Shirt High Quality Guide with a China Clothing Manufacturer: Build Premium Shirts that Last

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Garment Industry

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Garment Industry

October 14th, 2025

15 minute read

Shirt High Quality Guide with a China Clothing Manufacturer: Build Premium Shirts that Last

Shirt high quality starts with clear standards, measurable performance, and a repeatable process. Fashion brands in the US and EU want consistent fabric hand, stable sizing, clean construction, and lab-validated results. Working with a China Clothing Manufacturer adds depth in materials, skilled sewing teams, and predictable timelines when the specification, testing plan, and QC workflow are set from day one.

A high-quality shirt combines long-staple fabrics, precise construction, and verified performance. Partnering with a China Clothing Manufacturer brings repeatable outcomes through gated sampling, AATCC/ASTM testing, and disciplined inspections. To hit premium targets, codify fabric, trims, stitch density, tolerances, and lab test acceptance in your tech pack.

Introduction

Brands use the phrase shirt high quality when they want fabrics that feel refined, collars that hold shape, seams that sit flat, color that stays true, and sizes that remain consistent across shipments. The path to that outcome is practical: specify the right materials, document stitch and fit standards, validate performance in accredited labs, and control production through clear checkpoints. This article offers a standards-backed blueprint suited to US/EU retail expectations and built around OEM workflows common in China’s better shirt factories.

Quality starts at the yarn and ends at consumer wear tests. Long-staple cotton and stable blends reduce pilling and shrinkage. Good interlinings prevent collar collapse. Dense, balanced stitches and reinforced stress points bring durability. Grading rules and tolerances keep sizes aligned from XS through XXL. AATCC and ASTM test methods measure shrinkage, colorfastness, abrasion, and pilling, while OEKO-TEX and GOTS address chemical safety and organic claims. With the right China Clothing Manufacturer, these pieces move from specification to practice through disciplined pilot runs, inline inspection, and final audits.

Brands often hit turbulence: fabric shade shifts between rolls, fusing bubbles on collars, torque after washing, and size drift during seasonal ramp-ups. A step-by-step plan helps: define acceptance ranges, pre-approve materials, trial a pilot lot, lock PP samples, and formalize AQL inspections. This guide distills three decades of OEM practice, connecting design choices to tests, risks to mitigations, and sourcing regions to practical trade-offs.

What “High-Quality Shirt” Means for Fashion Brands

High-quality shirts blend long-staple fabrics, stable trims, precise construction, consistent fit, and validated performance. Write acceptance criteria into the tech pack, align them with AATCC/ASTM/ISO methods, and enforce them through sampling and inspections. When everyone shares the same targets, outcome variability drops.

- Fabric: Long-staple cotton (e.g., Egyptian, Pima) or balanced blends; target low pilling, low shrinkage, clean hand.

- Yarn & weave: High yarn count and compact weaving for smoothness; controlled finishes for wrinkle resistance without harsh hand.

- Trims: Stable interlinings, durable buttons (urea or mother of pearl), thread strength suited to seams.

- Construction: Balanced stitches per inch, seam reinforcement at stress points, aligned plackets and collars.

- Fit & grading: Size tolerances documented for chest, sleeve, collar, and length; grade rules applied consistently.

- Performance: Lab tests for shrinkage, colorfastness, pilling, abrasion, seam strength; wash-and-wear trials.

- Compliance: OEKO-TEX Standard 100 chemicals screening; GOTS for organic; traceability for fiber origin claims.

- Durability and value are rising purchase drivers — 2024 (Source: McKinsey State of Fashion)

- Material claims require traceability — 2023 (Source: Textile Exchange)

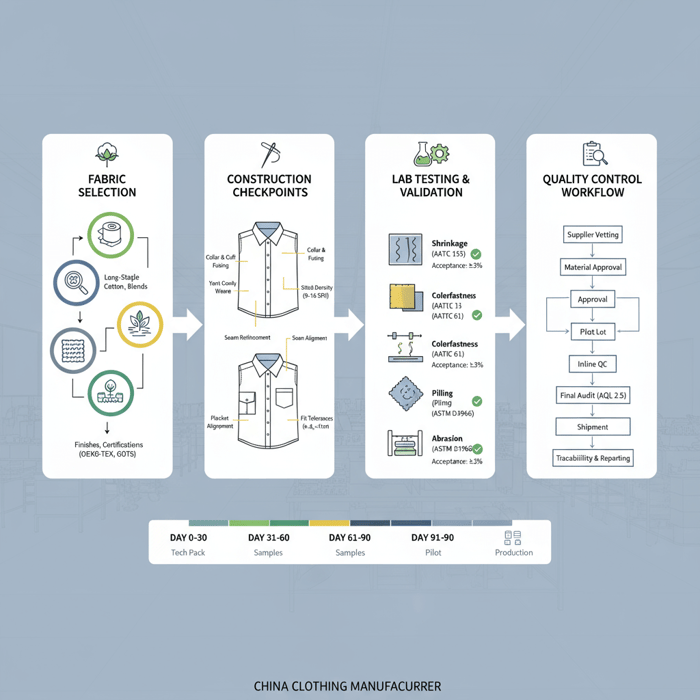

Fabric & Material Integrity

Favor long-staple cotton (Egyptian, Pima) for finer yarns and smoother surfaces. Target yarn counts and weave densities that suit dress shirts: poplin for crispness, twill for drape, oxford for texture. Add wrinkle-resistant finishes only when lab-tested for hand retention and minimal formaldehyde exposure (OEKO-TEX Standard 100). Acceptance ranges often include: dimensional change ≤3% after home wash (AATCC methods), pilling rating ≥3.5 after cycles (ASTM Textile Standards), and clean fabric appearance with no excessive slubs unless intentional.

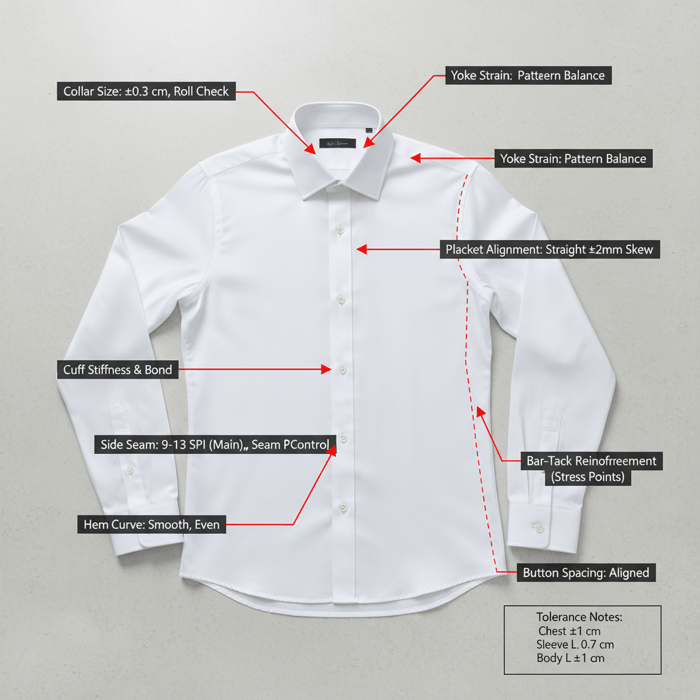

Construction & Workmanship

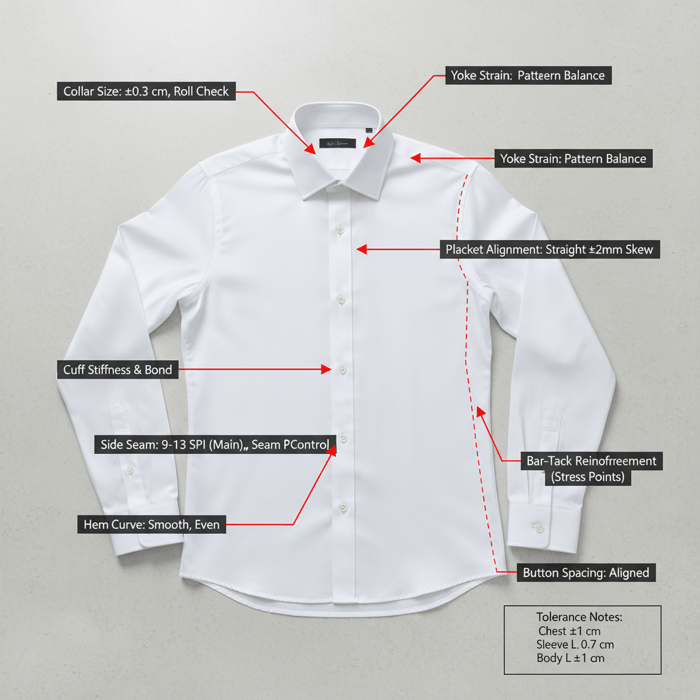

Balance stitch density: 9–13 SPI for main seams in standard cottons, 12–16 SPI for fine shirtings. Reinforce stress areas with bar-tacks and clean lockstitch usage. Keep placket alignment straight; avoid seam puckering with matched needle size, thread tex, and tension. Collar points mirror, seams sit flat, hems even, labels set square.

Fit Consistency & Grading

Document tolerances and hold them by size set approvals. Example tolerances: chest ±1 cm, sleeve length ±0.7 cm, collar ±0.3 cm, body length ±1 cm. Grade rules should deliver proportional changes across sizes, with fit blocks defined for slim, regular, and relaxed.

Performance Validation

Align each quality attribute to a test: shrinkage (AATCC 135), colorfastness to laundering (AATCC 61), colorfastness to perspiration (AATCC 15), pilling resistance (ASTM D3512 or D4970), abrasion resistance (ASTM D4966 Martindale), seam strength/slippage (ASTM D1683), and dimensional stability assessments. Add wash-and-wear cycles and torque checks to capture real use.

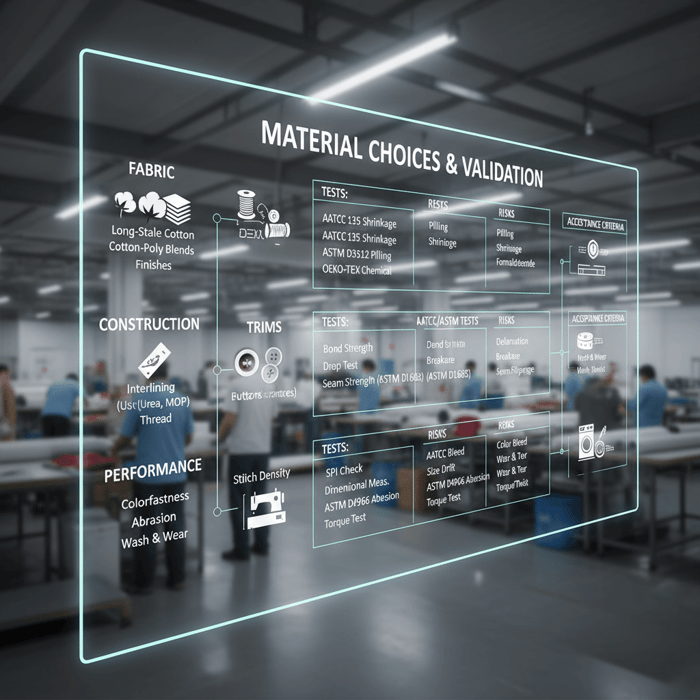

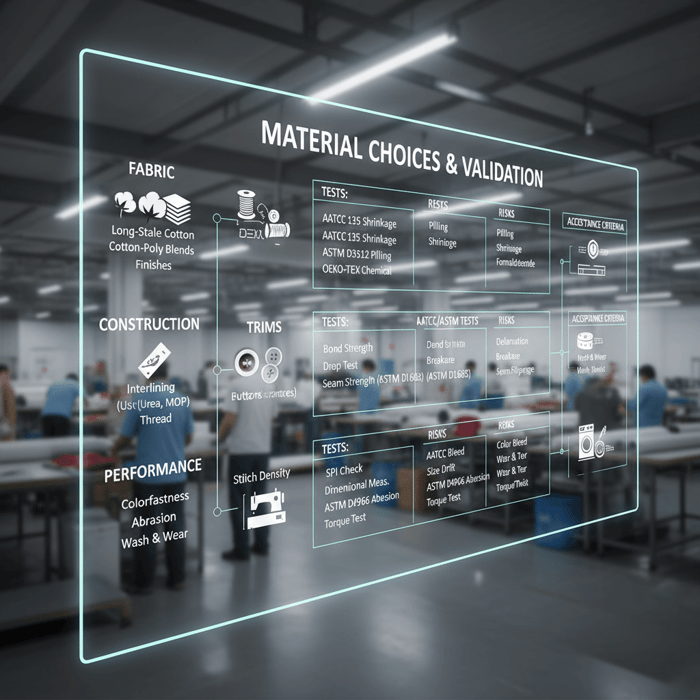

Fabric, Trims, and Validation Standards for Premium Shirts

Pick fabrics with long-staple cotton or balanced blends, choose stable interlinings, durable buttons, and threads that match seam demands. Validate with AATCC/ASTM tests for shrinkage, colorfastness, pilling, abrasion. When relevant, request OEKO-TEX or GOTS certificates. Lock these selections and acceptance ranges in the tech pack before booking.

| Material | Properties | Best Use | Risks | Linked Tests |

|---|---|---|---|---|

| Long-staple cotton poplin | Smooth hand, crisp look | Dress shirts, office wear | Puckering with poor tension | Dimensional change (AATCC 135), colorfastness (AATCC 61) |

| Oxford (cotton) | Textured weave, durable | Casual shirts, school wear | Heavier weight; shrinkage risk | Shrinkage (AATCC 135), abrasion (ASTM D4966) |

| Cotton–poly blend | Wrinkle resistance, quick dry | Travel, easy-care lines | Pilling if poor fiber balance | Pilling (ASTM D3512/D4970), colorfastness (AATCC 61) |

| Interlining (fusible) | Shape retention, collar/cuff structure | Collars, cuffs, plackets | Delamination with improper fusing | Bond strength checks; wash durability cycles |

| Buttons (urea, MOP) | High hardness; refined look | Premium styles | Chipping (MOP), breakage risk | Hardness checks; drop tests; shank pull |

| Thread (poly-core cotton) | Strength with soft hand | Main seams, topstitch | Seam slippage if mis-specified | Seam strength (ASTM D1683); SPI review |

Cotton, Blends, and Finishes

Long-staple cotton supports finer yarns for smooth surfaces. Cotton–poly blends suit easy-care lines but need pilling control through fiber balance and finishing. Wrinkle-resistant treatments should meet performance without harsh residues; verify using OEKO-TEX Standard 100 chemical criteria (OEKO-TEX Standard 100).

Interlinings, Collars, and Cuffs

Pick fusibles matched to shell fabric weight and finish. Target stable collar roll and cuff stiffness with bond strength verified across wash cycles. Document press temperature, pressure, and dwell time in the tech pack to avoid bubbles and edge lift.

Buttons, Thread, and Trims

Urea buttons deliver hardness and consistency; mother of pearl suits premium aesthetics with care in sewing to avoid chips. Thread selection balances tex, elongation, and hand; poly-core cotton fits many shirtings. Add shank strength checks and button pull tests to protect against loss during wear.

Lab Tests & Certifications

Use AATCC for shrinkage and colorfastness, ASTM for abrasion and pilling. For organic programs, align with GOTS and maintain chain-of-custody records (GOTS). OEKO-TEX Standard 100 helps screen harmful substances across trims and fabrics (OEKO-TEX Standard 100).

Tech Pack Material Specifications

List fabric composition, yarn count, weave, finishes, interlining type, button material, thread specs, and linked test methods. Add acceptance ranges per test, mill MOQs, and care label requirements aligned with US/EU rules (US FTC Textile Labeling; EU REACH).

Construction Details: Stitching, Fit, and Durability

Set stitch density, reinforcement, pattern accuracy, and finishing standards, then verify seam strength and dimensional stability with tests. Write tolerances and checkpoints into inspection routines. This brings uniformity across sizes and lots.

- Single-needle stitching — cleaner lines; slower output; suits premium dress shirts.

- Double-needle — faster; strong on side seams; risk of visible topstitch changes.

- French seam — refined inside; adds seam bulk; requires higher skill.

- Flat-felled — durable; classic casual look; higher effort and skill.

| Checkpoint | Tolerance Range | Notes |

|---|---|---|

| Collar size | ±0.3 cm | Match grading; check collar roll |

| Chest width | ±1 cm | Measure at defined point |

| Sleeve length | ±0.7 cm | Check both sleeves |

| Body length | ±1 cm | Back center measurement |

| Placket alignment | Straight; ±2 mm skew | Visual + measurement |

Stitch Density & Seam Reinforcement

Use 9–13 SPI for core seams; 12–16 SPI for finer fabrics. Reinforce with bar-tacks at pocket entries and side seam stress points. Align needle size to fabric weight and thread tex; set sewing tension to avoid puckering and seam grin.

Pattern, Fit, and Grading

Lock fit blocks for slim, regular, and relaxed. Apply grade rules systematically across size runs, then validate on size sets before PP sample. Fix common issues: sleeve twist from misaligned notches, yoke strain from pattern imbalance, chest pull from armhole geometry.

Finishing & Appearance

Plackets straight, topstitch lines clean, thread tails trimmed, labels placed square. Check button spacing and alignment, buttonholes clean without raw edges, hem curves smooth. Ironing settings matched to fabric type.

Performance & Wear Tests

Test seam strength and slippage (ASTM D1683), torque after laundering, and repeat wash-and-wear cycles. Include dimensional checks pre- and post-wash. For easy-care claims, run crease recovery tests and consumer-simulated wear.

Inspection Checkpoints

Set inline and final inspections with sampling frequency aligned to risk. Classify defects (critical, major, minor) and track defect rates versus KPIs. AQL 2.5 suits many shirt programs; adjust based on brand policy (Sofeast QualityInspection).

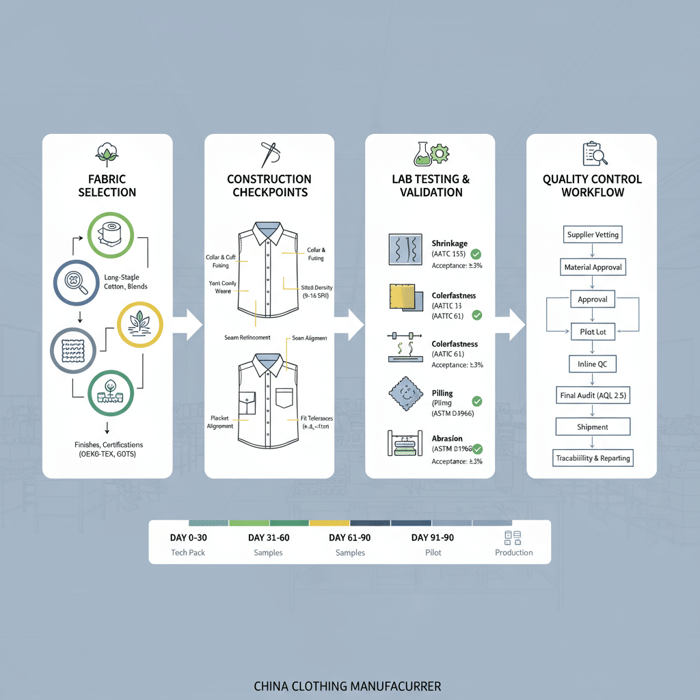

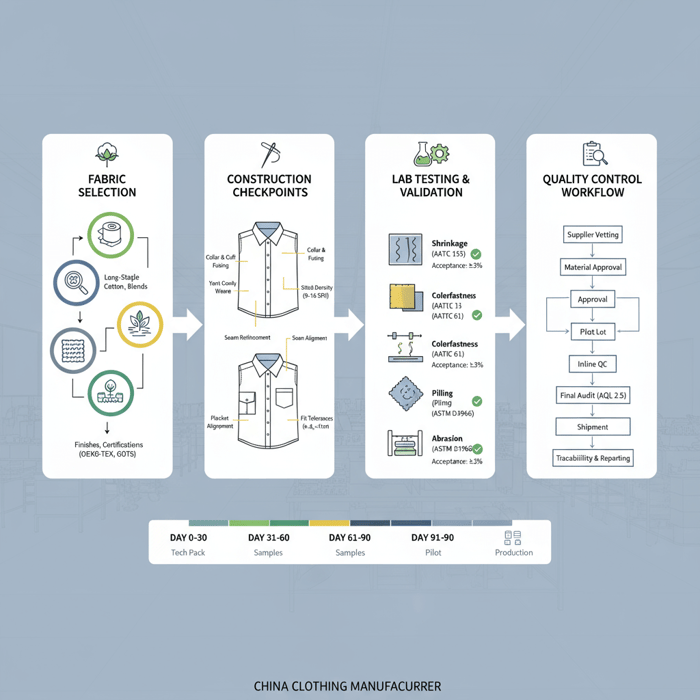

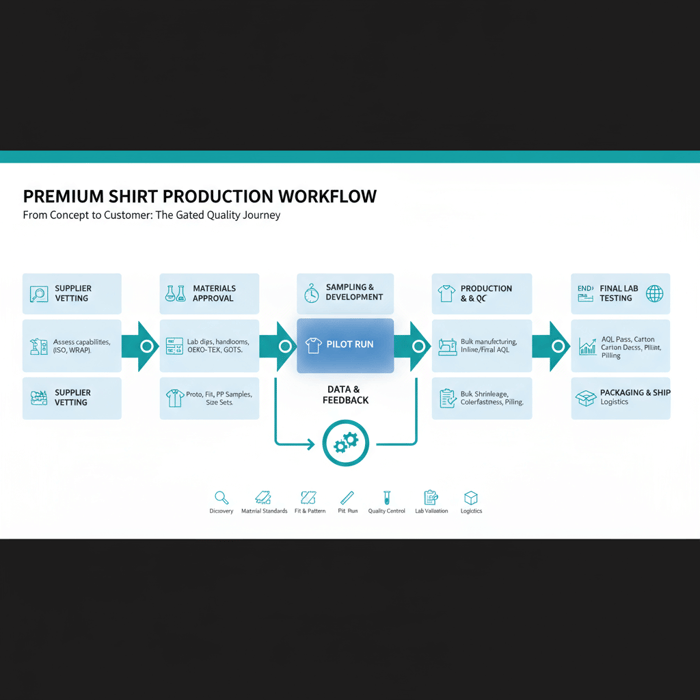

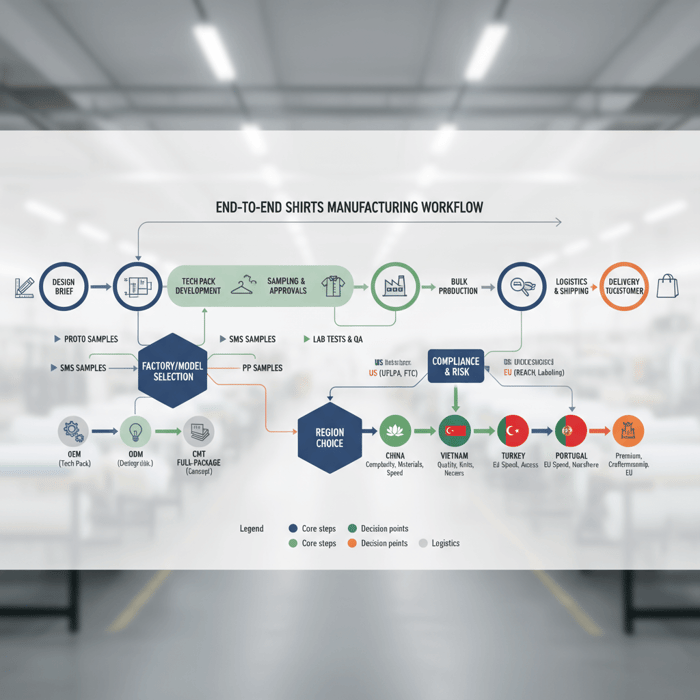

How to Manufacture High-Quality Shirts in China: Step-by-Step

Run a gated workflow: vet suppliers, finalize tech packs, approve materials, build samples and pilot lots, produce with inline QC, confirm lab tests, complete final inspection, package and ship. Each gate carries clear inputs, outputs, and sign-offs.

Preparation

- Tech pack: BOM, materials specs, stitch density, tolerances, finishing notes.

- Test plan: AATCC/ASTM methods, acceptance ranges, lab list (AATCC; ASTM).

- Compliance: OEKO-TEX/GOTS targets; US/EU labeling; REACH substance controls (EU REACH).

- Audit requirements: amfori BSCI, WRAP, or equivalent (amfori BSCI; WRAP).

- Size set plan: sample sizes for fit validation; grading rules documented.

Execution Steps

- Factory vetting: review shirts capability, sewing lines, fusing equipment, QC process; confirm ISO 9001 or internal QMS (ISO 9001:2015).

- Fabric booking: lock mills, target shade lots, confirm MOQs and lead times; collect COAs and compliance certificates.

- Lab dips and hand feel: approve shade and finish; keep retainers for reference.

- Proto sample: evaluate construction choices, stitching, basic fit; adjust patterns.

- Fit sample/size set: test across sizes; record changes; confirm grading behavior.

- PP (pre-production) sample: production-ready garment with all trims and finishes; sign off as the reference.

- Pilot lot: produce 2–5% of PO or minimum of 100–200 units; run full inline QC and lab tests on pilot outputs.

- Inline QC: defect classification, SPI checks, seam strength sampling; feed corrective actions to lines (Sofeast Apparel QC).

- Lab testing: shrinkage, colorfastness, pilling, abrasion, seam strength; keep reports for buyer records.

- Final inspection: AQL sampling, packaging checks, carton labeling; ship after pass and documentation sign-off.

Quality Assurance

Set defect rate KPIs, maintain inline records, track corrective actions, and retain PP sample and trims as references. Keep shade blankets for fabric lots and calibration records for fusing presses. Document all lab results and variance reports for transparency with buyers and auditors.

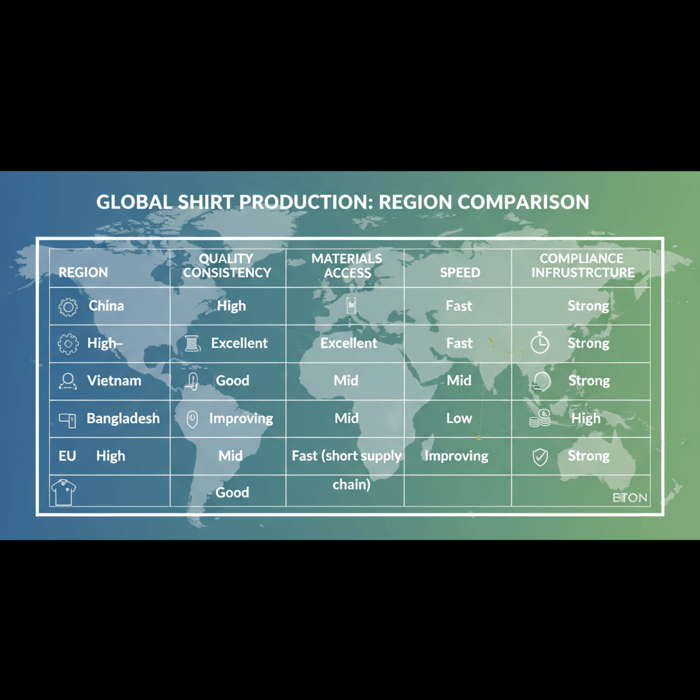

China vs. Other Regions for High-Quality Shirt Production

China offers deep materials, technical capacity, and speed for premium shirts. Vietnam and Bangladesh offer cost advantages; the EU brings proximity and niche craftsmanship. Choose based on quality tolerance, speed, compliance needs, and fabric ecosystem access.

| Region | Quality Consistency | Materials Access | Speed | Cost | Compliance Infrastructure |

|---|---|---|---|---|---|

| China | High | Excellent | Fast | Mid | Strong |

| Vietnam | High–Mid | Good | Mid | Mid | Strong |

| Bangladesh | Mid | Improving | Mid | Low | Improving |

| EU | High | Good | Fast (short supply chain) | High | Strong |

- Global apparel trade trends — 2023 (Source: WTO Trade Review)

- Sourcing shifts and capacity — 2024 (Source: McKinsey State of Fashion)

Criteria Overview

- Quality consistency and workmanship

- Lead time by season and SKU complexity

- MOQs from mills and factories

- Compliance capacity and audit readiness

- Sustainability claims and traceability

- Landed cost and logistics reliability

Decision Framework

- Shortlist: confirm shirt capability and fabric access.

- Trial order: run pilot with full lab tests and QC gates.

- KPI scoring: defect rate, fit variance, on-time delivery.

- Supplier consolidation: allocate volumes by score and risk profile.

Regional Nuances

China’s textile clusters give fast access to shirtings, interlinings, and buttons, with experienced teams for fusing and finishing. Vietnam offers solid sewing quality and compliance, often with imported fabrics. Bangladesh is cost-forward with growing shirts capacity; plan deeper oversight. EU production suits small runs with proximity advantages and niche craftsmanship.

Costs, MOQs, and Lead Times for Premium Shirts

Costs hinge on fabric grade, trims, workmanship choices, and order complexity. MOQs vary by mill and factory; lead times swing with seasonality and SKU counts. Plan ranges, choose smart levers, and keep quality targets intact.

- Fabric downgrading — reduces cost; risks hand and durability.

- Simplified trims — saves cost; test for longevity and appearance.

- Construction simplification — faster; may change aesthetics and seam strength.

- SKU rationalization — shorter lead time; narrower assortment.

Cost Drivers

Fabric grade and finishes set base cost. Interlinings, buttons (urea vs MOP), thread type, and fusing add layers. Construction choices (single-needle, French seams) increase labor minutes. Compliance testing and certifications add lab and paperwork costs; budget for AATCC/ASTM tests and OEKO-TEX/GOTS when claimed.

MOQs & Seasonality

Mills set MOQs by fabric type and finishing lines. Off-peak booking supports faster production and sometimes better shade control. For season launches, lock fabric early and hold buffer for shade approvals.

Lead Times & Buffers

Material readiness drives schedules. Pilot runs add days but remove downstream risk. Plan buffers for lab testing and shipping, and adjust based on regional holidays and port capacity.

Risks, Compliance & Localization (US/EU)

Reduce risk with documented specs, lab verification, AQL inspections, and ethical audits. Align to US/EU regulations, substance controls, and labeling rules. Build traceability for fiber origin and recycled or organic claims.

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Shrinkage variance | Medium | High | AATCC shrinkage tests; pre-shrink settings; acceptance ≤3% |

| Shade mismatch | Medium | Medium | Shade blankets; roll segregation; lab dip retainers |

| Size tolerance drift | Low–Medium | High | Size set approvals; inline measurements; tolerance control |

| Fusing delamination | Low–Medium | High | Press calibration; bond checks; wash durability tests |

| Pilling in blends | Medium | Medium | ASTM pilling tests; fiber balance; finish selection |

Regulatory Notes for US & EU

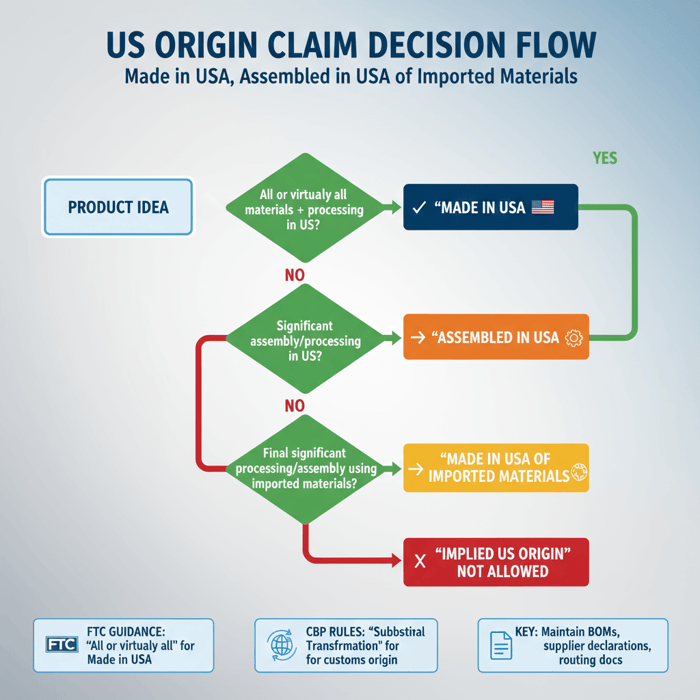

US: fiber content, country of origin, care labeling must meet FTC rules (US FTC Textile Labeling). EU: REACH governs chemical safety, and textile labeling rules set fiber content and language standards (EU REACH). For children’s apparel, align with safety policies and local standards (US CPSC).

Product/Service Integration: Clothing Manufacturing OEM Service

Eton’s Clothing Manufacturing OEM Service turns this blueprint into practice: standards-led development, vetted fabrics and trims, gated sampling, pilot lots, inline QC, lab validation, and compliant production in China and Bangladesh. The process fits premium shirts and scales with global retail calendars.

| Brand Need | OEM Feature | Outcome |

|---|---|---|

| Durable dress shirts | Fabric curation, fused collar program | Stable collar roll, low shrinkage |

| Fit consistency | Size set approvals, tolerance tracking | Lower returns, tighter measurements |

| Color stability | Shade control, lab dips, mill audits | Aligned lots across POs |

| Compliance assurance | OEKO-TEX/GOTS workflows, REACH checks | US/EU labeling and substance conformance |

| Timeline control | Pilot lots, inline QC gates | Predictable lead times, fewer surprises |

Use Case 1: Upgrade an Existing Shirt Program

A brand facing collar collapse and size drift moves to long-staple cotton with matched interlinings, recalibrates fusing, and locks tolerances through size set approvals. Defect rates drop, fit variance narrows, and returns decline. Reporting aligns QC findings with corrective actions.

Use Case 2: Launch a New Premium Capsule

A capsule line uses single-needle construction, French seams where visible, urea buttons, and a refined wrinkle-resistant finish vetted through OEKO-TEX and AATCC tests. A pilot lot validates torque and shrinkage before full run. The capsule lands on time with consistent shade and hand.

Implementation Support & Compliance

Audits and certifications are integrated across factory partners. Traceability records back up material claims, and lab reports are stored for buyer and auditor review. For fast fashion or premium lines, the same gates keep quality outcomes steady. Explore the program at Clothing Manufacturing OEM Service.

Conclusion & Next Steps

Shirt high quality is a managed system: define fabric and trims, set construction standards, secure fit tolerances, and validate performance through labs and inspections. Pick a China Clothing Manufacturer with shirts capability and run a gated plan across sampling, pilots, and production. Start with a discovery call, finalize your tech pack, approve PP samples, and publish acceptance ranges across teams.

- Day 0–30: Supplier vetting, tech pack finalization, lab dip approvals.

- Day 31–60: Proto, fit samples, size set approvals, material bookings.

- Day 61–90: PP samples, pilot lot, inline QC, lab testing.

- Day 91–120: Production run, final inspection, packaging, shipment.

References & Sources

- ISO — ISO 9001:2015 Quality Management Systems. https://www.iso.org/standard/62085.html

- AATCC — Test Methods Collection. https://www.aatcc.org/test-methods/

- ASTM — Textile Standards. https://www.astm.org/

- OEKO-TEX — Standard 100. https://www.oeko-tex.com/

- GOTS — Global Organic Textile Standard. https://global-standard.org/

- amfori — BSCI. https://www.amfori.org/

- WRAP — Workplace Compliance. https://www.wrapcompliance.org/

- McKinsey — State of Fashion (2024). https://www.mckinsey.com/industries/retail/our-insights

- WTO — World Trade Statistical Review (2023). https://www.wto.org/

- US FTC — Textile Labeling. https://www.ftc.gov/business-guidance/resources/threading-your-way-through-labeling-requirements-under-textile-fiber-products-identification

- EU — REACH Chemicals. https://health.ec.europa.eu/chemicals/reach_en

- US CPSC — Regulations and Standards. https://www.cpsc.gov/Regulations-Laws--Standards

- Sofeast — AQL Defects Guide. https://qualityinspection.org/aql-defects/

- Sofeast — Apparel Quality Standards. https://qualityinspection.org/apparel-quality-standards/

- Textile Exchange — Standards and Resources. https://textileexchange.org/

FAQs

Related Articles

Affordable American-Made Clothing vs China Clothing Manufacturer: A Practical Sourcing Guide for Fashion Brands

12 minute read

October 14th, 2025

Affordable American-Made Clothing vs China Clothing Manufacturer: A Practical Sourcing Guide for Fashion... more »

Shirts Manufacturers: A Complete Guide to Choosing the Right China Clothing Manufacturer

17 minute read

October 13th, 2025

Fashion brands searching for shirts manufacturers need clear choices, fast sampling, and reliable bulk... more »

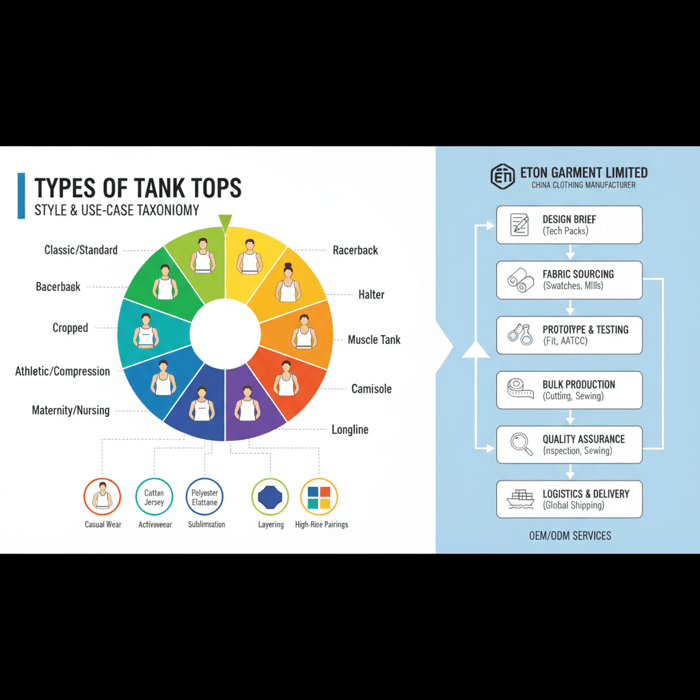

Types of Tank Tops: The Complete Style, Fabric, and Manufacturing Guide from a China Clothing Manufacturer

12 minute read

October 13th, 2025

Types of Tank Tops: The Complete Style, Fabric, and Manufacturing Guide from a China Clothing... more »

Custom Merch for Businesses: OEM Manufacturing Guide for US & EU Brands

6 minute read

October 13th, 2025

Custom Merch for Businesses: OEM Manufacturing Guide for US & EU Brands Custom merch for businesses... more »