Hoodie Supplier: Sourcing from a China Clothing Manufacturer

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

16 minute read

Hoodie Supplier: Sourcing from a China Clothing Manufacturer

Hoodie supplier selection shapes quality, timing, and margin for US/EU brands sourcing from a China Clothing Manufacturer. This guide maps hoodie-specific QA protocols, regional trade-offs (China, Bangladesh, EU), compliance checkpoints, and a step-by-step workflow. It integrates Eton’s 30+ years of OEM/ODM outerwear experience for predictable execution across design, testing, PP approval, and bulk production.

A hoodie supplier is a factory or OEM/ODM partner that makes hooded sweatshirts to your specs—fabric, fit, trims, and branding. Compare regional strengths (China/Bangladesh/EU), request lab tests, confirm certifications (OEKO-TEX, BSCI), align MOQs/lead times, and run sampling to PP approvals before bulk. Lock fit, shrinkage, and pilling targets to control returns.

Executive Summary

Hoodie supplier selection determines quality consistency, delivery windows, and margin health. For brands sourcing from a China Clothing Manufacturer, the strongest outcomes come from an integrated approach: hoodie-specific QA (fabric GSM, shrinkage, pilling), region comparisons (China/Bangladesh/EU) with quantitative ranges, and compliance-first sourcing aligned to US/EU regulations. This blueprint includes typical FOB prices, MOQs, and lead times; a vendor scoring rubric; and a full sampling-to-PP approval workflow. It leverages Eton’s Clothing Manufacturing OEM Service to deliver technical development, standardized lab testing, and scalable production. Use the testing matrix to codify acceptance criteria, the comparison table to choose the right region for each capsule, and the compliance navigator to prevent import delays and audit failures. With disciplined RFQs, inline QC, and final AQL, US/EU brands can move from concept to delivery—on schedule and on margin.

How to Choose a Hoodie Supplier for US & EU Brands

Choose hoodie suppliers by matching capability (fleece, French terry, brushed, technical knits), requesting lab tests and compliance documents, aligning MOQs/lead times, and scoring communication and capacity. Use a weighted rubric across quality, testing, compliance, price, timelines, and references to shortlist candidates for sampling.

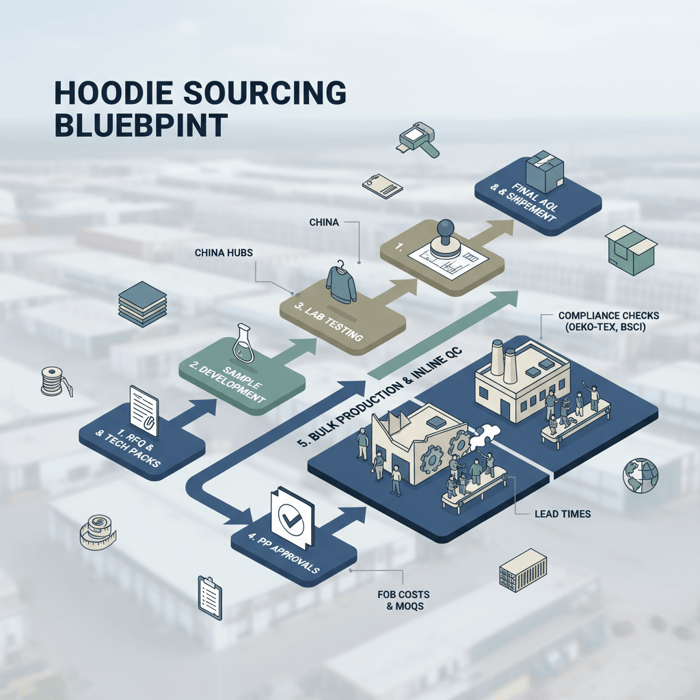

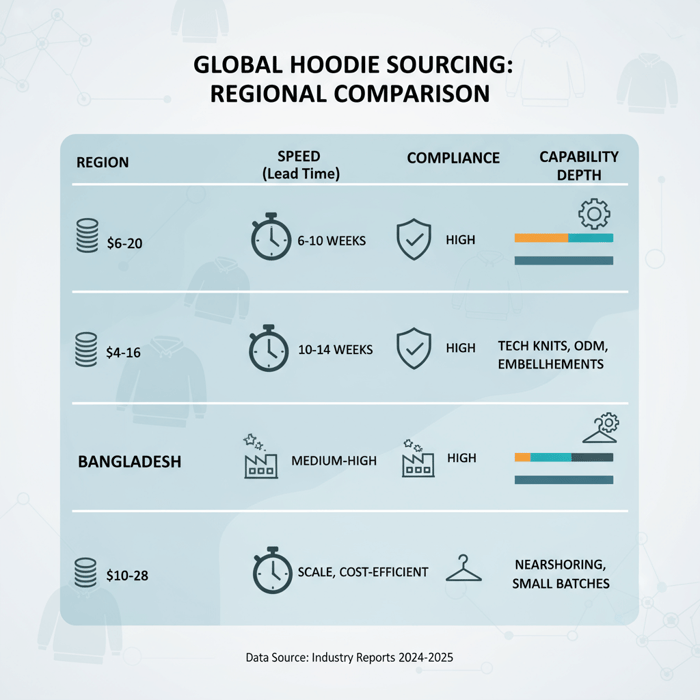

Supplier Evaluation Criteria & Scoring Rubric

- Capability: Fabric types, knitting gauges, rib and cuff control, embellishments (screen, DTG, embroidery, applique), zipper quality.

- Quality & Testing: AATCC/ASTM test readiness; shrinkage, pilling, colorfastness targets; PP sample discipline.

- Compliance: OEKO-TEX, BSCI, WRAP, factory audits; traceability; documentation cadence.

- Commercials: FOB ranges, cost transparency; MOQ flexibility; price stability over season.

- Timelines: Sample lead times; bulk production windows; capacity and holiday calendars.

- Communication: Response time; clarity on risks; proactive corrective actions.

- References: Past US/EU programs; defective rate history; lab pass rates.

| Criterion | Weight | Score (0–5) | Weighted | Evidence Required |

|---|---|---|---|---|

| Capability (fabrics/embellishments) | 20% | Factory list; sample swatches; embellishment portfolio | ||

| Quality & Testing | 20% | Lab reports (AATCC/ASTM); PP approval process | ||

| Compliance | 15% | OEKO-TEX; BSCI/WRAP; audit dates; traceability docs | ||

| Commercials | 15% | FOB breakdown; price lock terms; surcharge policy | ||

| Timelines & Capacity | 10% | Sample calendar; holiday map; machine capacity | ||

| Communication | 10% | Response SLAs; escalation path; weekly trackers | ||

| References & Track Record | 10% | US/EU client references; return rates; AQL pass rates |

[PAA] What goes into a hoodie RFQ? Provide complete tech packs, BOM, fabric specs (GSM, composition, finishing), measurement charts, tolerances, artwork files, embellishment placements, zipper specs, rib requirements, shrinkage/pilling targets, compliance documents, sample deadlines, PP approval criteria, and requested delivery window.

Apparel Sourcing Scoring Framework — pillar page Outerwear manufacturing excellence — pillar page

Supplier Capability & Specialization

Match your capsule to factory strengths. For fleece hoodies, assess control over GSM (280–380 gsm), yarn blends (100% cotton, CVC, poly-cotton), and finishing (brushed, anti-pilling, enzyme wash). Confirm rib quality (1x1/2x2), consistent recovery, and cuff/hem stability. For French terry, evaluate loop density, face smoothness, and shrinkage behavior under AATCC 135. For technical hoodies, check bonded knits, softshells, spacer fabrics, performance finishes (DWR, anti-microbial), seam construction, and zipper specs (YKK or equivalent, coil vs. molded, auto-lock pullers).

Evaluate embellishment capability across screen printing, DTG, embroidery, applique, puff/3D prints, silicone badges, and heat transfers—plus registration accuracy, handfeel, and wash durability. Map factory knitting gauges and dyehouse partners for shade consistency across body and rib. Confirm drawcord safety (tip types, length limits) and metal hardware nickel release compliance. [CITE: AATCC/ASTM standards and OEKO-TEX guidelines] [MENTION: YKK zippers, AATCC] Technical apparel lab standards — pillar page

Evidence-Based Quality & Compliance

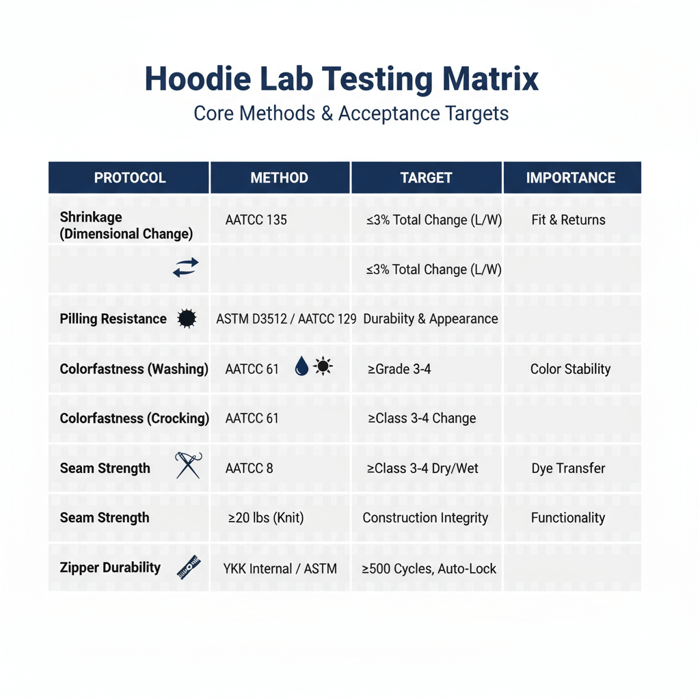

Request recent audit reports (BSCI, WRAP), certifications (OEKO-TEX Standard 100), and traceability documentation. Align lab tests to fabric blends and finishes: dimensional change (AATCC 135), pilling resistance (ASTM D3512 or AATCC 129/ASTM D4970), colorfastness to washing and crocking (AATCC 61/8), seam strength (ASTM D1683), and zipper endurance (company test plan or ASTM guidance). Set shrinkage targets (≤3% total change) and pilling grades (≥3–4 based on method and fabric), then lock them into PP acceptance criteria.

Require PP sample sign-offs and inline QC plans with AQL levels (e.g., 2.5 for major, 4.0 for minor). Verify UFLPA risk controls for US imports and EU CSDDD due diligence readiness. Establish a quarterly audit cadence and document retention. OEKO-TEX Standard 100 program details; BSCI/WRAP audit frameworks. [MENTION: OEKO-TEX, WRAP] Sustainability & Compliance for US/EU — pillar page

Commercials, Timelines & Communication

Clarify FOB ranges by spec, embellishments, and trims. Negotiate MOQs through fabric aggregation across colorways, shared dye lots for rib/body, and seasonal planning. Build a sample calendar: RFQ → proto (2–3 weeks China; 3–4 weeks Bangladesh; 1–2 weeks EU) → fit revisions → sales sample → PP approval. Confirm bulk windows and capacity buffers around Chinese New Year, Ramadan/Eid, and EU summer shutdowns.

Set communication SLAs (response within 24–48 hours), weekly trackers for risks and corrective actions, and clear escalation paths. Lock surcharge policies (yarn volatility, energy, freight) and price stability windows. [CITE: Typical apparel production calendars and regional holiday impacts] [MENTION: WTO apparel trade review, McKinsey State of Fashion] Bangladesh production base capabilities — regional page

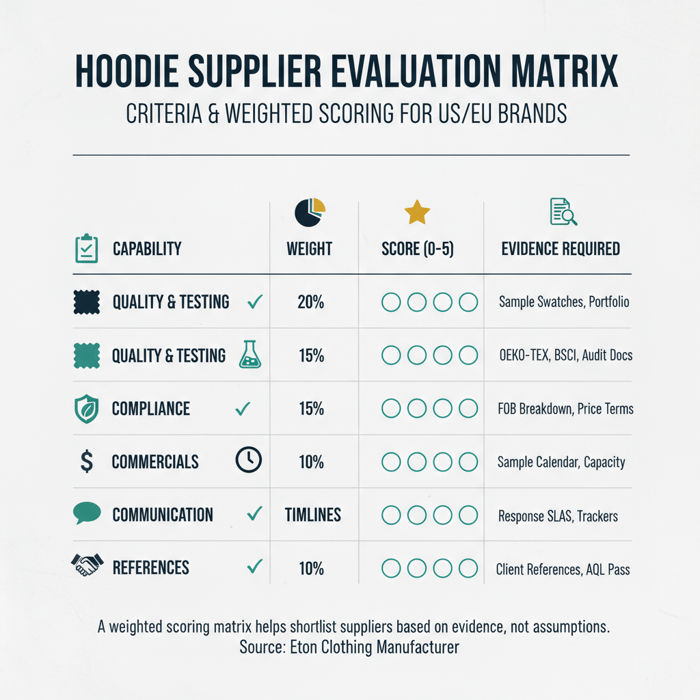

Hoodie Supplier Shortlist: China vs. Bangladesh vs. EU

China offers technical knits, speed, and strong ODM development; Bangladesh delivers cost advantages at scale; EU provides nearshoring speed and premium small runs. Select region by spec complexity, volume, compliance maturity, and delivery targets; many brands adopt a hybrid sourcing model.

| Region | Typical FOB (Basic/Technical) | MOQ | Sample Lead Time | Bulk Lead Time | Compliance Maturity | Notes |

|---|---|---|---|---|---|---|

| China | $6–$12 / $12–$20 | 500–1,000 | 2–3 weeks | 6–10 weeks | High | Strong ODM; fast development; wide embellishment range |

| Bangladesh | $4–$9 / $10–$16 | 2,000–5,000 | 3–4 weeks | 10–14 weeks | Medium–High | Best for scale; cost-efficient; plan longer bulk windows |

| EU | $10–$18 / $18–$28 | 100–300 | 1–2 weeks | 4–8 weeks | High | Nearshoring speed; premium small runs; higher labor costs |

- Global apparel trade shows regional share shifts — 2024 WTO World Trade Statistical Review 2024

- Athleisure remains resilient in US/EU markets — 2024 McKinsey The State of Fashion 2024

Criteria Overview

Use four gates: capability, cost, speed, and compliance. Capability: technical knits, bonded fabrics, embellishment breadth. Cost: FOB range and price stability. Speed: sample/bulk windows and calendar risk. Compliance: audits, certifications, traceability, and documentation readiness for US/EU import rules.

Quantify trade-offs with KPI anchors: lab pass rate, PP approval cycle count, AQL pass rate, on-time delivery percentage, and return rate due to shrinkage/pilling. Apply these KPIs to vendor scorecards by region. [CITE: Standard apparel KPIs in sourcing programs] [MENTION: BSCI, WRAP] Our foundational guide on ‘Outerwear Testing & QA’

Decision Framework

- Premium technical hoodies: China or EU for complex builds; EU for speed on small drops.

- Large-volume basics: Bangladesh for cost; China for faster development if cost gap is narrow.

- Hybrid: Split core basics to Bangladesh; limited capsules to EU; technical capsules to China.

- Risk controls: Add parallel sampling, pre-book materials, and stagger POs across regions.

[CITE: Case examples of regional hybrid sourcing in apparel] [MENTION: Nike sourcing patterns, Inditex nearshoring references] OEM & ODM hoodie services — conversion page

Hoodie Supplier Quality Standards: Fabrics, Fits, and Tests

Standardize quality with complete tech packs, fabric specs (GSM, blends, finishing), shrinkage and pilling targets, and trim tests. Apply AATCC/ASTM methods for colorfastness, dimensional change, seam strength, and zipper cycles. Lock fit with graded measurement charts, tolerance tables, and PP sample approvals.

- Define fabric specs and finishing (GSM, fiber blend, brushed/anti-pilling).

- Set shrinkage and pilling targets with relevant test methods.

- Codify measurements, size grading, and tolerances.

- Approve trims and zippers via functional tests.

- Run PP samples and inline QC with AQL.

[PAA] Which AATCC tests apply to hoodie fabrics? AATCC 135 for dimensional change; AATCC 61/8 for colorfastness; AATCC 129 or ASTM D4970 for pilling; pair with ASTM D1683 for seam strength. Select additional tests by fabric and finish.

Fabric & Trim Specifications

Fleece: 280–380 gsm; cotton-rich blends for handfeel; CVC/poly-heavy blends for durability and colorfastness. French terry: stable loops, smooth face, anti-shrink finishing. Rib: 1x1/2x2 with defined recovery; shade match body. Trims: YKK or equivalent zippers, auto-lock pullers, tape width fit to placket; drawcord length and tip safety; eyelets free of sharp edges and nickel release compliant; woven labels and care tags with US/EU labeling rules. OEKO-TEX labeling and chemicals guidance [MENTION: OEKO-TEX, YKK] Hoodie Tech Pack Template — resource page

Fit Blocks, Tolerances & Grading

Build core blocks for relaxed, regular, and oversized fits. Define measurement points: chest, waist, hem, sleeve length, across shoulder, body length, hood depth, and rib dimensions. Set tolerances (e.g., ±1 cm chest, ±1 cm body length) and track washdowns that affect measurements (pre-shrink programs). Grade rules by size scale (XS–XXL) and ensure rib tension aligns with cuff/hem recoveries across sizes. Include shrinkage-corrected measurement tables for PP sign-offs. [CITE: Industry grading practices for knit tops] [MENTION: ASTM sizing references] QA Checklist — resource page

Lab Test Protocols

Dimensional change: AATCC 135. Pilling: AATCC 129 or ASTM D4970 (Martindale). Colorfastness: AATCC 61 (washing), AATCC 8 (crocking), AATCC 16A (light). Seam strength: ASTM D1683. Zipper durability: cycles and locking tests per brand standard. Set acceptance limits: shrinkage ≤3% total change (length/width), pilling ≥3–4 grade, crocking pass per target fabric, seam strength minimums by spec. Document lab pass rates and corrective actions. AATCC official methods; ASTM standards [MENTION: AATCC, ASTM] Technical apparel lab standards — pillar page

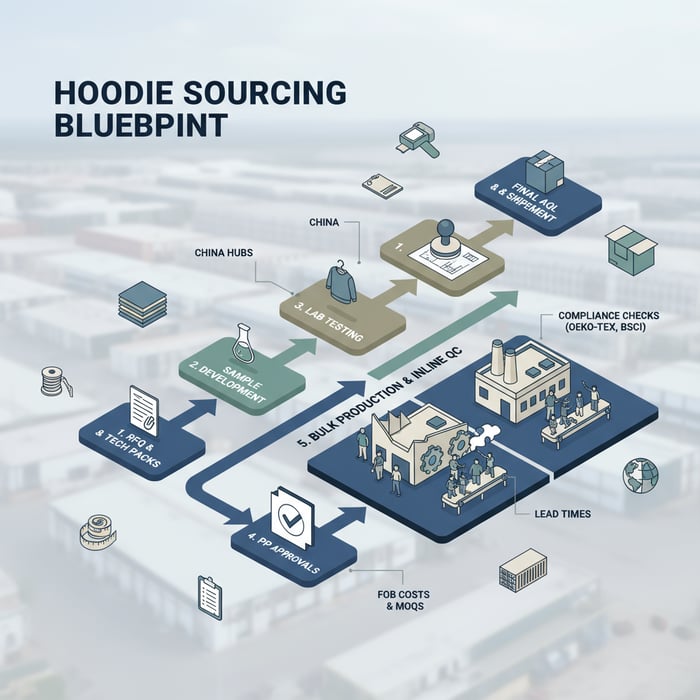

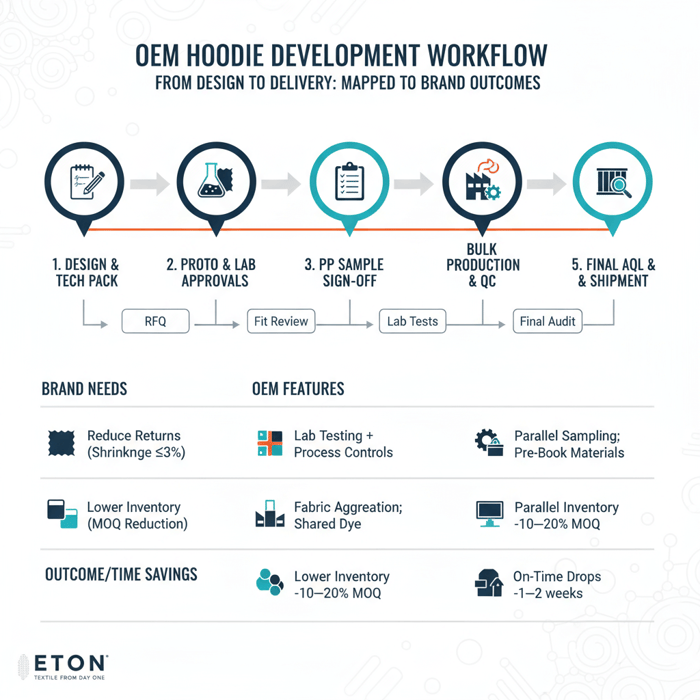

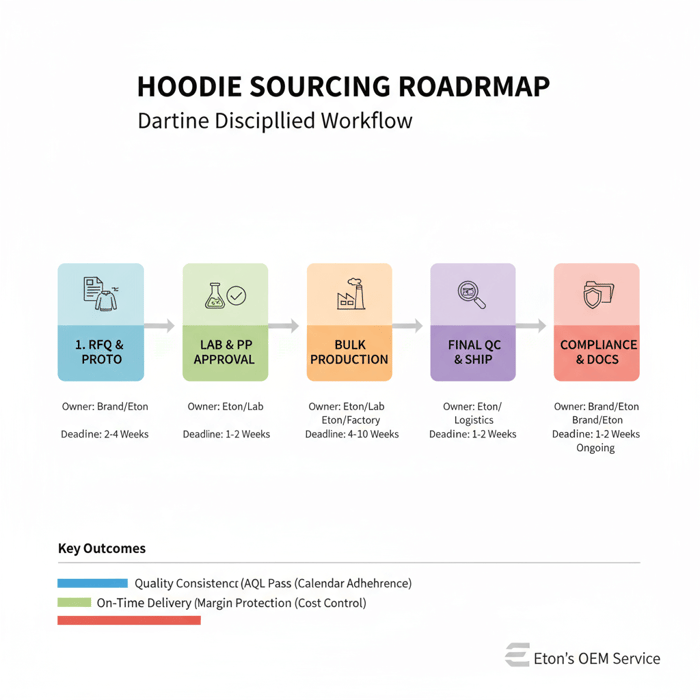

Sourcing Hoodies from a China Clothing Manufacturer: Step-by-Step

Run a disciplined workflow: RFQs with complete tech packs → sample rounds → fit and lab approvals → PP sample sign-off → bulk production with inline QC → final AQL. Track milestones, risks, and corrective actions to protect delivery dates and margins.

- RFQ: Send tech packs, BOM, measurements, tolerances, embellishment files, compliance asks.

- Proto & Fit: Receive samples; fit review; measure; issue revisions and targets.

- Lab: Test shrinkage, pilling, colorfastness, seam strength; approve or retest.

- Sales Samples: Prepare for buy meetings; lock visuals and specs.

- PP Approval: Sign off on production-ready sample with all trims and measurements.

- Bulk Production: Inline QC, risk tracking, CAPA; weekly updates.

- Final AQL: Inspect per standard; pack and ship with compliant labeling.

Preparation

Complete tech packs with BOM, measurements, tolerances, artwork, colorways, trims, care/laundry, labeling, packaging, and carton marks. Add QA plan with lab test list, acceptance criteria, and PP checklist. Request audit reports and certifications upfront. Define delivery window and buffer for compliance or lab retests. [CITE: Brand tech pack standards] [MENTION: WRAP, BSCI] Supplier Audit Calendar — resource page

Execution Steps

Fix acceptance criteria per milestone: proto pass with fit tolerances met; lab pass rates; PP sample exact to bulk plan; inline QC at 20/50/80% with documented findings; final AQL aligned to contract. Maintain trackers with risks (fabric delays, shade variance, embellishment failures) and corrective actions. Escalate early with pre-booked materials when timing is tight. Standard AQL practices [MENTION: ISO quality management references] Outerwear manufacturing excellence — pillar page

Quality Assurance

Use AQL levels (e.g., 2.5 major, 4.0 minor), define sampling sizes, and capture defect taxonomy (critical/major/minor). Pair inline inspections with lab spot checks. Monitor shrinkage and pilling through batch sampling; hold lots if failure risks appear. Close CAPA loops before shipment and retain records for US/EU compliance audits. AQL methodology references [MENTION: ANSI/ASQ standards] Technical apparel lab standards — pillar page

Cost, MOQ, and Lead Times with Hoodie Suppliers

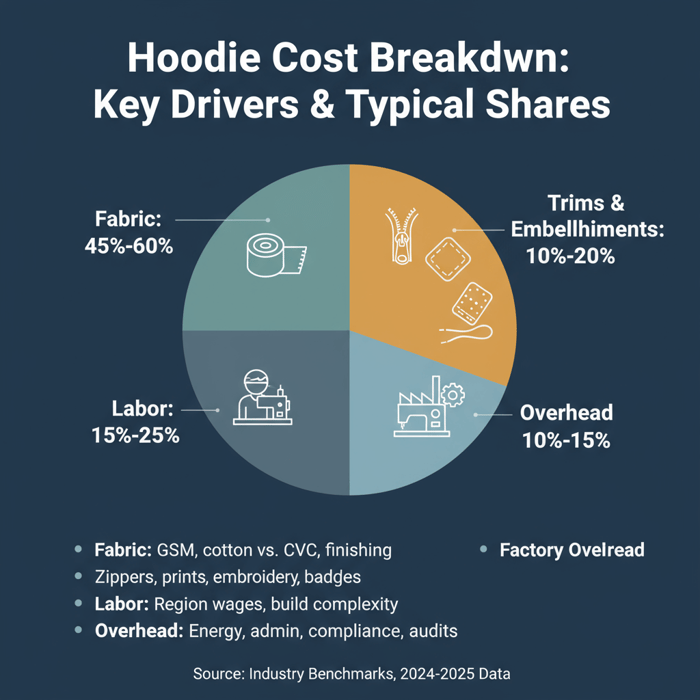

Expect FOB ranges by fabric, embellishment, and trims. Lower MOQs by fabric aggregation and shared dye lots, and plan production windows of 6–14 weeks by region. Use a cost breakdown (material/labor/overhead) and scenario planning to protect margin.

| Component | Typical Share | Notes |

|---|---|---|

| Fabric | 45%–60% | GSM, cotton vs. CVC vs. recycled poly; finishing costs |

| Trims & Embellishments | 10%–20% | Zippers, rib, drawcords, prints, embroidery, badges |

| Labor | 15%–25% | Region wage levels; complexity of build and QA steps |

| Overhead | 10%–15% | Energy, admin, compliance documentation, audits |

- Pros: Fabric aggregation reduces MOQ and dye costs; parallel sampling cuts calendars.

- Cons: Complex embellishments add rework risk; recycled materials may raise FOB and lead times.

- Lead time variance by region correlates with capacity and holiday calendars — 2024 WTO trade timing analysis

- Material volatility affects FOB stability; brands use price locks — 2024 McKinsey fashion procurement notes

Price Ranges & Cost Drivers

Basic fleece hoodies: $4–$9 FOB (Bangladesh), $6–$12 (China), $10–$18 (EU). Technical hoodies: $10–$16 (Bangladesh), $12–$20 (China), $18–$28 (EU). Cost drivers include fabric composition and GSM, recycled content premiums, print/embellishment layers, zipper brand/grade, and QA/testing scope. Lock price stability windows and define surcharge triggers (yarn, energy). [CITE: Regional FOB benchmarking studies] [MENTION: WTO, McKinsey] OEM & ODM hoodie services — conversion page

MOQs & Negotiation

Reduce MOQs by consolidating fabric across colorways, sharing dye lots for body/rib, and aligning season buys. Negotiate trims in bulk, pre-book materials for speed, and consider greige stocking for core colors. Use vendor scorecards and historical pass rates to validate MOQ flexibility—especially for small capsules. [CITE: Apparel MOQ negotiation guides] [MENTION: BSCI-compliant suppliers] Supplier Audit Calendar — resource page

Sample & Bulk Lead Times

Typical sample windows: China 2–3 weeks; Bangladesh 3–4 weeks; EU 1–2 weeks. Bulk windows: China 6–10 weeks; Bangladesh 10–14 weeks; EU 4–8 weeks. Add buffers around Chinese New Year, Ramadan/Eid, and summer shutdowns. Factor lab retest time (1–2 weeks) and audit readiness checks. [CITE: Regional production calendars] [MENTION: Industry holiday impacts] Outerwear manufacturing excellence — pillar page

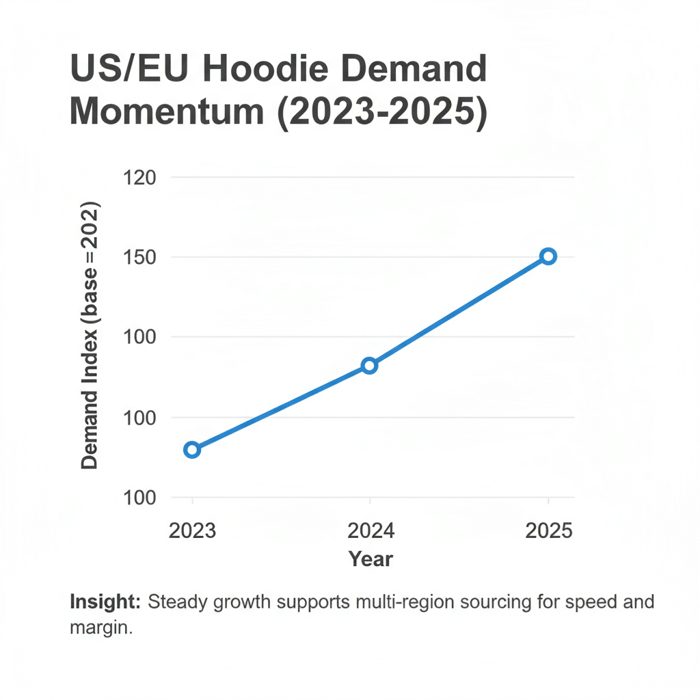

Market Data & Trends: Hoodies in US & EU 2024–2025

Hoodies remain core to athleisure and streetwear, with resilient demand and elevated basics. Brands pivot to recycled fibers, Better Cotton, and performance finishes while balancing cost, speed, and compliance. Sourcing strategies blend nearshoring speed with Asia scale.

- Athleisure demand remains resilient in US/EU — 2024 McKinsey State of Fashion 2024

- Trade flows show Asia’s continued strength with regional shifts — 2024 WTO Statistical Review 2024

Elevated Basics & Functional Details

Retailers upgrade hoodies with cleaner finishes, premium rib, tonal embroidery, silicone badges, and refined silhouettes. Functional tweaks—media pockets, breathable mesh panels, and double-layer hoods—move units. Capsule variety across oversized, regular, and cropped fits helps sell-through without overextending fabric SKUs. [CITE: Retail sell-through analyses] [MENTION: Inditex, H&M trend notes] Hoodie Tech Pack Template — resource page

Sustainable Materials & Traceability

Recycled polyester blends, Better Cotton sourcing, and OEKO-TEX certifications support compliance and consumer trust. Traceability systems capture yarn origin, dyehouse records, and factory audits, easing US UFLPA checks and EU CSDDD due diligence. Plan material documentation and audit cadence into calendars. OEKO-TEX program updates; UFLPA enforcement guidance [MENTION: OEKO-TEX, CBP UFLPA] Sustainability & Compliance for US/EU — pillar page

Product/Service Integration: Clothing Manufacturing OEM Service

Eton’s Clothing Manufacturing OEM Service covers design support, fabric sourcing, technical development, and compliant production across China and Bangladesh. The program scales hoodie lines with disciplined QA, PP approvals, and certifications aligned to US/EU requirements.

| Need | OEM Feature | Outcome | Time Range |

|---|---|---|---|

| Shrinkage ≤3% | Lab testing + process controls | Lower returns | +1–2 weeks in development |

| MOQ reduction | Fabric aggregation; shared dye | Lower inventory exposure | -10–20% MOQ |

| Faster lead times | Parallel sampling; pre-book materials | On-time drops | -1–2 weeks |

See the full capability map and request a pilot through Eton’s Clothing Manufacturing OEM Service. OEM & ODM hoodie services — conversion page Our foundational guide on ‘Outerwear Testing & QA’

Use Case: Premium Fleece Capsule

Objective: Elevated basics with smoother handfeel and consistent rib recovery. Approach: 320–360 gsm cotton-rich fleece, enzyme finish, OEKO-TEX trims, YKK zips. Lab: AATCC 135 shrinkage ≤3%, pilling ≥3–4. Result: Lower return rate and tighter shade matching across body/rib. [CITE: Case study style outcomes] [MENTION: YKK, OEKO-TEX] Outerwear manufacturing excellence — pillar page

Use Case: Technical Performance Hoodie Line

Objective: Breathable, moisture-wicking hoodies with bonded panels and durable zippers. Approach: Spacer knits or softshell blends with DWR; ergonomic patterning; high-cycle zipper spec. Lab: Seam strength to ASTM D1683 thresholds, colorfastness passes across methods. Result: Strong sell-through in activewear channels and stable margins. [CITE: Performance apparel testing references] [MENTION: ASTM, AATCC] Technical apparel lab standards — pillar page

Risks, Compliance & Localization

Mitigate risk with certified suppliers, transparent audits, and import compliance. Adopt traceability, material documentation, and periodic audits. Localize labeling and testing to US/EU market rules for frictionless entry.

Risk Matrix

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Forced-labor exposure | Medium | High | Approved sources; traceability; audits; documentation for UFLPA/EU CSDDD CBP UFLPA guidance; EU directive |

| Shrinkage variation | Medium | Medium | AATCC testing; PP approvals; inline checks |

| Capacity shortfalls | Medium | Medium | Capacity checks; staggered POs; parallel sampling |

Regulatory Notes for US & EU

US: UFLPA documentation and traceability; care/content labeling; flammability checks for specific materials; CBP entry packages with supplier/audit records. EU: Corporate Sustainability Due Diligence Directive obligations; chemicals and labeling compliance; due diligence and record retention. Keep documents current and accessible. U.S. Customs UFLPA enforcement; EU CSDDD official text [MENTION: CBP, European Commission] Sustainability & Compliance for US/EU — pillar page

Conclusion & Next Steps

Use the scoring rubric to shortlist hoodie suppliers, confirm regional fit with the comparison matrix, lock quality through testing and PP approvals, and integrate OEM for scale. Prioritize compliance and documentation to protect US/EU market access and margin.

- Shortlist vendors with the rubric and evidence pack.

- Run RFQ and proto sampling with full specs.

- Complete lab testing and PP approvals.

- Execute bulk with inline QC and AQL.

- Maintain compliance documentation for imports.

Start a pilot capsule through Eton’s OEM Service to validate timelines and QA. Hoodie Tech Pack Template — resource page QA Checklist — resource page Supplier Audit Calendar — resource page

Author & Review Notes

- Author: Eton Yip, Founder, 30+ years in apparel OEM/ODM and outerwear production. Eton Yip — Founder

- Reviewer: Senior Sourcing Manager (US/EU programs), Eton Garment Limited.

- Methodology: Competitor SERP scan; Eton’s first-hand OEM experience; citations from 2024 authoritative sources; hoodie-specific testing protocols.

- Limitations: Cost/MOQ/lead-time ranges vary by spec, seasonality, and capacity; regulations may change—verify current rules.

- Disclosure: Eton provides the Clothing Manufacturing OEM Service referenced.

- Last Updated: 2025-10-28.

- Motto: Textile From Day One.

References & Sources

- McKinsey & Company — The State of Fashion 2024 (2024). https://www.mckinsey.com

- World Trade Organization — World Trade Statistical Review 2024 (2024). https://www.wto.org

- OEKO-TEX — Testing and Certification Standards (2024). https://www.oeko-tex.com

- U.S. Customs and Border Protection — UFLPA Enforcement Guidance (2024). https://www.cbp.gov

- European Union — Corporate Sustainability Due Diligence Directive (2024). https://eur-lex.europa.eu

- AATCC — Textile Testing Methods (Accessed 2024–2025). https://www.aatcc.org

- ASTM International — Apparel and Textile Standards (Accessed 2024–2025). https://www.astm.org

- ANSI/ASQ — Sampling and Quality Standards (Accessed 2024–2025). https://asq.org

- ISO — Quality Management Systems references (Accessed 2024–2025). https://www.iso.org

- YKK — Zipper Standards and Product Data (Accessed 2024–2025). https://www.ykk.com

FAQs

Related Articles

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »