How to Get My Clothing Designs Manufactured: A Practical Guide with a China Clothing Manufacturer

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

6 minute read

How to Get My Clothing Designs Manufactured: A Practical Guide with a China Clothing Manufacturer

How to get my clothing designs manufactured starts with a complete tech pack and the right China Clothing Manufacturer by your side. This guide shows US/EU fashion brands how to move from sketch to shipment with clear steps, realistic timelines, and safeguards for cost, quality, compliance, and IP—drawing on Eton Garment Limited’s 30+ years in OEM/ODM outerwear.

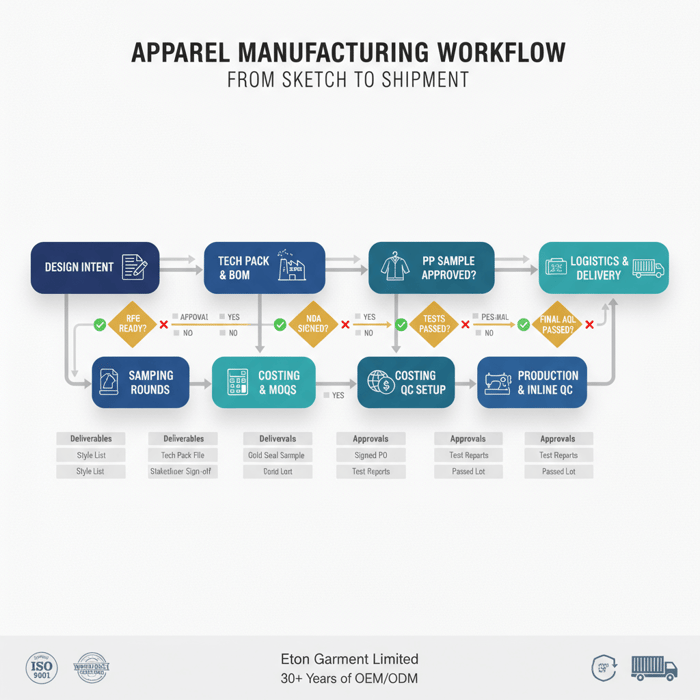

To get your clothing designs manufactured: prepare a full tech pack, shortlist vetted factories, request samples (proto → fit → PP), confirm costs/MOQs and testing, set AQL and QC checkpoints, approve PP, sign POs with clear Incoterms, monitor production with inline inspections, and book logistics to your US/EU destination.

The End-to-End Process: How to Get My Clothing Designs Manufactured (Step-by-Step)

A reliable path from design to delivery runs through eight stages: design intent, tech pack and BOM, factory shortlisting, sampling rounds, costing and MOQs, compliance/QC setup, production with inline inspections, and logistics under chosen Incoterms. Each stage locks specific deliverables and approvals to prevent overruns and rework.

[MENTION: ISO 9001 process discipline], [MENTION: WRAP or amfori BSCI factory programs]. [INTERNAL LINK: Our foundational guide on ‘garment factory process’]

-

Define design intent and range plan

- Inputs: sketches, reference garments, target MSRP, target margin, customer personas, region (US/EU).

- Outputs: prioritized style list, fabric/trim direction, target costs, colorways.

- Timing: 3–5 days to align stakeholders.

-

Build a tech pack with graded measurements and a BOM

- Inputs: construction details, stitch types, seam allowances, tolerances, label/packaging specs.

- Outputs: RFQ-ready tech pack; graded measurement chart; BOM with material specs.

- Timing: 5–10 days depending on complexity.

-

Shortlist factories and sign NDAs

- Inputs: capability fit (outerwear vs. knits), certifications, compliance scope, past work.

- Outputs: 2–4 vetted partners; mutual NDA and IP clauses.

- Timing: 7–14 days including reference checks.

-

Run sampling rounds: proto → fit → PP

- Inputs: RFQ-ready tech pack; measurement and fit standards; sample comments log.

- Outputs: approved PP sample (gold seal), sealed trims/fabrics, signed-off construction index.

- Timing: 3–8 weeks across rounds depending on complexity.

-

Lock costing, MOQs, and terms

- Inputs: finalized BOM, PP sample, test plan, delivery port, Incoterms preference.

- Outputs: signed PI/PO with unit cost, MOQ, size ratio, color split, payment terms.

- Timing: 3–7 days, including negotiation.

-

Set compliance tests and AQL plan

- Inputs: destination market, REACH/CPSIA scope, RSL, care labels, packaging rules.

- Outputs: test reports, inspection plan with AQL levels, defect taxonomy, QC forms.

- Timing: 1–3 weeks for lab tests; plan finalized before bulk starts.

-

Produce with inline and final QC

- Inputs: bulk materials, PP sample, approved trims, production PO, QC checkpoints.

- Outputs: passed lot against AQL; shipment-ready cartons; measurement reports.

- Timing: 6–12 weeks for outerwear; confirm based on line loading.

-

Book logistics under FOB/CIF/DDP

- Inputs: Incoterms, delivery window, customs documents, packing list, invoice.

- Outputs: booked vessel/airway; customs-cleared delivery to US/EU DC.

- Timing: 1–6 weeks transit; 1–5 days customs clearance.

Pre-production Essentials

Arrive factory-ready. Include: cover page (style code, season, target MSRP), flat sketches, callouts, stitch types, seam allowances, graded measurement chart with tolerances, BOM with fabrics/trims (fiber content, weight, finish, suppliers or locked alternates), colorways with Pantone codes, print/embroidery files, care/brand/size label layouts, packaging specs, fit standard and avatar, test plan, compliance marks (US/EU), barcode/UPC/EAN rules, and Incoterms preference.

RFQ etiquette: state order size, size ratio, target FOB, delivery port, requested sampling timeline, test scope, and required certifications. Attach NDAs before sharing artwork. [CITE: Official NDA/IP guidance for China], [MENTION: China National Intellectual Property Administration]. [INTERNAL LINK: Our ‘outerwear tech pack template’]

Sampling & Approvals

Label each round clearly: Proto (construction/shape), Fit (measurements/fit), Size Set (grading check), Pre-Production (final). Include a comment log with numbered issues, photos, and measurement variances. Use a pass/fail list for critical seams, functional details (zippers, snaps), and performance items (waterproof ratings, down fill weight). For outerwear, 2–3 rounds before PP is common; complex technical styles may need 3–4. [CITE: Industry sampling norms from apparel sourcing associations]

Production & Logistics

Confirm materials against the sealed swatches and lab test reports before cutting. Schedule inline inspections at 20–30% and 80% completion; final inspection at 100% packed. Book freight 2–3 weeks before ex-factory to secure space, especially for peak seasons. Create an as-built pack: PP sample photos, trim cards, labels, and final measurement reports for traceability. [INTERNAL LINK: Our foundational guide on ‘production calendar template’]

Costs, MOQs, and Unit Economics to Get Your Clothing Designs Manufactured

Unit cost reflects fabric, trims, labor minutes, construction complexity, order size, and testing. Build landed cost by adding FOB or CMT price, compliance tests, packaging, freight, duties/VAT, and last-mile fees. Back into MSRP with your margin targets for US/EU retail programs.

[MENTION: US Customs and Border Protection], [MENTION: European Chemicals Agency]. [INTERNAL LINK: Our ‘landed cost calculator for apparel’]

| Component | What It Includes | Key Drivers | How to Reduce/Control |

|---|---|---|---|

| Fabric | Shell, lining, interlining, specialty membranes | Fiber content, weight, finish, MOQ, wastage | Consolidate colors; use mill stock; confirm yields |

| Trims | Zippers, snaps, thread, labels, tapes | Brand (e.g., YKK), plating, logo processes | Standardize trims across styles; negotiate bulk |

| Labor | Sewing minutes, line balancing | Pattern complexity, operations count | Refine construction; reduce operations |

| Testing | REACH/CPSIA, RSL, performance tests | Destination, product category, lab scope | Batch tests; supplier LOAs where accepted |

| Freight | Sea/air rates, insurance, drayage | Mode, season, fuel/surcharges, lanes | Ship FOB in full containers; plan timelines |

| Duties/VAT | Import duty, VAT/GST where applicable | HS code, origin, trade programs | Correct HS codes; qualify for preferences |

- Larger MOQs: Lower unit cost and better line efficiency; higher cash tie-up and inventory risk.

- Air freight: Speed; heavy margin hit and carbon footprint.

- Sea freight: Lowest cost; longer lead time and space risk in peak.

- FOB: Buyer controls freight; needs freight expertise.

- DDP: Doorstep simplicity; embedded freight/duty premiums.

- US import compliance and duty rules — 2024 (Source: [CITE: “CBP Importing into the U.S.”])

- EU REACH restricted substances updates — 2024 (Source: [CITE: “ECHA REACH guidance updates”])

- Outerwear duty bands by HS code — 2024 (Source: [CITE: “Official tariff database for US/EU”])

FAQs

Related Articles

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »