Custom Jersey T Shirts: How Fashion Brands Work with a China Clothing Manufacturer

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

12 minute read

Custom Jersey T Shirts: How Fashion Brands Work with a China Clothing Manufacturer

Custom jersey t shirts anchor modern teamwear, fanwear, and athleisure, and working with a China Clothing Manufacturer shapes how fast brands move from sketch to shelf. For US & EU markets, success hinges on fabric performance, print durability, clear specs, and a disciplined OEM workflow backed by verified compliance.

Custom jersey t shirts are knitted tees customized through prints, embroidery, or transfers for performance and lifestyle. Brands should specify fabric GSM, shrinkage, pilling, colorfastness, and pick the right method—screen, DTG, DTF, sublimation—then follow an OEM process from tech pack to sampling and production with US/EU compliance.

What Are Custom Jersey T Shirts? Use Cases, Fabrics, and Fit

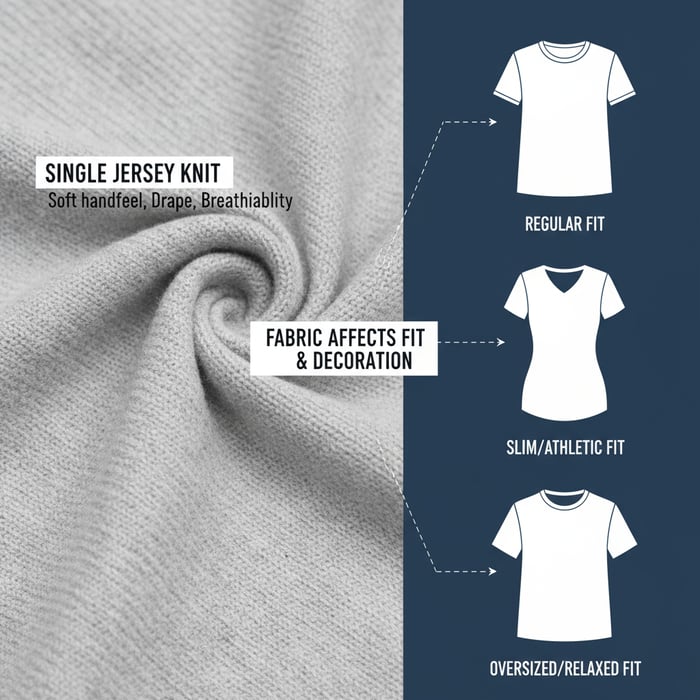

Custom jersey t shirts are knitted tees (jersey knit) customized with decoration and construction details. They span performance teamwear, fan merchandise, and athleisure. Align fabric type (cotton, polyester, blends), GSM, and silhouette with intended use and the chosen decoration method to achieve long-wearing comfort and stable color through repeated wash.

Mention AATCC as the leading textile testing body and the ISO 105 series as core colorfastness standards.

Core Use Cases: Teamwear, Fanwear, Athleisure

- Teamwear: Performance-first tees for training, match warm-ups, and staff. Favor polyester or high-poly blends for moisture management; DTF or sublimation for multi-color logos; reinforce shoulder taping to handle frequent washes.

- Fanwear: Graphic-led tees with high-definition prints. Combed cotton or soft blends deliver handfeel; screen printing or DTF for vibrant colors with repeatable bulk costs; consider puff or applique for texture.

- Athleisure: Balanced comfort and performance. Blends (e.g., 60/40 cotton/poly) for breathability with moisture-wicking; DTG for short-run detailed art on cotton-rich bodies; embroidery for premium chest hits.

Fabric Basics: Cotton, Polyester, Blends; GSM Ranges (160–220+)

Cotton: Natural handfeel, strong printability with screen/DTG, breathable. Target 160–200 GSM for standard tees; 200–220 GSM for a heavier, premium hand. Manage shrinkage and colorfastness to washing.

Polyester: Quick-dry, high durability, ideal for sublimation when white/light base. Choose 160–180 GSM for performance; check snag resistance and pilling. Colorfastness to perspiration and laundering is critical.

Blends: The middle ground—better moisture management than cotton, better handfeel than pure poly. Many brands adopt 50/50 or 60/40; align with DTF for robust multi-color art. Verify print adhesion and stretch recovery.

Fit & Construction: Neckline, Rib Collars, Coverstitch, Shoulder Taping

- Necklines and rib collars: Use stable rib (e.g., 1x1 or 2x2) with elastane content to hold shape through wash. Confirm rib stretch/return and color match.

- Shoulder taping and seams: Shoulder-to-shoulder taping increases longevity, reduces seam distortion, and helps prints sit cleanly.

- Coverstitch and hems: Double-needle hems and clean coverstitch signal quality; keep needle choice and thread specs compatible with fabric stretch.

- Patterns and grading: Maintain consistent chest, shoulder, and length grades by market; validate fit through size set trials with target consumer profiles.

Custom Jersey T Shirts Materials & Performance Specs

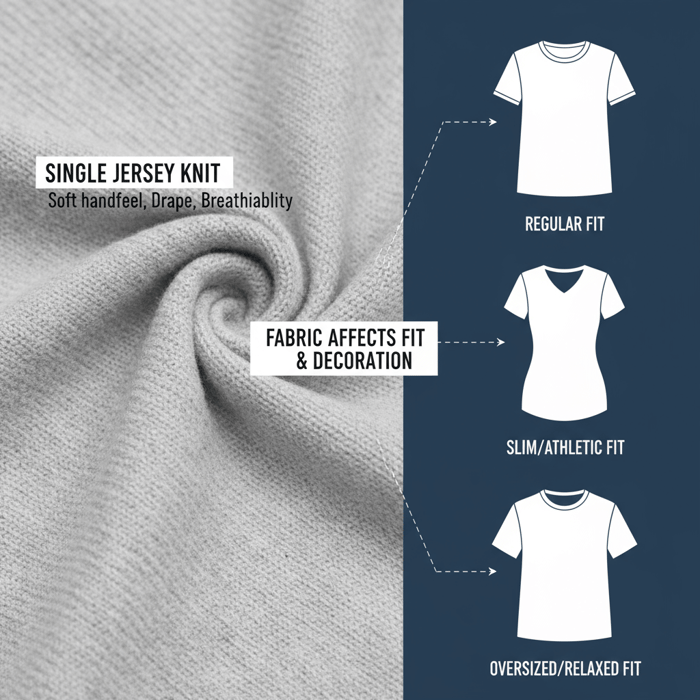

Choose fabric by performance: cotton for handfeel, polyester for moisture-wicking, blends for balance. Specify GSM, shrinkage, pilling, colorfastness, and breathability. Reference AATCC/ISO/ASTM tests to ensure decoration stays vivid and bonded under typical wear and wash cycles for US & EU consumers.

Mention AATCC 135 for dimensional change and ISO 12945 pilling resistance in your lab protocols.

| Spec | Target Range (US/EU) | Test Method | Why It Matters |

|---|---|---|---|

| GSM | 160–220 g/m² (segment-dependent) | ASTM D3776 | Weight drives drape, opacity, and perceived quality; affects print lay-down and cost. |

| Shrinkage | ≤ 3% warp/weft after wash | AATCC 135 | Controls fit stability and logo placement post-wash; reduces returns. |

| Pilling | Grade 3–4 minimum | ISO 12945-2 | Maintains fabric surface and graphic clarity; critical for blends and poly. |

| Colorfastness to Washing | Grade 4 for color change/bleeding | AATCC 61 or ISO 105-C06 | Preserves hue and contrast in multi-color art; protects adjacent garments. |

| Colorfastness to Perspiration | Grade 4 | ISO 105-E04 | Sportswear durability under sweat and body heat; mitigates staining. |

| Breathability | < 20 Pa·s/m (air resistance), or target MVTR | ASTM D737 (air permeability) | Comfort in motion; aligns with performance promises and athlete expectations. |

| Print Adhesion | No visible peel/crack after 10–20 cycles | Brand protocol + AATCC 88B appearance | Decoration integrity under home-launder conditions; protects brand logos. |

Cotton, Poly, Blends: Choosing for Handfeel vs. Performance

- Cotton (ringspun/combed): Premium hand and print clarity; manage shrinkage and colorfastness; DTG excels on cotton-rich bodies.

- Polyester: Quick-dry and abrasion-resistant; sublimation delivers crisp, photo-level art on white; verify anti-bleed dyes for deep colors.

- Blends (50/50, 60/40, tri-blend): Balanced handfeel and moisture management; DTF often yields reliable wash performance; test pilling and print stretch.

Spec Targets: GSM, Shrinkage, Pilling, Colorfastness, Breathability

Premium team tees often sit at 180–200 GSM to balance coverage with movement. Cap shrinkage at or below 3% to keep logos centered and sizing consistent. Aim pilling grade ≥ 3–4. Set colorfastness grade ≥ 4 to washing and perspiration. Choose air permeability targets aligned to end-use and climate.

Trims & Stability: Ribs, Interlinings, Thread Types

- Rib collars: Use stable rib with elastane; test stretch recovery after 10 washes.

- Interlinings: Minimal use on tees; when applied (e.g., plackets or special panels), ensure fusing temperatures do not affect prints or cause strike-through.

- Thread: Polyester core-spun for strength and low shrink; match colorfastness to fabric; needle selection minimizes skip on stretch knits.

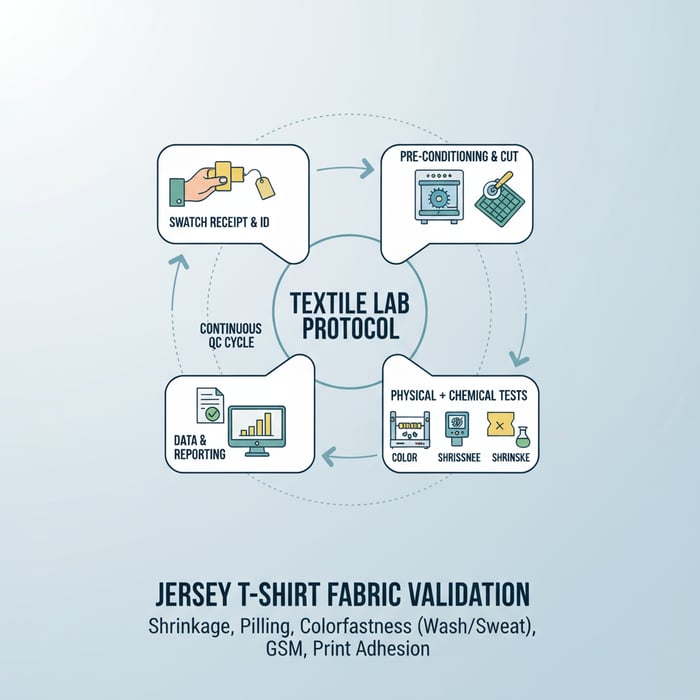

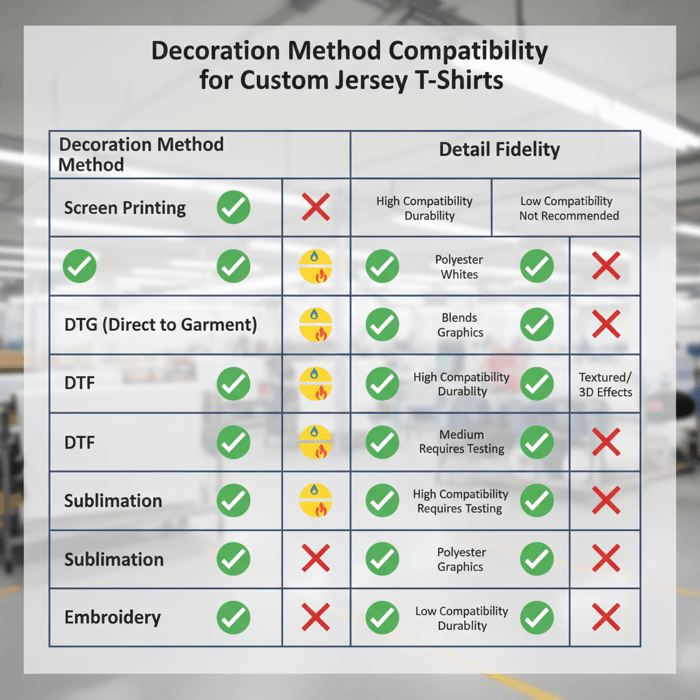

Decoration Methods Compared: Screen, DTG, DTF, Sublimation, Embroidery

Decoration drives aesthetics and durability. Screen printing suits bulk with bold color and low unit cost; DTG excels at detail on cotton; DTF offers versatility and wash performance across blends; sublimation is best on polyester whites; embroidery adds texture. Match method to fabric and art complexity, then validate colorfastness and wash durability.

| Method | Fabric Fit | Detail Fidelity | Durability (Wash) | Unit Cost (Bulk) | MOQ Flexibility |

|---|---|---|---|---|---|

| Screen Printing | Cotton, blends | High for spot colors | High with proper cure | Low at scale | Medium–High |

| DTG (Direct to Garment) | Cotton-rich | Very high (photo-grade) | Medium–High (cotton) | Medium | High (short runs) |

| DTF (Direct to Film) | Cotton, blends, some poly | High for multi-color | High | Medium at scale | High |

| Sublimation | Polyester whites | Very high on white | Very high | Medium | Medium |

| Embroidery | All (with stabilizers) | Low for gradients | Very high | High | Medium |

- POD adoption increased for short-run tees — 2024.

- Sportswear persists as a growth category — 2024.

Fabric–Method Compatibility Map

- Cotton: Screen or DTG for rich colors; DTF for multi-color small batch; embroidery for logos with texture.

- Polyester: Sublimation on white base for photographic clarity; DTF for colored poly with anti-bleed strategies.

- Blends: Screen for solid spot colors; DTF for detail; DTG performance depends on cotton content—test adhesion and wash.

Durability & Wash Performance Considerations

- Cure and dwell times: Screen inks require strict cure to prevent cracking; record oven profiles.

- Pre-treatment and humidity: DTG demands controlled pre-treatment and humidity; verify wash performance on darks.

- Transfer adhesion: DTF bonding depends on pressure, time, and temperature; conduct 10–20 wash cycle tests with peel checks.

- Dye migration control: Sublimation excels on white polyester; for colors, deploy block layers or alternative method.

From Concept to Production: Tech Packs, Sampling, and OEM Workflow

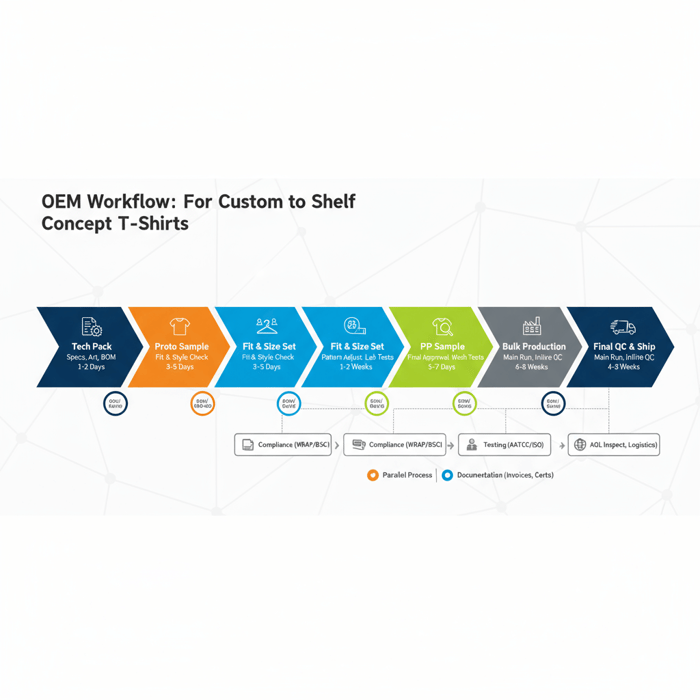

A successful OEM run follows specification-aligned tech pack → proto sample → fit and print tests → size set → PP sample → line production → inline/FR QC → shipment. Document decisions, lab results, and approvals at each gate to minimize rework, delays, and returns for US & EU deliveries.

Reference WRAP and amfori BSCI frameworks for factory audits and ICC Incoterms 2020 for shipping terms.

- Tech Pack: Finalize fabric specs, GSM, measurements, grading, art files, placements, decoration methods, and tests.

- Proto Sample: Validate silhouette, fabric hand, and preliminary print/embroidery execution.

- Fit Sample: Confirm measurement table across sizes; adjust pattern; lock fit blocks.

- Size Set: Produce full size run; run lab tests for shrinkage, pilling, colorfastness.

- Pre-Production (PP) Sample: Sign-off on final construction, trims, labeling, and decoration, including wash tests.

- Bulk Production: Launch line with defined SOPs; track output and QA checkpoints.

- Inline & Final (FR) QC: Inspect to AQL; retest critical parameters; verify labels and carton marks.

- Shipment: Book under agreed Incoterms; share test reports, inspection summaries, and compliance docs.

Building the Tech Pack (Specs, Art Files, Measurements, Tests)

- Fabric: Fiber composition; GSM; shrinkage/pilling targets; color standards; lab test list.

- Construction: Stitch types; seam allowances; rib spec; shoulder taping; thread type.

- Artwork: Vector files; colorways; placements; method and finish details; size scaling.

- Labels & Compliance: Fiber disclosure; RN/COO; care; REACH/OEKO-TEX references; social audit expectations.

Sampling & Approvals (Proto, Fit, Size Set, PP)

- Proto: Confirm silhouette and baseline decoration; note print hand and coverage.

- Fit: Measure against table; capture fit photos on model; adjust pattern for target consumer.

- Size Set: Run lab tests; lock measurement tolerances and shrinkage compensation.

- PP: Conduct 10–20 wash cycles on decorated samples; sign PP that matches production fabric lot and prints.

Production & QC (Inline, FR, AQL, Lab Retests)

- Inline: Early-in-line inspection to catch seam or print issues; confirm rib stability and shade bands.

- Final: Inspect to agreed AQL level; verify labels, barcodes, and cartons match US & EU requirements.

- Retests: Spot-check colorfastness on production lots; confirm wash outcomes match PP baselines.

- Docs: Share inspection reports, lab certificates, and compliance files with shipment notifications.

Product/Service Integration: Clothing Manufacturing OEM Service (Eton)

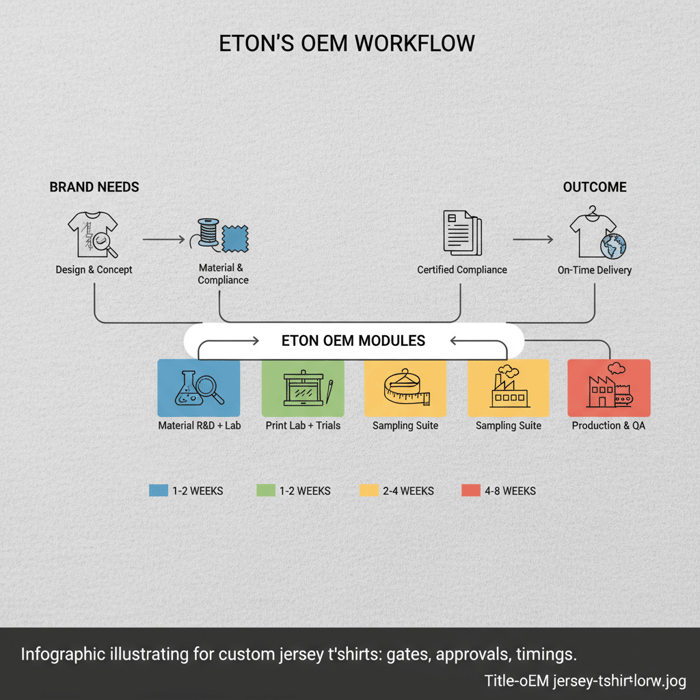

Eton’s OEM service translates brand specs into scalable custom jersey t shirts production across China and Bangladesh: fabric sourcing, lab testing, decoration alignment, compliance, and on-time delivery. Expect transparent costing, certified factories, and rigorous QA tuned to US/EU standards.

Eton’s partnerships with major retailers and OEKO-TEX Standard 100–aligned inputs support compliant, scalable apparel programs. Start OEM jersey tees production.

| Brand Need | Eton Module | Outcome | Typical Timing |

|---|---|---|---|

| Performance fabric selection | Material R&D + Lab | Tested GSM, shrinkage, pilling, colorfastness | 1–2 weeks |

| Decoration alignment | Print Lab + Trials | Validated screen/DTG/DTF/sublimation recipes | 1–2 weeks |

| Tech pack to PP | Sampling Suite | Proto, fit, size set, PP approvals | 2–4 weeks |

| Bulk production | China + Bangladesh lines | Predictable output and QC gates | 4–8 weeks |

| Compliance | QA & CSR Office | US/EU labeling, REACH/OEKO-TEX docs, social audits | Parallel to sampling/production |

Use Case 1: Teamwear Capsule → Performance Poly Blend, DTF + Embroidery

Brief: A club launches staff and training tees with bold multi-color crests and sponsor marks. Eton sources 180 GSM poly blend for quick-dry comfort, tests colorfastness to perspiration and washing, and validates DTF on darks plus embroidery on sleeve logos. PP sample clears 20-wash cycles; bulk ships FOB with audit docs.

Use Case 2: Premium Fanwear → Combed Cotton, Screen + Puff/Applique

Brief: A premium fan capsule demands handfeel and textured art. Eton selects 200 GSM combed cotton, runs shrinkage and pilling tests, screens main chest art for vivid ink lay-down, adds puff on secondary hits and applique on limited pieces. Labels meet FTC/EU rules; cartons pass customs with complete COO and fiber disclosure.

Costing, MOQs, Incoterms: Building a Realistic Budget

Price moves with fabric choice, decoration complexity, order size, factory location, and shipping terms. Define MOQs by method, estimate per‑unit cost bands, and use Incoterms to balance risk and speed. Build cushions for sampling, lab tests, and compliance documentation to avoid surprises at booking.

| Component | Typical Range | Levers |

|---|---|---|

| Fabric | $0.90–$2.20 per unit equivalent | Lock GSM; standardize colors; consolidate mills; choose China vs. Bangladesh by run size |

| Decoration | $0.30–$1.80 per unit | Limit colors on screen; batch DTF; optimize placement count; select method per art |

| Labor & Overhead | $0.50–$1.50 per unit | Stable line SOPs; reduce rework via PP rigor; align QC to risk |

| Trims & Labels | $0.10–$0.40 per unit | Standard care/RN sets; combine label runs; avoid excessive variants |

| Testing & Compliance | $0.05–$0.20 per unit | Bundle lab tests; reuse certified inputs; maintain template documents |

| Freight & Duties | Variable (incoterm-dependent) | FOB for control; DDP for simplicity; optimize carton packs; plan bookings early |

Use ICC Incoterms 2020 guidance and a freight forwarder for seasonally sensitive schedules.

MOQs by Decoration Method (Screen vs. DTG vs. DTF vs. Embroidery)

- Screen printing: 300–1,000+ per design/color for strong unit economics.

- DTG: 24–200 for art-heavy, short-run capsules on cotton-rich bodies.

- DTF: 50–500 per design; flexible for color-dense graphics and mixed fabrics.

- Embroidery: 100–500 depending on stitch count and hoop setup.

Incoterms 2020 & Lead Time/Cost Trade-offs (EXW, FOB, CIF, DDP)

- EXW: Buyer handles pickup and export—lowest supplier cost, highest buyer control.

- FOB: Supplier delivers to port—balanced control and visibility for most brands.

- CIF: Supplier covers freight and insurance—simplifies booking but adjust landed cost.

- DDP: Supplier delivers to door—highest simplicity; verify duty/tax assumptions for US/EU.

Risks, Compliance & Localization (US & EU)

US/EU compliance requires fiber labeling, care instructions, RN/COO disclosure, and chemical safety. Adopt OEKO-TEX and REACH-aligned inputs, plus social compliance frameworks (WRAP/BSCI). Document tests, labels, and audits to avoid customs delays and consumer complaints.

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Shrinkage beyond spec | Medium | High | AATCC 135 testing; pre-wash adjustments; PP verification |

| Color bleed/fade | Medium | High | ISO 105/AATCC 16 tests; dye/ink validation; wash cycle trials |

| Print peel/crack | Low–Medium | High | Cure profiles; DTF transfer optimization; 10–20 cycle tests |

| Labeling non-compliance | Low–Medium | High | FTC/EU 1007/2011 checklists; template labels; QA sign-off |

| Social audit failure | Low | High | WRAP/BSCI audits; corrective action plans; transparent reporting |

Regulatory Notes for US & EU (Labeling, REACH, OEKO-TEX, Social Compliance)

- US (FTC Textile & Wool Acts): Fiber content percentages, RN or company name, accurate country of origin, and care labeling.

- EU (Regulation 1007/2011): Fiber labeling rules, care symbols aligned to fabric/prints, and REACH chemical safety compliance.

- Social compliance: WRAP and amfori BSCI audits; maintain certificates and corrective action plans.

FAQs

Related Articles

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »