typical costs for manufacturing company logo clothing?

Costs range from $5-15 for basic t-shirts to $20-60 for technical jackets, depending on quantity, customization, and materials. Bulk OEM orders reduce per-unit pricing significantly. Additional factors include shipping and duties for US/Europe, but strategic budgeting with suppliers like Eton optimizes value.

Can company logo clothing be produced sustainably?

Yes, using eco-fabrics like recycled down for padded coats and certified factories ensures compliance. Look for suppliers with GOTS or Bluesign certifications to align with European sustainability demands. Eton's practices reduce impact while maintaining quality, inspiring eco-conscious branding.

How long does it take to source and produce custom logo apparel?

Typically 4-12 weeks, including design approval (1-2 weeks), production (3-6 weeks), and shipping. Efficient partners like Asian garment factories can accelerate for fast-fashion needs. Eton's streamlined process empowers timely delivery.

What should sourcing managers consider when selecting a logo clothing manufacturer?

Prioritize experience in OEM/ODM, compliance certifications, MOQs, and global shipping capabilities. Verify quality through samples and reviews from fashion clients. Eton's track record with brands like Forever 21 ensures reliable, inspirational partnerships.

Branded Apparel Market Report, 2023 (Statista)

Custom Clothing and Logo Integration Techniques, 2020 (Wikipedia - Embroidery)

Sustainable Manufacturing in Apparel, 2022 (Academic Paper on Green Textiles)

Top Competitor: Custom Logo Apparel Guide (Printful Blog, 2023)

Top Competitor: Branded Clothing Sourcing (Vistaprint Guide, 2022)

FAQs

Related Articles

Chinese dress shop vs China clothing manufacturer: how brands move from retail inspiration to scalable OEM/ODM

10 minute read

October 15th, 2025

Chinese dress shop vs China clothing manufacturer: how brands move from retail inspiration to scalable... more »

Screenprint T Shirts: A Fashion Brand’s Guide to Sourcing at Scale with a China Clothing Manufacturer

19 minute read

October 15th, 2025

Screenprint T Shirts: A Fashion Brand’s Guide to Sourcing at Scale with a China Clothing... more »

How Fashion Brands Can Buy Things from China: A Comprehensive Guide to Sourcing High-Quality Apparel and Maximizing Profits

10 minute read

October 15th, 2025

How Fashion Brands Can Buy Things from China: A Comprehensive Guide to Sourcing High-Quality Apparel... more »

Discover the World of Kinds of Hats: Essential Insights for Fashion Sourcing Managers Seeking Innovation and Excellence

8 minute read

October 15th, 2025

Discover the World of Kinds of Hats: Essential Insights for Fashion Sourcing Managers Seeking Innovation and... more »