Black Leather Motorcycle Jacket Manufacturing Guide for Fashion Brands (China Clothing Manufacturer Context)

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

October 28th, 2025

19 minute read

Black Leather Motorcycle Jacket Manufacturing Guide for Fashion Brands (China Clothing Manufacturer Context)

Black leather motorcycle jacket programs with a China Clothing Manufacturer demand clear claims, precise specifications, and a disciplined OEM/ODM workflow. For US & EU brands, define whether the jacket is protective or fashion, source from LWG-audited tanneries, meet REACH and EN requirements, and plan QA gates from proto to bulk. Eton helps brands move from concept to compliant scale—Textile From Day One.

A black leather motorcycle jacket that sells in the US/EU requires a defined claim set, leather grade and thickness selection, hardware and seam choices, and testing aligned to EN 17092 if protection is claimed. Source through LWG-certified tanneries, meet REACH chemical limits, and work with an experienced China Clothing Manufacturer for OEM/ODM execution, dual-shore resilience, and QA.

Executive Summary

Building a credible black leather motorcycle jacket for US/EU markets hinges on early claim clarity (protective vs fashion), responsible leather sourcing, and a structured manufacturing plan. This guide translates standards like EN 17092 into design implications, compares leather types by durability and feel, and sets expectations for cost, MOQ, and lead time. It also outlines REACH, OEKO-TEX Leather Standard, and LWG sourcing frameworks, with a lab/factory test matrix you can plug into your tech pack and development milestones. Eton’s Clothing Manufacturing OEM Service connects design to bulk across China and Bangladesh, integrating LWG leather, EN-aware patterning, and rigorous QA with traceability—so brands launch with confidence at target margins.

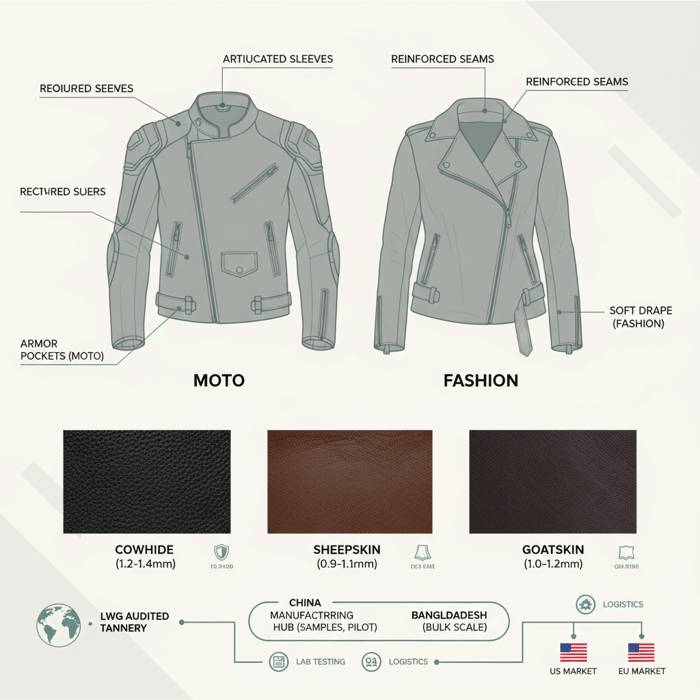

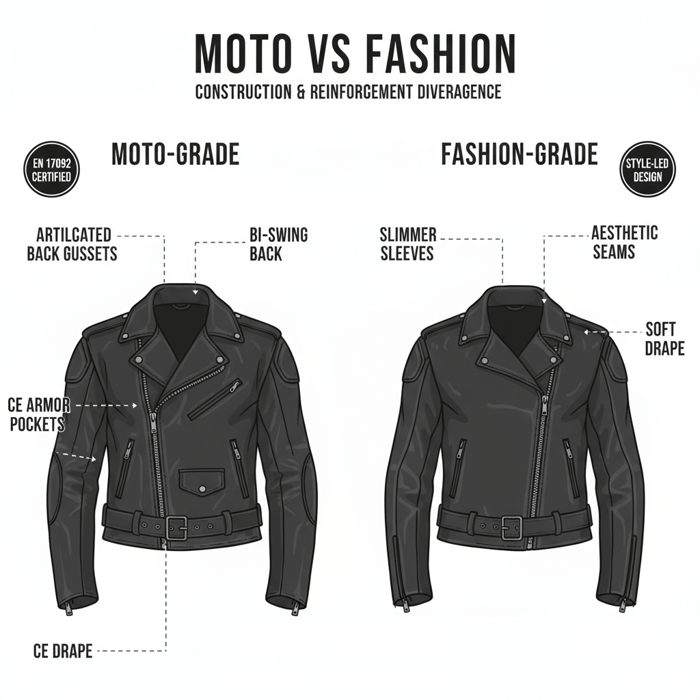

What Makes a Black Leather Motorcycle Jacket “Moto” vs “Fashion”

A black leather motorcycle jacket built for riding centers abrasion resistance, seam integrity, and mobility, while a fashion jacket prioritizes drape, hand-feel, and price. Your claim set determines leather thickness, reinforcements, pattern block, and tests. If no protection claim is made, avoid misleading labels and design to fashion performance targets.

- Moto intent: Ergonomics for riding (arm mobility, back length), abrasion-competent leather, reinforced seams, armor pockets, and CE-standard awareness.

- Fashion intent: Softer hand-feel, lighter weight, simplified seam construction, and aesthetic details (finish, stitch density) at defined cost targets.

- Claim clarity: If marketing implies protection, align to EN 17092 Classes (AAA/AA/A) and test accordingly. If not, stay fashion-led and avoid protective claims.

| Specification | Moto-Grade (Claimed) | Fashion-Grade (Unclaimed) |

|---|---|---|

| Leather thickness | ~1.2–1.4 mm cowhide/goatskin; consistent panel selection [CITE: EN 17092 overview from standards publisher] | ~0.9–1.2 mm sheepskin/cowhide for comfort and drape |

| Reinforcements | High-stress panels reinforced; double/triple-stitched critical seams | Selective reinforcements for seam stability; single/double-stitched |

| Armor | Shoulder/elbow/back armor pockets; CE-impact protection compatibility [CITE: CE impact protector standards explanation] | No armor; padding only as design detail |

| Seam construction | Lapped/seam variants emphasizing tear/abrasion | Standard topstitch; aesthetic seam placements |

| Labeling | EN 17092 class on care/content labels per regulation | Strictly fashion; no protective claims or symbols |

Core Silhouette Attributes

Start with riding posture. A moto jacket needs forward rotation in sleeves (articulated elbows), bi-swing back gussets or underarm panels for reach, and a drop-tail hem to cover the lower back while seated. Collar construction must balance wind protection and comfort at the neck under a helmet; lapels should secure with snaps to prevent flap at speed. Zippers should run smooth under tension; two-way front zippers allow better comfort on the bike. If building a fashion-oriented black leather motorcycle jacket, keep the iconic asymmetrical front, epaulettes, and waist belt, but reduce bulk with slimmer sleeve caps, lighter interlinings, and softer leather to improve off-bike wearability.

Armhole height is a common miss. For moto claims, slightly higher armholes with ergonomic sleeve pitch reduce binding. At the waist, side adjusters or belts ensure a stable fit; for fashion, consider hidden elastic tab adjusters to maintain a clean silhouette. Add cuff gussets for glove compatibility and ventilation eyelets where appropriate. Plan the lining so that sleeve-entry and back yokes glide over base layers; map labels and branding away from high-friction zones.

Claims & Labeling Implications

Protective marketing triggers regulatory obligations. If your black leather motorcycle jacket uses any protective language or iconography, align with EN 17092 and complete accredited testing for the claimed class. Keep a technical file with test reports, BOMs, traceability records, and labeling approvals. For fashion jackets, avoid suggestive phrases like “impact-ready” or “CE-grade” unless verified. Include care instructions that reflect leather finish and fastener types; for US retail, check Prop 65 labeling where applicable [CITE: California OEHHA Prop 65 apparel guidance]. EU markets require REACH compliance documentation; provide lab certificates for restricted substances. Maintain a single source of truth for claims across e-commerce PDPs, packaging, and hangtags.

[MENTION: RevZilla’s consumer education on CE ratings] can help merchandising teams phrase claims. For standards interpretation, reference [MENTION: European Committee for Standardization (CEN)] publications and test labs for definitive requirements.

[INTERNAL LINK: Moto vs Fashion outerwear design — pillar page linking pattern fundamentals]

Materials & Construction for Black Leather Motorcycle Jackets

Pick leather by durability, hand-feel, and sustainability. Cowhide leads for abrasion resistance; sheepskin wins on softness; goatskin balances weight and toughness. Match thickness to your claim set, select reliable hardware (YKK, RiRi), and construct seams to withstand stress. Source from LWG-certified tanneries and test for crocking, odor, and colorfastness.

| Material | Pros | Cons | Typical Thickness | Use Case |

|---|---|---|---|---|

| Cowhide | High abrasion resistance; firm hand; ages well | Heavier; longer break-in | 1.2–1.4 mm (moto) / 1.0–1.2 mm (fashion) | Moto-leaning, premium heritage |

| Sheepskin | Soft drape; lightweight; premium hand | Lower abrasion; higher variability by lot | 0.9–1.1 mm (fashion) | Fashion-led capsules, mid-tier |

| Goatskin | Grainy toughness; lighter than cowhide | Less luxurious feel than sheep | 1.0–1.2 mm (balanced) | Balanced durability vs comfort |

| PU / Bio-based | Chromium-free; consistent surfaces; cost control | Lower abrasion vs high-grade hides; breathability trade-offs | N/A — by microns/fabric gauge | Vegan/price-accessible fashion |

- LWG-certified capacity expanded across major regions — 2024 (Source: [CITE: Leather Working Group program data])

- US/EU consumers show growing interest in responsibly sourced leather — 2024 (Source: [CITE: recognized retail/market research])

Leather Types & Thickness Ranges

For moto claims, specify consistent cowhide or goatskin panels, curated from adjacent areas of the hide to reduce thickness variance. A working range of ~1.2–1.4 mm supports abrasion performance targets commonly associated with EN 17092 classes, subject to testing. If fashion-led, 1.0–1.2 mm cowhide or 0.9–1.1 mm sheepskin yields better drape and comfort while maintaining seam stability. Pre-approve finish: aniline for natural aging and premium appearance, semi-aniline for balanced protection, or pigmented for surface consistency. Request tannery COAs including pH, colorfastness to rubbing, and finish adhesion results.

Color consistency matters on black. Confirm dyestuff type and fastness; run dark-rub tests on wet and dry conditions for bulk acceptance benchmarks. For US & EU, validate restricted substances under REACH and OEKO-TEX Leather Standard where used. If you plan vegan capsules, align PU/bio-based materials to brand standards on durability and micro-cracking resistance, and validate hydrolysis resistance for humid markets [CITE: OEKO-TEX Leather Standard guidance; polymer durability research].

Hardware, Lining, and Seam Construction

Hardware must not be the weak link. Specify branded zippers (YKK #5/#8, RiRi) with anti-nick sliders, nickel-free trims for EU, and reinforced zipper tapes. Snap and buckle components require lot authentication and pull tests; counterfeit hardware risks warranty claims. Lining: twill or satin poly for sleeves to ease entry, mesh or quilted liners for comfort and seasonal insulation; confirm colorfastness and tear strength. Decide on an all-black story or tonal variations with stealth branding.

Seam engineering: prioritize lapped seams and double-needle topstitching in stress zones like shoulders, armholes, and side seams. Use bonded nylon thread (e.g., Tex 60–80) and calibrate SPI (stitches per inch) to leather thickness to avoid perforation weakening. Apply skiving at overlap points to control bulk. Spec backer tapes on zipper seams and bartacks on pocket entries. Record all seam types in the tech pack with diagrams and cross-sections for factory consistency.

[MENTION: YKK and RiRi hardware specifications] provide reliable baselines. For leather standards, rely on [MENTION: Leather Working Group] documentation for tannery practices and environmental metrics.

[INTERNAL LINK: Sustainable leather sourcing guide — link to a sustainability/compliance hub]

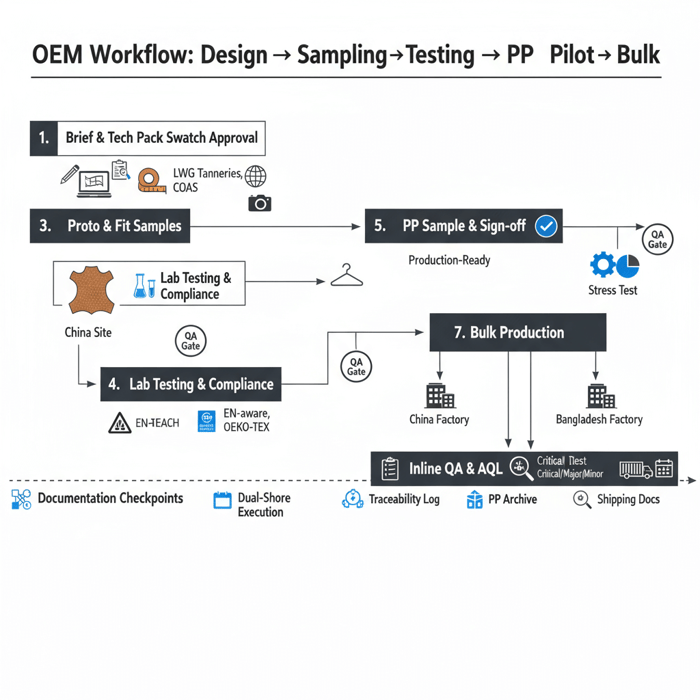

How to Manufacture a Black Leather Motorcycle Jacket with a China Clothing Manufacturer

A proven OEM/ODM workflow runs from brief and tech pack to proto, fit, and PP sample, followed by a pilot run and bulk. Lock LWG leather early, align REACH/OEKO-TEX testing, and maintain traceability from tannery to carton. Dual-shore execution (China/Bangladesh) can improve speed, cost, and resilience when managed through shared QA.

- Define the brief: claim set, silhouette references, target cost, size range, market.

- Build tech pack: pattern block notes, seam map, BOM, test plan, labeling.

- Source leather: shortlist LWG tanneries; approve swatches and COAs.

- Proto sample: validate silhouette and construction feasibility.

- Fit sample(s): refine pattern; confirm mobility and grading strategy.

- Lab tests: submit materials and finished sample against defined standards.

- PP sample: production-accurate garment; approve trims, labels, and workmanship.

- Pilot run: small lot to stress-test process; collect QA metrics.

- Bulk: monitored with inline inspections and final AQL.

- Logistics: finalize packaging, carton specs, and booking windows.

Preparation (Tech Pack, BOM, Sampling Plan)

Technical clarity saves weeks. Your black leather motorcycle jacket tech pack should include: front and back sketches with exploded seam map; panel list with thickness targets; finish notes; hardware callouts with brand, gauge, and plating; stitching specs (thread, SPI, seam types); lining and interlining materials; size chart with tolerances; and a test plan covering abrasion, tear, colorfastness to rubbing, perspiration, and odor limits. Define labeling and claim language early, including any EN 17092 class space if applicable. Outline sampling stages with decision criteria and owners; include a decision calendar to protect launch dates.

BOM accuracy underpins costing. Record leather yield estimates, expected cutting loss, and color standard references. Hardware counts by gauge and finish reduce late-stage variance. For dual-site execution, specify shared components to maintain parity. Maintain a separate compliance annex for REACH and OEKO-TEX test targets; create a traceability map from tannery to finished goods with lot numbers and batch labels.

Execution Steps (Proto → Fit → PP → Pilot → Bulk)

Proto confirms feasibility. Approve construction logic, seam placements, and hardware handling on leather. Fit samples then refine mobility: adjust sleeve pitch, biceps, and back shoulder width; validate collar comfort and front rise against a base layer. Record pattern changes and update the size spec. After fit lock, submit material and finished sample tests for REACH, colorfastness, and performance. PP (pre-production) samples must be production-line made with approved bulk materials, final labels, and packing. Approve PP with a documented checklist and annotations.

Run a pilot for the first style or major revision. A 50–200 piece pilot in China helps surface cutting yield, bulk color variance, and trimming consistency. Implement inline QA with defect categorization (critical/major/minor), then analyze patterns before bulk. For brands splitting production with Bangladesh, send master PP and golden size sets, conduct a first-article inspection, and require matching lab results. Keep calibration sessions between sites to prevent interpretation drift and safeguard stitch quality and label placement.

Quality Assurance (Lab + Inline + Final AQL)

Quality is a system, not a checkpoint. Set a lab test matrix: leather colorfastness to rubbing (wet/dry), perspiration, dimensional stability; seam strength; tear and tensile; abrasion performance (method aligned to claim set); and odor screening to detect residual chemistry. For hardware: zipper chain strength, slider pull, snap/buckle pull-off, and plating adhesion. Define pass/fail targets and escalation steps in your QA plan. Inline, audit critical seams, stitch density, backer usage, label language, and hardware counts; log results by workstation.

Final AQL: apply a sampling plan (e.g., AQL 2.5/4.0) tuned to risk tolerance; check size ratio, color uniformity on black under D65 light, and carton labeling compliance. Retain a retention sample per lot. Keep a compliance file: tannery LWG certificate, lab reports, PP approvals, golden samples photos, and packing specs. Brands selling in CA should include Prop 65 assessment; EU importers require REACH documentation at hand [CITE: EU REACH guide for textiles and leather; accredited lab protocols].

[MENTION: SGS, Bureau Veritas, or Intertek] can serve as accredited labs. Process steps here reflect Eton’s outerwear development workflows.

Cost, MOQ, and Lead Times for Black Leather Motorcycle Jacket Production

Plan for MOQs around 300–800 units per style/color, with lead times of roughly 90–150 days after PP approval. Unit cost drivers include leather grade and thickness, hardware brand and gauge, pattern complexity, and testing scope. Build buffers for leather allocation, lab queues, and regional holiday calendars.

| Driver | Impact on Cost | Typical Range | Notes |

|---|---|---|---|

| Leather grade/thickness | High | ±15–30% swing | Thicker, more uniform hides raise cost and yield complexity |

| Hardware brand & count | Medium | ±5–12% | Branded zippers/snaps add cost; counterfeit risk avoidance worth it |

| Construction complexity | Medium–High | ±10–20% | More seams, gussets, and armor pockets increase minutes |

| Testing & compliance | Low–Medium | ±2–6% | EN claims add test scope; REACH/OEKO-TEX baseline in EU |

| Order size & colorways | Medium | ±5–10% | Economies of scale; single-color bulk improves yield |

| Dual-shore strategy | Mixed | ±5–8% | China for sampling speed; Bangladesh for scale; coordination overhead |

- Dual-shore pros: capacity flexibility, risk diversification, potential landed cost savings.

- Dual-shore cons: alignment overhead, parallel QA workload, cross-site calibration needs.

MOQ & Allocation Strategy

Leather lot sizes steer MOQ. A typical lot supports ~300–800 jackets in black, depending on thickness and defect map. To minimize batch-to-batch shade variances, allocate per lot and avoid splitting across seasons without re-approval. For style/color runs under MOQ, consider consolidating trims and lining across a capsule, or mix sizes strategically to hit minimums while covering demand. Share forecast visibility with the factory to secure tannery capacity in advance. If channel tests require small drops, run a pilot with China production and switch scale-up to Bangladesh after fit and PP lock to balance speed and unit economics.

Timeline Planning (Sampling to Bulk)

From design lock to ex-factory, a 90–150 day window is common after PP approval. Typical cadence: proto in 7–14 days, fit in 10–20 days (with revision cycles), PP in 20–30 days post-materials, pilot 2–3 weeks, and bulk 45–75 days depending on complexity and capacity. Build 7–10 days buffer for lab testing queue and re-tests, and consider Chinese New Year or Eid holidays in planning. Reserve logistics: book vessel or air slots early in Q4 when space tightens. For US & EU, compare DDP vs FOB landed cost across seasons; fuel surcharges can shift best option [CITE: recent freight index or trade lane analysis].

[INTERNAL LINK: Outerwear OEM timelines — link to a process page concept]

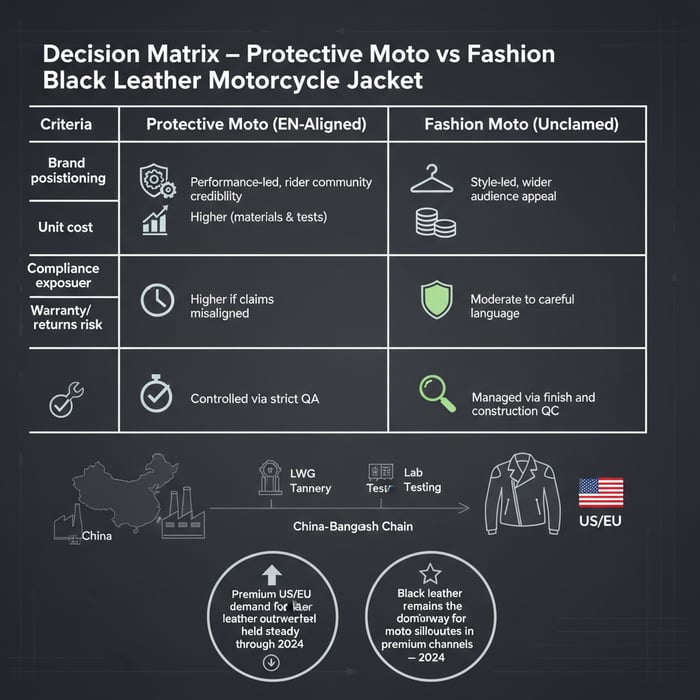

Comparison: Protective Moto vs Fashion Leather Jackets — What Should Your Brand Build?

Claimed protective builds need EN 17092 testing and higher-spec materials that raise cost and lead time. Fashion builds unlock softer hand, broader price bands, and faster calendars. Use the matrix below to align with positioning, margin targets, and risk tolerance for compliance and warranty.

| Criteria | Protective Moto (EN-Aligned) | Fashion Moto (Unclaimed) |

|---|---|---|

| Brand positioning | Performance-led, rider community credibility | Style-led, wider audience appeal |

| Unit cost | Higher (materials & tests) | Moderate to accessible |

| Time-to-market | Longer (testing gates) | Faster |

| Compliance exposure | Higher if claims misaligned | Lower with careful language |

| Warranty/returns risk | Controlled via strict QA | Managed via finish and construction QC |

- Premium US/EU demand for leather outerwear held steady through 2024 — (Source: [CITE: Statista or Grand View Research 2023–2025])

Criteria Overview

Start with audience. Rider-focused brands benefit from EN-validated builds that tell a performance story. Multi-category fashion labels often prioritize feel, styling range, and price bands. Map MSRP, gross margin, and sell-through targets to construction choices: leather thickness, hardware brand, seam count, and lining complexity. Validate channel fit—specialty moto retailers expect technical substance; department stores reward hand, fit, and finishing. Consider post-purchase care; protective jackets may require clearer maintenance guides to preserve performance attributes.

Decision Framework

Score each path across five axes: brand story, unit cost, calendar, compliance risk, and consumer expectation. Weight by strategy—impact of compliance risk may outweigh a small margin lift. If entering the category, start with fashion-led capsules to learn demand and fit preferences, then spin a technical sub-line with EN claims and lab-tested specs. For global brands, localize claim language and imagery per US/EU norms and legal review. Capture learnings in a master spec library and roll improvements into the next season’s block updates.

Market Data & Trends: Black Leather Motorcycle Jackets in US & EU (2023–2025)

Leather outerwear retains cultural pull in US/EU premium and mid-tier segments. Heritage moto designs surge in Q3–Q4 drops; consumer interest in responsible leather sourcing is growing, while price sensitivity remains in entry tiers. Plan capsules that spotlight material provenance and durability stories.

- EU consumers report higher trust in products with independent sustainability verification — 2023–2024 (Source: [CITE: EU consumer confidence or retail sustainability survey])

- Black leather remains the dominant colorway for moto silhouettes in premium channels — 2024 (Source: [CITE: fashion retail sell-through analysis])

Key Trend 1: Heritage Resilience

Heritage silhouettes remain anchor pieces, with black leather motorcycle jackets outperforming colored variants in many markets. Retailers combine timeless shapes with modern hardware finishes and subtle branding. Limited-edition capsules tied to music or motorsport narratives show strong attachment rates online. Invest in photography that highlights grain and construction storytelling; detail shots of lapped seams and branded zippers reinforce value at higher price points [CITE: retail merchandising performance commentary].

Key Trend 2: Responsible Sourcing Signals

Consumers scrutinize leather provenance. Brands that cite LWG-audited tanneries, chrome management, and third-party chemical testing see improved trust. QR-enabled traceability on hangtags bridges offline and online education. Vegan alternatives expand reach but should be marketed distinctly to avoid confusing claims. Keep narrative crisp: animal welfare standards, environmental audit credentials, and durability benefits as a counterweight to fast-disposable fashion [CITE: Textile Exchange or similar materials insights].

Product/Service Integration: Clothing Manufacturing OEM Service

Eton’s Clothing Manufacturing OEM Service accelerates black leather motorcycle jacket programs. We align EN-aware patterns, LWG leather sourcing, and dual-site production in China and Bangladesh with a QA plan that includes lab tests, inline audits, and final AQL—built for US & EU market standards.

| Brand Need | Eton OEM Feature | Outcome |

|---|---|---|

| Fast concept-to-shelf | Rapid proto/fit cycles in China; shared calibration to Bangladesh | Shorter lead times, consistent quality |

| Responsible leather sourcing | LWG-audited tannery network with COAs and traceability | Compliance confidence and credible storytelling |

| Compliance & testing | REACH and OEKO-TEX test coordination; EN-aware test plans | Reduced claim risk; cleaner market approvals |

| Cost clarity | Transparent BOM and labor-minute mapping | Predictable margins and scalable pricing |

Use Case 1: Premium Heritage Capsule → LWG Cowhide

A US premium label launches a 3-style black leather motorcycle jacket capsule with 1.2–1.3 mm LWG cowhide, RiRi zippers, and lapped seams. China site runs proto and fit, then a 100-piece pilot validates cutting yield and finishing. PP passes with lab compliance for REACH and colorfastness; final bulk splits across sites to meet drop deadlines. The result: consistent grain matching, authentic hand, and sell-through supported by a clear provenance story.

Use Case 2: Mid-Tier Fashion Moto → Sheepskin/PU Hybrid

An EU multi-brand retailer asks for a fashion-forward black leather motorcycle jacket silhouette at a strict MSRP. Eton proposes a sheepskin main body with PU trim panels to manage cost, branded YKK #5 hardware, and a satin sleeve lining for ease. Testing focuses on crocking and odor, with nickel-free hardware for EU markets. Production in Bangladesh delivers margin while China maintains sampling speed. The line hits the price band with high perceived value and clean compliance.

Explore how Eton executes leather programs end-to-end: Clothing Manufacturing OEM Service.

[MENTION: Casework from Liverpool F.C. apparel partners; Forever 21, Babyshop collaboration history] supports Eton’s track record in large-scale programs.

Risks, Compliance & Localization (US/EU)

Manage risk by locking claim language, validating chemicals under REACH, and using OEKO-TEX Leather Standard where applicable. For protective claims, align to EN 17092 with accredited testing. Build a risk matrix to monitor leather variability, black dye crocking, and hardware authenticity; document mitigation steps in the QA plan.

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Leather shade variance (black) | Medium | High | Lot-based allocation; bulk swatch controls; lightbox checks |

| Crocking/bleed on light garments | Medium | Medium | Wet/dry rub test thresholds; finish adhesion checks; care label clarity |

| Counterfeit hardware | Low–Medium | High | Approved vendor list; authentication docs; random pull tests |

| Chemical non-compliance (REACH/Prop 65) | Low–Medium | High | Material and finished-garment tests; restricted substance monitoring |

| Pattern misalignment between sites | Low | Medium | Golden size sets; first-article inspections; cross-site trainings |

Regulatory Notes for US & EU

EU: Meet REACH restricted substance limits, maintain technical documentation, and ensure labeling matches claims. For EN 17092 claims, retain accredited lab reports and correct class labeling. US: Review chemical disclosures and Prop 65 for California. Nickel-free hardware is preferred for EU; maintain heavy-metal limits across trims. Maintain supplier declarations for traceability from LWG-audited tanneries and keep COAs accessible for customs or retailer compliance teams [CITE: EU REACH official portal; OEKO-TEX Leather Standard; CEN documentation; California OEHHA Prop 65 portal].

Conclusion & Next Steps

Decide your claim set, pick the right leather and construction, and bake compliance into the plan. Then execute through a disciplined OEM workflow with QA gates. Eton’s dual-shore setup in China and Bangladesh helps brands move from brief to bulk with consistency, cost clarity, and on-schedule deliveries for US & EU launches.

- Week 0–1: Finalize claim set; confirm target cost and channels.

- Week 1–3: Build tech pack and BOM; shortlist LWG tanneries.

- Week 3–5: Proto and fit; align sizing and seam construction.

- Week 5–8: Lab tests; PP approvals and packaging sign-offs.

- Week 8–14+: Pilot and bulk with inline QA and final AQL.

[INTERNAL LINK: Compliance toolkit — downloadable checklist]

[INTERNAL LINK: Outerwear design templates — tech pack library]

[INTERNAL LINK: Sampling calendar — season-specific planning]

References & Sources

- Leather Working Group — Program overview and audit criteria (2024). [CITE: leatherworkinggroup.com]

- European Union — REACH regulation for textiles and leather (2023–2025). [CITE: echa.europa.eu]

- CEN — EN 17092 Motorcycle Protective Clothing standard (latest edition). [CITE: CEN or national standards body]

- OEKO-TEX — Leather Standard and testing methods (2024). [CITE: oeko-tex.com]

- California OEHHA — Proposition 65 apparel guidance (2024). [CITE: oehha.ca.gov]

- Market data — Leather outerwear demand (2023–2025). [CITE: Statista or Grand View Research]

- Hardware specifications — YKK/RiRi zipper performance data (2023–2024). [CITE: manufacturer technical sheets]

- Accredited labs — SGS/Bureau Veritas/Intertek test method notes (2023–2025). [CITE: lab websites]

- Textile Exchange — Materials insights on leather alternatives (2024). [CITE: textileexchange.org]

- Retail merchandising commentary — Premium outerwear performance (2024). [CITE: reputable retail analysis or trade press]

[INTERNAL LINK: Eton Garment Limited — About our team and compliance approach]

[MENTION: Eton Garment Limited’s 30+ years in outerwear, dual bases in China and Bangladesh, partnerships with international retailers]

FAQs

Related Articles

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer

16 minute read

October 28th, 2025

T Shirt Decal Maker: From DIY Designs to Scalable Production with a China Clothing Manufacturer A t... more »

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands

20 minute read

October 28th, 2025

Custom Clothing Embroidery: A China Clothing Manufacturer’s Complete Guide for Fashion Brands Custom... more »

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer

17 minute read

October 28th, 2025

Sustainable clothing manufacturers USA: A practical guide to partnering with a China Clothing Manufacturer... more »

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective

17 minute read

October 28th, 2025

Clothing production software: A fashion brand’s guide with a China Clothing Manufacturer’s perspective... more »