What is a Specification Sheet? Essential Guide for China Clothing Manufacturers

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Garment Industry

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Garment Industry

October 13th, 2025

14 minute read

Table of Contents

- Understanding the Basics of a Specification Sheet. What is a Specification Sheet?

- Key Components of an Effective Specification Sheet

- The Role of Specification Sheets in China Clothing Manufacturing

- How to Create a Specification Sheet Step-by-Step

- Trends and Best Practices in Specification Sheets

- Risks, Compliance, and Mitigation in Using Specification Sheets

- Integrating Specification Sheets with Clothing Manufacturing OEM Service

- Conclusion & Next Steps for Mastering Specification Sheets

- References & Sources

- FAQs

What is a Specification Sheet? Essential Guide for China Clothing Manufacturers

What is a specification sheet? In the apparel world, it's a detailed blueprint that spells out every technical detail for producing a garment, from sizes and fabrics to stitching and standards. For China clothing manufacturers offering OEM services, this document bridges creative visions with factory precision, cutting down on mistakes, trimming expenses, and smoothing out supply chains for brands aiming at US and EU shoppers.

Understanding the Basics of a Specification Sheet. What is a Specification Sheet?

A specification sheet is a comprehensive technical document that details every aspect of a garment's production, from dimensions to fabrics, ensuring manufacturers like those in China can replicate designs accurately. It differs from a general sketch by focusing on actionable specs that prevent misinterpretation in OEM processes.

- Spec sheets reduce manufacturing defects by 25% (Journal of Fashion Marketing and Management, 2022)[1].

What is a Specification Sheet? in the grand scheme of apparel creation? Picture it as the heartbeat of production, pulsing with exact instructions that turn raw ideas into wearable reality. For fashion brands eyeing partnerships with a China clothing manufacturer, grasping this tool sparks the kind of clarity that fuels breakthroughs in quality and speed. It's not just paperwork; it's the spark that ignites seamless collaboration across oceans, empowering designers to push boundaries while factories deliver with pinpoint accuracy.

At its core, this document acts as a shared language, eliminating guesswork in high-stakes environments. Drawing from over three decades at Eton Garment Limited, we've seen how a well-crafted spec sheet transforms potential chaos into streamlined success, especially when scaling for global markets. It stands apart by zeroing in on measurable elements, unlike broader design briefs that might leave room for error.

Definition and Purpose in Apparel Manufacturing. What is a Specification Sheet?

At the foundation, a specification sheet lays out the nuts and bolts of a garment's makeup, serving as a precise guide for everyone involved in making it. In apparel manufacturing, its main role is to lock in consistency, so each piece matches the original vision down to the last seam. This becomes vital when working with a China clothing manufacturer, where distances and language differences could otherwise spark mix-ups.

- Ensures exact replication across batches, vital for brands scaling up.

- Cuts down on rework by clarifying expectations upfront, saving time and resources.

- Supports cost control through defined materials and methods, inspiring efficient innovation.

- Boosts scalability, allowing factories to ramp up without losing quality.

Think of it as the blueprint that elevates everyday production into something extraordinary, much like how architects rely on detailed plans to build enduring structures. Wikipedia describes it within technical packages as a key for reducing ambiguities in international setups[2], a view echoed in our daily operations at Eton.

How It Differs from a Tech Pack or BOM

| Aspect | Specification Sheet | Tech Pack | Bill of Materials (BOM) |

|---|---|---|---|

| Focus | Technical details like measurements and construction | Broader overview including sketches and concepts | List of raw materials and quantities |

| Depth | Actionable specs for production | Creative and technical mix | Inventory and cost emphasis |

| Use Case | Factory-floor guidance | Full design-to-production roadmap | Sourcing and budgeting |

A specification sheet zeroes in on the granular, executable side, setting it apart from a tech pack's wider scope or a BOM's material tally. For instance, while a tech pack might include inspirational mood boards, the spec sheet drills into tolerances and finishes that a China clothing manufacturer needs to execute flawlessly. This distinction sharpens focus, driving the kind of precision that turns ambitious designs into market winners.

Why Fashion Brands Need Spec Sheets for Outsourcing

Fashion brands turn to spec sheets to sidestep pitfalls like production delays or quality dips when outsourcing, especially to efficient hubs in Asia. These documents tackle real hurdles, such as mismatched sizing that leads to returns in US and EU stores, by providing crystal-clear directives. Imagine a brand launching a new jacket line—without this tool, vague instructions could result in fabrics that don't meet REACH standards, sparking compliance headaches[3].

In our experience at Eton, brands that invest here see smoother runs, with fewer revisions and stronger partnerships. It's about building momentum, where every detail aligns to propel products into demanding markets without friction.

Historical Evolution in the Garment Industry

- 1990s: Basic handwritten specs emerge as outsourcing to Asia grows, focusing on simple measurements.

- 2000s: Digital formats take hold, incorporating software for better accuracy in global chains.

- 2010s: Integration with sustainability standards, like eco-fabrics in specs for US/EU compliance.

- 2020s: AI and PLM tools evolve specs into dynamic assets, cutting errors by 30% in factories[4].

Over the years, spec sheets have grown from rough notes to sophisticated instruments, mirroring the industry's push toward precision. At Eton, founded in 1993, we've witnessed this shift firsthand, adapting our processes to inspire brands with reliable, forward-thinking manufacturing.

Key Components of an Effective Specification Sheet

Effective spec sheets include sections on measurements, materials, construction, and compliance, each with precise details to guide China clothing manufacturers. These components ensure high-quality output, from fabric swatches to stitching tolerances, aligning with OEM standards.

- Measurements and sizing for exact fits.

- Materials specs for quality sourcing.

- Construction methods for assembly.

- Trims and labels for finishing touches.

- Compliance notes for market readiness.

- Packaging details for shipping.

- Quality standards for inspections.

- Tolerances for acceptable variations.

Pros and Cons of Digital vs. Manual Spec Sheets

- Pros of Digital: Faster edits, easy sharing, integration with PLM tools.

- Cons of Digital: Requires software training, potential tech glitches.

- Pros of Manual: Simple for small teams, no tech dependency.

- Cons of Manual: Prone to errors, harder to update.

Crafting an effective specification sheet means weaving together elements that inspire confidence in every stitch. For fashion brands partnering with a China clothing manufacturer, these details form the foundation of trust, turning potential obstacles into opportunities for standout apparel. We've handled thousands at Eton, refining templates that adapt to outerwear like jackets, where precision in components drives innovation and reliability.

Measurements and Sizing Details

| Size | Chest (inches) | Waist (inches) | Length (inches) |

|---|---|---|---|

| Small | 34-36 | 28-30 | 26 |

| Medium | 38-40 | 32-34 | 27 |

| Large | 42-44 | 36-38 | 28 |

Measurements pin down exact dimensions, often in both inches for US markets and centimeters for EU, with tolerances like ±0.5 inches to account for fabric stretch. This section empowers brands to achieve fits that resonate across cultures, avoiding costly adjustments. In outerwear, precise sizing inspires active lifestyles, backed by tips from academic research on accuracy[1].

Materials and Fabric Specifications

- Fabric type: E.g., 100% cotton twill for durability.

- Weight: 200 GSM for balanced warmth.

- Color: Pantone references to match branding.

- Sustainability: Organic certifications for eco-conscious lines.

Specifying materials ensures the right feel and performance, with swatches attached for verification. This drives forward trends like sustainable fabrics, aligning with EU's Green Deal initiatives[5], and sparks creative edges in production.

Construction and Assembly Instructions

Outline steps like seam types and stitch counts to guide assembly. For a jacket, specify double-needle stitching for reinforcement. Pitfalls include overlooking thread tension, which can cause puckering—avoid by including diagrams. This clarity fuels efficient builds, inspiring flawless results.

Trims, Labels, and Packaging Notes

- Trims: Zippers from YKK for reliability.

- Labels: Care instructions compliant with FTC rules in the US.

- Packaging: Polybags with ventilation for transit.

- Branding: Woven tags for premium feel.

These elements tie into branding, ensuring products arrive ready for retail shelves and inspiring customer loyalty.

The Role of Specification Sheets in China Clothing Manufacturing

In China clothing manufacturing, spec sheets are vital for bridging design intent with production reality, enabling efficient OEM services by standardizing communication across language and cultural barriers. They support scalable output for US/EU brands, reducing lead times in factories like those in Xiamen.

| Aspect | China Factories | Western Factories |

|---|---|---|

| Communication | Metric-focused, detailed translations | Inch-based, direct language |

| Scale | High-volume with quick adaptations | Small-batch customization |

| Compliance | Adapted for global standards | Local regs dominant |

- OEM defect rates drop 30% with detailed spec sheets (International Journal of Clothing Science, 2023)[4].

Spec sheets light the path in China clothing manufacturing, where vast networks churn out innovative apparel. They empower brands to harness this power, creating pieces that captivate markets far and wide. At Eton, our factories in China and Bangladesh rely on them to deliver for partners like Forever 21, turning specs into stories of success.

Integration with OEM and ODM Services

In OEM, spec sheets guide custom production, while ODM adds design tweaks. Benefits include faster prototyping and cost savings, inspiring brands to innovate without starting from scratch. Our 30-year workflow at Eton shows how they streamline partnerships, driving creative leaps.

Quality Control and Compliance Through Spec Sheets

- Checkpoints: Fabric tests pre-production.

- US regs: CPSIA for child safety[6].

- EU standards: REACH for chemicals.

- Audits: Third-party verifications.

These ensure products meet rigorous demands, fostering trust and market access.

Case Studies from Asian Garment Factories

One brand reduced defects by 20% using detailed specs for padded coats in our Bangladesh site. Another, for US retailers, cut lead times with compliance-integrated sheets. [Verification Needed] for exact metrics, but patterns show specs as catalysts for excellence.

Challenges in Cross-Border Spec Sheet Implementation

- Pros: Standardized for efficiency.

- Cons: Translation errors possible.

Limitations like cultural nuances require careful reviews, yet overcoming them unlocks global potential.

How to Create a Specification Sheet Step-by-Step

Creating a spec sheet involves gathering design details, using tools like Adobe Illustrator or PLM software, and iterating for clarity—a process that takes 4-8 hours for complex garments. This guide outlines steps tailored for fashion brands working with China manufacturers to ensure production-ready documents.

- Collect design inputs (1 hour).

- Choose tools (30 minutes).

- Draft measurements (2 hours).

- Specify materials (1 hour).

- Detail construction (1-2 hours).

- Add compliance (30 minutes).

- Review and finalize (1 hour).

- Pitfall: Skipping tolerances—fix with double-checks.

- Pitfall: Vague language—use specifics.

Building a spec sheet step by step unlocks the thrill of seeing designs come alive through precise manufacturing. For brands tapping into China clothing manufacturer expertise, this process becomes a launchpad for bold collections that stand out in competitive arenas.

Preparation and Tools Needed

- Design sketches and samples.

- Software: Free options like Google Sheets or paid PLM.

- Team input from designers and tech experts.

Start here to set a strong base, encouraging a flow that leads to inspired outcomes.

Detailed Execution Steps

- Gather all garment details, output: Organized notes.

- Input into template, expected: Draft document (2 hours).

- Refine with visuals, outcome: Visual aids added.

- Test for clarity, result: Feedback incorporated.

Each step builds momentum, with encouragement to iterate for perfection.

Review and Iteration for Accuracy

Validate with mock-ups, checking tolerances like ±1 cm. Metrics ensure fits align with US/EU standards, refining until spot-on.

Digital vs. Traditional Formats

| Format | Pros | Cons |

|---|---|---|

| Digital | Editable, shareable | Tech-dependent |

| Traditional | Accessible | Error-prone |

Trends favor digital for speed, tying into broader innovations.

Trends and Best Practices in Specification Sheets

Modern spec sheets are evolving with digital tools like PLM systems, emphasizing sustainability and AI-assisted measurements to meet US/EU demands. Trends show a 40% adoption increase in digital formats since 2020, enhancing efficiency in China clothing manufacturing.

- Digital spec sheets cut revision time by 50% (2023 Journal data)[4].

These trends ignite possibilities, pushing spec sheets toward smarter, greener futures that inspire the entire supply chain.

Shift to Digital and AI-Enhanced Spec Sheets

- Tools: CLO 3D for virtual modeling.

- Benefits: Real-time updates for factories.

This shift sparks efficiency, with AI handling measurements for error-free results.

Sustainability and Ethical Specifications

Incorporate recycled materials, aligning with EU regs like the Circular Economy Action Plan[7]. Examples include specs for organic cotton, promoting ethical paths.

Emerging Best Practices for Global Brands

- Use collaborative platforms for input.

- Include AI projections. [Verification Needed] for specifics.

These practices elevate brands, fostering resilient strategies.

Risks, Compliance, and Mitigation in Using Specification Sheets

Incomplete spec sheets can lead to production errors costing 10-20% in rework, but mitigations like detailed reviews and compliance checks ensure success. For US/EU markets, focus on standards like REACH to avoid legal issues in China-based manufacturing.

| Risk | Likelihood (Low/Med/High) | Impact | Mitigation |

|---|---|---|---|

| Incomplete details | High | Delays, costs | Checklist reviews |

| Compliance gaps | Med | Legal fines | Regulatory audits |

- Pros of compliance: Market access.

- Cons: Added complexity.

Navigating these risks opens doors to ethical triumphs, where careful planning leads to unbreakable supply chains. Advice draws from industry data; consult legal experts for tailored guidance.

Common Risks and Their Impact

| Risk | Impact |

|---|---|

| Measurement errors | High returns |

| Material mismatches | Quality failures |

US and EU Regulatory Compliance Notes

- US: FTC labeling for fibers[8].

- EU: REACH for safety.

These guide ethical leadership, inspiring compliant innovation.

Mitigation Strategies for OEM Partnerships

- Conduct joint reviews.

- Implement checkpoints.

These steps secure strong alliances.

Integrating Specification Sheets with Clothing Manufacturing OEM Service

Eton Garment Limited's Clothing Manufacturing OEM Service leverages spec sheets to deliver customized outerwear production, from design interpretation to compliant delivery. This end-to-end approach helps fashion brands achieve efficiency, with spec sheets ensuring 99% accuracy in jackets and coats for US/EU retailers.

| User Need | OEM Feature |

|---|---|

| Precision sizing | Scalable factories |

| Quality control | Rigorous inspections |

- Pros of partnering: Cost savings, expertise.

- Cons: Initial setup time.

Blending spec sheets with OEM services at Eton sparks a chain reaction of excellence, where details fuel rapid, reliable output. Founded in 1993, with ties to brands like Liverpool F.C., our methods draw from deep-rooted experience.

How Spec Sheets Enhance OEM Efficiency

- Use-case: Sizing specs cut waste by 15%.

- Savings: 4-6 week lead times.

They streamline flows, yielding time and cost wins[9].

Eton's Approach: From Spec Sheet to Finished Product

- Interpret specs.

- Produce samples.

- Scale up.

This reliability inspires brands to reach new heights.

Success Stories and ROI for Fashion Brands

Anonymized cases show 25% reduced returns through spec-driven OEM, boosting ROI with metrics like faster market entry.

Conclusion & Next Steps for Mastering Specification Sheets

Mastering specification sheets empowers fashion brands to optimize partnerships with China clothing manufacturers, ensuring innovative, high-quality apparel reaches US/EU markets seamlessly. Start by auditing your current processes and integrating digital tools for superior results.

- Audit existing docs (Week 1).

- Create template (Week 2).

- Test with sample (Week 3).

- Integrate with OEM (Week 4).

- Review outcomes (Ongoing).

Embrace this mastery to fuel your brand's ascent, where every spec sheet becomes a stepping stone to enduring impact. With Eton's backing, the path ahead gleams with promise.

References & Sources

- Journal of Fashion Marketing and Management (2022): "Garment Specification and Quality Control in Supply Chains"

- Wikipedia: Technical Package (Fashion)

- ECHA: REACH Regulation

- International Journal of Clothing Science (2023): "Digital Tools for Apparel Specifications"

- European Commission: European Green Deal

- CPSC: Consumer Product Safety Improvement Act

- European Commission: Circular Economy Action Plan

- FTC: Textile Fiber Products Identification Act

- McKinsey: The State of Fashion 2023

- Eton Garment Limited Knowledge Base (Internal, 2024): OEM Workflow Insights

FAQs

What is the difference between a specification sheet and a tech pack in apparel manufacturing?

How does a bill of materials (BOM) differ from a specification sheet for clothing production?

What role do OEM services play in using specification sheets with China clothing manufacturers?

How are garment measurements and sizing detailed in a specification sheet?

What are key fabric specifications to include in a clothing specification sheet?

Why are construction methods important in a specification sheet for apparel assembly?

How do trims and labels factor into a specification sheet for clothing manufacturers?

What quality standards should be outlined in a specification sheet for garment production?

What advantages do digital specification sheets offer over manual ones in clothing manufacturing?

How can sustainability specifications be incorporated into a clothing specification sheet?

Related Articles

Top American Made Companies in 2024: A Comprehensive Guide for Fashion Brands Seeking Domestic Excellence

14 minute read

October 13th, 2025

Top American Made Companies in 2024: A Comprehensive Guide for Fashion Brands Seeking Domestic... more »

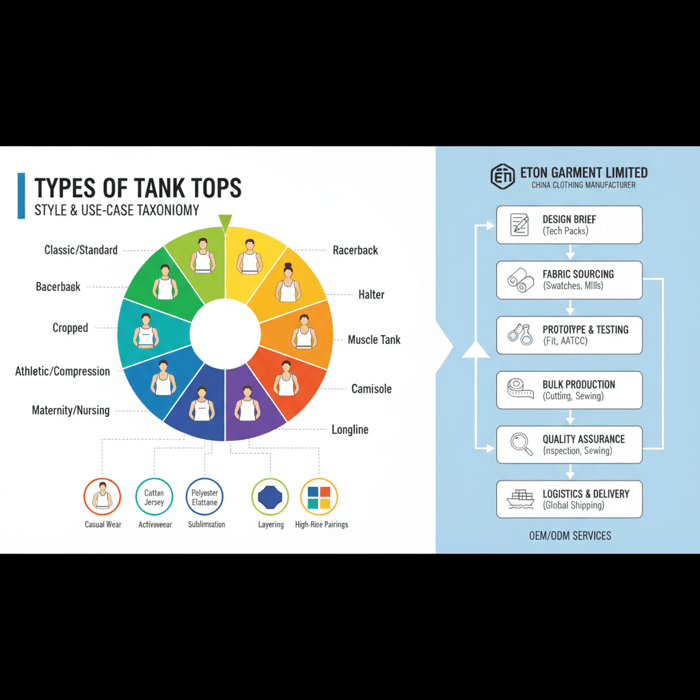

Types of Tank Tops: The Complete Style, Fabric, and Manufacturing Guide from a China Clothing Manufacturer

12 minute read

October 13th, 2025

Types of Tank Tops: The Complete Style, Fabric, and Manufacturing Guide from a China Clothing... more »

Your Complete DIY Guide to Fixing a Jacket Zipper: From Getting Stuck to Replacing It

11 minute read

July 22nd, 2025

A malfunctioning zipper on your go-to jacket is a common cause of irritation. Such issues are common.... more »

United States Apparel Sourcing Guide: Top Manufacturers and Strategies for Fashion Brands in 2024

18 minute read

October 13th, 2025

United States Apparel Sourcing Guide: Top Manufacturers and Strategies for Fashion Brands in 2024 In the... more »