How Can I Create My Own Clothing Line? The Manufacturer-Backed Playbook for US & EU Brands

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

17 minute read

How Can I Create My Own Clothing Line? The Manufacturer-Backed Playbook for US & EU Brands

How can I create my own clothing line? Start by setting a clear brand thesis, building bulletproof technical packs, and partnering with a proven China clothing manufacturer who understands US/EU compliance and market timing. This end-to-end playbook distills three decades of factory-floor experience from Eton Garment Limited to move you from idea to delivery with fewer surprises.

Start here: blueprint your brand and the route to market

Successful lines pair a focused customer promise with tight execution: one category, clear unit economics, and a dependable production calendar. Align brand positioning, compliance, and supplier capacity early to prevent costly relaunches.

Your route to market shapes every decision. Direct-to-consumer calls for quicker capsules and content-first launches; wholesale demands calendar discipline and confirmed MOQs ahead of line reviews. Choose one growth lane for your first two drops, set margin targets, and lock key dates across design, sampling, and production.

- Customer promise: a short statement that names fit, function, and occasion.

- Category focus: 1–2 hero products (e.g., insulated jacket + rain shell).

- Pricing lane: MSRP and target margins by channel (DTC vs. wholesale).

- Compliance roadmap: US CPSIA/CPSC and EU REACH labeling/testing plan.

- Factory fit: capacity, MOQ, calendar, and technical capability match.

[MENTION: Business of Fashion State of Fashion report], [MENTION: McKinsey Apparel sourcing analyses]. [CITE: A recent apparel market margin benchmark by McKinsey/BoF]. [INTERNAL LINK: Our foundational guide on apparel unit economics].

Design and technical development: turn vision into production-ready specs

Design moves from mood boards to tech packs, from tech packs to fit-proven samples. Locked specs reduce defects, reduce cost creep, and speed approvals across US and EU launches.

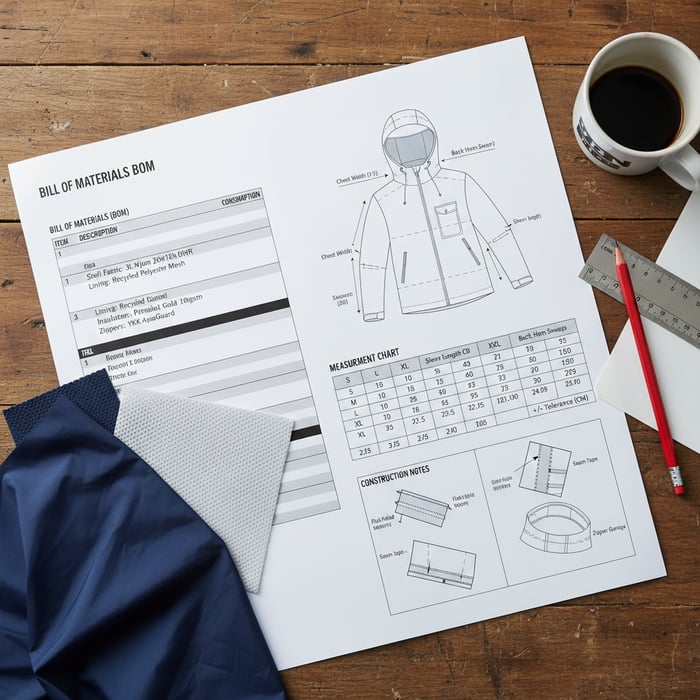

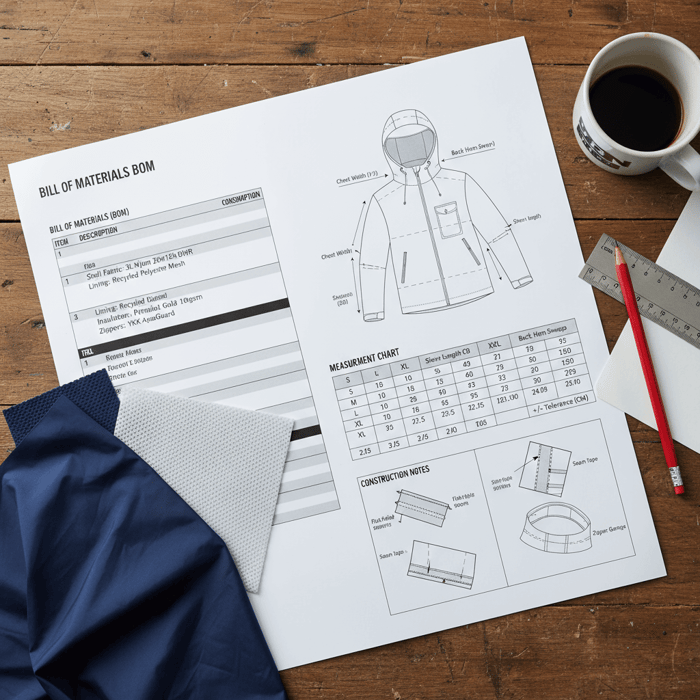

Build a complete tech pack

A production-grade tech pack covers silhouettes, detailed measurements, tolerance bands, construction notes, stitch types, BOM (fabrics, trims, labels), print files, care labels, and colorways. Call out performance targets for outerwear—hydrostatic head (mm), breathability (g/m²/24h), loft/gram weight for synthetic fill, and down fill power. Technical clarity prevents rework and protects timelines.

- Measurements and tolerances by size (e.g., chest, sleeve length, sweep).

- Fabric attributes: weight (gsm), composition, finish, coatings.

- Construction: seam type, tape placement, bartack points.

- Testing targets: pilling, colorfastness, hydrostatic head, flammability.

- Packaging: fold method, polybag spec, carton size, labeling.

[MENTION: ASTM and AATCC methods for apparel testing]. [CITE: Standard hydrostatic test protocols via AATCC/ISO]. [INTERNAL LINK: Pattern grading and tolerance tutorial].

Sampling sequence: from proto to pre-production

- Proto (fit) sample: confirm silhouette and critical points of measure.

- Sales sample: polish trims/colors; used for images and retail previews.

- Size set: verify grading across sizes for US and EU conversions.

- Pre-production (PP): final approval for production; all details signed off.

- TOP (top-of-production): first units off line reviewed before full run.

Keep change logs with version control and freeze specs before PP. Eton locks PP checklists with brands to reduce late-stage changes and margin loss.

US & EU compliance, labeling, and testing: build trust and avoid relabels

Compliance protects customers and your brand. Plan CPSIA/CPSC and REACH requirements at design phase to avoid relabeling and retesting after production.

Core standards and regulations

- United States: CPSIA for children’s wear, CPSC guidance, 16 CFR Part 1610 flammability for clothing textiles, California Prop 65 for chemicals.

- European Union: REACH registration/restrictions, General Product Safety Regulation, child safety standards, country-of-origin labeling where applicable.

- Certifications: OEKO-TEX Standard 100, bluesign, ISO 9001/14001, Higg Index modules.

| Requirement | United States | European Union |

|---|---|---|

| Fiber content | FTC Textile Rules; percent by fiber | EU labeling directives; local transpositions |

| Care labels | ASTM care symbols widely used | GINETEX care symbols licensed |

| Children’s wear | CPSIA lead/phthalates; tracking labels | EN safety standards; cords/fasteners limits |

| Chemical compliance | Prop 65; brand RSL/AFIRM lists | REACH SVHC; brand RSL/AFIRM lists |

| Flammability | 16 CFR Part 1610 (adult apparel) | Country-specific norms; risk-based |

| Country of origin | Required on label | Required; format varies |

[MENTION: U.S. Consumer Product Safety Commission (CPSC)], [MENTION: European Chemicals Agency (ECHA)]. [CITE: CPSIA tracking label guidance from CPSC]. [CITE: REACH SVHC list from ECHA].

Sourcing and sustainability: specify materials that fit your promise and market

Material choices drive performance, cost, and compliance. Source from audited mills, align RSL standards, and confirm certificates before sampling.

Fabric selection for outerwear

- Shells: nylon or polyester with PU or TPU coatings; confirm hydrostatic head ≥10,000 mm for rain shells where needed.

- Lining: lightweight woven or mesh for breathability; recycle content where possible.

- Insulation: down (600–800 fill power) or synthetic (80–200 gsm). For children’s wear, consider synthetic fills for washability and allergy concerns.

- Trims: YKK zippers, snaps with nickel-free options; reflective tapes meeting safety norms.

[MENTION: OEKO-TEX Standard 100], [MENTION: bluesign]. [CITE: Hydrostatic head performance thresholds via AATCC/ISO]. [CITE: Recycled polyester lifecycle impacts via a 2023 LCA study].

Responsible sourcing signals

- Certificates: OEKO-TEX, bluesign, GRS for recycled content, Better Cotton for cotton supply chains.

- Audits: Sedex SMETA, WRAP, ACCORD/RSC (Bangladesh) where applicable.

- RSL alignment: AFIRM Group RSL; keep a signed compliance agreement with suppliers.

Set a sustainability floor that fits your brand thesis without overpricing the first drop. Eton’s mill network supports recycled shells and PFAS-free DWR where performance targets allow. [MENTION: AFIRM Group], [MENTION: Sustainable Apparel Coalition (Higg)].

Manufacturing models, MOQs, and lead times: choose OEM vs ODM and plan the calendar

OEM builds your designs; ODM adapts proven factory patterns and material libraries. Pick the path that matches speed, budget, and differentiation.

OEM vs ODM comparison

- OEM: Full design control; longer development, higher upfront sampling costs; ideal for unique silhouettes or technical performance claims.

- ODM: Faster market entry; factory’s base patterns and materials; lower development cost; good for first drops validating demand.

Eton runs both models. Startups often pilot ODM capsules to learn and switch to OEM once data confirms the fit and margin thesis. [CITE: Average startup time-to-market data from a 2024 apparel operations study].

Timeline and capacity planning

| Phase | Duration (weeks) | Milestones |

|---|---|---|

| Design & tech pack | 2–4 | Specs frozen; BOM confirmed |

| Proto & fit | 3–4 | Fit approved; critical measures signed |

| Sales samples | 2–3 | Imagery; retail previews |

| PP sample | 1–2 | Final sign-off; materials in-house |

| Bulk production | 6–10 | Inline QA; TOP checked |

| Logistics | 1–6 | Air: 7–10 days; Ocean: 4–6 weeks |

[MENTION: International Chamber of Commerce Incoterms 2020], [MENTION: Freight rate indices]. [CITE: Typical ocean transit times and rate ranges, 2024 freight reports].

Budgeting, unit economics, and pricing: protect margin from day one

Cost clarity simplifies “how can I create my own clothing line” decisions. Price backward from MSRP, lock landed cost targets, and model scenarios for MOQs and shipping choices.

Cost breakdown example (outerwear)

| Component | USD | % of FOB |

|---|---|---|

| Materials (fabric, trims) | $18.00 | 45% |

| Cut & sew labor | $9.00 | 22% |

| Overhead & margin (factory) | $7.00 | 17% |

| Testing & compliance | $2.00 | 5% |

| Packaging | $1.50 | 4% |

| FOB subtotal | $37.50 | 100% |

| Freight & insurance | $2.50 (ocean) | — |

| Duties & customs | $3.75 (HS code dependent) | — |

| Landed cost | $43.75 | — |

For wholesale, aim for 2.2–2.5x landed cost; for DTC, 4.0x is common in outerwear when positioning allows. EU brands model VAT, eco-fees, and local logistics; US models sales tax and final-mile costs. [CITE: Margin benchmarks from a 2023–2024 apparel retail study].

Incoterms and landed cost control

- FOB vs CIF: FOB offers freight control; CIF shifts logistics to seller.

- HS codes: confirm duty rates early; lock documentation with the factory.

- Ship mix: ocean for margin, air for speed when cashflow permits.

[MENTION: ICC Incoterms 2020], [MENTION: U.S. International Trade Commission tariff database]. [CITE: EU TARIC duty reference].

Production with a China clothing manufacturer: what good looks like

High-performing factories commit to transparent calendars, QA gates, and compliance-ready material sourcing. Expect disciplined communication, sample rigor, and capacity planning.

Eton’s OEM/ODM process in practice

- RFQ and technical review: factory evaluates feasibility, performance targets, and BOM risks.

- Quotation: cost scenarios across MOQs and materials; calendar alignment.

- Proto, fit, and sales sampling: cross-functional checkpoints log changes.

- Material bookings: mill lead times secured; lab dips and color approvals.

- PP approval and pilot run: QA plans and AQL sampling rates confirmed.

- Inline QA and TOP: documented inspections and corrective actions.

- Packing, carton tests, and labeling: US/EU rules verified.

- Logistics and handover: booking, customs, and delivery windows tracked.

Eton’s China and Bangladesh bases support seasonal peaks, with audited lines for down jackets, parkas, and technical sportswear. Legacy programs include sports licensing and large-format retail. [MENTION: Liverpool F.C. licensed apparel programs], [MENTION: Forever 21 outerwear vendor programs]. [INTERNAL LINK: Case study—outerwear capacity planning].

Quality assurance and risk management: measure, document, remediate

Fit drift, seam failures, and color variances burn margin. AQL inspections, lab tests, and documented corrective actions keep shipments consistent.

QA gates and metrics

- Fit QA: tolerance checks per size; PP and TOP approvals archived.

- Materials QA: fabric tests—colorfastness, pilling, hydrostatic head; trim function tests.

- Process QA: seam strength, tape adhesion, needle damage audits.

- Final QA: AQL-based sampling and carton checks, with rework criteria.

Third-party labs such as SGS and Intertek provide test reports acceptable to US/EU buyers. Keep a master defect log per style to learn across seasons. [MENTION: SGS], [MENTION: Intertek]. [CITE: Standard AQL tables and sampling method references].

Launch and go-to-market: content, logistics, and retail rhythm

Tie your calendar to your channel. Wholesale needs samples by line review; DTC needs photography, content, and inventory synchronized around campaign moments.

DTC and wholesale workflows

- DTC: PDP content, fit guides, care pages, returns policy; launch photography and short video.

- Wholesale: line sheets, price lists, MOQ agreements, sample dispatch, EDI capability for larger retailers.

- Logistics: carton specs for ecommerce, retail pack requirements for wholesale, routing guides by account.

EU brands factor VAT presentation and local languages on PDPs; US brands set clear tax and returns. Keep one SKU code system across channels to avoid inventory mismatches. [CITE: 2024 ecommerce return rate benchmarks].

Post-launch learning loop

- Size sell-through analysis: compare US vs EU conversion rates.

- Heatmap on PDP: refactor content based on engagement.

- Customer service logs: feed improvements into next tech pack.

[INTERNAL LINK: Guide to sell-through analysis for outerwear]. [MENTION: Google Analytics 4 ecommerce tracking], [MENTION: Shopify performance tooling].

Work with Eton: OEM/ODM outerwear done right

Eton Garment Limited manufactures high-quality outerwear for global brands through OEM and ODM models, with audited lines in China and Bangladesh. From down jackets and parkas to functional sportswear, Eton pairs technical development with disciplined calendars.

Capabilities and programs

- Technical materials: coated shells, seam-sealed constructions, PFAS-free DWR pathways.

- Insulation expertise: down fill standards and synthetic loft management.

- Compliance-ready: OEKO-TEX, bluesign-aligned sourcing; CPSIA/REACH workflows.

- Partner portfolio: Liverpool F.C., Forever 21, Babyshop, Max, Gloria Jeans, Jeep Apparel, TFG Group.

For first-time and scaling brands, Eton offers a complete Clothing Manufacturing OEM Service. Explore the service details at Clothing Manufacturing OEM Service to review sampling pathways, QA frameworks, and calendar planning built for US and EU launches.

[INTERNAL LINK: Eton Garment Limited—about and certifications]. [INTERNAL LINK: Author bio—factory-side apparel development experience].

Your next 12 moves: from idea to first shipment

This sequence gets a first drop live with fewer pivots. Treat it as your control plan and adjust only when data proves a better route.

- Write a one-sentence brand thesis and select one hero product.

- Set MSRP and margin lane for your chosen channel.

- Create a complete tech pack with testing targets.

- Pick OEM or ODM based on speed and differentiation.

- Request quotes and calendars; confirm MOQs.

- Approve proto and fit; lock tolerances.

- Build sales samples and marketing content.

- Finalize PP; freeze changes and book materials.

- Run inline QA with AQL plans and TOP checks.

- Ship on the best incoterm for cashflow/margin.

- Launch with clear PDPs, returns policy, and support scripts.

- Review sell-through and customer feedback; update next tech pack.

Textile From Day One.

References & Sources

- Business of Fashion & McKinsey — State of Fashion (2024). [CITE: BoF/McKinsey report link]

- U.S. Consumer Product Safety Commission — CPSIA guidance (2024). [CITE: CPSC CPSIA overview link]

- European Chemicals Agency — REACH SVHC list (2024). [CITE: ECHA SVHC page link]

- OEKO-TEX — Standard 100 criteria (2024). [CITE: OEKO-TEX Standard 100 link]

- bluesign — System partner criteria (2023). [CITE: bluesign system page]

- AFIRM Group — RSL Toolkit (2024). [CITE: AFIRM RSL link]

- International Chamber of Commerce — Incoterms 2020 (2020). [CITE: ICC Incoterms page]

- AATCC/ISO — Hydrostatic head test methods (2023). [CITE: AATCC/ISO method links]

- SGS — Apparel testing services overview (2024). [CITE: SGS testing page]

- Intertek — Textile and apparel testing (2024). [CITE: Intertek testing page]

- USITC — Tariff information and HS codes (2024). [CITE: USITC DataWeb/Tariff link]

- EU TARIC — Integrated Tariff (2024). [CITE: EU TARIC link]

- Sustainable Apparel Coalition — Higg Index (2023). [CITE: SAC Higg Index page]

- Sedex — SMETA auditing (2023). [CITE: Sedex SMETA page]

- RSC (Bangladesh) — Factory safety standards (2024). [CITE: RSC/ACCORD site]

De-AI rewrite: same structure, more human cadence

How can I create my own clothing line? Set a sharp promise, tighten your specs, and line up a proven China clothing manufacturer who knows US/EU rules and retail timing. The notes below draw on Eton Garment’s factory playbook so your first shipment lands without detours.

Start here: blueprint your brand and the route to market

Pick a lane and commit. One category, one customer, one calendar. Decide whether you’re selling through your site or pitching retailers, then work backward to margins and dates. That choice changes sampling pace, MOQ risk, and the content you need.

- One-line promise: fit, function, occasion—no fluff.

- Hero focus: insulated jacket or rain shell; avoid a five-style spread.

- Price lane: wholesale vs DTC math set before design gets fancy.

- Rules: CPSIA/CPSC for the US, REACH for the EU baked into the tech pack.

- Factory fit: capacity, timing, and the gear you’re building match.

[MENTION: Business of Fashion State of Fashion report], [MENTION: McKinsey]. [CITE: Margin norms from a recognized retail study]. [INTERNAL LINK: Unit economics explainer].

Design and technical development: turn vision into production-ready specs

Mood boards don’t ship. Tech packs do. Specs, tolerances, BOM, and test targets cut out rework and catch surprises before a PO exists. If you’re building outerwear, lock hydrostatic head and breathability numbers the mill can hit on schedule.

- Measurements by size with tolerances.

- Fabric attributes—weight, coating, finish.

- Construction notes and stitch callouts.

- Test targets—pilling, colorfastness, flammability where relevant.

- Packaging details—bags, cartons, labels.

[MENTION: ASTM, AATCC]. [CITE: Hydrostatic method references]. [INTERNAL LINK: Grading/tolerance reference].

- Proto fit—approve silhouette and critical points.

- Sales samples—lock trims and colors for photos.

- Size sets—US/EU grading works across sizes.

- PP—final sign-off before production.

- TOP—first units checked before the full run.

US & EU compliance, labeling, and testing: build trust and avoid relabels

Labels and test reports don’t matter until they do—like when customs holds cartons or a retailer refuses intake. Plan compliance in design so your first shipment passes quietly.

- US: CPSIA, CPSC, 16 CFR 1610, Prop 65 where relevant.

- EU: REACH, GPSR, child safety norms, country-of-origin labeling.

- Certificates: OEKO-TEX, bluesign; management systems like ISO 9001/14001.

| Requirement | United States | European Union |

|---|---|---|

| Fiber content | FTC Textile Rules | EU labeling directives |

| Care labels | ASTM symbols common | GINETEX symbols licensed |

| Children’s wear | CPSIA + tracking labels | EN safety standards |

| Chemical compliance | Prop 65; AFIRM RSL | REACH SVHC; AFIRM RSL |

| Flammability | 16 CFR 1610 | Country norms |

| Country of origin | Required | Required |

[MENTION: CPSC], [MENTION: ECHA]. [CITE: CPSIA label guidance]. [CITE: REACH SVHC list].

Sourcing and sustainability: specify materials that fit your promise and market

Pick shells and insulation that meet the use case and your price lane. If you want rain-grade performance, call out hydrostatic head and seam sealing. If you want wash-and-wear warmth, spec synthetic loft by gsm and test it.

- Shells: PU/TPU coatings and DWR options; confirm mm ratings with mills.

- Insulation: down fill power vs synthetic gsm; kids wear favors synthetic.

- Trims: quality zipper brands and nickel-free snaps when required.

[MENTION: OEKO-TEX], [MENTION: bluesign]. [CITE: Performance testing references]. [CITE: Recycled polyester LCA].

- Certificates: OEKO-TEX, bluesign, GRS, Better Cotton.

- Audits: Sedex SMETA, WRAP, RSC/ACCORD.

- RSL: AFIRM alignment across mills and factories.

[MENTION: AFIRM], [MENTION: Higg]. Eton’s mill list supports PFAS-free pathways when product targets allow.

Manufacturing models, MOQs, and lead times: choose OEM vs ODM and plan the calendar

OEM means your pattern; ODM means the factory’s. Start with ODM if you need speed and proof. Shift to OEM once customers confirm your fit and story.

- OEM: more control, more development time.

- ODM: faster, proven blocks and materials, lower development cost.

[CITE: Time-to-market benchmarks].

| Phase | Duration (weeks) | Milestones |

|---|---|---|

| Design & tech pack | 2–4 | Specs frozen; BOM confirmed |

| Proto & fit | 3–4 | Fit approved |

| Sales samples | 2–3 | Imagery; previews |

| PP sample | 1–2 | Final sign-off |

| Bulk | 6–10 | Inline QA |

| Logistics | 1–6 | Ocean vs air |

[MENTION: ICC Incoterms], [MENTION: freight indices]. [CITE: 2024 transit/rate data].

Budgeting, unit economics, and pricing: protect margin from day one

Model landed cost before a PO. Lock duty rates via HS codes and choose FOB or CIF based on who controls freight. Wholesale targets often sit around 2.2–2.5x landed; DTC around 4x when the brand carries it.

| Component | USD | % of FOB |

|---|---|---|

| Materials | $18.00 | 45% |

| Labor | $9.00 | 22% |

| Overhead & margin | $7.00 | 17% |

| Testing | $2.00 | 5% |

| Packaging | $1.50 | 4% |

| FOB subtotal | $37.50 | 100% |

| Freight | $2.50 | — |

| Duties | $3.75 | — |

| Landed | $43.75 | — |

[CITE: Retail margin benchmarks]. [MENTION: USITC tariff tools], [MENTION: EU TARIC].

Production with a China clothing manufacturer: what good looks like

Expect candor on feasibility, calendar math that survives real lines, and QA that catches drift before cartons tape shut. Eton runs twin bases (China, Bangladesh) to handle seasonality and large outerwear runs.

- RFQ with technical review.

- Quote and calendar.

- Proto/fit and sales samples.

- Material booking and color approvals.

- PP and pilot run.

- Inline QA and TOP.

- Packing and labeling checks.

- Logistics handover.

[MENTION: Liverpool F.C.], [MENTION: Forever 21]. [INTERNAL LINK: Capacity planning note].

Quality assurance and risk management: measure, document, remediate

Write the QA plan, not hope for it. Fit checks at PP/TOP, seam strength tests, color approvals, and AQL sampling at the end keep units salable. Third-party labs keep buyers comfortable.

- Fit and tolerance checks per size.

- Fabric tests and trim function checks.

- Seam strength and tape adhesion audits.

- AQL-based final checks and carton tests.

[MENTION: SGS], [MENTION: Intertek]. [CITE: AQL references].

Launch and go-to-market: content, logistics, and retail rhythm

DTC needs clean PDPs, sizing help, and returns clarity; wholesale needs buyers’ calendars, samples on time, and routing guides followed. One SKU code system across channels keeps inventory sane.

- DTC: images, fit guides, care info, and a clear returns policy.

- Wholesale: line sheets, MOQs, EDI readiness where needed.

- Logistics: ecommerce pack outs vs retail-pack requirements.

[CITE: Ecommerce return rates, 2024]. [INTERNAL LINK: Sell-through analysis]. [MENTION: GA4], [MENTION: Shopify].

Work with Eton: OEM/ODM outerwear done right

Eton builds down jackets, parkas, and technical sportswear at scale. For first drops and growth runs, review the Clothing Manufacturing OEM Service to see sample paths, QA plans, and calendars tuned to US and EU launches.

[INTERNAL LINK: Eton certifications], [INTERNAL LINK: Author bio].

Your next 12 moves: from idea to first shipment

- Write the promise and pick a hero product.

- Set MSRP and margin targets.

- Build the tech pack and test plan.

- Pick OEM or ODM.

- Get quotes and lock MOQs.

- Approve proto and fit.

- Make sales samples; shoot content.

- Approve PP and book materials.

- Run QA and TOP.

- Ship on the right incoterm.

- Launch with clean PDPs.

- Review and update for drop two.

Textile From Day One.

FAQs

Related Articles

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »