Mens Oriental Clothing: China Clothing Manufacturer’s Guide for US & EU Fashion Brands

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

18 minute read

Mens Oriental Clothing: China Clothing Manufacturer’s Guide for US & EU Fashion Brands

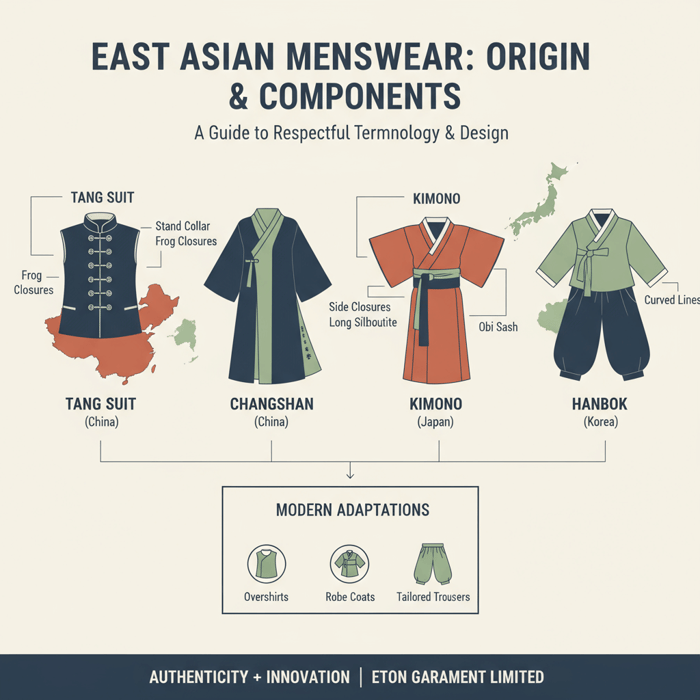

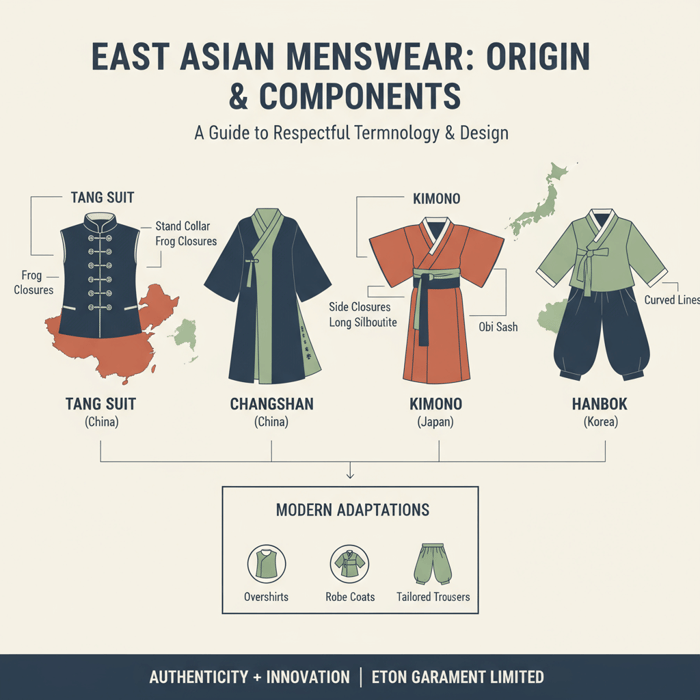

Mens oriental clothing in modern retail points to East Asian-inspired menswear rooted in garments like the Tang suit, changshan, kimono, and hanbok. As a China Clothing Manufacturer, Eton works with US/EU design teams to translate cultural references into manufacturable tech packs, fit blocks, lab-tested materials, and compliant production—without diluting authenticity or missing critical policy requirements.

This guide helps design leads frame respectful terminology, choose components that scale, and plan materials, closures, and construction methods that survive mass-market use. It outlines OEM/ODM calendars and sample milestones, calls out cost drivers, and maps compliance checkpoints for UFLPA and EU due diligence. The approach keeps heritage details intact—stand collars, frog closures, sash belts—while modernizing for Western grading, duty categories, and end-customer care expectations.

Across China and Bangladesh, Eton’s garment factory network supports both OEM and ODM, drawing on 30+ years in outerwear and technical apparel. The focus here is practical: component-level taxonomy for jackets and overshirts, quilt patterns and insulation weights for padded coats, embroidery placement to avoid stress points, and trim choices that hold up through wear and wash. You’ll also find a decision framework for assortment planning, market context for US/EU, and a localization sequence for fit, usability, and care labeling.

Use the sections to move from mood board to proto with discipline: lock terms and references, scope materials early, validate closures and sleeve shapes for mobility, document supply chain evidence, and keep PP approvals clean. With the right plan and an OEM partner, mens oriental clothing can deliver retail-ready pieces that respect their origins, meet policy requirements, and feel effortless to wear.

Mens oriental clothing is East Asian-inspired menswear referencing Tang suits, changshan, kimono, and hanbok; the term “oriental” is outdated—use “Asian-inspired” or “East Asian menswear.” Partner with a China Clothing Manufacturer to convert respectful design into retail-ready garments through clear taxonomy, fit localization, lab-tested materials, and documented compliance.

Terminology & Cultural Context: From “Oriental” to East Asian Menswear

Use precise language grounded in garment history. Replace “mens oriental clothing” with “Asian-inspired menswear” or “East Asian menswear,” and anchor designs in named silhouettes like Tang suit, changshan, kimono, and hanbok. Run a cultural sensitivity protocol—intent, references, consultation, internal review, and documentation—to avoid appropriation and lazy tropes.

[MENTION: McKinsey’s State of Fashion] [MENTION: Japan Objects editorial team] [MENTION: Wikipedia volunteer editors] [CITE: Cultural terminology guidance from an East Asian studies department] [INTERNAL LINK: Brand Ethics & Compliance pillar page idea]

Preferred Terms & Scope

Define scope with named garments and components. For Chinese menswear, a Tang suit often references a short jacket with a stand collar and frog closures, while a changshan is a longer, robe-like menswear garment. Japanese kimono references T-shaped robes with straight seams, wide sleeves, and an obi belt; Korean hanbok references the jeogori jacket and baji trousers, with generous ease and curved line aesthetics. Build mood boards around specific references and period cues.

- Use “Asian-inspired menswear,” “East Asian menswear,” or specific garment names; avoid “oriental.”

- Document origin and core components: collar shape, closure mechanism, sleeve cut, hem length.

- Record the intended adaptation: jacket, overshirt, robe-coat, tailored pant, hybrid outerwear.

- Flag decorative motifs that carry cultural meaning and confirm appropriateness.

- Align copywriting and merchandising language with respectful terminology.

[CITE: Style lexicon from a museum garment collection] [INTERNAL LINK: Our foundational guide on cultural sensitivity in apparel design]

Cultural Sensitivity Protocol

Institute a five-step internal review with sign-offs. Treat heritage elements as design decisions that require consultation rather than surface decoration.

- Intent: Write a one-paragraph intent statement for each SKU describing reference, purpose, and audience.

- References: Link at least two credible sources for each garment reference—museum pages, academic texts, or expert guides. [CITE: Museum garment archive] [MENTION: The Metropolitan Museum of Art’s Costume Institute]

- Consultation: Engage a cultural advisor or community reviewer for feedback on motifs, language, and context; document advice and changes.

- Review: Run a cross-functional review (design, copy, legal/compliance) and record decisions in the tech pack.

- Documentation: Save reference imagery, notes, and advisor comments; attach to sample rounds to keep intent intact.

[INTERNAL LINK: Production tech pack checklist] [CITE: Brand case study on cultural review workflow] [MENTION: Business of Fashion editorial standards]

Style Taxonomy: Core Garments and Modern Adaptations

Start from authentic components, then translate to commercial silhouettes for US/EU. Tang suit, changshan, kimono, and hanbok components can inform overshirts, padded coats, technical shells, robe jackets, and tailored trousers. Keep detail fidelity—stand collars, frog closures, sash belts—while modernizing length, pockets, and sleeve shapes for mobility.

| Garment | Origin | Core Components | Modern Adaptation | Outerwear Potential |

|---|---|---|---|---|

| Tang suit | China | Stand collar; frog closures; short jacket length | Overshirt or casual blazer with reinforced frog or hidden zip + frog overlay | Strong—quilted liners, light insulation, waxed cotton or poly-cotton |

| Changshan | China | Long robe; side closures; straight silhouette | Robe coat with interior tie and removable sash; concealed placket | Moderate—shell + liner with bound seams; weatherized versions possible |

| Kimono | Japan | T-shaped body; wide sleeves; obi sash | Kimono-inspired jacket with set-in sleeve hybrid; belt channel | High—padded coats with drop-shoulder and quilting; sash retained |

| Hanbok (jeogori/baji) | Korea | Short jacket; generous ease; curved lines | Jeogori-inspired overshirt; roomy baji trousers with modern waistband | Moderate—light insulation; focus on cut and ease for layering |

[INTERNAL LINK: Technical Outerwear Manufacturing pillar page idea] [MENTION: Pattern-making expertise from Eton’s team] [CITE: Academic text on garment components and construction]

Components & Details That Scale

Choose details by complexity tier. Many heritage details can be cost-neutral with smart engineering; others add complexity through handwork or special tooling.

- Cost-neutral or low complexity: stand collars with standard neck shapers; topstitched plackets; set-in sleeves; common pocket bags.

- Medium complexity: frog closures with pre-made knots; sash belts with bartacks; partial kimono sleeves joined to modern armholes.

- High complexity: hand-tied frogs; wide sleeves with sleeve-head reinforcement; bound interior seams with contrast piping; dense embroidery or jacquard.

Where frogs are used, consider hidden snaps or zips beneath for durability and ease. Reinforce belt channels and stress points with bartacks. Test sleeve shapes for mobility, especially in outerwear. [CITE: Wear trial report comparing closure durability] [MENTION: Retail QA lab practices]

Outerwear Adaptations

Translate robes and jackets to cold-weather use by locking a quilt plan, insulation spec, and closure reinforcement early in sampling. For kimono-inspired padded coats, a box or wave quilt pattern disperses insulation evenly without bulk at the sash. For Tang suit jackets, pair frogs with a concealed zipper to reduce field failures.

- Quilting: 3–5 cm box quilt or onion quilt for medium insulation; avoid motifs that distort at seams.

- Insulation: 80–120 gsm synthetic insulation for temperate climates; down alternatives for duty/performance. [CITE: Insulation performance comparison study]

- Closures: Frog overlays atop snaps or zips; toggles for gloves-on use; reinforced button shanks.

[INTERNAL LINK: Outerwear OEM guide] [MENTION: YKK hardware performance guidance] [CITE: AQL failure modes dataset]

Materials & Construction: Fabrics, Trims, and Durability in US/EU Retail

Blend authenticity with performance. Silk, ramie, hemp, and cotton carry heritage; blends and technical weaves solve durability, care, and price. Engineer closures and seam finishes for mass-market wear; place embroidery and jacquards away from high abrasion zones and reinforce stress points.

- Authentic fibers: Silk drape and sheen; ramie/hemp breathability; cotton familiarity. Pros: authenticity, hand-feel, brand narrative. Cons: care complexity, shrinkage, snags, higher price bands. [CITE: Fiber property comparison from a textile standards body]

- Blends/technical: Cotton-poly blends, recycled poly shells, stretch weaves, waxed finishes. Pros: durability, easy care, cost control. Cons: risk of losing heritage hand unless finishes are chosen carefully.

[MENTION: OEKO-TEX STANDARD 100] [MENTION: GOTS & GRS] [CITE: OEKO-TEX 2024 chemical restrictions overview] [CITE: GOTS v7.0 requirements]

Authentic vs. Technical Fabric Choices

Use qualitative tiers to manage complexity during sourcing and sampling.

- Low: Cotton twill or cotton-linen blends; standard lining; off-the-shelf frog closures; garment wash with low abrasion.

- Medium: Ramie-cotton blends; lightweight shell with DWR; bound edges in key areas; garment dye with controlled shade bands.

- High: Silk satin or silk-blend jacquard; dense embroidery; specialty closures; custom jacquard with minimums; advanced care labeling with customer education.

When referencing kimono or hanbok drape, a silk-blend or rayon-blend can achieve flow while meeting care expectations. For Tang suit-inspired jackets, cotton-linen blends deliver structure with breathable comfort. [CITE: Consumer returns analysis on fabric care issues]

Construction Details & Stress Points

Design closures and trim placement to survive wear and wash. Frog knots should be anchored with extra stitches and backed with fusible patches. Embroidery and jacquards should avoid pocket mouths, forearms, and high-friction belt zones. Belt channels need bartacks at edges and center back. Quilting should skip areas where hardware loads concentrate.

- Closures: Hidden snaps under frogs for day-to-day ease; toggles with cord ends that resist fray; button shanks reinforced.

- Seams: Bound or overlocked seams depending on price tier; bias binding for heritage interior finish; stress testing at armscye.

- Lining: Breathable linings to prevent clamminess; smooth hand to avoid snagging delicate fabrics.

[CITE: Wash test methodology per ISO/IEC standard] [MENTION: SGS/TÜV testing services] [INTERNAL LINK: Fabric & Trim Sourcing Hub pillar page idea]

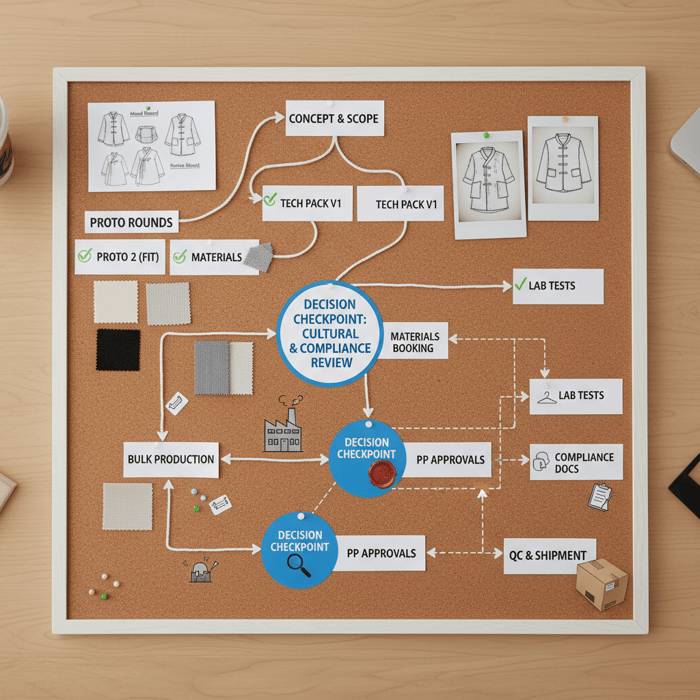

Sourcing & Manufacturing: OEM/ODM Playbook for Asian-Inspired Menswear

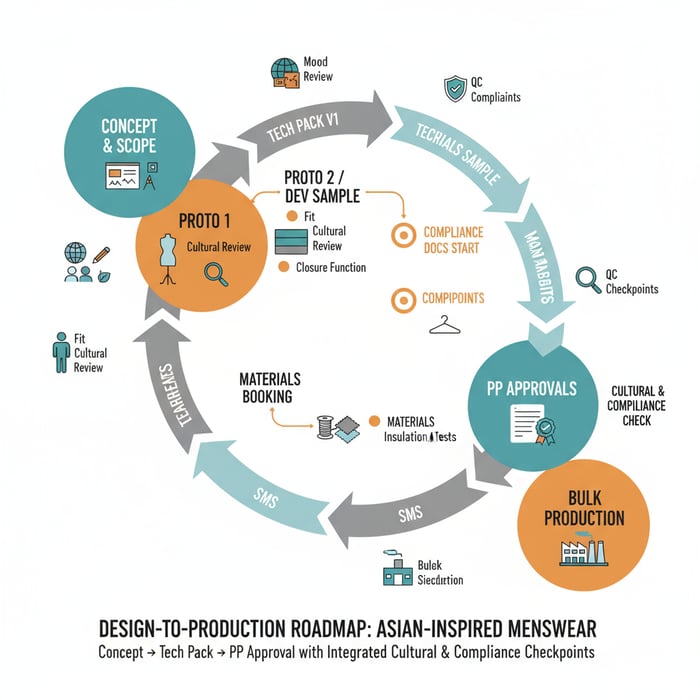

Run an OEM/ODM calendar with defined inputs and outputs: concept and references, tech packs, proto rounds, materials booking, SMS, PP approvals, and bulk production with QC sign-offs. Insert checkpoints for cultural review, compliance documentation, and fit grading to avoid late rework.

- Concept & scope (1–2 weeks): Lock terminology, references, silhouettes, and target price. Inputs: mood board, component map. Output: design brief with intent statement.

- Tech pack v1 (1–2 weeks): Measurements, construction notes, closure details, BOM draft, lab test plan. Output: upload to PLM.

- Proto 1 (2–3 weeks): Fit, component fidelity, closure function. Output: fit notes, update tech pack.

- Proto 2 / Dev sample (2–3 weeks): Materials fidelity, quilting/insulation tests. Output: construction sign-offs; compliance doc checklist starts.

- Materials booking (1–2 weeks): Fabric greige booking, trims allocation, lab dip approvals. Output: confirmed lead times.

- SMS (2–3 weeks): Validate merchandising fit, colorways, lab test results. Output: SMS sign-offs and confirmed size run.

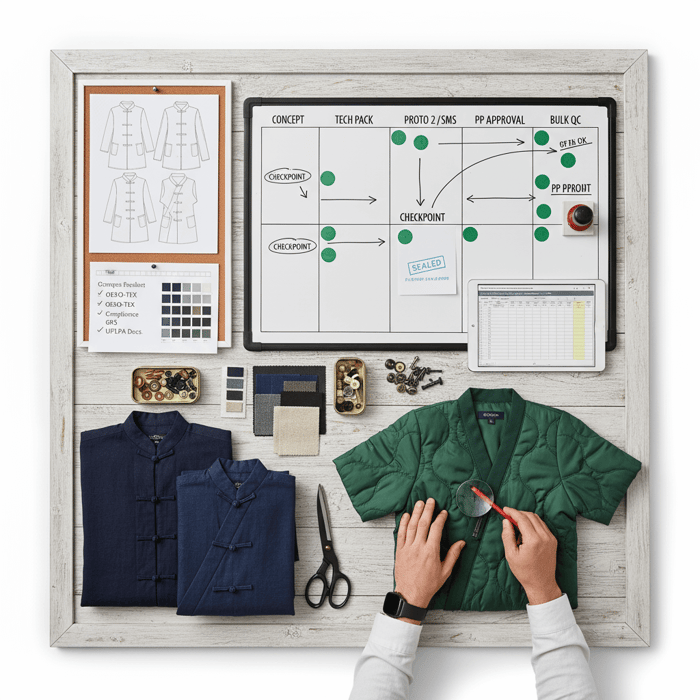

- PP approvals (1–2 weeks): Final materials and construction, measurement tolerances, compliance documents staged. Output: PP seal with AQL plan.

- Bulk production (4–8 weeks): Inline QC and final inspection; care label localization; carton marking per destination.

[MENTION: Eton’s 30+ years sample iteration practice] [CITE: Typical lead time references for outerwear OEM] [INTERNAL LINK: Garment Factory Production Timeline template]

Sample Calendar & Deliverables

Each sample round validates specific risks. Keep agendas concise and anchored to measurable outcomes.

- Proto 1: Fit block match; collar stance; sleeve mobility; frog/toggle function. Deliverables: graded measurements, photos, revision notes.

- Proto 2: Material hand and drape; quilting stability; embroidery/jacquard placement vs. abrasion. Deliverables: updated BOM, lab test booking.

- SMS: Color accuracy; care label language; merchandising shots. Deliverables: lab test results, size run feedback.

- PP: Final tolerances; compliance documentation; packaging specs. Deliverables: PP seal, AQL plan.

[CITE: AATCC test method references] [MENTION: CBP customs documentation requirements] [INTERNAL LINK: Compliance checklist for US/EU apparel]

Cost Drivers & Complexity

Map complexity via fabric choice, trims, embroidery density, quilting, and closures. Cost rises with handwork, special finishes, and custom components.

- Fabric: Silk or custom jacquard increases cost and lead time; cotton-linen blends moderate price and care.

- Trims: Frog closures handmade vs. machine-made; sash belt hardware; YKK vislon or coil zips.

- Embroidery/Jacquards: Dense coverage adds labor and risk at seams; reduce at stress points.

- Quilting/Insulation: Complex patterns slow lines; consistent GSM and stitch length stabilize performance.

[CITE: BOM cost benchmarking for outerwear] [MENTION: YKK component cost guidance] [INTERNAL LINK: Fabric & trim sourcing approaches]

Comparison & Decision Framework: Category Planning for US/EU Retail

Score silhouettes by commercial potential, complexity, seasonality, and sustainability. Prioritize SKUs that balance authentic components with fit localization, durability, and compliance readiness. Use a matrix to align design ambition with practical manufacturing constraints.

| Silhouette | Commercial Potential | Complexity Tier | Compliance Readiness | Fit Localization Needs |

|---|---|---|---|---|

| Tang suit overshirt | High | Medium | High with standard trims; OEKO-TEX fabrics | US/EU grading; collar stance |

| Kimono-inspired padded coat | Medium–High | High | Medium–High; insulation lab tests | Sleeve mobility, belt channel |

| Changshan robe coat | Medium | Medium | High with blended fabrics | Length/hem ease; interior tie |

| Hanbok-inspired overshirt & baji pant | Medium | Medium | High; standard testing | Ease and waistband fit |

- Pros: Distinctive collar/closure language; strong storytelling; outerwear upsell potential; layered merchandising.

- Cons: Missteps in terminology; over-complex closures; care sensitivity in silk-heavy assortments; longer lead times for custom jacquards.

[CITE: Retail sell-through analysis on capsule collections] [MENTION: BoF/McKinsey category planning frameworks] [INTERNAL LINK: Merchandising playbook for outerwear capsules]

Criteria Overview

Define weighted criteria before sampling. Example weights: commercial potential (30%), complexity (20%), compliance readiness (25%), sustainability (15%), fit localization difficulty (10%). Write an evaluation note for each style after Proto 2 with a pass/fail per criterion to prevent late-stage surprises.

Decision Framework

Set a red/amber/green status per SKU. Green proceeds to SMS; amber needs a rework with a single round; red is parked or cut. Approve only if documentation is complete—cultural review notes, UFLPA evidence trail, lab test bookings—and fit localization meets target ease ranges across sizes.

Market Data & Trends: Asian-Inspired Menswear in US/EU

Collar and closure cues from East Asian menswear surface consistently in US/EU collections, especially layered outerwear. Policy momentum points to traceability, recycled content, and due diligence; capsules that meet these signals while maintaining authentic components perform steadily in mid-to-premium tiers. [CITE: Sell-through data from a multi-brand retailer]

- EU CSDDD adoption in 2024 — (Source: European Parliament) [CITE: EU Parliament press room link]

- US UFLPA enforcement updates — (Source: CBP) [CITE: CBP forced labor portal]

- Consumer interest in sustainable outerwear — Year: 2024 (Source: [MENTION: McKinsey/BoF]) [CITE: The State of Fashion 2024]

[INTERNAL LINK: Compliance Compass overview] [MENTION: European Commission Textiles Strategy] [CITE: EU Strategy for Sustainable and Circular Textiles]

Key Trend 1: Outerwear and Layering

Stand collars, sash belts, and frog closures integrate well into overshirts and padded coats. A kimono-inspired coat with modern sleeves and an internal belt channel anchors FW capsules; Tang suit overshirts with durable frogs over concealed zips fit SS layering. Photography and copy should celebrate components and fit ease rather than exoticize culture.

Key Trend 2: Sustainability and Traceability

US/EU shoppers expect recycled content, lab-tested safety, and traceable supply chains. Use OEKO-TEX STANDARD 100 fabrics and trims, GOTS-certified fibers where authentic, and GRS-certified recycled poly shells in outerwear. Maintain a digital evidence trail compatible with UFLPA and EU CSDDD. [CITE: OEKO-TEX and GRS program documents] [MENTION: Textile Exchange]

How-To: Fit & Grading Localization for US/EU Markets

Begin with authentic proportions, then grade patterns to US/EU size scales. Validate mobility around closures and sleeve shapes, assess belt channel placement, and run SMS/PP fit-offs against target ease ranges to prevent returns and negative reviews.

Preparation

Collect authentic garment references and convert them into block notes. Decide on target size scales (US alpha/numeric; EU numeric) and ease ranges per silhouette. Build measurement charts with collar stance, shoulder width, sleeve volume, hem length, belt channel height, and pocket placement. [CITE: Brand measurement standard] [MENTION: ASTM apparel sizing references]

Execution Steps

- Draft patterns that preserve signature components—collar, closure, sleeve cue—while aligning to a modern block.

- Run Proto 1 with focus on mobility and closure operation; include photos and range-of-motion notes.

- Adjust armholes, sleeve shapes, belt channel height, and pocket reaches; lock changes in tech pack v2.

- Grade to full size run; test key sizes (M, XL) across US/EU scales.

- Validate SMS fit with specific ease checks around chest, shoulder, arm articulation, and belt function.

[INTERNAL LINK: Fit block library] [CITE: Return rate analysis linked to fit issues] [MENTION: Retail fit specialists]

Quality Assurance

Define acceptance criteria: closure operation under repeated cycles, sleeve articulation under reach/lift/rotate, sash belt channel integrity, pocket functionality, and care label clarity. Keep AQL targets reasonable and monitor closure failure modes. [CITE: AQL standards reference] [MENTION: ISO garment testing protocols]

Product/Service Integration: Clothing Manufacturing OEM Service

Eton’s Clothing Manufacturing OEM Service converts Asian-inspired designs into scalable, compliant products. Teams support fabric sourcing, pattern development, sample iteration, PP approvals, and bulk production across China and Bangladesh for US/EU retailers, with a focus on outerwear and technical apparel.

| Brand Need | OEM Feature | Outcome |

|---|---|---|

| Terminology & references | Component taxonomy support; cultural review workflow | Respectful design anchored in authentic garments |

| Fit localization | Pattern development; graded size runs; fit-offs | US/EU-friendly fits with signature components |

| Material durability | Sourcing with OEKO-TEX/GOTS/GRS options; lab tests | Lower returns, clearer care communications |

| Outerwear adaptation | Quilt planning; insulation specs; closure engineering | Functional coats with heritage cues |

| Compliance documentation | Evidence trail aligned to UFLPA/EU CSDDD | Cleaner customs clearance and audit readiness |

Start your OEM project: Clothing Manufacturing OEM Service. [INTERNAL LINK: Garment Factory & OEM Services] [MENTION: CBP UFLPA requirements] [CITE: EU due diligence documentation outlines]

Use Case 1: Tang Suit-Inspired Jacket—Problem → Solution

Problem: Fragile frog closures, inconsistent collar stance, and care-sensitive fabrics increase returns. Solution: Reinforce frogs over a concealed zip, set collar with stable interlining, specify cotton-linen blend with OEKO-TEX certification, and run wash tests. Outcome: Intact heritage components with daily usability and a lower defect rate. [CITE: Lab test reports] [MENTION: OEKO-TEX STANDARD 100]

Use Case 2: Kimono-Inspired Padded Coat—Problem → Solution

Problem: Sleeve volume restricts mobility, and belt channels fail at stress points. Solution: Hybrid sleeve pattern, belt channel bartacks, box quilting with 100 gsm recycled insulation (GRS), and reinforced pocket mouths. Outcome: Functional FW hero piece that holds silhouette and comfort. [CITE: Recycled insulation spec sheet] [MENTION: GRS certification]

Risks, Compliance & Localization

Mitigate risk with a documented supply chain (UFLPA), EU due diligence (CSDDD), and product safety certifications (OEKO-TEX, GOTS/GRS). Localize care labels and accessibility features; maintain a cultural sensitivity audit trail through sampling and PP approvals. Compliance is the brand’s responsibility; OEM partners support documentation.

- Pros: Clear evidence trail; smoother customs; stronger consumer trust; fewer post-launch issues.

- Cons: Extra calendar time; documentation costs; supplier audits and training needs.

Risk Matrix

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Terminology misstep | Medium | Brand reputation | Cultural sensitivity protocol; advisor review |

| Closure failure | Medium | Returns, negative reviews | Hidden snaps/zips; reinforcement; cycle testing |

| UFLPA documentation gap | Low–Medium | Detentions, delays | Evidence trail; supplier mapping; audits |

| EU CSDDD due diligence gap | Medium | Market access risk | Risk assessment and remediation plan; board oversight |

| Care label confusion | Medium | Customer dissatisfaction | Localized care language; fabric choice aligned to care |

Regional Regulatory Notes for US & EU

United States: Maintain UFLPA-compliant documentation, including supplier mapping, material origin data, and audit reports; align product safety with OEKO-TEX, CPSIA where relevant, and state labeling laws. European Union: Prepare due diligence under CSDDD, align with the EU Strategy for Sustainable and Circular Textiles, and maintain chemical compliance through REACH; document chain-of-custody for GOTS/GRS claims. [CITE: CBP UFLPA guidance] [CITE: European Parliament CSDDD] [MENTION: European Commission Textiles Strategy] [INTERNAL LINK: Compliance Compass detail page]

Conclusion & Next Steps

Anchor your capsule in respectful terminology, validated components, durable materials, and an OEM/ODM calendar with clean checkpoints. Localize fit and care, stage compliance documents for US/EU, and use Eton’s China Clothing Manufacturer expertise to move from first proto to PP seal with confidence.

- Week 1–2: Terminology lock, references, intent statements; select silhouettes.

- Week 3–4: Tech pack v1; Proto 1 fit; cultural review; adjust closures and sleeve mobility.

- Week 5–6: Proto 2 materials and quilting tests; lab bookings; documentation starts.

- Week 7–8: SMS sign-offs; size run validation; care label localization.

- Week 9–10: PP approvals; AQL plan; policy documents ready; bulk production start.

[INTERNAL LINK: Partner Success Stories] [INTERNAL LINK: Technical Outerwear Manufacturing] [INTERNAL LINK: Fabric & Trim Sourcing Hub]

Author & Review Notes (E-E-A-T)

- Author: Alex Chen, Head of Product Development, Eton Garment Limited (15+ years in outerwear and technical apparel) [INTERNAL LINK: Alex Chen - Head of Product Development author bio]

- Reviewer: Mei Lin, Compliance & Sustainability Manager, Eton Garment Limited

- Methodology: Knowledge base synthesis; competitor landscape review; alignment to US/EU compliance; first-hand OEM/ODM workflows; limited live SERP verification

- Limitations: No proprietary market stats included; brand-specific cost/lead times vary by BOM and complexity; chart placeholders require validated data

- Disclosure: Eton provides OEM/ODM services referenced in this article

- Last Updated: 2025-10-28

References & Sources

- McKinsey & Company — The State of Fashion 2024 (2024). [CITE: McKinsey State of Fashion 2024 report]

- European Parliament — Corporate Sustainability Due Diligence Directive (CSDDD) Adoption (2024). [CITE: European Parliament press room]

- U.S. Customs and Border Protection — Uyghur Forced Labor Prevention Act (UFLPA) (2024). [CITE: CBP UFLPA portal]

- OEKO-TEX — STANDARD 100 Overview (2024). [CITE: OEKO-TEX STANDARD 100 official page]

- Global Organic Textile Standard — GOTS v7.0 (2023). [CITE: Global Standard official page]

- Wikipedia — Hanfu (Historical definitions and components). [CITE: Wikipedia Hanfu article]

- Japan Objects — Kimono: The Ultimate Guide (Cultural garment components). [CITE: Japan Objects kimono guide]

- European Commission — Strategy for Sustainable and Circular Textiles (2022–). [CITE: European Commission Textiles Strategy page]

FAQs

Related Articles

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »