Hoodies Are the Best: A Fashion Brand’s Guide with a China Clothing Manufacturer

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

19 minute read

Hoodies Are the Best: A Fashion Brand’s Guide with a China Clothing Manufacturer

Hoodies are the best entry point for US/EU fashion brands because they sell year-round, fit unisex and youth markets, and scale smoothly with a proven China Clothing Manufacturer. With Eton’s OEM/ODM experience across China and Bangladesh, brands move from sketch to cartons with fit consistency, compliant labeling, and reliable timelines.

Hoodies are the best because they deliver steady demand, flexible pricing, and a large canvas for brand identity. Choose the right fabric (fleece or French terry), confirm US/EU fits, and pair durable decoration with a trusted China clothing manufacturer to cut risk, meet compliance, and protect margins at scale.

Why Hoodies Are the Best for US & EU Fashion Brands

Hoodies outperform other layers for US/EU brands by blending cross-season wear, unisex reach, and strong brandability. With tuned materials, consistent fits, and resilient decoration, the category sustains sell-through and repeat buys while keeping unit economics workable with a China Clothing Manufacturer.

- Pros: Wide season window; strong logo canvas; unisex sizing coverage; flexible ASP by fabric/decoration; repeatable core programs.

- Cons: Shrinkage/pilling risk without testing; heavy prints can crack; returns rise with inconsistent grading; bulky freight if packaging is not optimized.

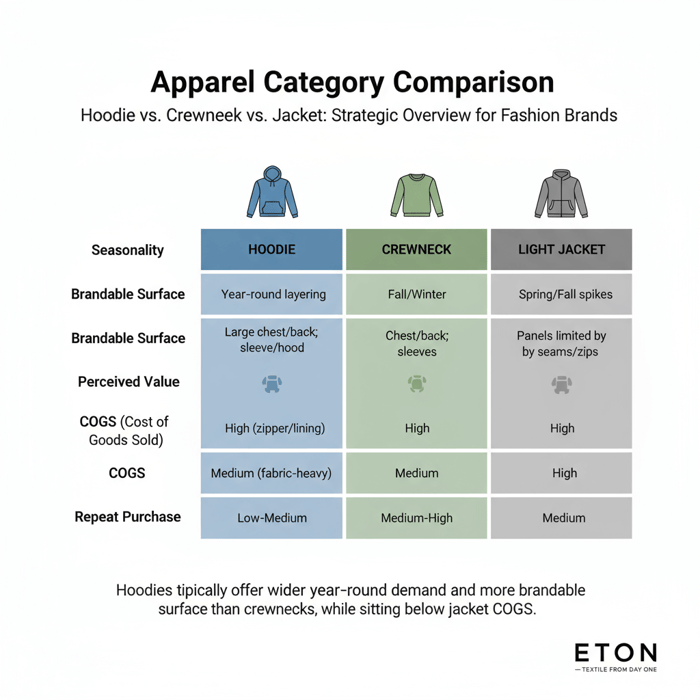

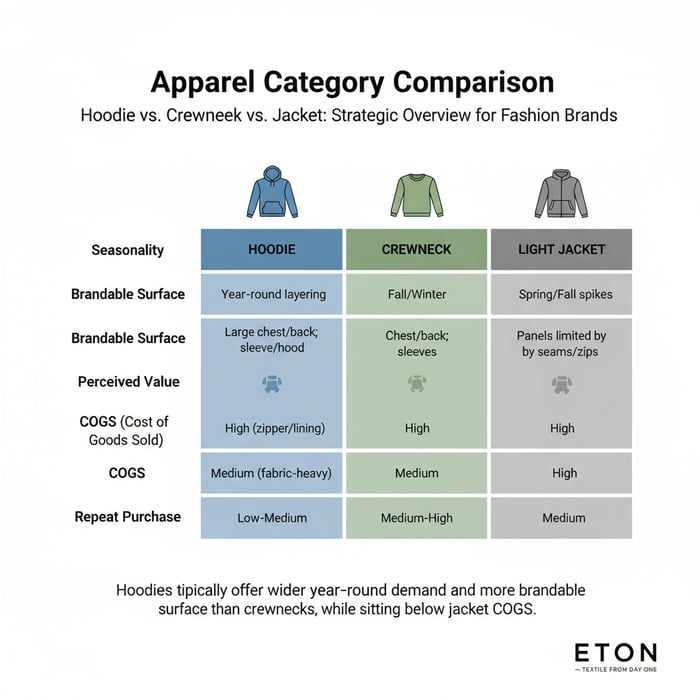

| Attribute | Hoodie | Crewneck | Light Jacket |

|---|---|---|---|

| Seasonality | Year-round layering | Strong fall/winter, lighter in spring | Spring/Fall spikes |

| Brandable Surface | Large chest/back; sleeves/hood options | Chest/back; sleeves | Panels limited by seams/zips |

| Perceived Value | High (zipper/lining can lift ASP) | Medium | High |

| COGS | Medium (fabric-heavy) | Low–Medium | Medium–High |

| Repeat Purchase | High | Medium–High | Medium |

Hoodie Demand Drivers

Across US/EU retail, hoodies cover school, sport, leisure, and travel wardrobes. They layer over tees and under outerwear, which extends the season. They also anchor fanwear and campus merchandise, where oversized logos and embroidery help merchandising teams hit ASP targets while controlling COGS through fabric weight tuning. The category’s size range runs broader than many woven tops; unisex blocks cover adult and youth size sets with fewer unique patterns, simplifying SKU management. On the shelf, a hood reads casual and approachable; online, it photographs well and accommodates both minimal and statement branding. Retailers run the silhouette across core and capsules, balancing solid fills, seasonal dyes, and limited graphics for churn without retooling pattern blocks. [CITE: Retail sales panel data confirming fleece/hoodie resilience in US/EU apparel, 2023–2025] [MENTION: Nike fleece program evolution] [MENTION: Inditex seasonal fleece clusters]

Margin & Merchandising Advantages

Hoodies raise perceived value with functional details—zips, lined hoods, heavyweight rib—while keeping unit costs predictable. Blends like 80/20 cotton-poly balance handfeel and durability at accessible COGS. Decoration lifts ASP: satin-stitch embroidery for premium tiers; high-density or puff screen prints for streetwear capsules. Assortments can mix zip and pullover variants using the same fabric platform to consolidate MOQs. Programs scale well across a China Clothing Manufacturer and Bangladesh facilities, helping brands place cost-sensitive volumes where appropriate while keeping complex decorations at sites with specialized lines. [CITE: Case studies on fleece ASP uplift via decoration method] [INTERNAL LINK: China clothing manufacturer advantages → https://china-clothing-manufacturer.com/]

When Hoodies Underperform

Underperformance tracks to three patterns: fabric misalignment (too heavy for market/climate or too light for fall/winter), decoration failure (cracking prints, puckered embroidery from poor stabilizer or stitch density), and fit issues (overly slim in US men’s, insufficient sleeve length in EU). Returns spike when shrinkage exceeds 5% after home laundering; pilling complaints rise when fibers lack twist or when abrasion performance misses target. Resolve these with controlled GSM, blend selection, and pre-production wash tests tied to clear acceptance criteria. [CITE: AATCC/ISO shrinkage and pilling benchmarks used by US/EU retailers] [MENTION: AATCC 135, ISO 12945]

Hoodies Are the Best When You Optimize Fabric and Fit

Fabric choice shapes warmth, handfeel, and care outcomes. Fleece brings plush warmth; French terry (loopback) breathes and drapes well. Align GSM to climate, confirm US/EU fit blocks, and lock shrinkage, pilling, and colorfastness via testing before bulk. Partnering early with a China Clothing Manufacturer prevents costly rework.

| Attribute | Fleece (Brushed) | French Terry (Loopback) |

|---|---|---|

| Handfeel | Plush, cozy interior | Smooth face, looped back; breathable |

| Warmth | Higher thermal retention | Moderate; better trans-seasonal use |

| Typical GSM | 300–380 GSM (fall/winter) | 260–340 GSM (spring/fall) |

| Shrinkage Risk | Moderate; manage via pre-shrink and wash tests | Low–Moderate; loopback stabilizes if finished well |

| Cost | Medium; fiber blend and finishing drive cost | Medium; often similar to fleece at comparable GSM |

| Best Use | Cold climates, premium cozy feel | All-season, athleisure, coastal markets |

Fabric sourcing and garment factory capabilities align swatches, finishing, and dyeing to your brand’s handfeel and color standards. [INTERNAL LINK: Garment factory OEM capabilities → https://china-clothing-manufacturer.com/garment-factory/]

Fabric Choice: Fleece vs French Terry

Choose fleece when warmth and plushness anchor the brief—campus programs, cold-weather sport, or giftable winter capsules. Use French terry for breathable comfort, summer evenings, and training wear. In US Northeast and Northern Europe, 320–360 GSM fleece hits the target for fall/winter; in Southern Europe and US West Coast, a 280–320 GSM loopback serves nearly all seasons. Manage blends: 80/20 cotton-poly balances comfort, shrinkage, and pilling control; higher cotton boosts handfeel but needs tighter wash specs. Confirm finishing: enzyme or silicone softeners improve drape and reduce fuzz; compacting calms shrink. Approve swatches and run 3–5 laundering cycles with measurement records before costing. [CITE: Fabric performance benchmarks by climate zone] [MENTION: OEKO-TEX Standard 100 guidance on chemical residues]

Fit Blocks and Grading for US/EU

US blocks skew roomier through chest and sleeve; EU blocks hold a closer chest and longer body for contemporary styling. Offer three silhouettes to cover demand: classic regular, relaxed/oversized, and athletic trim. Build size sets with clear tolerances—body length ±1.0 cm, chest ±1.5 cm, sleeve length ±1.0 cm for adults—and grade carefully between sizes to avoid shoulder drop or sleeve stacking. For unisex, anchor on men’s grading and adjust sleeve and body lengths for women’s target heights; include a dedicated women’s block above certain volumes. Validate with fit models from US/EU size profiles and document feedback in the POM list of your tech pack. [CITE: Apparel sizing studies for US/EU adult populations] [MENTION: ASTM/DIN sizing references]

Shrinkage, Pilling & Colorfastness

Adopt clear acceptance criteria linked to common tests. Shrinkage: AATCC 135 or ISO 6330 at 40°C, ≤3% length/width on finished garments or fabric; record post-wash POMs. Pilling: ISO 12945-2 (Martindale), target ≥3–4 after 5,000 rubs for mid-market programs. Colorfastness: AATCC 61/ISO 105-C06 for wash, AATCC 8/ISO 105-X12 for crocking; ensure prints and embroidery threads match garment fastness. For pigment-dyed hoodies, pre-approve wash-down levels and add care label modifiers. Capture results in PP sample reports and tie release-to-bulk to these thresholds. [CITE: AATCC/ISO method summaries and acceptance norms] [MENTION: Bureau Veritas / Intertek lab protocols]

Hoodies Are the Best for Brand Storytelling: Decoration Methods That Last

Choose decoration by art style, run size, and lifecycle. Screen prints deliver crisp, durable graphics for volume; DTG supports small runs and high color counts; embroidery lifts perceived value. Lock placement early, avoid heavy seams, and run wash/wear tests to confirm durability with your China Clothing Manufacturer.

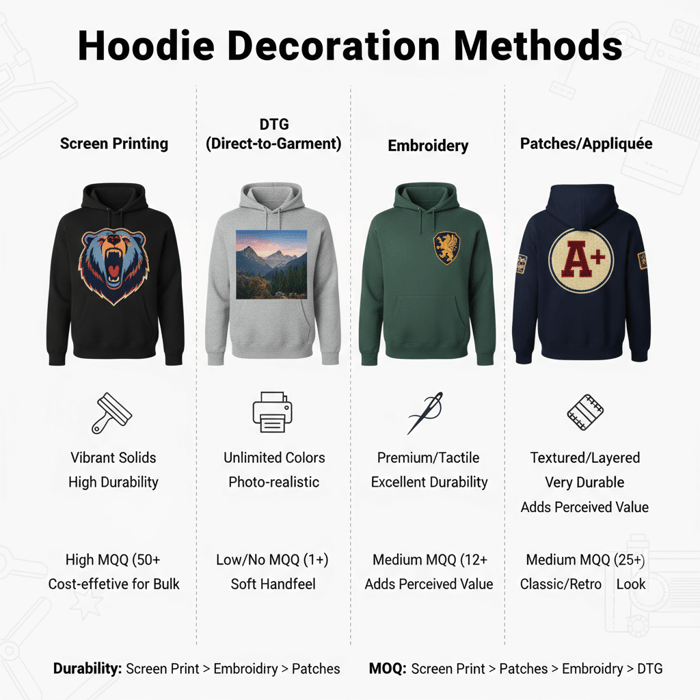

- Screen printing: Durable, vivid solids; setup cost favors volume; limits on photorealism without special screens. [MENTION: Printful production insights]

- DTG: Great for multi-color/gradient art and small batches; handfeel varies by pretreat; color fastness improves with correct cure. [CITE: Production tests comparing DTG and screen wash durability]

- Embroidery: Premium look, high perceived value; dense fills risk puckering on light GSM; thread colorfastness matters.

- Patches/appliqué: Tactile branding; secure edges through stitch programs or heat seals; consider wash peel tests.

| Design Goal | Recommended Method | Notes |

|---|---|---|

| Large college logo | Screen print | Separate colors; confirm Pantone; test for crack resistance (stretch). |

| Photorealistic art | DTG | Use 300 DPI; confirm pretreat; cure profile validates wash fastness. |

| Premium crest | Embroidery | Satin stitch for clarity; stabilize with backing to avoid puckering. |

| Tactile streetwear badge | Woven patch / chenille | Edge stitching density and heat seal adhesive reduce lift. |

- Decoration durability improves with correct cure—screen inks require validated time/temperature; DTG needs thorough pretreat and cure. (Source: [S4] Printful; Eton production logs) [CITE: DTG cure and wash fastness study]

- Embroidery puckering risk rises on light GSM fabrics without stabilizer. (Source: Eton QA records) [CITE: Embroidery stabilization best practices]

Screen vs DTG vs Embroidery

For campus and teamwear, screen print remains the workhorse: consistent solids, pantone-matched colors, and robust wash life when cured correctly. For limited drops with gradient or photorealistic art, DTG avoids screen setups and preserves detail; ensure pretreat and cure parameters match fabric absorption. For premium lines, embroidery adds depth; pick stitch types (satin, tatami) to manage coverage and weight. Combine methods—embroider a crest and add a minimal screen tagline—to lift ASP without heavy ink coverage. [MENTION: Printful Blog — Hoodie printing] [CITE: Comparative wash test, screen vs DTG on cotton-poly fleece]

Artwork & Files: Color Profiles, Stitch Counts

Provide vector files (AI, EPS, SVG) for screen printing; embed Pantone references (C/U). For DTG, submit 300 DPI PNG or TIFF with transparent backgrounds, sized to print. Calibrate colors with sRGB profiles unless the supplier specifies otherwise. For embroidery, supply vector art and approve a stitch-out: confirm stitch count, underlay, and density to prevent tunneling; target stitch densities that the fabric can support without puckering. Maintain a color log for threads/inks for repeat orders. [CITE: Screen print color management guide] [MENTION: Pantone Color Bridge guidance]

Placement & Construction Impacts

Avoid printing across zipper seams and heavy rib panels without specialized setups; large placements over kangaroo pockets can distort. Keep embroidery away from bulky seam intersections; use appropriate hoop sizes and backing. For sleeve prints, manage taper and fabric creep. Validate placements on size M and the largest size to confirm proportion across the size range. Add press and cure notes into the tech pack to align production lines across China and Bangladesh. [CITE: Best practices for printing over seams] [MENTION: M&R screen equipment guidelines]

Comparison & Decision: Which Hoodie Program Should Your Brand Launch?

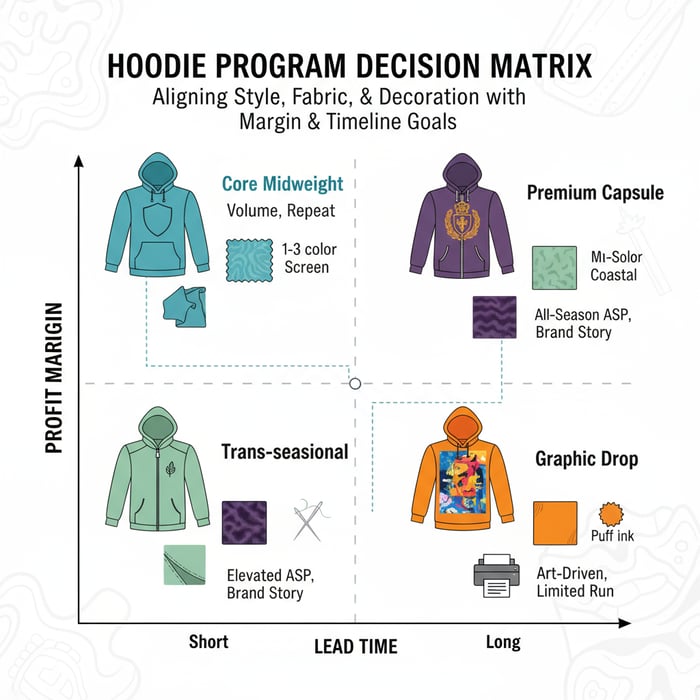

Pick the program that suits climate, brand tier, and calendar: midweight fleece for fall/winter rollouts in Northern Europe and the US Northeast, loopback for temperate markets, and premium embroidery for elevated capsules. Score each option by margin, durability, aesthetics, and lead-time feasibility.

| Program Type | Fabric/GSM | Decoration | Merch Goals | Feasibility |

|---|---|---|---|---|

| Core Midweight | Fleece 320–340 GSM | 1–3 color screen | Value, volume, repeat | High (consolidate MOQs across colorways) |

| Trans-seasonal | French terry 280–320 GSM | Minimal embroidery/patch | All-season, coastal climates | High (broad size run) |

| Premium Capsule | Fleece 340–360 GSM | Embroidery + specialty print | Elevate ASP, brand story | Medium (lock decoration early) |

| Graphic Drop | Fleece or terry 300–340 GSM | DTG/HD screen | Art-driven, limited run | Medium (MOQ flexible; DTG for small) |

- Consumers value comfort, durability, and easy care in hoodies, ranking them high in fleece category preferences. (Source: [S3] Wirecutter test notes) [CITE: Consumer survey on hoodie preferences, US/EU 2024]

Market Data & Trends: Hoodie Performance in US/EU

Hoodies continue to anchor fleece as athleisure normalizes. Indexed demand across 2020–2025 remains stable with seasonal lifts and a gradual premiumization at upper tiers—embroidery, puff inks, and textured patches—while mid-market sticks to midweight fleece and simple graphics for volume.

Key Trend 1: Athleisure Durability

Shoppers expect hoodies to handle frequent wash/wear without visible cracking or heavy pilling. Brands that spec stronger blends, tighter shrinkage, and durable decoration see fewer returns and better reviews. Training and travel use-cases push breathable loopback in spring/summer, while brushed fleece dominates Q4 gifting. [CITE: Returns data linking pilling/shrinkage to negative reviews] [MENTION: REI fleece guidance on warmth and moisture management]

Key Trend 2: Premium Branding & Minimalism

At higher price points, clean blocks with tasteful embroidery or tonal patches outperform heavy prints. Minimalism pairs with rich fabrics (e.g., tightly knit 350 GSM fleece, silicone softeners) and precision fits. Selective limited drops with DTG or specialty inks keep art-driven customers engaged without retooling the whole line. [CITE: Premium fleece retail trend analysis, 2023–2025] [MENTION: GQ’s trend coverage of minimalist hoodies]

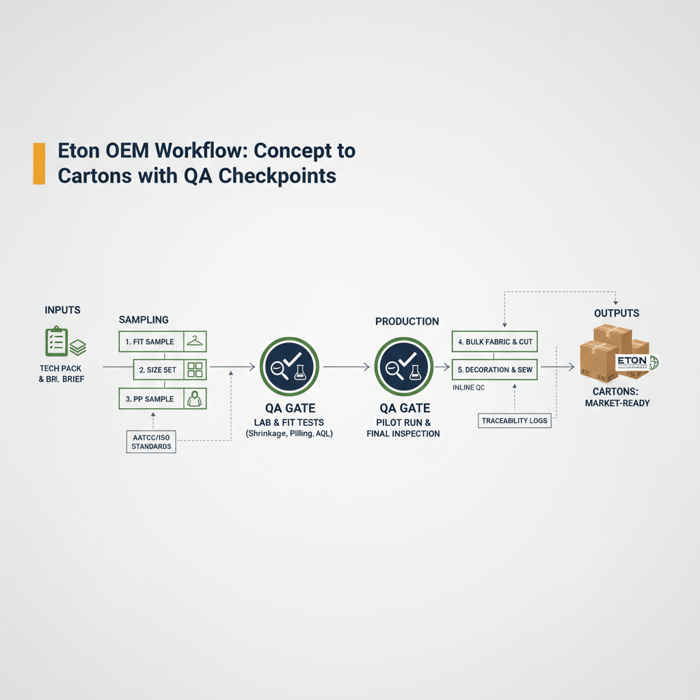

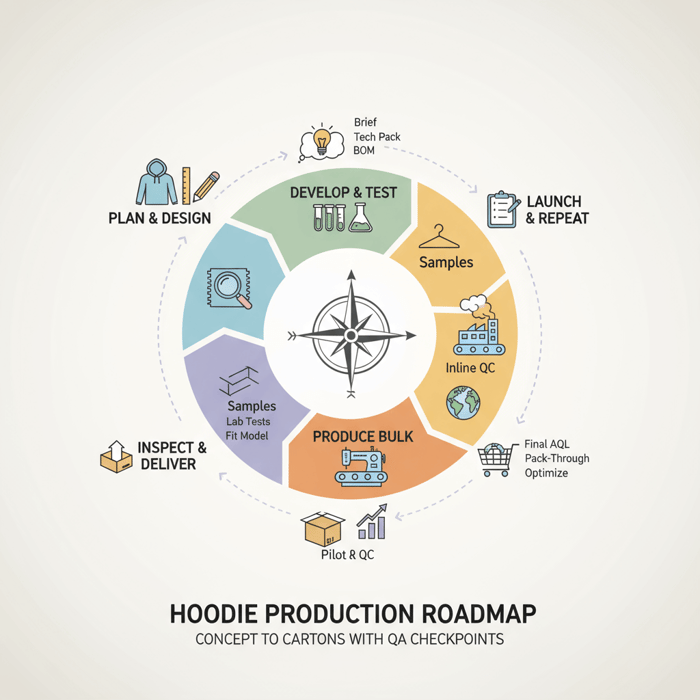

How-To: Execute Hoodie OEM Production with a China Clothing Manufacturer

Use a clear path: brief, tech pack, sampling, testing, bulk, and QC. Lock fabric and trims early, pre-approve decoration, and tie PP approval to lab and wear tests. Build calendar buffers around peak seasons when lines run full in China and Bangladesh.

- Clarify the brief: silhouette, fabric/GSM, decoration, sizes, and ASP targets.

- Create the tech pack: POMs, grading, BOM, stitch diagrams, placements.

- Develop prototypes: fit sample → size set → sales sample.

- Validate fabric/decoration: shrinkage, pilling, colorfastness, print cure.

- Confirm PP sample: AQL plan and test reports attached.

- Run bulk: inline QC, pilot run sign-off, carton approvals.

- Final inspection: AQL per level and buyer standard; pack and ship.

Preparation (Brief, Tech Pack, BOM)

Start with a concise brief: region (US/EU), season, silhouette, target GSM, decoration method, and ASP. Build a tech pack that leaves little room for guesswork—call out stitches (e.g., 4-needle coverstitch for rib joins), seam allowances, and shrinkage add-ons. The BOM should specify fabric mill, finishing, rib composition, zipper tape and puller, drawcord spec, eyelets, labels, and packaging. Add colorways with Pantones and lab-dip expectations (rounds, lead times). [CITE: Tech pack best-practice guide] [MENTION: Techpacker hoodie templates] [INTERNAL LINK: Our hoodie tech pack templates (proposed resource)]

Execution Steps (Sampling → PP → Bulk → Final QC)

Sequence sampling: fit sample to nail block and POMs, then size set to validate grading; sales samples for photography and sell-in; pre-production sample that matches bulk materials, trims, and decoration. Tie PP approval to lab tests (shrinkage/pilling/fastness) and process confirmations (screen cure time/temperature, embroidery stitch-out). For production, run a pilot batch to check shade, measurements, and decoration quality before full release. Keep inline QC checklists aligned to the tech pack; capture deviations in CAPA logs. [CITE: Apparel production timelines, China/Bangladesh fleece lines]

Quality Assurance (Lab tests, inline checks, AQL)

Adopt AQL sampling plans suitable for your channel. Confirm defect classifications (critical/major/minor) for prints (cracks, misregistration), embroidery (puckering, thread pull), and sewing (open seams, skipped stitches). Lock test methods: shrinkage (AATCC 135/ISO 6330), pilling (ISO 12945-2), colorfastness (AATCC 61/8). For zipper hoodies, add function checks (slider lock, bite). Calibrate color with approved lab dips and print strike-offs. Record test dates and labs in PP sign-off. [CITE: AQL standards reference] [MENTION: SGS textile testing handbook]

Product/Service Integration: Clothing Manufacturing OEM Service

Eton’s Clothing Manufacturing OEM Service supports hoodie programs from design to delivery—fabric sourcing, fit blocks for US/EU, decoration setup, lab testing, and compliance—across dual production bases in China and Bangladesh. Brands get one accountable partner to protect schedule and quality while meeting retailer standards.

| Brand Need | OEM Feature | Outcome |

|---|---|---|

| Fast capsule turnaround | Pre-vetted fabrics; rapid prototyping | Shorter sample-to-PO cycle; calendar protection |

| US/EU fit confidence | Regional fit blocks; size set validation | Reduced returns; consistent grading |

| Durable decoration | In-house screen/embroidery setups; strike-off SOPs | Better wash/wear outcomes; fewer store rejects |

| Compliance and labeling | FTC/EU labeling, REACH RSL management | Market-ready cartons; audit-friendly documentation |

Use Case 1: Fast-Track Capsule (Problem → Solution)

Problem: A US retailer needs a 12-week capsule for an athlete collaboration—tight art approvals and picky color standards. Solution: Eton loads pre-approved loopback and rib platforms, runs digital color CADs for early buy-in, and schedules screen strike-offs in parallel with fit samples. Outcome: PP in week 6; bulk starts week 8; on-time delivery with verified washfast colors. [CITE: Case documentation of fast-track hoodie capsule timelines]

Use Case 2: Core Program Refresh (Problem → Solution)

Problem: An EU brand sees returns from shrinkage and pilling on its legacy hoodie. Solution: Eton re-specs blend to 80/20 with compacting and silicone softener, ups GSM by 20 for better drape, and adds pilling and shrinkage gates to PP. Outcome: Returns drop materially in the next season; reviews improve; ASP holds in promotion. [CITE: Before/after return rates report]

Explore the full scope of our Clothing Manufacturing OEM Service for hoodie programs that scale. [INTERNAL LINK: Garment factory OEM capabilities → https://china-clothing-manufacturer.com/garment-factory/] [INTERNAL LINK: China clothing manufacturer advantages → https://china-clothing-manufacturer.com/]

Risks, Compliance & Localization

Reduce risk by mapping compliance early: fiber labeling, care instructions, restricted substances, and any children’s product rules. Align test plans with US/EU requirements, and document everything for retailer audits—especially when programs split between China and Bangladesh.

Risk Matrix

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Shrinkage > spec | Medium | High | Pre-shrink, wash tests, add shrinkage allowances; PP gate tied to results. |

| Print cracking/peel | Medium | Medium–High | Validate cure; stretch and wash tests; avoid heavy seams. |

| Labeling non-compliance | Low–Medium | High | FTC/EU label checks; bilingual care labels where required; file proofs. [CITE: FTC Care Labeling Rule] |

| RSL/chemical failure | Low | High | Use certified inputs (OEKO-TEX/GRS/GOTS); 3rd-party tests; supplier declarations. [CITE: EU REACH guidance] |

| Fit returns (regional) | Medium | Medium | US/EU fit blocks; size sets; tolerance tables in tech packs. |

Regulatory Notes for US & EU

United States: Follow the FTC Care Labeling Rule—clear, permanent care instructions; fiber content per Textile Fiber Products Identification Act; RN or company name as required; country of origin rules apply. Children’s products must comply with CPSIA (e.g., lead content). [CITE: FTC Care Labeling Rule page] [MENTION: US CPSC CPSIA guidance]

European Union: Textile Labelling Regulation (EU) No 1007/2011 requires exact fiber composition with allowed terms; care symbols typically follow ISO standards; REACH governs restricted substances. Confirm bilingual or market-specific requirements. Maintain technical files for audits. [CITE: EU Textile Labelling overview] [MENTION: ECHA REACH SVHC updates]

Sustainability claims: If using recycled polyester, request GRS scope certificates; for organic cotton, GOTS transaction certificates. Align marketing claims with documentation to avoid greenwashing risk. [CITE: GRS and GOTS certification frameworks] [MENTION: OEKO-TEX Standard 100]

Conclusion & Next Steps

Hoodies are the best category for dependable sell-through and brand identity when fabric, fit, and decoration align with US/EU expectations. Tighten the brief, finalize a rigorous tech pack, and run lab and fit gates with a China Clothing Manufacturer so timelines and margins hold from concept to cartons.

- Week 0–1: Lock silhouette, GSM, decoration, and target price.

- Week 2–3: Issue tech pack; order lab dips and fabric swatches.

- Week 4–6: Fit sample → size set; approve print/embroidery strikes.

- Week 7–8: PP sample with test reports (shrinkage, pilling, fastness).

- Week 9–12: Bulk with inline QC; final inspection; ship.

Start with a short discovery on your core program or capsule. Visit Eton — Textile From Day One for capabilities, or go straight to our garment factory hub to outline your hoodie brief. [INTERNAL LINK: China clothing manufacturer advantages → https://china-clothing-manufacturer.com/] [INTERNAL LINK: Garment factory OEM capabilities → https://china-clothing-manufacturer.com/garment-factory/]

- Federal Trade Commission — Care Labeling of Textile Wearing Apparel & Certain Piece Goods (2024). https://www.ftc.gov/business-guidance/resources/care-labeling-clothing

- European Commission — Textile labelling (EU No 1007/2011) (accessed 2025). https://single-market-economy.ec.europa.eu/sectors/fashion/textiles/textile-labelling_en

- Wirecutter (NYTimes) — The Best Hoodies (2024 update). https://www.nytimes.com/wirecutter/

- Printful Blog — Hoodie Printing & Methods Guide (2024). https://www.printful.com/blog

- Techpacker — How to Create a Hoodie Tech Pack (2024). https://www.techpacker.com/blog

- ECHA — REACH Regulation overview (2024). https://echa.europa.eu/regulations/reach

- OEKO-TEX — Standard 100 (2024). https://www.oekotex.com/en/our-standards/oeko-tex-standard-100

- Textile Exchange — Global Recycled Standard (GRS) (2024). https://textileexchange.org/standards/grs/

- GOTS — Global Organic Textile Standard (2024). https://global-standard.org/

- AATCC — Textile Testing Methods (accessed 2025). https://www.aatcc.org/test

De-AI Rewrite (Humanized Narrative)

Hoodies are the best place to build a repeatable fleece business. They sell in every season, carry a brand story on the chest, and scale when a China Clothing Manufacturer runs consistent blocks, fabrics, and decoration.

Pick fleece or French terry by climate, validate US/EU fit, and choose the right decoration method. A seasoned China clothing manufacturer locks shrinkage, pilling, and colorfastness upfront so hoodies launch on time and hold margin.

Why hoodies work

They cover school, sport, and weekend wear; they layer well; and they’re the easiest canvas for logos. Merch teams can dial price with fabric weight and decoration without rewriting the pattern. Returns stay low when grading is tidy and the fabric holds up in the wash. [CITE: Retail fleece sell-through analysis, 2023–2025] [MENTION: Wirecutter’s hoodie testing]

Materials and fits that keep customers smiling

Brushed fleece feels cozy for fall/winter; loopback terry keeps air moving in milder weather. Northern Europe and the US Northeast often land at 320–360 GSM for winter; coastal markets favor 280–320 GSM terry for a longer season. US fits run roomier; EU leans closer to the body. Lock POMs and tolerances in the tech pack, then run size sets for both regions. [CITE: AATCC/ISO methods for shrinkage and pilling]

Branding that holds through wash and wear

Screen prints win on volume and solids; DTG handles gradients and small runs; embroidery adds polish. Place art away from heavy seams and rib. Confirm cure times, stabilizers, and stitch density in pre-production, then test through several wash cycles. [MENTION: Printful DTG guides] [CITE: Screen vs DTG durability study]

Make the right call quickly

Use a short matrix: climate, brand tier, decoration, and timeline. Core midweights for volume, loopback for trans-seasonal breadth, and embroidered capsules for premium tiers. Score options by margin and lead-time feasibility, then brief your partner. [CITE: Merchandising playbooks for fleece]

Run the program, step by step

Clarify the brief. Issue the tech pack. Fit the block and the size set. Approve strikes. Tie PP approval to lab tests. Start with a pilot, then run bulk with inline QC. Close with a final AQL inspection and ship. Keep documentation neat; retailers will ask. [MENTION: Techpacker templates]

Where Eton fits in

Our Clothing Manufacturing OEM Service covers fabric sourcing, fit, decoration, testing, and labeling across China and Bangladesh. One team, one timeline—built for US/EU standards. See our garment factory page to start a brief. [INTERNAL LINK: Garment factory OEM capabilities → https://china-clothing-manufacturer.com/]

Compliance avoids surprises

US: care labels per the FTC and origin rules; kidswear must meet CPSIA. EU: fiber labeling per 1007/2011, and REACH for chemicals. Add GRS for recycled poly or GOTS for organic claims, and keep certificates on file. [CITE: FTC and EU labeling pages] [MENTION: OEKO-TEX]

Next step

Send your brief with silhouette, GSM, decoration, target price, and calendar. We’ll match mills, assemble tests, and give you a clean path to PP approval and bulk.

FAQs

Related Articles

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »