Custom Jersey Tee Shirts with a China Clothing Manufacturer: The OEM Guide for US & EU Fashion Brands

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

19 minute read

Custom Jersey Tee Shirts with a China Clothing Manufacturer: The OEM Guide for US & EU Fashion Brands

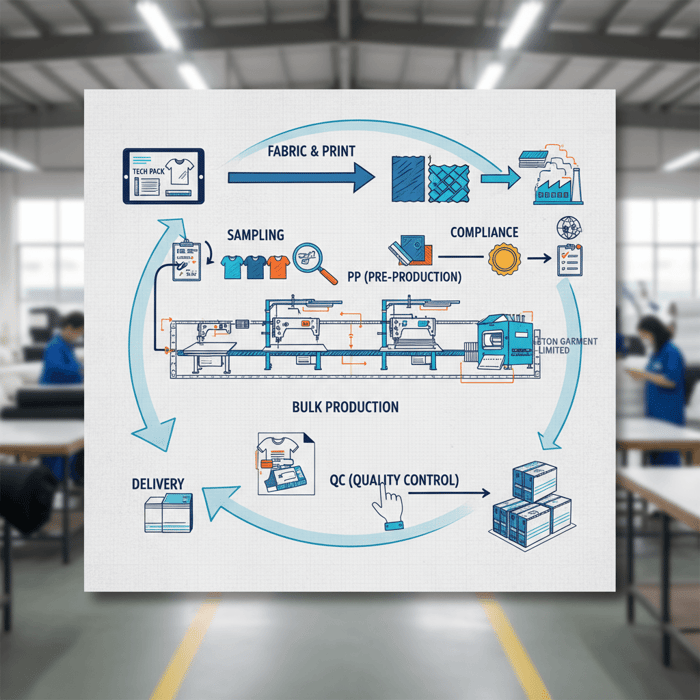

Custom jersey tee shirts give US/EU brands a fast path from creative direction to scale when paired with a capable China Clothing Manufacturer. Eton Garment Limited brings three decades of OEM/ODM experience, dual production bases in China and Bangladesh, and a compliance-first workflow that connects fabric engineering, print compatibility, and audited production. Textile From Day One.

Custom jersey tee shirts are performance-ready knit tops engineered for breathability, stretch, and print durability. To scale with a China Clothing Manufacturer, align tech packs, fabric GSM/knit structure, and print methods; run fit and lab tests; lock compliance (REACH, CPSIA, Oeko-Tex); and select China vs Bangladesh based on speed, MOQ, and cost.

Executive Summary

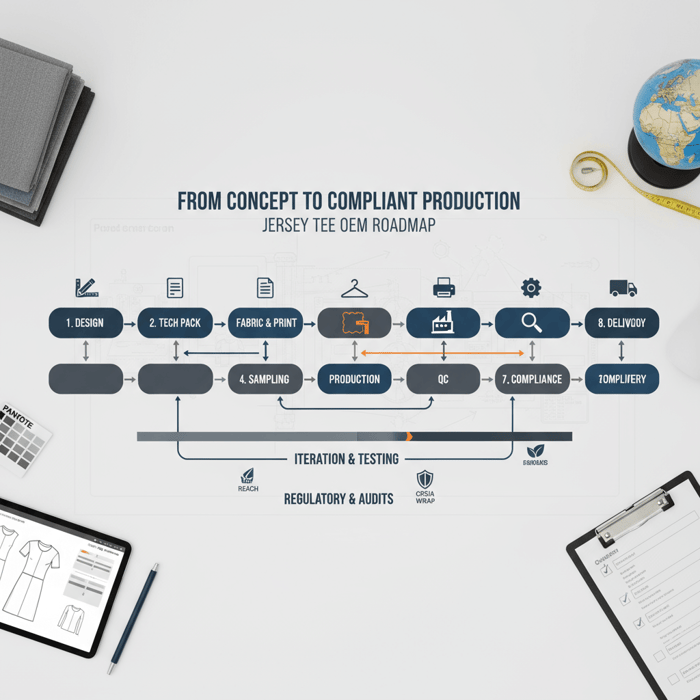

Producing custom jersey tee shirts at scale requires a clear OEM roadmap: translate design into a production-grade tech pack, choose the right jersey knit (single or double) and GSM, pair fiber blends with the correct print method, and bake in compliance checkpoints for US and EU markets. This guide offers a practical workflow, print compatibility matrix, calendar-based MOQ/lead time planning for China vs Bangladesh, and risk controls that reduce surprises in bulk.

Eton’s Clothing Manufacturing OEM Service integrates design support, fabric development, decoration at scale, and social/chemical compliance across audited facilities. The result: a single accountable partner for concept-to-delivery with the engineering depth of outerwear applied to performance tees.

What Are Custom Jersey Tee Shirts? Fabric, Fit, and Performance Fundamentals

Custom jersey tee shirts rely on knitted structures (single or double jersey), fiber blends (cotton, polyester, spandex), GSM, and finishing to meet breathability, stretch, drape, and durability targets. Each choice influences print quality, shrinkage, torque, and wearer comfort in sport and athleisure use.

Material factors that drive outcomes:

- GSM (grams per square meter): weight affects opacity, drape, and thermal comfort.

- Fiber blend: cotton for comfort/hand, polyester for wicking and quick-dry, spandex for stretch/recovery.

- Knit type: single jersey for softness and breathability; double jersey for structure, opacity, and reduced torque.

- Yarn quality: combed/ring-spun, filament vs staple, microfiber poly for smoother prints and less pilling.

- Finishing: enzyme/silicone wash, heat-setting, compaction, and moisture-wicking finishes guide stability and performance.

- Dimensional stability: shrinkage and torque control via pre-shrink/compaction and balanced patterns.

- Tolerances: knit garments need wider but consistent tolerances; lock them early in sampling.

PAA: What GSM range balances opacity and breathability for athletic tees? For performance-oriented custom jersey tee shirts, 140–180 GSM in polyester or cotton-poly blends often balances airflow and coverage, while 180–220 GSM suits lifestyle tees requiring more opacity and print coverage. Validate with wear tests and wash cycles before PP approval. [CITE: “Apparel engineering text or standards-based reference on knit GSM and comfort performance”]

[MENTION: Textile Exchange’s materials guidance] [MENTION: AATCC methods for wicking and colorfastness] [INTERNAL LINK: Our foundational guide on 'Jersey knit fabric library' to map GSM and blends]

Jersey Knit Structures: Single vs Double

Single jersey delivers a soft hand, good breathability, and a natural drape suited to lifestyle and training tops. It can skew or torque after washing if yarn twist and finishing aren’t dialed in. Print coverage looks vibrant on combed cotton or high-filament poly, but multi-pass screen designs need stretch-aware inks to reduce cracking. Double jersey (interlock) uses two needle beds to create a denser, more stable fabric with improved opacity, reduced curling at edges, and fewer torque issues. It resists “grin through” on prints and supports cleaner line work, though breathability can run lower at the same GSM.

For performance, single jersey in 150–170 GSM with engineered wicking and a small percentage of spandex can feel cooler in training. For teamwear basics or corporate programs where print consistency and opacity rule, double jersey or higher-GSM single jersey may provide better coverage and durability. Balance fabric selection with print method and intended use—sublimation needs polyester, screen and DTG prefer higher cotton content.

Fiber Blends & Finishes (Cotton/Poly/Spandex)

Cotton delivers soft hand and breathability; ring-spun combed yarn improves surface uniformity for screen prints and DTG. Polyester brings moisture-wicking, fast dry, and shape retention; microfiber filaments offer smoother print surfaces and less pilling in abrasion-prone zones. Spandex (2–8%) adds stretch and recovery, reducing seam stress and improving wearer mobility. Common blends include 100% cotton (premium ringspun for DTG), 60/40 cotton/poly (balanced comfort and stability), and 100% polyester or 90/10 poly/spandex for wicking sports tees.

Finishes shape performance: hydrophilic or cationic treatments improve wicking; heat-setting stabilizes spandex; compacting reduces shrinkage; enzyme/silicone washes soften cotton and improve print handle. Match finish to print method—pretreatment for DTG on dark cotton improves color yield; sublimation requires cationic-dyeable poly or standard disperse-compatible poly. Validate colorfastness to washing, perspiration, and rubbing per AATCC/ISO. [CITE: “AATCC/ISO test method summaries for colorfastness and wicking”] [MENTION: AATCC] [MENTION: ISO]

Tolerances, Shrinkage & Stability

Knit garments behave differently from wovens, so planned tolerances and stability treatments matter. For tees, a typical tolerance framework might run ±1.0 cm for chest width and ±1.5 cm for body length in sizes S–XL, tightening or widening by style. Pre-shrink and compaction target residual shrinkage ≤3–5% on cotton jerseys; polyester knits often show lower shrinkage when heat-set correctly. Control torque by balancing patterns, aligning grain, and specifying twist-balanced yarn where possible. Require wash-and-dry test reports during SMS and PP stages to lock expectations.

Note dimensional stability in your tech pack and QC plan: define test protocols, number of wash cycles before measurement, and relax time before measuring. Live-model fit reviews help catch recovery issues at hems and neck ribs. [INTERNAL LINK: Our OEM & ODM apparel development hub for tolerances and fit workflows]

How to Design and Produce Custom Jersey Tee Shirts with an OEM China Clothing Manufacturer

Use a staged OEM process: define the brief, build a complete tech pack, select fabric and print via a compatibility matrix, run sampling with fit and lab tests, freeze specs, complete compliance and labeling, and align capacity with your calendar. Detailed documentation reduces revisions and accelerates PP approval.

- Align concept: confirm target use (sport vs lifestyle), silhouette, decoration zones, compliance scope, and volumes.

- Build the tech pack: BOM, graded specs, tolerances, stitch types, seam constructions, labels, and packaging.

- Material selection: jersey knit, GSM, fiber blend, finish; print method matched to fiber/artwork.

- Sampling: proto → SMS → size set → PPS; include wash, print, and color fastness tests.

- Fit and function: wear tests, stretch/recovery checks, breathability/comfort feedback.

- Compliance: REACH/CPSIA/Oeko-Tex planning; labeling templates; social audit scheduling.

- Pre-production: PP meeting, gold seal, bulk QC plan, capacity booking, and production timeline.

- Bulk production: inline QC, print controls, finishing consistency, and packing verifications.

- Final QA and shipment: final inspection AQL, documentation, and logistics plan.

PAA: What must be in a jersey tee tech pack to avoid sample misalignment? Include graded specs with knit-specific tolerances, shrinkage/torque targets, stitch types and SPI, rib specs, fabric GSM and composition, finish details, artwork placements with color callouts, approved inks/transfers, labeling/packaging, test methods, and compliance requirements. [INTERNAL LINK: Our OEM & ODM apparel development process hub]

[MENTION: Techpacker’s tech pack methodology] [MENTION: A leading sportswear brand’s public sourcing guidelines] [CITE: “Publicly available tech pack checklist from an industry authority or trade school”]

Build the Tech Pack

Start with a precise BOM listing base jersey fabric (GSM, knit, fiber), rib details, thread, labels, and packaging. Add graded size specs for all sizes with tolerances suitable for knits. Specify seam types (e.g., overlock + coverstitch), SPI, and needle size; call out reinforcement at shoulder seams. Include print/decoration details: artwork vectors, Pantone references, print size/placement by size, ink type, stretch requirements, flash/cure notes, and any pre/post-print handling.

Document finishing (enzyme/silicone wash, heat-set), shrinkage targets, and test methods (AATCC/ISO) for colorfastness, pilling, and dimensional stability. Note labeling requirements for US/EU, fiber content, care symbols (ISO or ASTM), and country-of-origin. Provide packaging guidelines—fold size, polybag specs, carton count, labeling formats—to avoid packing differences that impact logistics and retailer routing. Lock a clear change-control process to keep sampling on track. [CITE: “ASTM/ISO care labeling standards overview”]

Sampling & Fit Approval

Sampling stages typically run: Proto (fit silhouette and construction), SMS (show quality and materials), Size Set (grade validation), and Pre-Production Sample (PPS) as the final production reference. For performance tees, include wash tests at each critical stage to validate shrinkage/torque. Run stretch/recovery assessments on body and rib; note neck opening stability across sizes. Pre-test print durability with stretch/flex cycles and accelerated wash to evaluate cracking or delamination.

Use fit models aligned to your size base. Record shoulder slope, chest girth, bicep circumference, and neck comfort; assess mobility under arm lift and cross-body reach. Consolidate measurable feedback into a single tracker shared with the factory. Confirm that all sign-offs are based on the same lab-tested fabric and approved trims to avoid surprises at PP. [MENTION: AATCC test method for colorfastness to perspiration] [CITE: “Best-practice guide on knit garment fit and grading”]

Production Readiness & Pre-Pro

Pre-production (PP) is where your project gains stability. Host a PP meeting to confirm the gold seal sample, sealed print swatches, approved trims, and finalized spec sheet. Align on QC acts: fabric inspection criteria, in-line print checks (e.g., film thickness or cure swabs), and post-wash measurements. Confirm compliance documents: REACH/CPSIA test plans, Oeko-Tex Standard 100 certificates, and social audit dates (WRAP/SMETA).

Freeze artwork and colorways; create a lot-by-lot shade band for cotton heathers or cationic-dyed poly. Reserve factory capacity and book testing windows with your lab. Align production, inspection, and shipping calendars, including holiday and peak-season buffers in China and Bangladesh. [INTERNAL LINK: Production planning and capacity booking page]

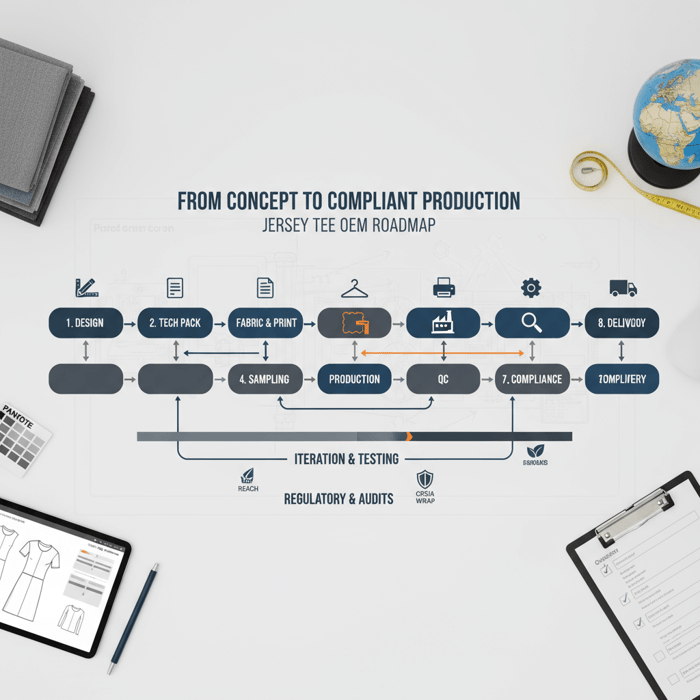

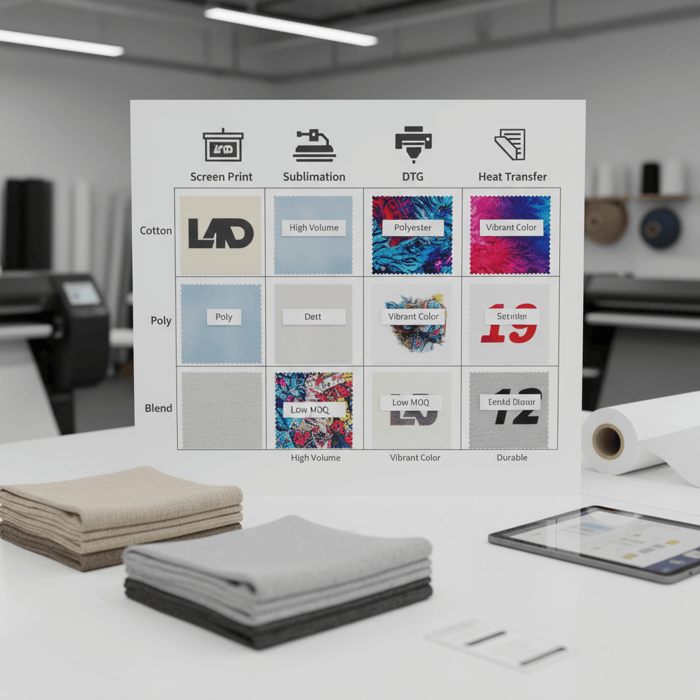

Printing Methods for Custom Jersey Tee Shirts: Compatibility, Durability, and Cost

Screen printing, sublimation, DTG, and heat transfer have distinct strengths for jersey knits. Pair method with fabric content, artwork complexity, color vibrancy needs, hand-feel targets, stretch, and budget. Validate wash durability and flex on the chosen knit before locking PP.

Criteria Overview (Artwork, Fiber, Budget, Durability)

- Artwork: spot colors and bold graphics favor screen; photoreal detail or small runs fit DTG; all-over prints align with sublimation; numbers/names or low-volume designs often suit heat transfer.

- Fiber: 100% cotton favors DTG/screen; 100% polyester favors sublimation; blends can run screen and some transfers.

- Budget and scale: screen shines at volume; DTG suits small runs; sublimation is efficient for poly teamwear; transfers bridge variable personalization.

- Durability and hand: match stretch inks or transfers to spandex; sublimate for permanent hand-free color on poly; control cure for screen to prevent cracking.

Decision Framework (Sport vs Lifestyle; Cotton vs Poly)

Sport teamwear with 100% polyester or high-poly blends usually adopts sublimation for vivid color, all-over placements, and minimal hand. Lifestyle cotton tees lean on screen printing for opacity and color pop, or DTG for intricate short-run art. For athleisure blends, use screen with stretch-modified inks or high-stretch heat transfers; confirm flex resistance under repeat movement and wash. [MENTION: Printful’s print method breakdown] [MENTION: A screen ink manufacturer’s technical datasheets] [CITE: “Durability comparisons of DTG vs screen on cotton jerseys by a print lab”]

| Method | Best Fabric | Pros | Cons | Typical Use |

|---|---|---|---|---|

| Screen Printing | Cotton, cotton/poly blends | High opacity; durable at scale; cost-effective at volume | Higher setup cost; multi-color registration; stretch risk without proper ink | Lifestyle tees; brand logos; athleisure graphics |

| Sublimation | 100% polyester or high-poly content | Vibrant, permanent color; no added hand; all-over capability | Limited to poly; whites/light shades work best; color shift on cotton | Teamwear basics; performance tees; all-over prints |

| DTG | 100% cotton (ringspun) | Detailed art; low MOQ; quick changes | Pre-treatment on darks; less vibrant on blends; cost at scale | Short runs; drops; detailed illustrations |

| Heat Transfer | Blends and cotton; stretch transfers for spandex | Fast turnaround; personalization; clean edges | Cracking/peeling risk if under-cured or overstretched | Names/numbers; small batches; variable graphics |

- Sportswear category resilience cited in 2024 outlooks — Year (Source: [CITE: “McKinsey State of Fashion 2024”])

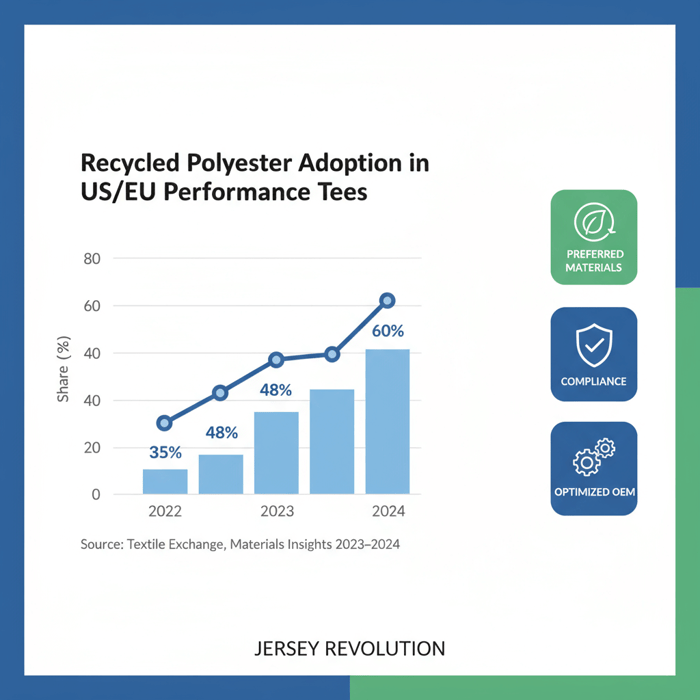

- Recycled polyester adoption rising in performance tees — Year (Source: [CITE: “Textile Exchange, Materials Insights 2023–2024”])

- DTG favored for on-demand small runs — Year (Source: [CITE: “POD industry benchmark or printer OEM whitepaper”])

Cost, MOQ, and Lead Times for Custom Jersey Tee Shirts (China vs Bangladesh)

Total cost depends on fabric and yarn, knit structure and GSM, print method, trims/labels, testing/compliance, and logistics. MOQs and lead times vary by season and production base. China usually offers engineering speed and agile sampling; Bangladesh offers scale and cost leverage for volume programs.

| Cost Driver | Impact | Notes |

|---|---|---|

| Yarn/Fabric | Medium to High | Ringspun cotton, microfiber poly, spandex content, and finishes move cost and hand-feel. |

| Printing/Decoration | Medium to High | Screen setup vs DTG per-piece; sublimation coverage; stretch-ink systems; color count. |

| Trims/Labels | Low to Medium | Heat-transfer neck labels vs woven; packaging spec; hangtags. |

| Compliance & Testing | Low to Medium | REACH, CPSIA, Oeko-Tex; lab fees; audit costs; documentation time. |

| Freight & Duties | Medium | Transit time and cost by ocean vs air; HS code and duty; seasonal congestion. [CITE: “HS code reference and duty calculator by official customs”] |

| Region | Typical MOQ | Sample Lead Time | Bulk Lead Time | Notes |

|---|---|---|---|---|

| China | 500–1,000 units/style/color (screen); lower for DTG/transfers | 10–20 days (fabric in hand) | 45–75 days, style/print dependent | Best for rapid development, complex engineering, smaller color runs. |

| Bangladesh | 2,000–5,000 units/style/color | 15–25 days | 60–90+ days, volume/season dependent | Best for large programs, cost leverage, and standardized platforms. |

PAA: How do lead times shift during peak seasons (Q3–Q4)? Expect 10–20 additional days in both regions for booking, fabric finishing, print queues, and ocean freight congestion. Book capacity early, lock lab windows, and confirm carrier schedules 6–8 weeks ahead. [CITE: “Peak-season logistics advisories from major forwarders, 2024”]

MOQ Strategy and Style Rationalization

Consolidate graphics onto a shared fabric platform (same GSM, finish, and color family) to hit MOQ while retaining design variety. For screen prints, reduce color count or share screens across artwork families. For transfers, group purchase of heat-transfer sheets can trim unit costs. Reserve DTG for tests, drops, or smaller wholesale partners. Align color breaks with retailer buys to minimize overages and markdowns. [MENTION: A major retailer’s public vendor manual on MOQ planning]

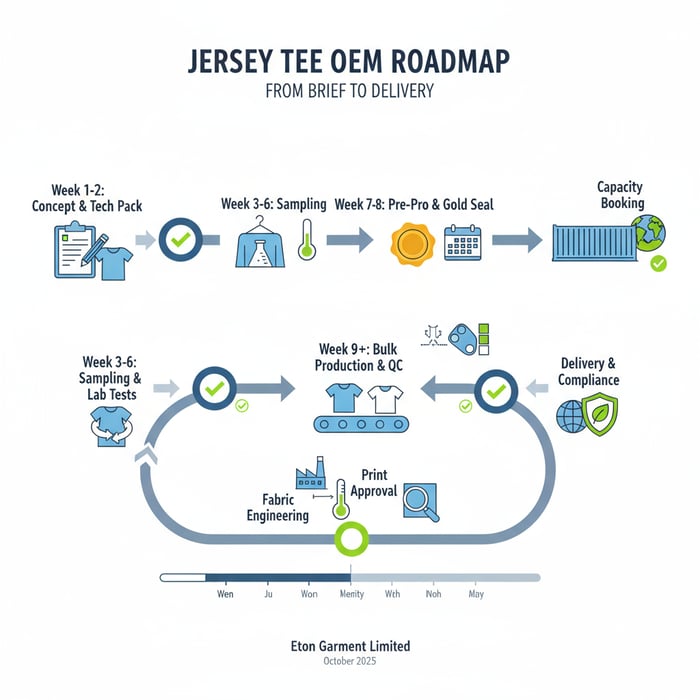

Lead Time Planning and Buffers

Build a calendar from brief to DC arrival: 2 weeks tech pack, 3–6 weeks sampling, 1–2 weeks PP, 6–12 weeks bulk, and 4–6 weeks ocean. Insert buffers for holiday periods in each region. Add testing windows for CPSIA children’s products or special finishes. Use a gating checklist that ties approvals to capacity reservations so delay risk shows early. [INTERNAL LINK: Production planning and capacity booking page]

Data & Trends: US/EU Demand, Materials Adoption, and Compliance Momentum

Sportswear and athleisure show resilient demand in US/EU, while brands continue shifting to recycled polyester and preferred materials. Compliance expectations are rising, with buyers asking for verifiable chemical safety and social audits as standard.

- Sportswear demand remained resilient in 2024 — (Source: [CITE: “McKinsey State of Fashion 2024”])

- Preferred materials (incl. recycled polyester) gained share through 2023–2024 — (Source: [CITE: “Textile Exchange Materials Insights”])

- US/EU buyers increasing compliance asks on tiered supply chains — (Source: [CITE: “Recent procurement/retailer sustainability reports”])

Key Trend 1: Performance + Sustainability

Performance tees serve workout and everyday use, so comfort and moisture management matter. US/EU buyers now look for recycled polyester and traceable cotton backed by recognized standards. Clear documentation on recycled content and chemical safety helps secure buy-in from merchandising and sustainability teams. Expect more programs built on a single performance platform with interchangeable graphics to reduce sampling and lab overhead. [MENTION: Textile Exchange] [CITE: “Brand sustainability reports on recycled fiber adoption, 2023–2024”]

Key Trend 2: Compliance as a Differentiator

Retailers treat REACH, CPSIA for children’s products, and Oeko-Tex Standard 100 as table stakes. Social audits like WRAP and SMETA are requested early to de-risk buying decisions. Brands using verified frameworks gain smoother onboarding and fewer delays at PP. Keep a structured compliance pack ready: certificates, audit summaries, lab test histories, and labeling templates. [MENTION: WRAP] [MENTION: Sedex/SMETA] [CITE: “ECHA REACH updates and CPSC CPSIA pages, 2023–2025”]

Risks, Compliance & Localization for US/EU Markets

Common risks include print cracking on high-stretch knits, color migration on polyester, and knit shrinkage/torque after washing. Align early with REACH and CPSIA requirements, integrate Oeko-Tex Standard 100 where possible, and schedule social audits to avoid capacity holds near PP. Confirm label formats for each destination market.

- Pros: Early lab tests reduce rework; pre-booked audits speed onboarding; regional labeling templates save time.

- Cons: Added upfront planning; strict documentation control; calendar discipline required near peak seasons.

Risk Matrix

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Print cracking on stretch | Medium | High | Use stretch inks or transfers; calibrate heat/pressure; run flex/wash tests before PP. |

| Color migration on polyester | Medium | Medium | Barrier/low-bleed inks; correct cure; pre-wash tests for dye stability; shade bands by lot. |

| Shrinkage/torque on knits | Medium | High | Pre-shrink/compaction; balanced patterns; enforce tolerances; wash testing at SMS/PPS. |

| Audit scheduling conflicts | Medium | Medium | Book WRAP/SMETA early; align with PP windows; accept multi-standard audit coverage. |

Regulatory Notes for US & EU

- REACH (EU): Restricted substances, SVHC, and labeling. Build a chemical management plan and maintain supplier declarations. [CITE: “ECHA REACH regulation portal”]

- CPSIA (US): Lead content limits and tracking labels are required for children’s products. Adult tees still need accurate fiber content and care labeling. [CITE: “CPSC CPSIA page and garment labeling guidelines”]

- Oeko-Tex Standard 100: Confirms chemical safety at the component level; helpful for retailer onboarding. [CITE: “Oeko-Tex Standard 100 site”]

- Social Compliance: WRAP and Sedex/SMETA audits cover labor, health, and safety practices. [CITE: “WRAP official”] [CITE: “Sedex/SMETA overview”]

Always verify product category-specific rules and age grading with your lab, especially for children’s sizes and prints that contact skin. [CITE: “Third-party lab guidance for apparel compliance”]

Product/Service Integration: Eton’s Clothing Manufacturing OEM Service

Eton’s Clothing Manufacturing OEM Service aligns design intent, fabric engineering, printing, sampling, QC, and compliance to deliver custom jersey tee shirts at scale. Dual production bases in China and Bangladesh give US/EU brands a choice between speed and scale, under audited facilities and proven standards.

| Brand Need | Eton OEM Feature | Outcome |

|---|---|---|

| Performance fabric with consistent hand | Engineered jersey platforms (GSM, blends, finishes) | Repeatable feel and fit across styles and seasons |

| Print durability on stretch knits | Stretch-ink systems and calibrated curing; lab pre-tests | Fewer returns; stable graphics after wash and wear |

| US/EU compliance readiness | REACH/CPSIA plans; Oeko-Tex components; WRAP/SMETA audits | Smoother onboarding; faster PP approval |

| Calendar alignment for Q3–Q4 | Capacity booking across China/Bangladesh; critical path tracking | On-time deliveries in peak windows |

Learn more: Eton’s Clothing Manufacturing OEM Service

Use Case 1: Athleisure Capsule (Problem → Solution)

Problem: A US brand needed a four-style capsule with a shared hand-feel and consistent screen prints across cotton/poly blends, with first delivery inside 12 weeks.

Solution: Eton standardized a 170 GSM single jersey platform with enzyme/silicone finish, aligned stretch-capable inks, and ran a single PP approval covering all colorways. China production delivered speed, while lab-tested swatches controlled cure and opacity. Results: consistent hand and graphics across styles, with reduced sampling rounds. [CITE: “Case-study format: anonymized buyer project metrics”]

Use Case 2: Teamwear Basics (Problem → Solution)

Problem: A European distributor needed durable, moisture-wicking tees in high volumes with all-over graphics and verified audits.

Solution: Eton developed 100% polyester interlock for sublimation, confirmed WRAP/SMETA audits, and booked Bangladesh capacity. The program shifted artwork personalization to heat-pressed player names post-sublimation for flexibility. Results: long-run consistency, stable color, and per-team customization at scale. [CITE: “Case-study format: anonymized performance and lead-time data”]

[INTERNAL LINK: Explore OEM jersey manufacturing services on our garment factory page] [MENTION: Liverpool F.C. as a long-term partner reference where applicable to category context]

Conclusion & Next Steps

Success with custom jersey tee shirts comes from clear tech packs, the right knit platform, decoration matched to fiber and use, disciplined sampling, and compliance built into the calendar. Book capacity early—especially for Q3–Q4—and centralize sign-offs to keep the line moving.

- Week 1–2: Finalize tech pack; shortlist fabrics and print methods.

- Week 3–6: Sampling; fit and lab tests; update specs; confirm compliance scope.

- Week 7–8: PP meeting; gold seal; book capacity and testing windows.

- Week 9+: Bulk production; inline QC; final inspection; dispatch planning.

Start now: Kick off your OEM jersey project with Eton. [INTERNAL LINK: Production planning and capacity booking page]

Author & Review Notes (E-E-A-T)

- Author: Eton Yip, Founder, Eton Garment Limited — 30+ years in apparel OEM/ODM; outerwear and technical jersey programs. [INTERNAL LINK: {{author_name}} - {{author_title}} {{author_bio_url}}]

- Reviewer: Senior Technical Manager, Eton Garment Limited.

- Methodology: Synthesized Eton’s OEM standards, jersey engineering practices, and print constraints; aligned with US/EU compliance guides and audit frameworks.

- Limitations: Cost, MOQ, and lead-time ranges vary by season, fabric, artwork, and lab scope. Verify test matrices per product category with your lab.

- Disclosure: Eton provides OEM/ODM services for custom jersey tee shirts.

- Last Updated: October 2025

References & Sources

- McKinsey & Company — The State of Fashion 2024 (2024). [CITE: “McKinsey 2024 State of Fashion URL”] [MENTION: McKinsey]

- Textile Exchange — Preferred Fiber & Materials / Material Insights (2023–2024). [CITE: “Textile Exchange Materials Insights URL”] [MENTION: Textile Exchange]

- Oeko-Tex — Standard 100 (2024). [CITE: “Oeko-Tex Standard 100 URL”] [MENTION: Oeko-Tex]

- ECHA — REACH Regulation (Accessed 2025). [CITE: “ECHA REACH portal URL”] [MENTION: ECHA]

- CPSC — CPSIA (Accessed 2025). [CITE: “CPSC CPSIA URL”] [MENTION: CPSC]

- WRAP — Certification & Programs (Accessed 2025). [CITE: “WRAP official URL”] [MENTION: WRAP]

- Sedex — SMETA Audit (Accessed 2025). [CITE: “Sedex SMETA URL”] [MENTION: Sedex]

- Statista — Sportswear Market Overview and Trends (2024). [CITE: “Statista sportswear market topic page”] [MENTION: Statista]

- AATCC/ISO — Test Methods for Colorfastness, Wicking, and Dimensional Stability (Latest Editions). [CITE: “AATCC and ISO method summaries”] [MENTION: AATCC]

- Printer OEM or Print Lab — DTG vs Screen Durability on Cotton Jerseys (Recent whitepaper/report). [CITE: “Reputable print lab or OEM document”]

- Global Forwarder Advisory — Peak-season lead-time impacts (2024). [CITE: “Maersk/DHL/FedEx seasonal advisory page”]

FAQs

Related Articles

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »