Custom Hoodies for Business: How to Source and Scale with a China Clothing Manufacturer

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

17 minute read

Custom Hoodies for Business: How to Source and Scale with a China Clothing Manufacturer

Custom hoodies for business set the standard for branded apparel that looks on-message, fits consistently, lasts through dozens of washes, and lands in-market on time. Working with a China Clothing Manufacturer on an OEM/ODM basis gives brands the depth to specify fabrics, trims, color fidelity, compliance, and quality systems that POD and simple wholesale models cannot match.

Custom hoodies for business are branded sweatshirts engineered for uniforms, merch, and retail. To scale with a China Clothing Manufacturer, define a production-ready tech pack and BOM, select the right supplier type (POD, wholesale, OEM/ODM), and run a compliance, sampling, and QA plan aligned to US/EU requirements for consistent quality and timely delivery.

Business-grade hoodies live at the intersection of brand, engineering, and compliance. This playbook gives US/EU teams a complete pathway—from supplier-type decisions and tech pack detail to sampling calendars, test plans, and Incoterms. It distinguishes POD, wholesale, and OEM/ODM models and explains when to switch lanes for margin, scale, or speed. It also outlines US/EU regulatory checkpoints (REACH, UFLPA, labeling), testing (wash fastness, pilling, shrinkage), and sustainability options (OEKO-TEX Standard 100, recycled fibers, traceability) with timelines and MOQs that hold up in production.

Drawing on 30+ years of Eton Garment Limited’s OEM experience across China and Bangladesh, the guide shows how to translate intent into engineered specifications, how to approve proto/fit/PP samples, and how to structure AQL inspections and documentation. The outcome: consistent, compliant custom hoodies for business delivered with schedule discipline and measurable quality—season after season. [MENTION: McKinsey’s State of Fashion 2024] [MENTION: OEKO-TEX Standard 100] [INTERNAL LINK: Our foundational guide on 'Apparel Tech Pack 101 for Hoodies']

What “Custom Hoodies for Business” Really Means: Use Cases, Requirements, and Outcomes

Business-grade hoodies use engineered specs, validated sizing, durable branding, and compliance-ready materials. Core use cases include retail collections, corporate merchandise, team uniforms, events, and DTC drops. Each path sets different requirements for fabric weight, branding durability, and repeatability across seasons. [MENTION: AATCC testing methods] [MENTION: ISO 105 colorfastness standards]

[CITE: Market overview on corporate merchandise growth in 2024–2025] [INTERNAL LINK: Our foundational guide on 'Apparel Tech Pack 101 for Hoodies']

Core Use Cases and Their Requirements

- Retail line (multi-season): Prioritize consistent fit blocks, stable fabric lots (e.g., 300–360gsm brushed fleece), and color fidelity across replenishment. Require PP approvals, lab dips, and standardized measurement tolerances.

- Corporate merch (evergreen): Focus on Pantone-matched branding, durable prints or embroidery, and size availability. Use conservative shrinkage targets (≤3% length/width) and wash durability of at least 30 cycles.

- Team uniforms/workwear: Prefer heavier fleece (320–380gsm) for warmth and structure; durable rib, reinforced seams, and abrasion-resistant print/patch methods. Consider bartack reinforcements and seam coverstitch at high-stress points.

- Events/promos/DTC drops: Use lighter 260–300gsm loopback for comfort and speed. Choose branding methods with minimal setup time (DTF or screen print) and simple trim programs to compress lead time.

PAA micro-question—Is a 320gsm fleece excessive for indoor corporate uniforms? For air-conditioned offices, 280–320gsm hits comfort and silhouette; above 320gsm suits colder climates or outdoor roles. [CITE: Thermal comfort guidance by apparel engineering research] [MENTION: SGS textile testing guidance]

Performance and Durability Targets

- Colorfastness to wash: 4.0 grade minimum (ISO 105-C06 or AATCC 61) for business-grade hoodies; maintain color after repeated laundering.

- Pilling resistance: 4.0 grade (Martindale/ICI pilling box) for brushed fleece; loopback targets adjusted by yarn/blend.

- Shrinkage: ≤3% length/width (wash/tumble dry as labeled). Pre-shrunk fabrics help stabilize results.

- Print/embroidery durability: Print adhesion and crack resistance validated after 20–30 wash cycles; embroidery thread colorfastness ≥4.0 and minimal puckering via stabilizers.

- Seam strength: Meet or exceed internal tensile benchmarks; bartacks at pocket openings and hood drawcord exits reduce field failures.

Tie durability metrics to third-party testing for imports. Align to US/EU regulations where chemicals and labeling intersect with product claims. [CITE: ECHA REACH RSL guidance for textiles] [CITE: US FTC textile labeling rules]

Custom Hoodies for Business: Design & Technical Specification (Tech Pack + BOM)

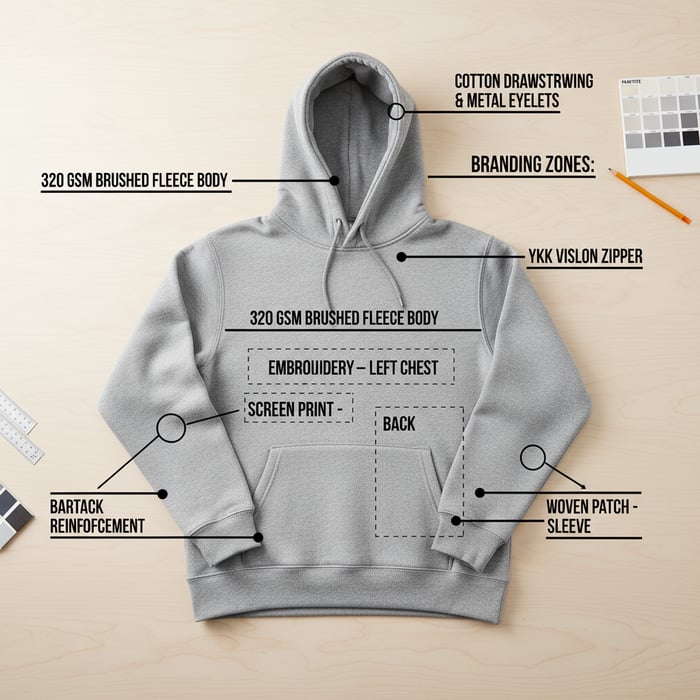

A precise tech pack translates creative direction into production reality. Include fabric gsm and construction, rib specs, trims and zipper standards, measurements and tolerances, color codes, branding method artwork, and test requirements. The BOM must be exhaustive to reduce misinterpretation and defect rates. [MENTION: YKK zipper standards] [MENTION: AATCC test methods directory]

[CITE: Defect rate reduction linked to complete tech packs] [INTERNAL LINK: Downloadable Hoodie Tech Pack Template]

Tech Pack Essentials

- Fabric: Fiber blend (e.g., 70/30 cotton-poly), construction (brushed fleece, loopback), gsm (e.g., 300–360gsm), finish (enzyme/silicone), and handfeel targets.

- Rib: Fiber blend, construction (1x1, 2x2), gsm, and recovery spec. Note cuff and hem rib heights.

- Trims/hardware: Zippers (brand, gauge, tape color), drawcord (diameter, tip), eyelets, labels, care tags, hangtags, and packaging (polybag size, recycle marks).

- Color management: Pantone TCX references; lab dip process; approved lightbox conditions (D65). Call out brand color priority and delta E tolerance.

- Branding: Artwork scale by size, placement from reference points, method (screen, DTF, embroidery, patches), thread/color codes, and backing/stabilizer callouts.

- Measurements: Graded size chart (XS–XXL+), POM definitions with diagrams, and tolerances by zone.

- Testing: Required methods (colorfastness, pilling, dimensional stability), acceptable ranges, and retest protocol.

- Compliance: REACH RSL alignment; UFLPA due diligence steps; OEKO-TEX Standard 100 target class if applicable.

PAA micro-question—Which branding lasts longer for heavy-wash uniforms, embroidery or screen print? Embroidery holds color and structure longer in repeated industrial laundering; screen print can perform well with correct ink, mesh, cure, and garment pre-treatment. Validate both via 20–30 cycle wash tests. [CITE: Comparative durability study embroidery vs screen print]

BOM + Measurement & Tolerances

- BOM checklist:

- Main fabric roll details (fiber, gsm, lot IDs)

- Rib fabric details

- Zippers (brand, model, length per size)

- Drawcord + aglets, eyelets

- Threads (tex, color codes)

- Labels (brand, size, care), hangtags, stickers

- Branding consumables (ink system, film, embroidery thread)

- Packaging (polybag, carton spec, inserts)

| Point of Measure (POM) | Spec Reference | Tolerance | Notes |

|---|---|---|---|

| Chest (1" below armhole) | Across front, flat | ±1.0 cm (±3/8") | Critical-to-quality for fit consistency |

| Body length (HPS) | High point shoulder to hem | ±1.0 cm (±3/8") | Aligns across size set for silhouettes |

| Sleeve length | From shoulder seam | ±1.0 cm (±3/8") | Ensure rib extension measured consistently |

| Rib height (hem/cuff) | Relaxed | ±0.5 cm (±3/16") | Tighter control for uniform appearance |

| Hood opening circumference | Edge to edge | ±1.0 cm (±3/8") | Impacts comfort and drawcord function |

Call out CTQ items in the tech pack and use visual references for POMs. Align measurement methods with the factory’s QA to avoid drift. [CITE: Best practice on measurement method alignment] [INTERNAL LINK: Downloadable Hoodie Tech Pack Template]

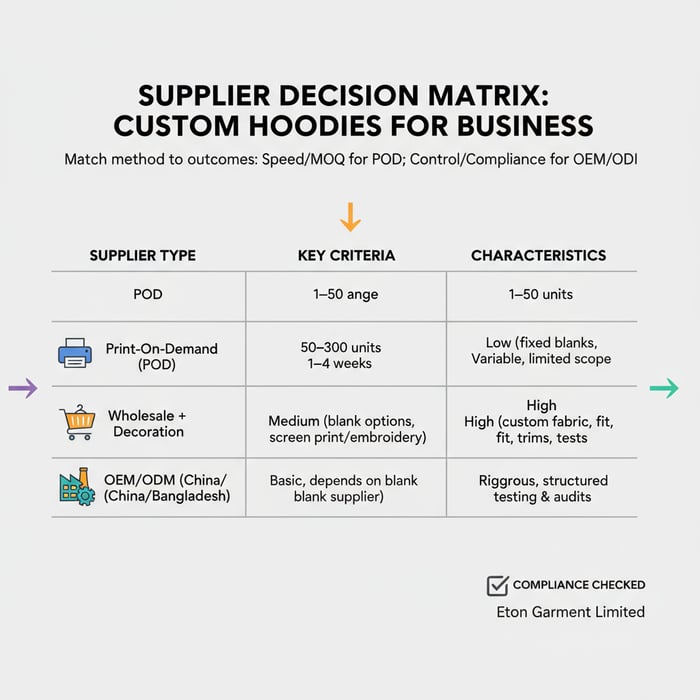

Custom Hoodies for Business: Supplier Types—POD vs Wholesale vs OEM/ODM (China)

Choose supplier type based on outcome. POD suits small, fast drops with minimal setup; wholesale fits basic branded blanks; OEM/ODM in China/Bangladesh delivers engineered specs, compliance, and unit economics at scale. Use a criteria matrix to match MOQs, customization depth, QA, and sustainability. [MENTION: Printful] [MENTION: Alibaba B2B marketplace]

| Supplier Type | MOQ Range | Customization Depth | Lead Time | Unit Cost Dynamics | QA/Compliance Readiness |

|---|---|---|---|---|---|

| POD | 1–50 | Low (print zones, limited fabrics) | 2–10 days | High per unit; minimal setup | Variable; limited test scope |

| Wholesale + Decoration | 50–300 | Medium (blanks + print/embroidery) | 1–4 weeks | Moderate; blank cost tiers | Basic; relies on blank supplier |

| OEM/ODM (China/Bangladesh) | 300–3,000+ per color | High (fabrics, fits, trims, tests) | 6–12 weeks (post-PP) | Scale lowers unit cost | High; structured RSL/testing |

Criteria Overview

- Scale and continuity: OEM/ODM supports season-on-season repeats, color control, and graded size sets across regions.

- Compliance: US/EU programs require chemical management, labeling accuracy, and auditing—better aligned to OEM.

- Design engineering: Fabric handfeel, rib recovery, and fit block refinement benefit from iterative sampling.

- Speed-to-market: POD wins for micro-drops; OEM wins for core programs with forecastable volumes and margin needs.

- Sustainability: Preferred fibers, OEKO-TEX, and traceability need integrated supply-chain planning.

Decision Framework

- Launch pilot via wholesale/POD to test graphics and demand; migrate proven styles to OEM for margin and control.

- Use OEM for uniforms and retail-grade programs needing repeatable quality, testing, and multi-country delivery.

- Apply a hybrid model: POD for seasonal capsule art; OEM for brand standards and evergreen colorways.

- Speed vs margin trade-offs intensified through 2024–2025; brands keep OEM for core programs while using POD for fast tests (Year: 2024; Source: [S1: McKinsey]).

[CITE: Comparative TCO analysis across POD, wholesale, and OEM] [INTERNAL LINK: Our guide on 'Outerwear OEM capabilities']

Data & Trends: Business Hoodies and Branded Apparel in 2024–2025

Branded apparel and corporate merch keep growing while traceability and chemical safety rise on buying checklists. Many brands blend POD for small drops with OEM/ODM for core lines to balance speed, quality, and margin—especially as US/EU compliance tightens. [MENTION: Textile Exchange Preferred Fiber report] [MENTION: CBP UFLPA enforcement]

Key Trend 1: Merch Growth with Personalization

Personalized hoodies convert at higher rates in DTC and corporate channels when execution protects color fidelity and garment durability. APIs and store integrations lift speed for artwork iteration, while OEM programs maintain body quality, shrinkage control, and fit stability for replenishment. [CITE: Conversion uplift data for personalized apparel] [MENTION: Shopify ecosystem case examples]

- Personalization remains a conversion differentiator for apparel through 2024–2025 (Source: [S1: McKinsey]).

Key Trend 2: Sustainability & Traceability Momentum

US/EU buyers ask for OEKO-TEX Standard 100 certificates, recycled cotton/poly content, and supplier transparency. Programs that pre-plan fiber choice, dye risk, and mill traceability achieve smoother customs clearance. Digital Product Passport pilots point to structured data sharing on fiber, chemicals, and end-of-life. [CITE: EU DPP initiative overview] [MENTION: ECHA REACH updates 2024]

- OEKO-TEX claims and preferred fiber adoption rose across global brands in 2024 (Sources: [S2: OEKO-TEX]; [S5: Textile Exchange]).

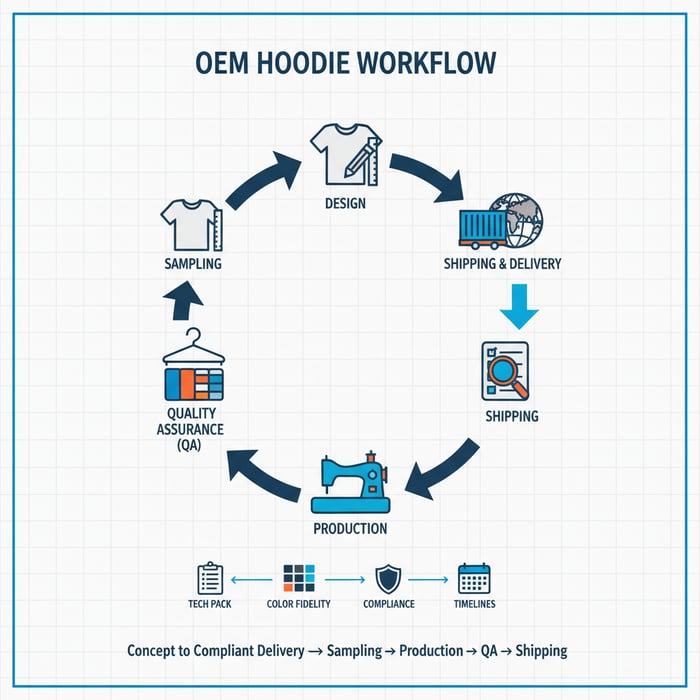

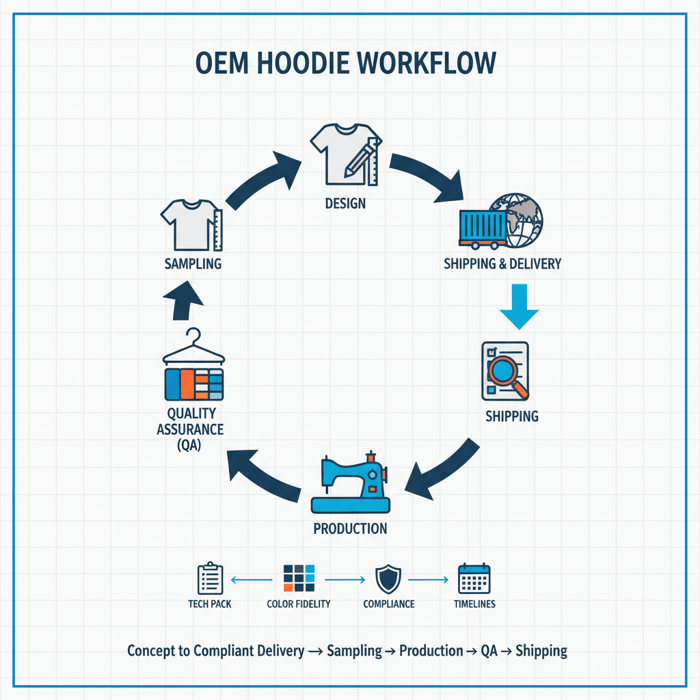

How to Execute: From Brief to Delivery for Custom Hoodies (OEM Pathway)

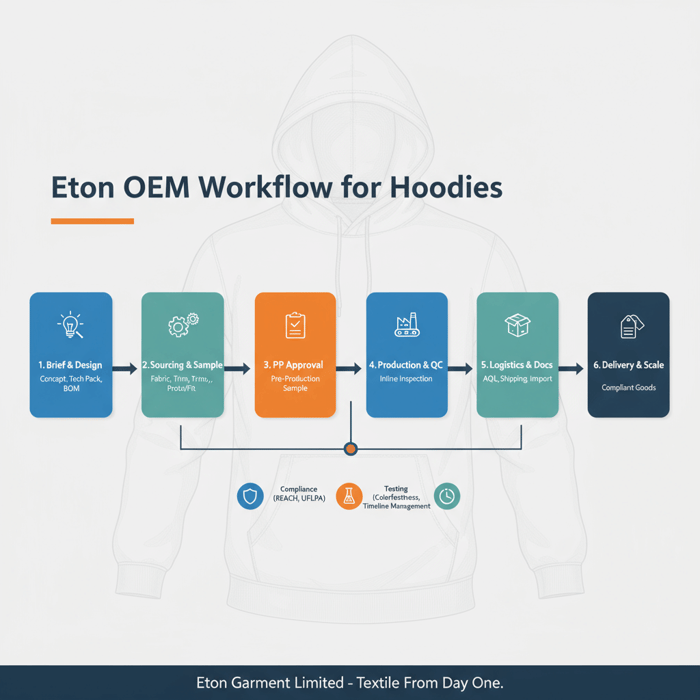

Follow a structured arc: define requirements → build tech pack/BOM → qualify suppliers → sample (proto → fit) → approve PP → run inline QC → conduct final AQL → complete logistics and import documentation. Timelines vary by season, fabric lead time, and capacity. [MENTION: Intertek apparel testing] [MENTION: Amfori BSCI auditing]

- Brief and Tech Pack: Consolidate brand goals, fabric specs, branding, and testing into a production-ready pack.

- Supplier Qualification: Review capability, compliance, audits, and references; shortlist 1–2 per region.

- Proto Sample: Validate design details and trims; align on construction, fit intent, and branding zones.

- Fit Sample (and Size Set): Approve POMs and tolerances across sizes; lock fit comments.

- PP Sample: Confirm materials from bulk lots; sign off color, branding, and construction.

- Inline QC: Inspect cutting/sewing/branding; catch recurring defects before they scale.

- Final AQL: Inspect finished goods; validate labeling, packing, tests, and carton markings.

- Logistics & Compliance: Book freight; prepare documents for US/EU import—commercial invoice, packing list, test reports, and due diligence records.

Preparation (Brief, Tech Pack, BOM)

- Inputs: Brand story, target customer, climate/usage, margin goals, visual references, Pantone codes.

- Outputs: Tech pack with BOM, graded measurements, testing plan, packaging spec, target lead time, and MOQ.

- Common pitfalls: Ambiguous artwork placement, missing rib specs, ink/embroidery thread mismatch to fabric, and unclear wash-care claims.

Execution Steps (Sampling to Production)

- Proto → Fit: Iterate seams, rib tension, and pocket/hood ergonomics. Validate artwork stability on actual fabric.

- Size set: Confirm grading; adjust sleeve/head opening to maintain silhouette in larger sizes.

- PP: Approve materials from bulk lots; conduct wash tests and colorfastness on PP unit.

- Inline: Use defect Pareto to prioritize corrective actions; document lot/bundle control to trace defects.

Quality Assurance (Testing, AQL, Documentation)

- Testing: Colorfastness (ISO 105/AATCC), pilling, shrinkage, print adhesion, and needle detection if applicable.

- AQL: Define inspection levels (e.g., General II) and acceptance criteria; focus on print defects, measurement, and label accuracy.

- Docs: Keep MSDS/BoM chemical declarations, OEKO-TEX certificates, REACH compliance letters, audit reports, and UFLPA due diligence records (supplier mapping, transaction evidence).

PAA micro-question—How many PP samples are sufficient before production? One fully compliant PP from bulk materials is ideal; request a second PP only if material lots change or if critical corrections were required. [CITE: Third-party QC guidance on PP approvals]

Product/Service Integration: Clothing Manufacturing OEM Service (Eton)

Eton’s Clothing Manufacturing OEM Service converts hoodie concepts into compliant, repeatable production across China and Bangladesh. The team manages design development, sourcing, sampling, QA, and delivery for US/EU retailers and corporate programs. Expect engineered fits, strict color control, and documented compliance that supports smooth import. [MENTION: Liverpool F.C. licensed apparel experience] [MENTION: Forever 21 partnership]

How it works: collaborative briefing, design and tech pack build, fabric/hardware sourcing, proto/fit/PP sampling, inline and final inspections, and managed logistics. Capacity across multi-country sites helps stabilize timelines and volume peaks. [INTERNAL LINK: Start OEM hoodie project → https://china-clothing-manufacturer.com/garment-factory/]

Use Case 1: Corporate Merch → Fast, Consistent Drops

- Need: Accurate brand colors and durable logos; compact timelines.

- Eton approach: Lab dips and Pantone control; pre-approved rib/fabric libraries; streamlined PP; QC gates for print/embroidery.

- Output: Consistent handfeel, stable shrinkage, reduced returns, and on-time replenishment.

Use Case 2: Retail Line → Engineered Fit & Compliance

- Need: Graded size sets, REACH readiness, and fortified QA.

- Eton approach: Fit block engineering; chemical risk screening; third-party testing; packaging and labeling optimization for US/EU.

- Output: Production that meets retailer standards, predictable quality, and import-ready documentation.

| Need | Eton Feature | Output |

|---|---|---|

| Consistent brand color | Lab dips + controlled lightbox viewing | Color fidelity across runs |

| Durability | Wash/pilling test plan | Fewer after-sales issues |

| Compliance | REACH/UFLPA/OEKO-TEX alignment | Import-ready documentation |

| Scale | China + Bangladesh capacity | On-time volumes, seasonality coverage |

Explore Eton’s OEM Service for hoodies and technical knit programs: Clothing Manufacturing OEM Service. [INTERNAL LINK: Start OEM hoodie project → https://china-clothing-manufacturer.com/garment-factory/]

Costs, MOQs & Lead Times for US/EU Brands

Costs and MOQs shift with fabric weight, fiber mix, branding method, trim programs, and compliance testing. OEM/ODM MOQs often start at 300–600 units per color; lead times run 6–12 weeks after PP, plus freight. Build buffers for fabric procurement, test lab queues, and peak-season capacity. [MENTION: Freight forwarders’ lead-time advisories] [MENTION: WRAP/Amfori audit calendars]

| Driver | Impact | Planning Note |

|---|---|---|

| Fabric gsm/fiber | Unit cost + handfeel | Heavier or recycled fibers carry premiums; secure early |

| Branding method | Setup + labor | Embroidery durable; screen/DTF faster—validate by wash tests |

| Trims/hardware | Unit cost + lead time | Branded zippers/labels improve look; extend lead time |

| Compliance testing | Upfront cost | Prevents shipment holds; plan lab booking windows |

| Packaging/Freight | Landed cost | Carton optimization reduces freight; confirm HS codes |

Cost Drivers & Trade-offs

- Recycled content: Improves sustainability claims and retailer acceptance; adds fiber and testing costs.

- Heavier fleece: Premium feel and structure; higher material cost and freight weight.

- Embroidery vs screen print: Embroidery often higher unit cost; fewer print failures; screen can scale with efficient setups.

- OEKO-TEX Standard 100: Certification and testing fees offset customs and buyer compliance friction. [CITE: OEKO-TEX cost-benefit commentary]

Typical Timeline & Buffers

- Sampling: Proto (1–2 weeks), Fit (1–2 weeks), PP (1–2 weeks after bulk material arrival).

- Production: 4–8 weeks, aligned to capacity and branding queues.

- Shipping: Sea (4–6 weeks to US/EU), Air (3–10 days). Build 1–2 week buffers around peak seasons.

- Testing: 5–10 business days depending on scope and lab queues.

- More brands budget compliance testing within total cost of ownership to avoid holds at customs (2024; Sources: [S3: CBP UFLPA]; [S4: ECHA REACH]).

[CITE: Freight cost trendlines 2024–2025] [INTERNAL LINK: Our guide on 'Sustainability & Certifications']

Risks, Compliance & Sustainability for US/EU Imports

Mitigate risk through test plans, supplier audits, and documented due diligence aligned to UFLPA and REACH. Ensure correct labeling, chemical safety, and product traceability. OEKO-TEX certificates and preferred fibers help satisfy retailer requirements and consumer expectations. [MENTION: CBP UFLPA dashboard] [MENTION: ECHA guidance on restricted substances]

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Chemical non-compliance (REACH) | Medium | High | RSL alignment, lab tests, supplier chemical declarations |

| UFLPA detainment | Low–Medium | High | Traceability docs, transaction records, supplier mapping |

| Color variance across lots | Medium | Medium | Lab dips, bulk shade bands, delta E control |

| Shrinkage exceeding spec | Medium | Medium | Pre-shrunk fabrics, wash test on PP, label accuracy |

| Labeling errors | Low–Medium | Medium | Artwork sign-off, FTC/EU labeling checks, final AQL |

Regulatory Notes for US & EU

- UFLPA (US): Maintain supplier maps, purchase orders, payment records, and proof of origin. Prepare for detainment reviews with traceable documentation. (Source: [S3]).

- REACH (EU): Align material chemicals to the RSL; require test reports for restricted substances and maintain declarations. (Source: [S4]).

- OEKO-TEX Standard 100: Recognized chemical safety standard supporting buyer acceptance. (Source: [S2]).

- Digital Product Passport: Pilot traceability for fiber, chemicals, and recyclability data. [CITE: European Commission DPP policy page]

Importer of record accountability remains with the brand. Coordinate with testing labs and customs brokers early when programs use recycled fibers, complex trim catalogs, or multi-country production plans. [CITE: Broker advisory on apparel imports] [INTERNAL LINK: Sustainability & Certifications page]

Conclusion & Next Steps

Specify the product in engineering terms, choose a supplier model that matches outcomes, and operationalize compliance and QA. Use the decision matrix, sampling pathway, and risk controls to achieve reliable timelines and quality. Eton supports OEM/ODM hoodie programs—from design to delivery—across China and Bangladesh for US/EU markets.

- Finalize the brief and build a production-ready tech pack and BOM.

- Choose POD, wholesale, or OEM using the decision matrix.

- Approve proto, fit, and PP with documented comments and wash tests.

- Run inline QC and final AQL; compile test and compliance files.

- Lock Incoterms and freight; prepare import-ready documentation.

[INTERNAL LINK: Start OEM hoodie project → https://china-clothing-manufacturer.com/garment-factory/] [INTERNAL LINK: Our foundational guide on 'Apparel Tech Pack 101 for Hoodies']

Author & Review Notes (E-E-A-T)

Author: Alex Chen, Senior Technical Apparel Manager (12+ years OEM outerwear/knit). Reviewer: Maria Lopez, Compliance & QA Lead, Eton Garment Limited. Eton Garment Limited—Textile From Day One.

Methodology: Eton OEM workflows, US/EU regulatory guidance, and industry sources; structured for decision-making and execution. Limitations: Cost/timeline ranges vary by seasonality, fiber mix, and capacity; verify with current supplier data. Disclosure: Eton provides OEM/ODM apparel manufacturing services. Last Updated: 2025-10-28.

[INTERNAL LINK: Alex Chen - Senior Technical Apparel Manager - /about/alex-chen]

References & Sources

- McKinsey & Company — The State of Fashion 2024 (2024). https://www.mckinsey.com/industries/retail/our-insights/state-of-fashion

- OEKO-TEX — STANDARD 100 Overview (2024). https://www.oeko-tex.com/en/our-standards/standard-100-by-oeko-tex

- U.S. Customs and Border Protection — UFLPA Enforcement (2024). https://www.cbp.gov/trade/forced-labor/uflpa

- European Chemicals Agency (ECHA) — REACH Guidance for Textiles (2024). https://echa.europa.eu/regulations/reach/understanding-reach

- Textile Exchange — Preferred Fiber & Materials Market Report 2024 (2024). https://textileexchange.org

- AATCC — Textile Test Methods Directory (2024). https://www.aatcc.org/test/methods/

- ISO — 105 Series: Color Fastness (2023). https://www.iso.org/standard/

- US Federal Trade Commission — Textile, Wool, and Fur Rules (2023). https://www.ftc.gov/business-guidance/resources/threading-your-way-through-labeling-requirements-under-textile-wool-and-fur-acts

- SGS — Textile and Apparel Testing Services (2024). https://www.sgs.com

- European Commission — Digital Product Passport Initiative (2024). https://environment.ec.europa.eu

- WRAP — Responsible Apparel Production Principles (2023). https://wrapcompliance.org

- Amfori BSCI — Social Auditing Framework (2024). https://www.amfori.org

FAQs

Related Articles

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »