Made in America Dresses vs China Clothing Manufacturer: A Practical Guide for Fashion Brands

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

19 minute read

Made in America Dresses vs China Clothing Manufacturer: A Practical Guide for Fashion Brands

Made in America dresses sit at the crossroads of compliance, cost, and brand storytelling for US and EU labels weighing a China Clothing Manufacturer partnership. This practical guide clarifies the FTC’s labeling rules, maps unit economics and lead times, and offers a step-by-step sourcing framework—grounded in factory-side experience and aligned to modern QA and social compliance expectations. The goal: a decision-ready path that protects claims, margins, timelines, and reputation.

Made in America dresses must meet the FTC’s “all or virtually all” origin standard. Domestic production supports speed and oversight yet carries higher unit costs and capacity limits. A China Clothing Manufacturer offers scale, broader capabilities, and lower costs with longer lead times and freight variability. Document claims rigorously and pilot before scaling.

What “Made in America Dresses” Really Means (FTC Rule, Origin Marking, Supply Chain Reality)

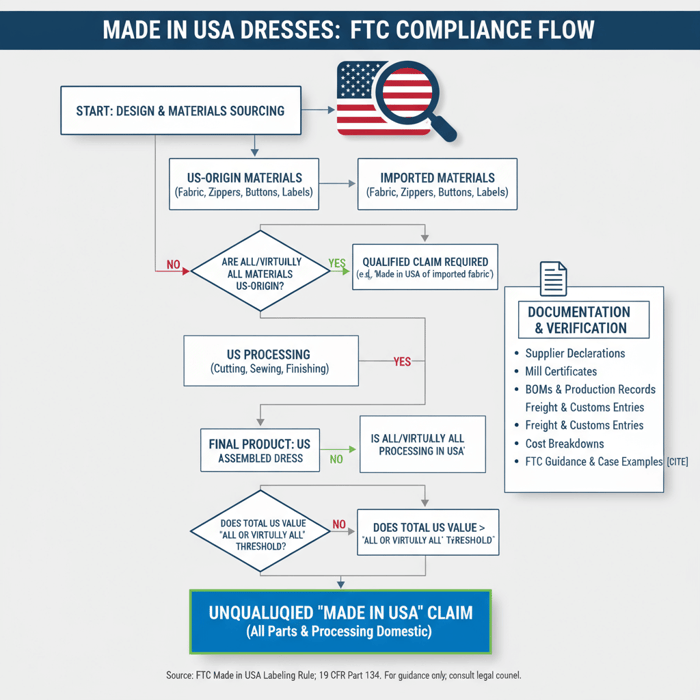

“Made in USA” claims for dresses require that all or virtually all significant parts and processing are of US origin. Imported fabric, trims, or key processing often push brands toward qualified claims. For imports, country-of-origin marking under 19 CFR Part 134 dictates labeling rules. Substantiation rests on traceable evidence, not intent [CITE: FTC Made in USA Labeling Rule; official guidance and case examples]. [MENTION: U.S. Federal Trade Commission; U.S. Customs and Border Protection] [INTERNAL LINK: Our foundational guide on ‘Compliance & labeling standards for apparel’]

The FTC “All or Virtually All” Standard for Apparel

For an unqualified “Made in USA” claim, the FTC expects dresses to be composed of “all or virtually all” US-origin components, with processing that happens domestically. This bar is high: if the fabric is woven or knit abroad, if zippers, buttons, linings, fusibles, labels, or embellishments are imported, the claim is likely not supported. The FTC looks at the percentage of total manufacturing costs attributable to US parts and processing, the origin of significant components, and where the final substantial transformation occurs. A dress cut and sewn in Los Angeles from imported fabric and trims typically requires a qualified claim such as “Made in USA of imported fabric,” avoiding consumer deception while conveying domestic value-add [CITE: FTC enforcement actions and staff guidance summarizing apparel claims]. [MENTION: WRAP (Worldwide Responsible Accredited Production); amfori BSCI (Business Social Compliance Initiative)]

Substantiation is documentary. Brands should maintain supplier declarations, mill certificates, bills of materials, production records, freight and customs entries, and cost breakdowns showing US value-add. Internal reviews must test the claim against the FTC’s standard, not marketing preference. If any component remains uncertain or undocumented, use qualified wording and tighten vendor documentation controls. Mislabeling carries enforcement risk and reputational harm [CITE: FTC penalty examples; “Made in USA” cases and consent orders].

Country of Origin Marking for Imported Dresses

For imported dresses entering the US, origin marking follows U.S. Customs and Border Protection rules under 19 CFR Part 134. The country of origin is where the dress underwent substantial transformation—generally where cut-and-sew of the finished garment occurred, not where fabric was woven or trims produced. Labels must be conspicuous and legible, placed where the consumer can find them (e.g., neck area or waistband), and accurately reflect the origin, e.g., “Made in China” or “Made in Bangladesh.” This is separate from FTC advertising claims; both must align and never mislead [CITE: CBP rulings clarifying apparel origin; apparel marking compliance guidance]. [MENTION: U.S. Customs and Border Protection; U.S. International Trade Commission]

Documentation should include invoices, purchase orders, packing lists, origin declarations, and HS classification data. EU imports require origin marking aligned to customs rules and consumer law, and any sustainability or “local” claims must be substantiated under prevailing EU guidance. Maintain consistent label templates, broker instructions, and QA checkpoints to avoid mixed origin on bulk runs and rework penalties [CITE: eCFR 19 CFR Part 134; EU product labeling guidance for textiles].

Qualified vs Unqualified Claims

Unqualified claims (“Made in USA”) are reserved for dresses where all or virtually all content and processing are domestic. Qualified claims communicate truth while preventing deception: “Made in USA of imported fabric,” “Designed and cut in the USA; sewn in China,” or “Assembled in USA from imported parts.” The phrasing should be specific, not vague. Marketing should mirror the claim used on labels and websites; if the supply chain varies by style, avoid blanket language and confine claims to SKUs where evidence meets the bar [CITE: FTC examples of acceptable qualified phrasing]. [MENTION: Better Business Bureau National Programs; Truth in Advertising watchdogs]

Practical rule of thumb: when US sewing leverages imported fabric and trims, expect a qualified claim. Build the process: legal review of wording, periodic audits of documentation, and training for design and merchandising teams. Introduce a claims approval checklist before copy goes live or labels are sent to print [INTERNAL LINK: Compliance & labeling standards for apparel — process checklist].

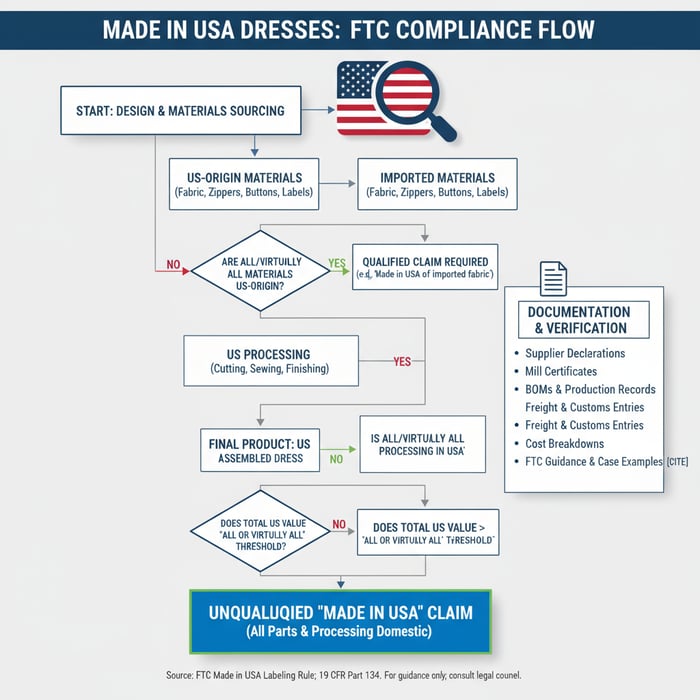

Made in America Dresses: Benefits, Trade-offs, and When It Makes Sense

US-made dresses offer proximity, faster local logistics, and close QA oversight. They also carry higher labor costs, limited MOQs, and tighter fabric availability. This path fits capsule launches, premium price points, and storytelling-led brands—provided the economics and capacity align.

Advantages of Domestic Dress Production

Proximity reduces communication lag and cuts transit time. Fit approvals, lab dips, and PP samples move quickly; teams can visit the line and adjust construction before bulk. Local production also supports a transparent QA chain—inline checks, finishing control, and corrective action plans become easier to implement. For brands pursuing premium pricing, domestic-made dresses support narrative value, regional capsule drops, and responsive replenishment cycles that keep inventory in balance [CITE: Case studies where domestic proximity reduced sample-to-PO cycle time by weeks]. [MENTION: Council of Fashion Designers of America; American Apparel & Footwear Association]

Domestic production also streamlines compliance: origin claims are clearer to substantiate, and country-of-origin labeling is consistent. Marketing can leverage “Made in USA” when the FTC standard is met—or precise qualified claims when components are imported. When speed-to-market and brand story outweigh raw unit margin, US production helps meet design deadlines, secure retailer windows, and respond to demand signals without transoceanic freight [INTERNAL LINK: Our foundational guide on ‘Sustainability & social compliance in apparel’].

Constraints and Hidden Costs

Labor is the largest driver: US cut-and-sew wages for NAICS 3152 are materially higher than offshore benchmarks [CITE: U.S. Bureau of Labor Statistics, 2024 wage data]. Factory capacity for dresses may be tight, pushing MOQs upward or lead times longer than anticipated. Fabric, linings, interlinings, zippers, and specialty trims often remain imported, undermining unqualified claims and introducing longer component lead times. Embellishments (appliqué, beading, embroidery) and performance processes (bonded seams, seam sealing) are less available domestically at scale, raising outsourcing and coordination overhead [CITE: Industry capability surveys of US apparel manufacturing; capacity maps].

Hidden costs stack up: smaller runs translate into higher per-unit overhead; domestic logistics are faster but rarely offset labor differentials; and limited access to certain textiles can slow approvals. Brands should run a margin model capturing all inputs—labor, fabric sourcing, trims, testing, QA, compliance, freight, duties, and risk buffers—and validate with pilot runs. Sustainability claims require lifecycle thinking; local sewing does not automatically reduce emissions if materials are flown in. Tie claims to evidence and certifications, not assumptions [CITE: Life cycle assessment studies for apparel supply chains; verified sustainability claims guidance].

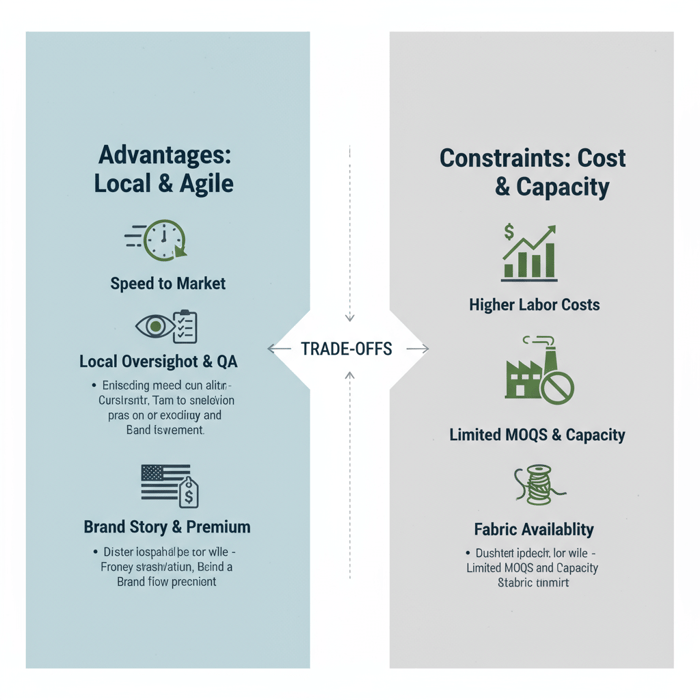

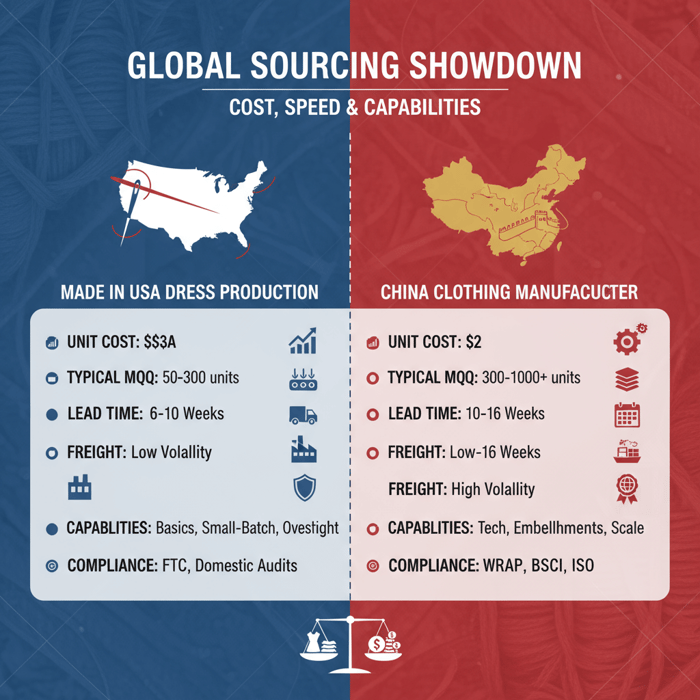

Cost & Lead-Time Comparison: Made in America Dresses vs China Clothing Manufacturer

Domestic production shortens logistics and offers close oversight at higher unit labor costs. A China Clothing Manufacturer provides broader capabilities, lower unit costs, and larger MOQs, with longer lead times and freight variability. Shipping indices and fabric origin choices materially influence landed costs and delivery cadence.

| Dimension | US Dress Production | China Dress Production |

|---|---|---|

| Indicative Unit Labor Cost | Higher; driven by NAICS 3152 wage bands [CITE: BLS 2024 wage benchmarks] | Lower; greater labor specialization and scale [CITE: Industry cost benchmarking reports] |

| Typical MOQs | 50–300 units per style/color (varies by factory) | 300–1,000+ units per style/color; flexible with established vendors |

| Lead Times (Dev → Bulk) | 6–10 weeks (design-dependent); domestic transit 1–5 days | 10–16 weeks (design-dependent); ocean transit 3–6 weeks |

| Freight Volatility | Lower volatility; trucking rates apply | Moderate–high; container indices swing seasonally [CITE: Drewry World Container Index 2024–2025] |

| Capabilities | Strong in cut/sew basics and small-batch; limited advanced bonding/sealing capacity | Broad textile base; technical processing, embellishments, scalable QA and testing |

| Compliance & Certifications | Clear FTC claim substantiation; domestic audits possible | WRAP, amfori BSCI, ISO-based systems; third-party audits common |

- Cut & Sew Apparel Manufacturing wages — 2024 (Source: BLS NAICS 3152) [CITE: BLS wage page]

- World Container Index — 2024–2025 average and peaks (Source: Drewry) [CITE: Drewry weekly compound indices]

- State of Fashion — supply chain resilience indicators — 2025 (Source: McKinsey & BoF) [CITE: McKinsey & BoF report]

Unit Economics and MOQ Benchmarks

Run dress unit economics as a range, not a single number. Base costs on labor minutes, line balance, and fabric/trims cost per yard or per unit. Add testing (colorfastness, shrinkage), packaging, QA inspections, administrative overhead, and a realistic scrap/waste rate. Domestic wages drive higher conversion cost, while China line specialization unlocks efficiency at scale. MOQs are a lever: US factories may accept smaller runs with higher per-unit charges; China partners often prefer 300+ per colorway, offering cost breaks past 1,000 units [CITE: Apparel cost engineering texts; factory MOQs from industry surveys]. [MENTION: SGS (testing); Intertek (inspection)]

Expect cost shifts with fabric origin. If US mills supply the fabric, negotiate ex-mill pricing and lead times; if imported, factor duties and transit. Embroidery, appliqué, and prints can swing costs significantly—budget embellishment by stitch count or strike-off complexity. Always build a sensitivity table: +10% fabric price, +2-week lead time, +1 inspection cycle, and ±$1 freight per unit to see margin exposure. Keep quotes comparable by standardizing tech packs, measurements, seam allowances, and testing protocols [INTERNAL LINK: Our foundational guide on ‘OEM & ODM Clothing Manufacturer’].

Lead Times, Freight, and Volatility

Domestic timelines compress travel and communication, often delivering development-to-bulk in 6–10 weeks on straightforward dresses. Offshore timelines lengthen with sampling, fabric procurement, and ocean freight windows—10–16 weeks is common for non-technical styles, with additional time for embroidery, special prints, or performance finishes. Freight volatility changes landed costs and delivery cadence; container rates can swing substantially year-over-year, influencing whether air, expedited ocean, or standard ocean is viable [CITE: Drewry index and seasonal patterns].

Build buffers: 1–2 weeks for fabric delays, 3–5 days for QA rework, and 1–2 weeks for freight fluctuations during peak seasons. Align approvals to the critical path—final spec lock, PP sample sign-off, bulk fabric release—so you avoid idle lines. For EU-bound dresses, add time for customs clearance and any product testing requirements under local regulations. Keep production calendars visible to merchandising and finance, ensuring buy windows and promotional calendars reflect reality [CITE: Supply chain planning best practices in apparel].

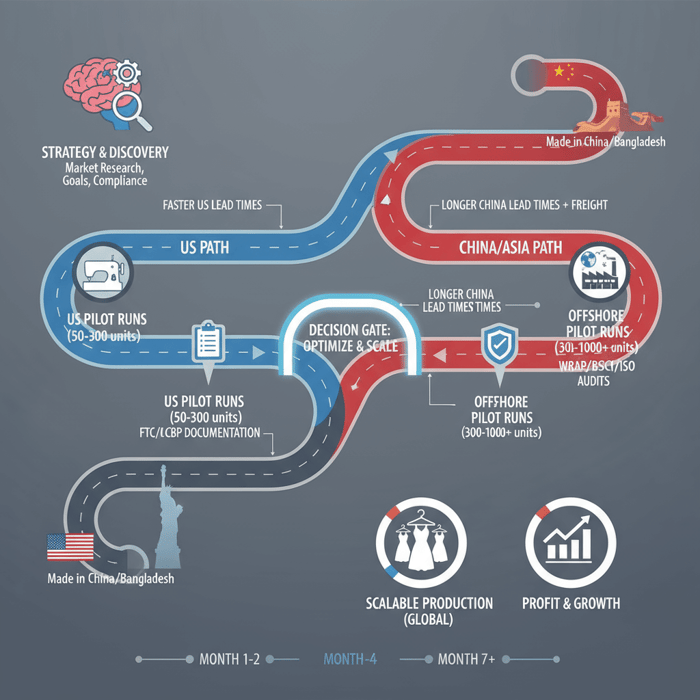

How to Decide: A Step-by-Step Framework for Sourcing Dresses in the US or China

Use a criteria-weighted framework: compliance risk, margin, capacity, speed-to-market, sustainability, and QA. Prototype locally when narrative and speed matter; scale offshore when margin and capability prevail. Validate assumptions with pilots, inspections, and documentation audits before committing to bulk.

Preparation (Briefing, Assumptions, Metrics)

Define the goal for your dress line: margin target, launch date, assortment breadth, and pricing. Establish assumptions—fabric type and origin, embellishments, colorways, and MOQ appetite. Set KPIs: sample turnaround days, AQL targets, defect rates, on-time delivery, and first-pass yield. Map compliance risk: “Made in USA” feasibility, qualified claim wording, and country-of-origin marking. Create a scoring matrix where each criterion carries a weight aligned to brand strategy, e.g., margin 30%, speed 20%, capability 20%, compliance 15%, sustainability 15% [CITE: Apparel sourcing frameworks; weighted decision models]. [MENTION: ISO 9001 for quality systems; SA8000 for social accountability]

Gather data: factory capability lists, historical lead times, wage benchmarks, freight indices, and material availability from mills. Pre-brief vendors with complete tech packs—measurements, seam constructs, finishing specs, fabric/trim standards, and testing protocols. Attach claim guidance so vendors understand documentation standards and labeling expectations [INTERNAL LINK: Our foundational guide on ‘Outerwear manufacturing (jackets, padded coats)’ — methodology applies to dresses].

Execution Steps (Sourcing Path A/B)

- Run dual RFQs: domestic and China Clothing Manufacturer, using identical tech packs and quantity ranges.

- Score responses against your matrix: margin, lead time, capability fit, compliance evidence, and QA systems.

- Prototype Path A (domestic): 30–100 units pilot; lock spec on-site; monitor inline checks and finishing.

- Prototype Path B (offshore): 60–200 units pilot; require AQL sampling, lab testing, and records for origin/claims.

- Validate consumer fit and shrink risk with wash tests; run wear trials on sample sizes.

- Set claims: “Made in USA” or qualified phrasing; confirm CBP origin marking for imports.

- Approve bulk with clear SLAs: PP approvals, inspection cadence, defect thresholds, and corrective action timelines.

- Lock freight plans: ocean contracts, buffers for peak periods, and contingency for expedited shipments.

Use pilot data to refine margin models and delivery calendars. If Path A hits speed and narrative but misses margin, reserve it for capsules. If Path B meets margin and capability with acceptable lead time, scale for core assortment. Keep both relationships active when mixed strategies provide resilience [CITE: Resilience case studies in apparel sourcing].

Quality Assurance (Audits, Inline Checks, Final AQL)

Set AQL standards matched to dress complexity—e.g., AQL 2.5 for major defects, 4.0 for minor, using a recognized sampling plan. Require vendor QC plans covering incoming fabric inspection, cut panel checks, inline stitch and seam checks, finishing review, and final inspection with records. Implement first-article inspection on the first dozen units of bulk; authorize ongoing production only after pass. For offshore runs, add a pre-shipment inspection by a third party and keep evidence linked to POs and style numbers [CITE: ANSI/ASQ Z1.4 sampling tables; apparel QA textbooks]. [MENTION: Bureau Veritas; TUV Rheinland]

Tie QA to labeling claims. If a qualified claim is used, verify that labels match phrasing and origin marking. Store photos of label placement and legibility. Post-launch, track returns and customer feedback by defect code to inform the next cycle’s corrective actions.

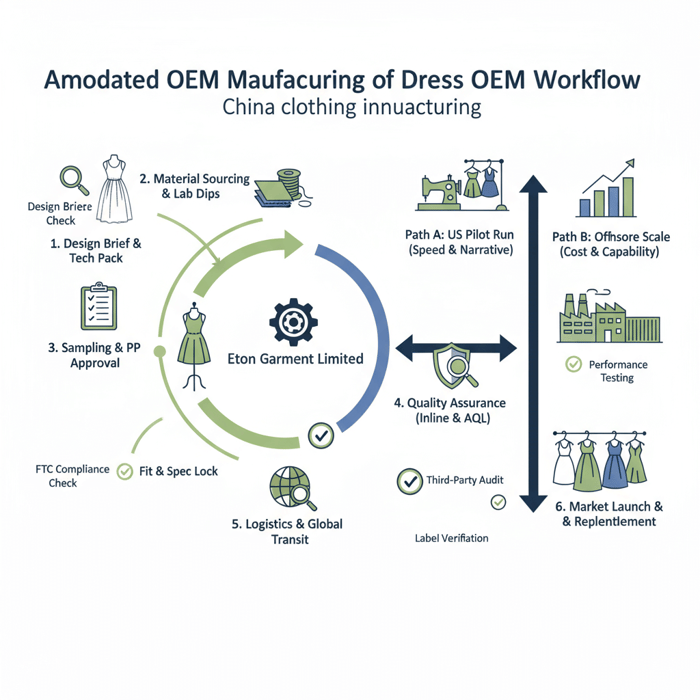

Product/Service Integration: Clothing Manufacturing OEM Service (Eton)

Eton’s Clothing Manufacturing OEM Service scales dress production with end-to-end development, sourcing, QC, and compliance workflows across China and Bangladesh. Brands use it to extend beyond domestic capacity, hold quality bars, and hit margin and timeline targets without losing specification control or documentation rigor.

| Brand Need | OEM Feature | Outcome |

|---|---|---|

| Scale capsules into core assortment | Multi-factory capacity planning; line balancing | Stable volumes, repeatable lead times, unit cost control |

| Technical dresses and embellishments | Access to bonded seams, seam sealing, embroidery | Capability expansion with performance validation |

| Compliance and documentation | Origin tracking, label control, audit-ready files | Clean claims; consistent CBP/EU marking; lower risk |

| QA discipline at scale | Inline checks, final AQL, third-party inspections | Reduced defects; reliable first-pass yield |

| Timeline resilience | Dual-country production (China/Bangladesh) | Buffer against shocks; flexible capacity routing |

Eton Garment Limited began in 1993 and operates modern factories across China and Bangladesh, specializing in outerwear and technical apparel with a strong QA backbone. That infrastructure benefits dress programs requiring consistent stitch quality, stable fit across sizes, and embellishment execution at volume. Eton’s teams maintain PP sample discipline, lab testing, and documentation trails aligned to US/EU claims and import requirements [MENTION: Liverpool F.C. licensed apparel; Forever 21; amfori BSCI].

Learn how Clothing Manufacturing OEM Service slots into a hybrid strategy: prototype domestically for speed and storytelling, then scale through Eton’s network with intact specifications, documented origin, and aligned QA standards.

Use Case 1: Capsule Collection → Low-Risk Scale

Start with a 60–120 unit US capsule to confirm fit, fabric hand, and silhouette demand. Once sell-through validates the design, Eton translates the tech pack into offshore development with like-for-like materials and stitch constructs. PP samples are cross-checked against domestic pilots; any adjustments are documented and approved before bulk. Inline QC tracks stitch density, seam allowance, and finishing against preset tolerances; pre-shipment inspections target AQL 2.5/4.0. This path preserves the capsule’s narrative while unlocking cost breaks for replenishment and extended colorways [CITE: Case example where capsule lead-time and margin improved through hybrid sourcing].

Use Case 2: Technical Dresses → Capability Expansion

Technical dresses with bonded seams, seam sealing, performance linings, or complex embroidery demand access to specialized equipment and experienced operators. Eton routes styles to factories with the right process stacks, conducts fabric and seam tests, and confirms performance under wash/wear protocols. Documentation compiles lab results, operator instructions, and QA records per PO/style. Brands gain access to processes underrepresented domestically for dresses, with the testing assurance needed to sell confidently into US/EU markets [CITE: Performance testing standards for seam sealing and bonded seams].

Risks, Compliance & Localization (US & EU)

Avoid FTC labeling errors and ensure clean country-of-origin marking for imports. In the EU, prepare for due diligence expectations around supply chain claims and sustainability. Build risk matrices tied to audit actions and keep documentation audit-ready. Confirm language with counsel when claims or regulations change.

Risk Matrix

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| FTC claim mislabeling | Medium | High (penalties; reputational harm) | Legal review; documentation audit; qualified claims when needed [CITE: FTC enforcement examples] |

| Incorrect origin marking (CBP) | Low–Medium | Medium (rework; delays) | Broker instruction packs; label placement SOP; pre-shipment verification |

| Freight cost spikes | Medium–High | Medium–High (margin squeeze) | Contracted rates; buffer in landed cost; contingency volumes [CITE: Drewry volatility] |

| QA defects on bulk | Medium | High (returns; markdowns) | Inline checks; AQL plans; corrective actions; operator training |

| Fabric availability delays | Medium | Medium | Approved alternates; dual sourcing; early mill bookings |

| EU due diligence lapses | Low–Medium | Medium–High | Supplier audits; certification tracking; claim substantiation files [CITE: EU due diligence guidance] |

Regulatory Notes for US & EU

US: The FTC’s “Made in USA” rule frames unqualified claims; qualified claims should be precise and supported by evidence. CBP manages origin marking under customs law; the substantial transformation test defines the country of origin for apparel. Keep claims and marking in sync, and review copy with counsel before launch. Maintain records for at least the duration of sell-through [CITE: FTC and CBP guidance pages].

EU: Consumer law and sustainability claims face scrutiny under green claims guidance and due diligence frameworks. Ensure any “local” or environmental claims are substantiated via recognized methods (e.g., LCA) and audit trails. If importing into the EU, confirm labeling obligations, fiber content labeling, and any language requirements for care labels in target markets [CITE: European Commission guidance on green claims; EU textile labeling rules]. [MENTION: European Commission; European Union Agency for Fundamental Rights]

Trends & Data: Demand for “Made in USA” Apparel vs Offshore Capacity

Consumer interest in local production coexists with price sensitivity; offshore networks retain scale advantages. Freight cost swings and resilience priorities influence the sourcing mix. Brands often adopt hybrid models: domestic capsules for speed and narrative, offshore scale for margin and capability [CITE: McKinsey & BoF State of Fashion 2025; consumer sentiment studies].

Localization Signals vs Price Reality

US and EU consumers respond to local stories and transparent supply chains, but price points still guide conversion. Dresses with clean lines and familiar fits can be viable domestically at elevated MSRPs if the brand story resonates. Highly embellished or technical dresses often require offshore capacity, where specialized processes deliver consistent quality at scale. Brands balance assortment: local hero pieces that cast the narrative, supported by offshore volume that sustains margins [CITE: Retail pricing elasticity studies; consumer willingness-to-pay for local labels]. [MENTION: National Retail Federation; BOF Insights]

Capacity & Capability in Offshore Networks

China and Bangladesh offer depth in textiles, embellishment, and technical processing for dresses, alongside established QA ecosystems and third-party testing. Access to mills, embroidery houses, and printing partners reduces development friction. Offshore networks adapt quickly to categories adjacent to outerwear—structured dresses, performance linings, and durable stitching—where experience carries over. Freight and lead-time management remain the balancing act; disciplined calendars and contracted rates mitigate shocks [CITE: Industry capacity maps; third-party testing coverage studies].

Conclusion & Next Steps

Choose a path that serves claims, economics, and capability. Prototype domestically where speed and storytelling lift conversion; scale with a China Clothing Manufacturer when margin and specialized processing matter. Keep labeling rigorous from sample to bulk, and back every claim with documentation. Validate with pilots, audits, and performance testing before expanding volume.

- Run a side-by-side RFQ for US and China options using identical tech packs.

- Build a scoring matrix aligned to your priorities: margin, speed, capability, compliance, sustainability.

- Pilot both paths with small runs; measure AQL pass rates, fit consistency, and timeline fidelity.

- Set claims and origin marking; document and review with counsel.

- Lock freight and QA plans; add buffers for fabric availability and seasonal transit swings.

- Scale assortments with clear SLAs and inspection cadences; update the matrix quarterly with real data.

Talk to our garment factory team: Eton Clothing Manufacturing OEM Service for hybrid strategies that protect your spec, margin, and calendar across China and Bangladesh. [INTERNAL LINK: OEM & ODM Clothing Manufacturer — pillar page] [INTERNAL LINK: Sustainability & factory compliance — pillar page]

- FTC — Complying with the Made in USA Labeling Rule (2024). FTC (2024)

- eCFR — 19 CFR Part 134: Country of Origin Marking (Current). eCFR

- U.S. Bureau of Labor Statistics — Occupational Employment and Wage Statistics: Cut and Sew Apparel Manufacturing (NAICS 3152), 2024. BLS (2024)

- Drewry — World Container Index, 2024–2025. Drewry (2025)

- McKinsey & Company and The Business of Fashion — The State of Fashion 2025. McKinsey & BoF (2025)

- SGS — Apparel testing services overview (Yearly program pages). SGS [CITE: Third-party testing provider pages; lab tests for textiles]

- Intertek — Textile and apparel inspection and testing. Intertek [CITE: Inspection frameworks and AQL programs]

- European Commission — Green Claims Guidance (2023–2025). European Commission [CITE: EU sustainability claims guidance]

- AAFA — Apparel compliance and labeling resources. AAFA [CITE: Labeling and compliance summaries]

- CBP — Apparel marking and origin rulings (Selected). CBP Rulings [CITE: Origin determination examples under substantial transformation]

Author: Eton Yip, Founder, Eton Garment Limited; 30+ years in apparel manufacturing across outerwear and technical apparel; OEM/ODM operations in China and Bangladesh. [INTERNAL LINK: Eton Yip — Founder — {{author_bio_url}}]

Reviewer: Head of Compliance, Eton Garment Limited (WRAP/BSCI liaison). Methodology: Comparative analysis using FTC guidance, BLS wages, Drewry container indices, and industry reports; ranges validated against factory-side experience. Limitations: Benchmarks vary by design complexity, fabric/trims, and market conditions; confirm specifics via RFQs and audits; regulatory updates may change requirements. Disclosure: Eton manufactures in China and Bangladesh and does not represent US domestic manufacturing capacity; claims herein refer to general guidance and must be confirmed for each SKU.

FAQs

Related Articles

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »