Make T‑Shirt No Minimum: A China Clothing Manufacturer’s Guide for Fashion Brands

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 15th, 2025

23 minute read

Make T‑Shirt No Minimum: A China Clothing Manufacturer’s Guide for Fashion Brands

What “Make T Shirt No Minimum” Really Means for Fashion Brands

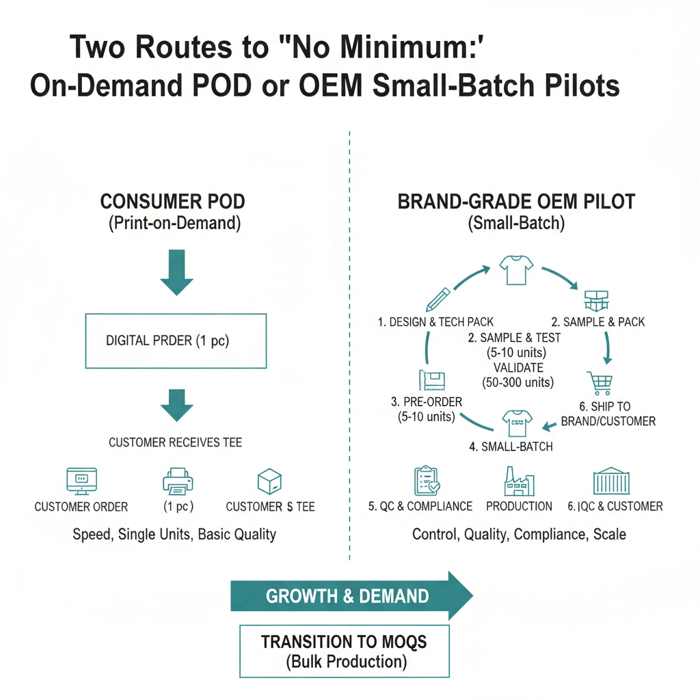

Answer-first summary: “No minimum” differs for consumers vs brands. POD enables single-unit fulfillment; OEM/ODM can offer zero-MOQ pilots through samples and pre-orders. Success requires quality standards, compliance, and a plan to transition to MOQs as demand grows.

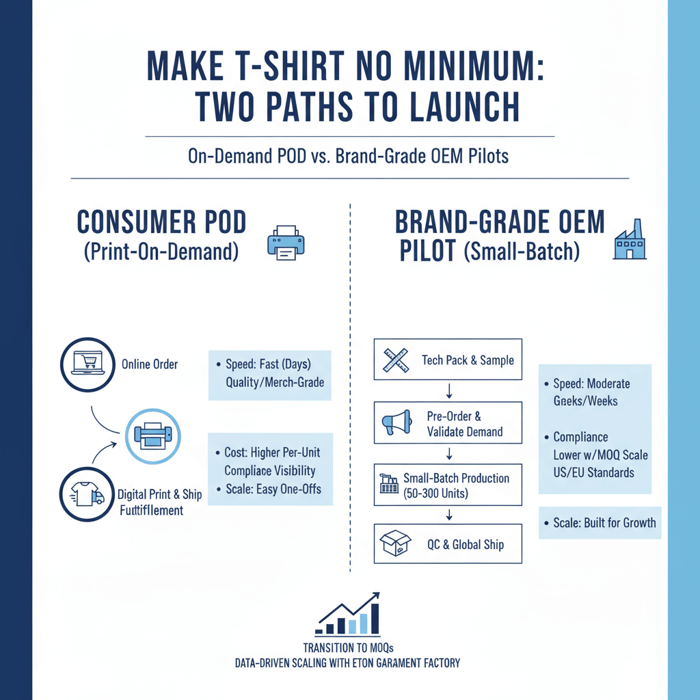

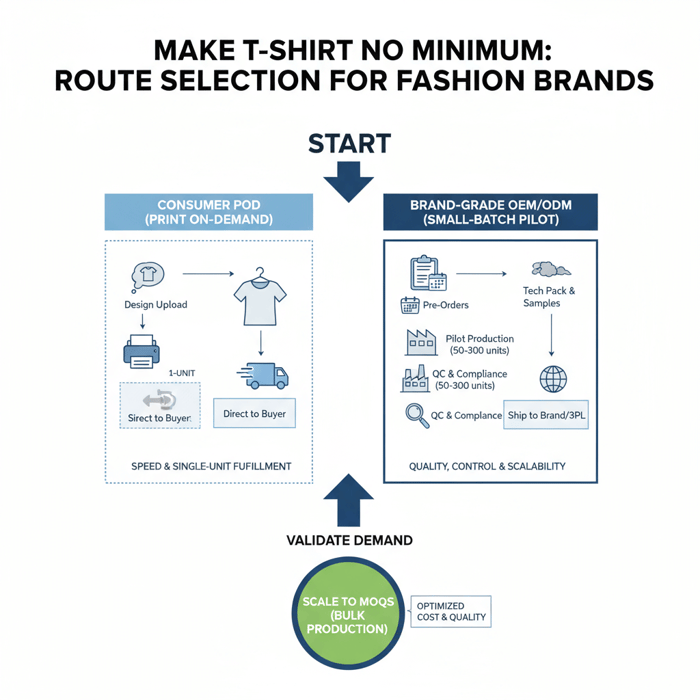

When you search “make t shirt no minimum,” the result often points to consumer print-on-demand storefronts that ship one shirt at a time. For fashion brands, the phrase “make t shirt no minimum” translates into a launch strategy rather than a perpetual production model. The commercial path involves two routes: on-demand fulfillment with POD and brand-grade manufacturing through OEM/ODM pilots. As a China Clothing Manufacturer, we’ve helped brands interpret “no minimum” the right way—lower risk at the start, uncompromised standards, and a clear roadmap to scale.

In consumer POD, the platform accepts a single order, prints digitally, and ships direct to the buyer. Quality is adequate for merch, community tees, or testing, yet it rarely reaches the level of full brand-grade garments with tailored fits, engineered fabric, and regulated chemical compliance. For professional labels, the goal is to “make t shirt no minimum” as a pilot, then move to controlled MOQs once the design, price point, and fit win real demand.

For brand-grade small batches, zero-MOQ pilots rely on pre-orders and samples to validate demand without holding inventory. You can open pre-orders with photography and tech pack renders, secure deposits, and produce a small batch—sometimes under 100 units—through an OEM partner. This approach preserves retail-grade fit, trims, labeling, and color standards while limiting upfront inventory risk.

[MENTION: AAFA overview of industry standards] helps frame expectations around labeling, testing, and due diligence. “Clarify ‘zero MOQ’ feasibility and typical small-batch ranges—source from industry reports or manufacturer disclosures” can further quantify what “no minimum” looks like in practice: pilot runs often range from 50–300 units, with some factories agreeing to fewer pieces if the project transitions to MOQs after demand proves out. To understand how Eton supports pilot runs and full-scale programs, see Eton Garment Factory Overview.

Consumer POD vs Brand-Grade Manufacturing

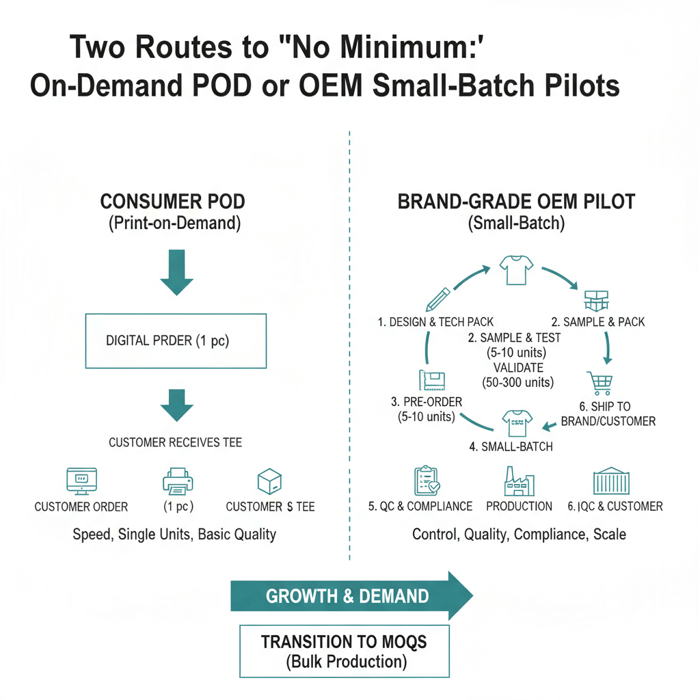

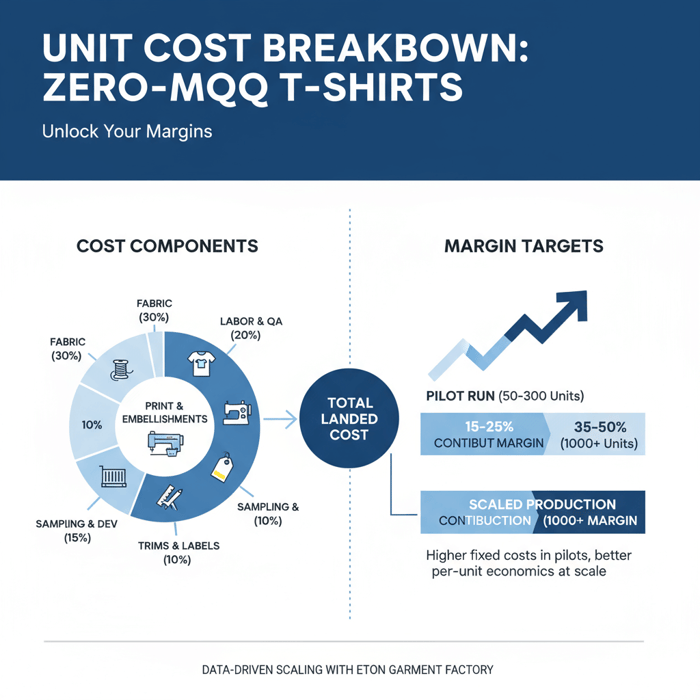

Consumer POD turns “make t shirt no minimum” into an immediate solution: single-piece orders, published prices, and turnkey integrations with Shopify or marketplace platforms. POD excels at speed to market and cash-flow simplicity. You can load artwork, pick a blank, set price, and go live—no factory onboarding required.

Brand-grade OEM/ODM manufacturing demands more preparation. You build a tech pack, choose fabrics, specify print methods, trims, labeling, and compliance requirements. You sample, test fit and wash, and lock color standards. The payoff is control and reliability: the fit is consistent, the fabric meets your performance goals, and print durability aligns with retail-grade expectations. When your brand needs repeatability, regulated labeling, and chemical safety aligned with US/EU rules, this route preserves standards while enabling scale.

In short, “make t shirt no minimum” starts with POD for hyper-fast pilots or with OEM small-batch pilots for brand-grade launches. When your shoppers respond—units sell through and returns remain low—you graduate to MOQs, negotiate better fabric pricing, and stabilize costs for long-term growth.

How Pre-Orders Enable Zero-MOQ Launches

Pre-orders bridge the gap between idea and inventory. You publish the design, fabric specs, and size chart; collect deposits or full payments; and only produce what’s sold plus a small buffer. This approach makes “make t shirt no minimum” feasible for brands because you avoid large inventory commitments.

As a China Clothing Manufacturer trained in pilot workflows, we encourage brands to stage pre-orders with clarity. Use strong product visuals and size charts based on your sample. Outline expected shipping windows and return policies. Share compliance signals so customers trust the quality. The objective is to prove demand while gathering feedback on fit, fabric hand-feel, and print execution.

Pre-orders also tighten operations. Forecast numbers inform factory scheduling and fabric reservations. Deposits improve working capital. Customers become part of the journey, giving insight that shapes your scaled production. This is how brands “make t shirt no minimum” responsibly while building the foundation for MOQs.

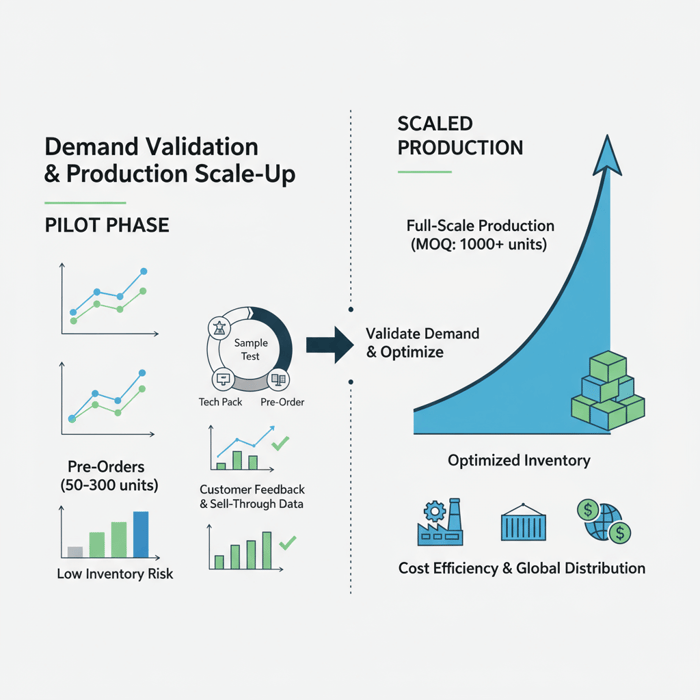

When “No Minimum” Transitions to MOQs

Once your pilot sells through and returns sit within acceptable limits, the transition to MOQs improves margins and repeatability. MOQs unlock volume pricing on fabric and trims, stabilize dye lots, and streamline QA. Larger runs distribute fixed costs—sampling, lab testing, and compliance—across more units, increasing contribution margins.

From our experience, the decision gate involves three metrics: sell-through rate, defect rate, and customer feedback on fit and feel. When sell-through surpasses your threshold and the feedback validates the product, “make t shirt no minimum” has served its purpose. Now you can negotiate MOQs and secure consistent supply through an audited partner. We’ve guided brands through pilot runs, wash testing, and MOQ negotiations, aligning fit blocks and print methods with the intended scale. “[E-E-A-T NOTE: Use first-person experience from Eton on pilot runs and MOQ negotiations.]”

Make T Shirt No Minimum: POD vs OEM/ODM—Quality, Cost, Compliance

Answer-first summary: Choose POD for speed and single-unit fulfillment; choose OEM/ODM for brand-grade quality, control, and compliance. Many brands start with POD pilots, then move to OEM small runs once demand and standards are established.

Speed matters when you’re testing, yet standards define lasting value. “Make t shirt no minimum” with POD suits drops, fandom merch, and low-risk market tests. OEM/ODM suits brands that must protect labeling, chemical safety, fit consistency, and traceability.

[MENTION: McKinsey State of Fashion report referencing on-demand and agility trends] supports the idea that agile launches unlock growth while reducing inventory risk. “Lead time benchmarks for POD vs OEM small batches—industry sources or provider pages” can help set expectations for planning and customer communications. For details about OEM vs ODM responsibilities, see “[INTERNAL LINK: OEM vs ODM Services (description) -> Internal services page describing OEM/ODM distinctions]”.

| Criteria | POD (On-Demand) | OEM/ODM (Small-Batch) |

|---|---|---|

| Quality | Good for merch; limited fabric and fit control | Retail-grade fit blocks, fabric control, print durability |

| Methods | DTG, DTF, embroidery on pre-defined blanks | Full method choice—screen, DTG/DTF, discharge, flocking, embellishments |

| Branding | Limited trims/labels; basic tear-away tags | Custom neck labels, trims, pack, hangtags, barcodes |

| Compliance | Consumer-grade; limited visibility | US/EU labeling, RSL, audits, traceability, lab testing |

| Unit Cost | Higher per-unit; no inventory risk | Lower per-unit with MOQs; small-batch pilots carry setup costs |

| Scale | Easy for one-offs | Built for growth—repeatability, fabric reservations, QA systems |

Quality & Methods: DTG, Screen, DTF, Embellishments

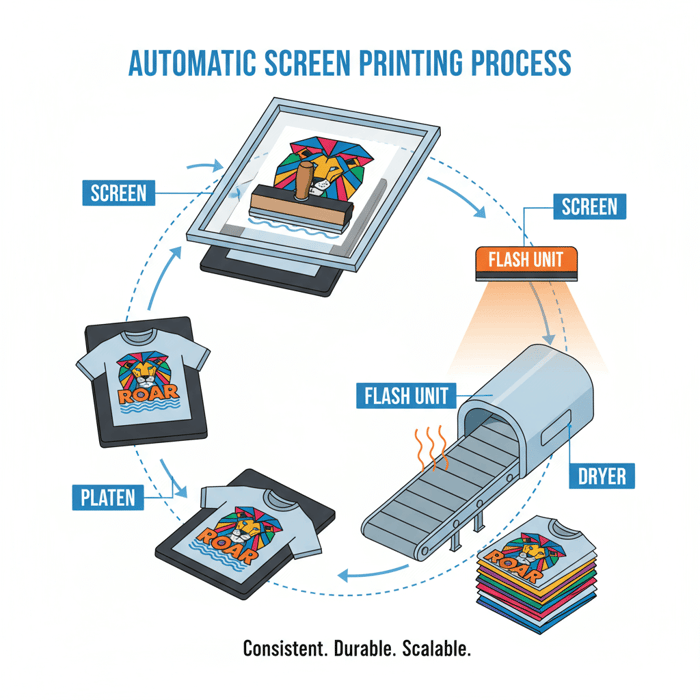

Method choice shapes hand-feel, color saturation, durability, and cost. DTG excels at multi-color art with gradients and photo-level detail. DTF improves stretch and color vibrancy on certain fabrics. Screen printing offers unmatched opacity and longevity for spot colors, especially on dark tees. Specialty methods—discharge for soft-hand on dyed garments or puff ink for tactile interest—create dimension at a higher setup cost.

To “make t shirt no minimum,” pilot with the method that represents the scaled product. If your collection will use screen printing, sample in screen rather than DTG—even if unit costs are higher for the pilot—so your test accurately reflects the final quality. “[CITE: Method performance/hand-feel differences by print technology—technical sources]” can guide selection based on your fabric blend, GSM, and color requirements. In OEM/ODM programs, you can spec accessories like woven labels, neck tapes, care labels, hangtags, and branded packaging to build a retail-grade experience.

Compliance & Traceability: US/EU Labeling, Chemicals, Labor

Professional brands must meet regulations even when volumes are low. Label content rules (fiber, country of origin, care instructions) dictate what appears on the neck label, care label, or exterior tags. Chemical compliance requires adherence to restricted substance lists under US/EU frameworks, and labor compliance involves audited factories and documented due diligence.

“Make t shirt no minimum” does not exempt you from responsibility. Use certified partners and documented QA. [MENTION: OEKO-TEX Standard 100, WRAP, amfori BSCI, EU REACH] are the signals buyers and marketplaces expect. “[CITE: US FTC apparel labeling rules; EU REACH chemical restrictions; children’s apparel CPSIA where applicable]” should be built into your compliance checklist. Eton leverages process discipline across facilities in China and Bangladesh—securing consistency in fabric sourcing, testing, labeling, and ethical manufacturing aligned to international expectations.

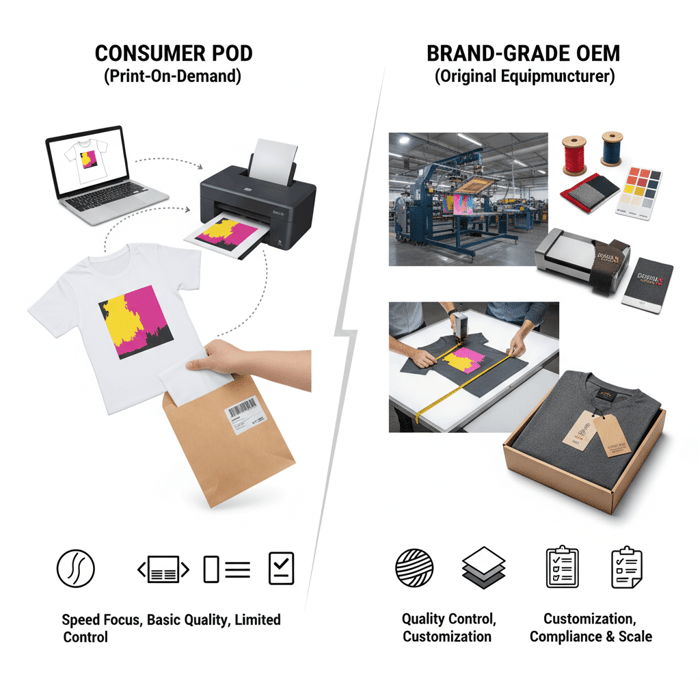

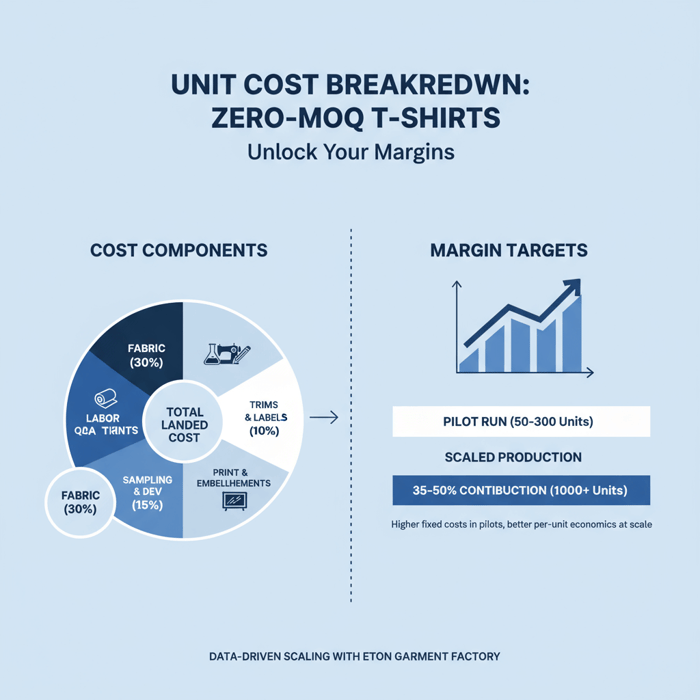

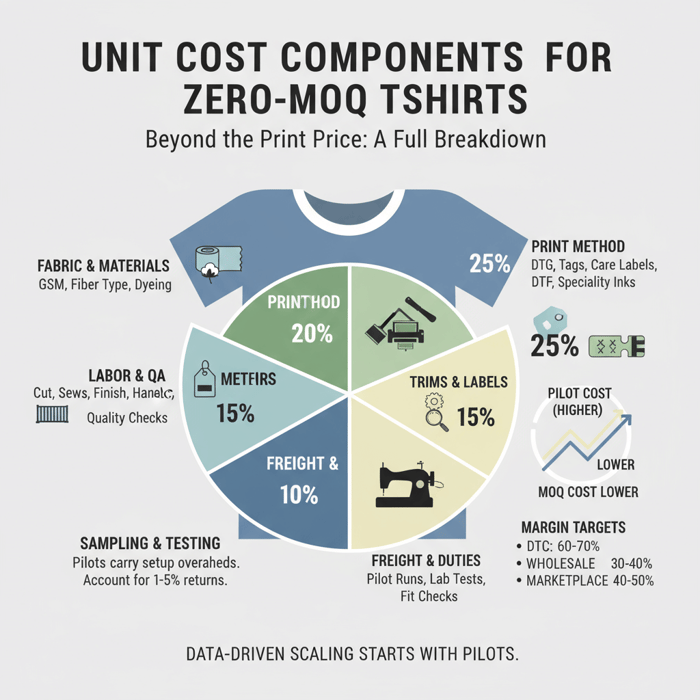

Unit Economics: Cost Drivers and Margin Considerations

Your margin depends on more than the print price. Fabric cost varies by GSM, fiber composition, and dye/finish. Print costs change by method, colors, and coverage. Trims, labels, and packaging add value and cost. Labor includes cutting, sewing, finishing, and QC. Logistics involves freight, tariffs/duties, and delivery. Returns and defects must be considered in pilot economics.

To launch “make t shirt no minimum” responsibly, price with a view of landed cost—including compliance fees, testing, and buffers. “[CITE: Example cost components—fabric, print, trims, labor, freight, duties; source guidelines from trade bodies or research]” can provide a baseline. As you shift from POD to OEM pilots, your unit cost may rise first because pilots carry setup overheads. The payoff arrives with MOQs, where negotiated fabric and streamlined processes lower per-unit costs. Track contribution margins by channel (DTC vs wholesale), then adjust pricing strategies accordingly.

Cost & Profit Model for Zero-MOQ T‑Shirts

Answer-first summary: Build margins around realistic unit costs, sampling and testing fees, freight/duties, and potential returns. Use pre-orders to de-risk and target contribution margins appropriate for your channel (DTC, wholesale, marketplace).

To “make t shirt no minimum” with confidence, build a simple calculator that models inputs and outputs. Include fabric GSM, fiber type (cotton, organic cotton, cotton/poly), print method, trim set, label requirements, labor steps, and quality checks. Then add freight, duties, and returns assumptions to reach a landed cost. The final margin should reflect your channel strategy and brand positioning.

Use “[CITE: Duty/tariff references (US CBP), Incoterms definitions (ICC)]” to determine landed cost under FOB, CIF, or DDP structures. When working with a China Clothing Manufacturer, clarify Incoterms early in the process to avoid surprises. For more detail on material selection and sourcing trade-offs that impact cost, see “[INTERNAL LINK: Fabric Sourcing & Cost Drivers -> Internal page describing fabric sourcing]”.

| Inputs | Description | Typical Range |

|---|---|---|

| Fabric GSM | Weight and drape—impacts feel and durability | 140–220 GSM |

| Fiber Composition | 100% cotton, organic cotton, cotton/poly blends | Varies by spec |

| Print Method | DTG, DTF, screen, discharge, specialty inks | Method-dependent |

| Trims & Labels | Neck label, care label, hangtag, packaging | Basic to premium |

| Labor & QA | Cut, sew, finish, measurement check, print QA | Setup + unit cost |

| Freight | Air vs ocean; courier for pilots | Service-dependent |

| Duties/Tariffs | HS code classification and country of origin | CBP/EU schedules |

| Returns/Defects Assumptions | Expected percentages in pilot | 1–5% (example) |

Key Inputs: Fabric, Print Method, Trims/Labels

Fabric sets the foundation. High-GSM cotton offers structure and durability, while lighter GSM serves a drapey, summer-weight feel. Organic cotton supports sustainability claims and marketing. Cotton/poly blends improve wrinkle recovery and sometimes enhance print appearance. Your “make t shirt no minimum” pilot should mirror the fabric planned for scale to ensure authentic feedback.

Print method affects cost and feel. DTG suits complex art with short runs. Screen leads on coverage and saturation for spot colors but carries setup costs. Trims and labels define brand identity and compliance. Include a proper care label, fiber content, and country-of-origin statement alongside neck branding that matches your retail vision.

Freight, Duties, and Returns Handling

Freight can shift margins quickly, especially in pilots. Air courier speeds delivery but adds cost—use for urgency or limited volumes. Ocean reduces cost at scale; it’s impractical for micro-launches unless you consolidate. Duties and tariffs depend on HS codes and origin. Model them upfront so your “make t shirt no minimum” price reflects total landed cost. “[CITE: Duty/tariff references (US CBP), Incoterms definitions (ICC)]” will ensure accurate assumptions by destination market.

Plan for returns and defects in pilot economics. Offer clear sizing charts, care instructions, and realistic delivery windows. A robust QA plan reduces defects. Start small, track customer feedback carefully, and fold the learning into your scaled run.

Pricing Strategies: DTC vs Wholesale

DTC pricing targets higher contribution margins to cover marketing costs and returns. Wholesale pricing supports retailer markups and shared risk. For “make t shirt no minimum,” pilot DTC to learn demand and refine costs. As you progress to MOQs, negotiate input costs and rebalance margins for wholesale partners if that’s your route.

Keep a tight margin model. Assign fixed costs to pilots—sampling, testing, compliance—then re-evaluate at scale when those fixed costs dilute across more units. “[E-E-A-T NOTE: Include Eton’s pricing considerations seen in pilot programs.]”

Product/Service Integration: Clothing Manufacturing OEM Service

Answer-first summary: Eton’s OEM service supports zero-MOQ pilots through sampling, pre-orders, and small-batch production—then scales with consistent quality and compliance across China and Bangladesh facilities.

Eton is a China Clothing Manufacturer and garment factory with 30+ years producing brand-grade apparel. Our Clothing Manufacturing OEM Service is built around end-to-end rigor: design support, tech packs, sampling, testing, compliance, production, and QC. We help brands “make t shirt no minimum” through pilots—then scale efficiently into MOQs once demand is proven. Explore “Clothing Manufacturing OEM Service” and see how this integrates with your strategy.

We operate audited facilities across China and Bangladesh, offering fabric sourcing options, lab tests aligned with US/EU standards, and ethical manufacturing credentials. Our workflow delivers repeatability and transparency from development to delivery, giving brands the confidence to pilot and scale.

| Brand Need | OEM Feature | Outcome |

|---|---|---|

| Zero-MOQ Pilot | Sampling, pre-order support, small-batch production | Test demand with brand-grade standards |

| Fabric Control | Fabric sourcing, GSM/finish alignment, lab testing | Consistent feel, shrinkage control, colorfastness |

| Print Quality | DTG, DTF, screen, discharge, specialty inks | Correct hand-feel, durability, color saturation |

| Compliance | Labeling, RSL management, audits | US/EU readiness and traceability |

| Scale-Up | MOQ planning, fabric reservation, QA systems | Stable costs and reliable replenishment |

Use Case 1: Capsule Collection—Design to Delivery

Capsule collections benefit from controlled fit and fabric story. “Make t shirt no minimum” with a curated range of colors, fabric weights, and prints—then use pre-orders to validate your assortment. Eton collaborates on tech packs, lab tests, and pilot runs that mirror the quality you’ll carry into a full season. We ensure labeling and care instructions align to US/EU rules, and we document specs so the capsule scales easily into MOQs.

Use Case 2: Influencer/Microbrand Drops—Rapid Validation

Influencer drops thrive on speed and authenticity. POD may suit a first test if the design changes frequently. For brand-grade drops, an OEM pilot adds credibility—custom neck labels, consistent fit, and reliable print durability. With Eton, your “make t shirt no minimum” approach evolves into a premium experience that builds brand equity while staying agile.

Use Case 3: Retail Replenishment—Forecast-Driven Small Runs

Retailers often need quick top-ups on proven styles. Small-batch OEM runs, backed by reserved fabric and standardized QA, serve this need. If your pilot forecast hits, Eton scales the replenishment through harmonized fit blocks and controlled dye lots—delivering continuity that keeps shelves stocked and margins stable.

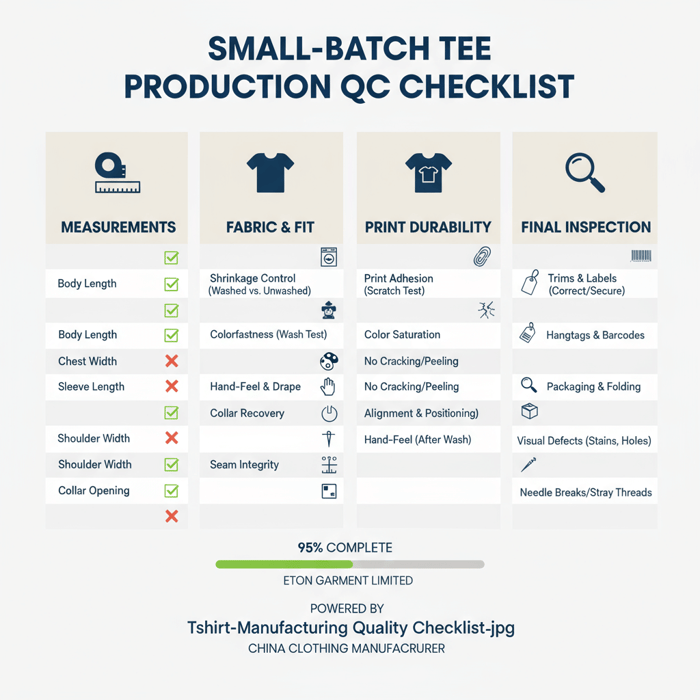

Compliance, Quality, and Sustainability for Small-Batch Tees

Answer-first summary: Even low volumes must meet labeling, chemical safety, and labor standards. Build QA into each step and choose certified partners to ensure consistency and brand safety in the US and EU.

“Make t shirt no minimum” invites agility; it still demands responsibility. The OECD Due Diligence Guidance and [MENTION: AAFA] frameworks outline expectations for responsible sourcing and compliance. Eton integrates compliant labeling, chemical management, and ethical audits into pilot and scale programs so brands can move fast without compromising safety or integrity.

Our quality system aligns sampling, fit testing, wash tests, and print durability checks with documentation. See “[INTERNAL LINK: Quality Control Process -> Internal page describing Eton’s QC stages]” to learn how we structure QA from development through final inspection.

Labeling & Fiber Content Requirements

US/EU markets require specific fiber content declarations, care instructions, and country of origin labeling. The US FTC rules govern the format and placement of labels on apparel. EU requirements mirror these principles, with variations in language and placement by member state. “[CITE: US FTC apparel labeling rules; EU REACH chemical restrictions; children’s apparel CPSIA where applicable]” should be embedded in your pilot plan to avoid rework later.

For “make t shirt no minimum,” define labeling early: neck branding, care label with wash instructions, fiber content, and origin. This clarity prevents delays, protects the brand, and ensures your pilot tees meet professional standards.

Chemical Safety & Restricted Substances

Restricted substance lists (RSLs) set chemical limits for dyes, finishes, and prints. Alignment to [MENTION: OEKO-TEX Standard 100] offers confidence in textile safety. EU REACH governs registration and restrictions on chemicals used in apparel; US standards depend on federal and state rules. Children’s apparel must satisfy CPSIA requirements, including testing and tracking labels. “[CITE: US FTC apparel labeling rules; EU REACH chemical restrictions; children’s apparel CPSIA where applicable]” underscores these obligations.

We integrate chemical safety checks early in fabric sourcing and printing. That means selecting compliant inks, managing dye processes, and testing finished goods for limits relevant to your market. This discipline turns “make t shirt no minimum” pilots into a stable platform for scale.

Ethical Manufacturing & Audits

Ethical manufacturing isn’t optional for modern brands. Audits from [MENTION: WRAP, amfori BSCI] and participation in programs like the International Accord (Bangladesh) demonstrate commitment to labor safety and rights. The Higg Index supports self-assessment and improvement in environmental impact. “[MENTION: OECD Due Diligence Guidance]” helps structure accountability across the supply chain.

Eton operates audited facilities and maintains documentation to support your compliance needs. We align policies to international standards and deliver transparency for brands pursuing “make t shirt no minimum” pilots that must meet retail-grade expectations.

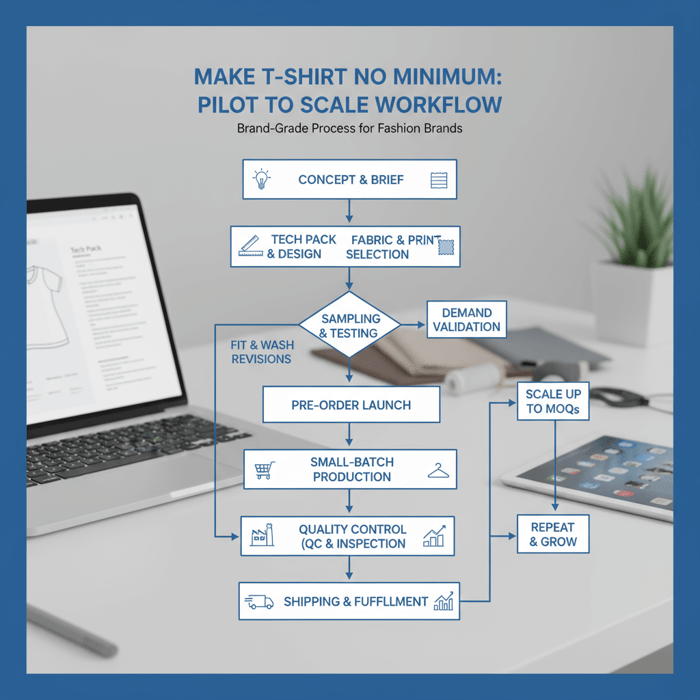

Step-by-Step: How to Make T‑Shirt No Minimum (Brand-Grade)

Answer-first summary: Follow this playbook to launch zero-MOQ tees: finalize design and tech packs, choose fabrics/prints, sample and test, open pre-orders, produce small batch, QC, ship, and learn before scaling.

Use this repeatable plan to “make t shirt no minimum” with discipline and speed. It blends agility with retail-grade rigor for US/EU markets.

Design + Tech Pack Essentials

Start with a clear brief: target customer, silhouette, fabric GSM, fit intent, and print artwork. Build a tech pack that specifies measurements, tolerances, fabric/fiber composition, color standards, print method, trims, and labels. Include neck label layout and care label text that matches US/EU requirements. Define QC checkpoints and measurement tolerances so samples reflect your standards.

When your target is “make t shirt no minimum,” tight documentation is non-negotiable. It prevents drift between pilot and scale and aligns all parties—brand, factory, QA, and logistics—around a shared definition of success. “[MENTION: Business of Fashion (BoF) on agility and test-and-learn merchandising]” affirms that well-documented agile processes amplify learning and speed.

Sampling, Fit, and Wash Testing

Request a development sample to verify measurements and construction. Test fit across sizes. Run wash tests to confirm shrinkage control and colorfastness. Evaluate print durability and hand-feel after laundering. Capture feedback—comfort, drape, collar recovery, sleeve shape—and adjust the tech pack as needed. “[CITE: Fit and wash testing best practices—industry textile testing references]” ensures your tests mirror retail-grade expectations.

To “make t shirt no minimum,” make decisions decisively. Lock specs once the sample passes. Confirm labeling content and artwork positioning. Align packaging and barcoding if needed. The result is a pilot-ready product that stays true at scale.

Pre-Orders, Production, and Logistics

Open pre-orders with strong visuals—sample photography and color-accurate images. Share shipping windows, returns policy, and compliance signals. Collect deposits or full payments to validate demand. Once pre-orders close, produce the batch, execute QC, and ship. For pilots, air courier supports speed; for scale, consider ocean freight after negotiating MOQs.

“Make t shirt no minimum” succeeds when operations communicate well. Track KPIs—sell-through, defect rate, and customer feedback. Prepare the bridge from pilot to MOQ production. To start a pilot with Eton, contact us via “[INTERNAL LINK: Contact & Start a Pilot -> Internal contact page or form]”.

Use Cases & Mini Case Studies: Zero-MOQ in Action

Answer-first summary: From capsule drops to team merch, small-batch tees can validate demand and build brand equity—then scale with confidence.

Zero-MOQ pilots empower brands to learn fast while protecting standards. We’ve supported capsules, influencer drops, and retail replenishments—each mission starts with “make t shirt no minimum,” then evolves into stable production with reliable QA and compliance. “[E-E-A-T NOTE: Use first-person experience from Eton on pilot outcomes (without disclosing sensitive client data).]” “[CITE: Market trend tying test-and-learn approaches to gross margin improvements—seek McKinsey/BoF sources]” strengthens the value of pilot-first strategies.

Capsule Collections & Seasonal Tests

Seasonal capsules benefit from a focused set of styles and colors. Run a “make t shirt no minimum” pilot to confirm which prints and fabric weights resonate. Use pre-orders to measure appetite, then scale into MOQs for top-performing SKUs. Eton ensures continuity between pilot and season by locking fit blocks, fabric reservations, and QC plans.

Influencer & Community Drops

Community drops thrive on energy and speed. Start with POD if the art changes constantly and you need one-off fulfillment. As the brand grows, shift to OEM pilots for consistent fit and labeling that meets US/EU requirements. The move elevates perceived value and creates a repeatable system for future drops.

Corporate/Team Merch With Brand-Grade Standards

Organizations require consistency across sizes and repeat orders. “Make t shirt no minimum” pilots ensure the chosen fabric, fit, and print meet expectations. Once validated, we scale through MOQs to secure pricing and stable supply. Ethical sourcing and compliance signals matter—many corporate clients require documented standards for procurement.

FAQs—Make T Shirt No Minimum for Fashion Brands

Answer-first summary: Quick answers for brands evaluating zero-MOQ tees—covering POD vs OEM, timelines, costs, compliance, and how to scale.

Learn more about Eton and our garment factory history at “[INTERNAL LINK: About Eton Garment Limited -> Internal About page]”. Explore compliance programs at “[INTERNAL LINK: Sustainability & Certifications -> Internal page with certifications (e.g., OEKO-TEX, WRAP)]”.

Is “no minimum” realistic for brand-grade tees?

Yes—through pre-orders, sampling, and OEM small-batch runs. “Make t shirt no minimum” pilots often range from dozens to a few hundred units, then transition to MOQs for better pricing and consistency. “[CITE: Clarify ‘zero MOQ’ feasibility and typical small-batch ranges—source from industry reports or manufacturer disclosures]”

How fast can we launch a pilot?

POD pilots can go live in days. OEM pilots usually require several weeks for sampling, testing, and production. Timelines depend on fabric availability, print method, and compliance requirements. “[CITE: Lead time benchmarks for POD vs OEM small batches—industry sources or provider pages]”

What print method should we choose?

Choose a method aligned to your fabric and art. DTG suits complex graphics; screen excels at opacity and durability for spot colors; DTF offers stretch and vivid results. Sample methods that match your scaled vision. “[CITE: Method performance/hand-feel differences by print technology—technical sources]”

How do we ensure US/EU compliance in small runs?

Document labeling, chemical safety, and ethical manufacturing. Use partners with audits and certifications. “[MENTION: OEKO-TEX Standard 100, WRAP, amfori BSCI, EU REACH]” and “[CITE: US FTC apparel labeling rules; EU REACH chemical restrictions; children’s apparel CPSIA where applicable]”

Can we switch from POD to OEM later?

Yes—many brands start with POD to validate demand, then move into OEM pilots for quality and compliance. Align tech packs and QA to guide the transition. “Garment Factory Capabilities”

What’s the typical sample count before a pilot?

Expect 1–3 development samples, then 1–2 size sets for fit reviews. Complex prints or specialty inks may require extra iterations to lock hand-feel and durability. “[CITE: Fit and wash testing best practices—industry textile testing references]”

How do returns/defects work in zero-MOQ?

Plan for returns in your margin model. Reduce defects by setting measurement tolerances, running wash tests, and documenting QC. Publish clear policies for customers during pre-orders. “[INTERNAL LINK: Quality Control Process -> Internal page detailing QC steps]”

What KPIs should we track?

Track sell-through, defect rate, and customer feedback on fit and feel. Monitor contribution margin and landed cost. These metrics determine when to graduate from “make t shirt no minimum” pilots to MOQs.

Which trims/labels are required?

At minimum: neck branding, care label with fiber content and country of origin, and any retailer barcoding or hangtags. Define this in your tech pack to avoid delays. “[CITE: US FTC apparel labeling rules]”

How do duties/tariffs affect small batches?

Duties depend on HS codes and country of origin. For pilots, factor higher freight and handling costs into your landed cost, then rebalance at scale. “[CITE: Duty/tariff references (US CBP)]”

Planned Internal Links

- Clothing Manufacturing OEM Service

- Garment Factory Capabilities

- [INTERNAL LINK: Quality Control Process -> Internal page detailing QC steps]

- [INTERNAL LINK: Sustainability & Certifications -> Internal page with certifications (e.g., OEKO-TEX, WRAP)]

- [INTERNAL LINK: Contact & Start a Pilot -> Internal contact page/form]

Planned Images

Author & Review Notes

- Author: [TBD, TBD]

- Reviewer: [TBD, Compliance/QA Lead]

- Methodology: Comparative analysis of POD and OEM small-batch workflows; mapping to US/EU compliance; Eton’s pilot production experience and OEM/ODM processes.

- Last Updated: [Insert Date]

Textile From Day One. As a China Clothing Manufacturer, Eton helps fashion brands “make t shirt no minimum” with the right balance of speed, quality, compliance, and scale—so you learn fast, protect your reputation, and grow with confidence.

FAQs

Related Articles

Chinese dress shop vs China clothing manufacturer: how brands move from retail inspiration to scalable OEM/ODM

10 minute read

October 15th, 2025

Chinese dress shop vs China clothing manufacturer: how brands move from retail inspiration to scalable... more »

Screenprint T Shirts: A Fashion Brand’s Guide to Sourcing at Scale with a China Clothing Manufacturer

19 minute read

October 15th, 2025

Screenprint T Shirts: A Fashion Brand’s Guide to Sourcing at Scale with a China Clothing... more »

Empowering Your Brand: The Ultimate Guide to Sourcing Company Logo Clothing as a Leading Clothing Manufacturer

15 minute read

October 15th, 2025

Empowering Your Brand: The Ultimate Guide to Sourcing Company Logo Clothing as a Leading Clothing Manufacturer... more »

Discover the World of Kinds of Hats: Essential Insights for Fashion Sourcing Managers Seeking Innovation and Excellence

8 minute read

October 15th, 2025

Discover the World of Kinds of Hats: Essential Insights for Fashion Sourcing Managers Seeking Innovation and... more »