How to Design a Dress Online and Seamlessly Work with a China Clothing Manufacturer

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Garment Industry

Mr. Eton Yip | 32+ Year Garment Manufacturing Expert & Founder of Eton Garment

Garment Industry

October 13th, 2025

12 minute read

How to Design a Dress Online and Seamlessly Work with a China Clothing Manufacturer

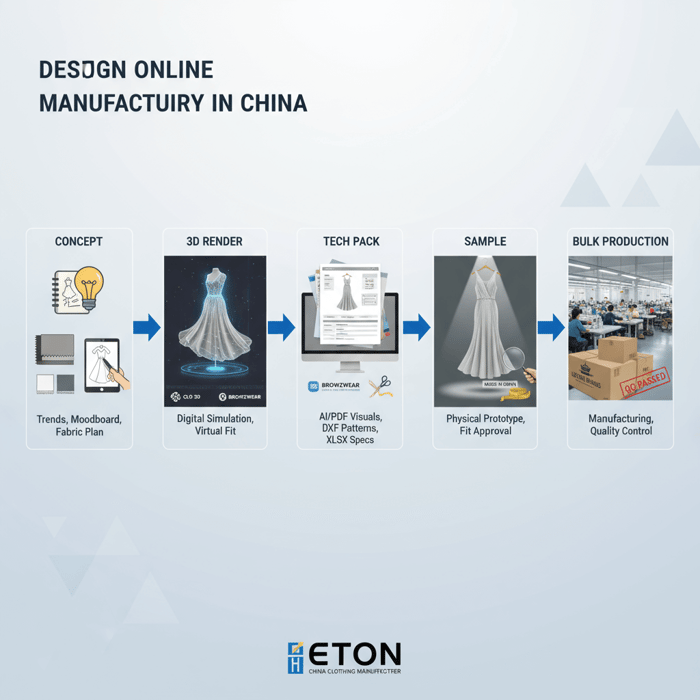

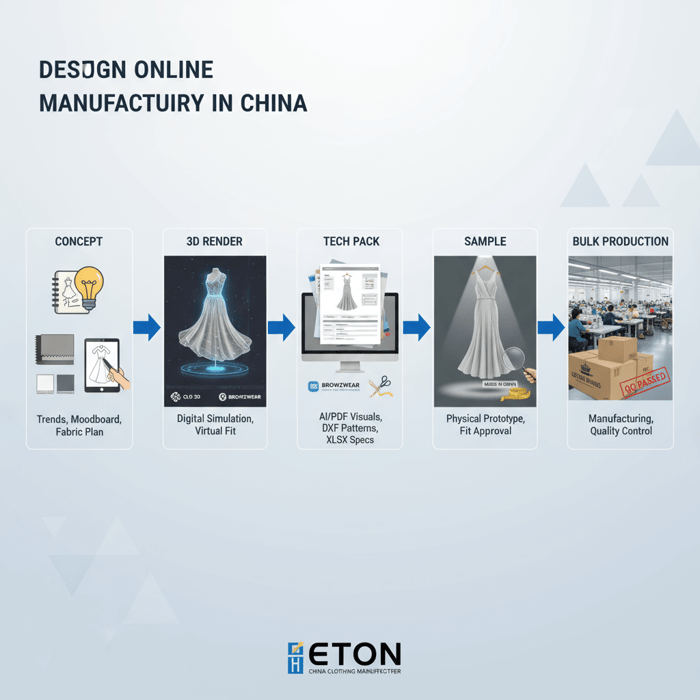

Design dress online workflows now give US and EU brands a direct path from concept to a production-ready garment with a China Clothing Manufacturer. The stack blends 2D flats, 3D clothing design, graded measurements, and a factory-ready tech pack. Done well, it reduces sampling rounds, protects IP, and accelerates delivery without sacrificing fit or compliance.[1][2]

Designing a dress online means creating flats, patterns, and 3D simulations, then packaging specs into a tech pack for a China Clothing Manufacturer. Success hinges on interoperable files, realistic fabric simulation, and a factory-proven handoff that delivers accurate samples, clear tolerances, and US/EU-compliant labeling.

What “Design a Dress Online” Really Means in 2025

Online dress design spans moodboards, sketches, 2D CAD for flats/patterns, 3D simulation for drape and fit, and a tech pack that a garment factory can execute without ambiguity. Digital product creation (DPC) works when your assets map cleanly to factory requirements: patterns and grading, BOM, tolerances, construction notes, colorways, and testing plans.[3][1][4]

Each online asset should be traceable to a factory deliverable. For example, a 3D dress render validates silhouette and drape; graded patterns, measurement specs, and stitch types instruct construction; BOM and lab dips define materials and color accuracy; labeling notes align to US FTC and EU 1007/2011 rules.[5][6]

Core Components of a Production-Ready Online Design

- 2D flats and annotated sketches: silhouette, seam lines, topstitching, hardware placements.[7]

- Patterns and grading: base size pattern plus graded size sets aligned to US/EU charts.

- 3D simulations: CLO 3D dress or Browzwear renders with fabric properties and fit notes.[4][8]

- Dress tech pack template: cover, BOM, measurement spec, tolerances, construction notes, colorways, lab dips, testing, packaging, labeling, QA plan.

- File standards: AI/PDF for visuals; DXF AAMA ASTM apparel for patterns; OBJ/FBX/GLB for 3D; CSV/XLSX for measurements.[1]

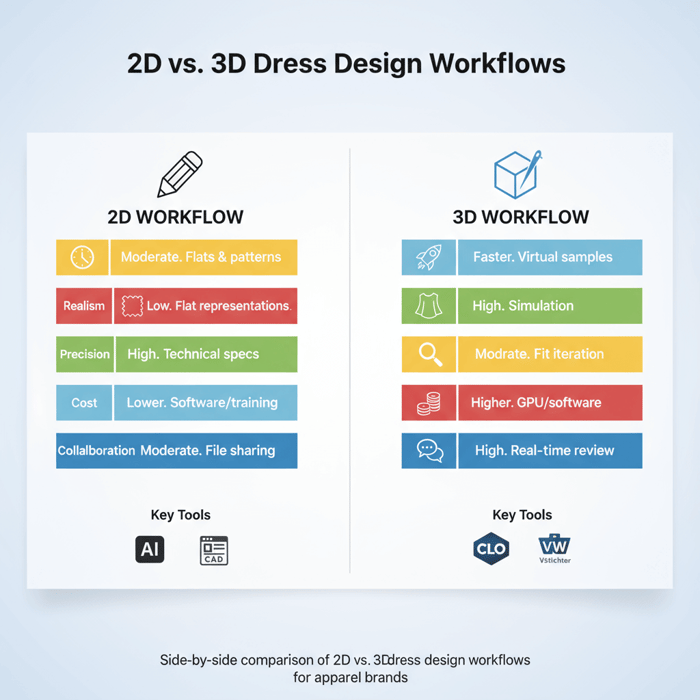

2D vs 3D in Apparel: What Changes for Dresses?

2D excels at precise flats, pattern drafting, and final tech pack documentation. 3D adds drape realism, movement, and virtual sampling apparel that can cut sample rounds. Dresses benefit visibly: you see pleats, bias cut behavior, and lining effects before sewing. Many teams combine both—2D for patterns/specs and 3D for fit, drape, and sell-in visuals.[4][8]

File Standards & Interoperability Basics

Manufacturers typically accept AI/PDF for flats, DXF (AAMA/ASTM variants) for patterns, and OBJ/FBX/GLB for 3D. Export with consistent units, naming, and version control. Keep trims and fabric references synchronized between 2D tech pack and 3D scene. If you rely on fashion PLM integration, align field names for BOM, measurements, and revisions across systems.[1]

From Digital to Physical: Key Real-World Constraints

- Fabric availability: align simulated fabrics with mill-available GSM, composition, and finishes.

- Trims: specify suppliers or generics with tolerances; confirm lead times.

- Color management: lab dips and bulk swatches bridge screen-to-fabric accuracy.[2]

- MOQ realities: dresses with custom prints, specialty zippers, or molded hardware often require higher MOQs.

2D vs 3D Tools: Which Online Dress Design Stack Fits Your Brand?

Choose 2D tools like Adobe Illustrator for flats and fashion CAD for dresses and patterns; add CLO 3D or Browzwear for drape, fit, and virtual sampling. Consider realism needs, team skills, training budgets, collaboration options, and manufacturer compatibility. Pilot on one silhouette to validate exports and approvals.[7][4][8]

- Brands scaling DPC and 3D — 2024–2025 (Source: McKinsey State of Fashion)[2]

Tool Landscape Overview

- Adobe Illustrator (2D): industry standard for flats, vector trims, and spec visuals.[7]

- CLO 3D (3D): garment simulation, garment sewing logic, materials library; strong for dresses.[4]

- Browzwear (3D): enterprise features, apparel workflows, PLM integrations; strong simulation fidelity.[8]

- Marvelous Designer (3D): powerful simulation; fewer apparel enterprise features.

- Free or low-cost options: online dress designer templates, design a dress online free tools for ideation—not factory-ready unless paired with CAD/PLM.

Decision Criteria for Your Stack

- Learning curve: team CAD skills, pattern knowledge, and 3D familiarity.

- Realism: drape accuracy, collision handling, and material libraries for dresses.

- Collaboration: version control, vendor access, and fashion PLM integration.

- Exports: AI/PDF, DXF AAMA ASTM apparel, OBJ garment simulation; factory intake compatibility.

- Budget: software subscriptions, training courses, and GPU needs for 3D.

Interoperability & Export Settings

- 2D: export AI + print-ready PDFs; keep layers for seams, stitches, topstitching, and callouts.

- Patterns: export DXF with AAMA/ASTM conventions, consistent naming, and grainlines/notations preserved.

- 3D: export OBJ/FBX/GLB with scale, material assignments, and embedded textures for vendor review.

- Specs: measurements and grading in CSV/XLSX; align size charts to US/EU standards.

Training & Onboarding Tips

- Phase adoption: start with one CLO 3D dress silhouette or Browzwear style; benchmark fit outcomes.

- Create a dress tech pack template: standardized sections and version control ease factory intake.

- Run a file handoff rehearsal: export, share, and validate with your manufacturer before sampling.

| Tool | Type | Learning Curve | Realism | Collaboration | Exports | Notes |

|---|---|---|---|---|---|---|

| Adobe Illustrator[7] | 2D | Moderate | N/A | Strong with cloud tools | AI, PDF | Industry standard for flats/spec visuals |

| CLO 3D[4] | 3D | Higher | High | Good | OBJ, FBX, GLB | Best-in-class garment simulation |

| Browzwear[8] | 3D | Higher | High | Enterprise features | OBJ, FBX, GLB | Strong PLM ecosystem |

| Marvelous Designer | 3D | Moderate | High | Basic | OBJ, FBX | Great physics; fewer apparel enterprise tools |

| Free options | 2D/3D | Low | Low–Medium | Varies | PDF, limited 3D | Good for ideation, not factory-ready alone |

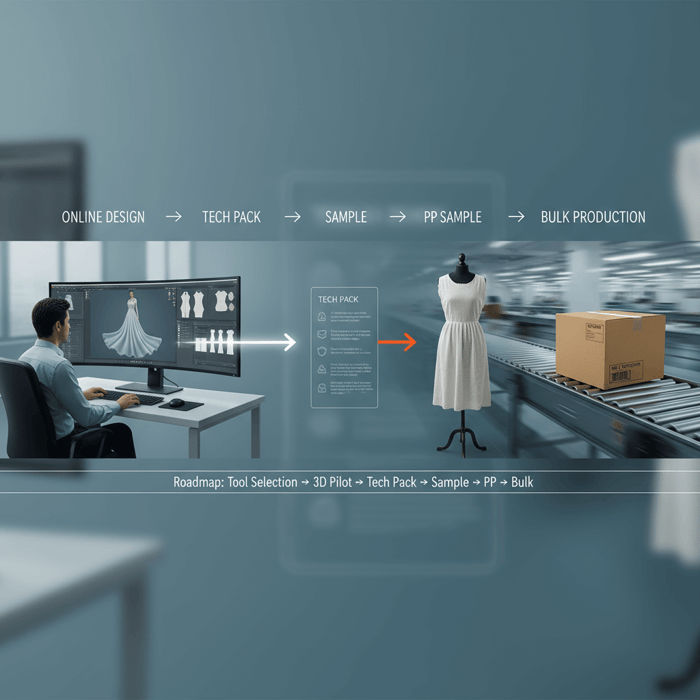

Step-by-Step: From Online Dress Design to Production-Ready

Start with trends and silhouette; build flats and patterns; simulate in 3D; iterate fit; finalize the tech pack; validate with a sample and pre-production checkpoints. Gate each step with outputs and acceptance criteria to avoid rework and file conversion errors.[4][8]

Preparation: Trends, Silhouette, and Fabric Plan

- Define silhouette and intended fit: evening dress, day dress, performance dress.

- Create moodboards and color palettes aligned to US/EU seasonality.

- Pre-select fabrics and linings: composition, GSM, stretch, handfeel, finish, and availability.

- Identify trims: zippers, buttons, hooks, elastic; confirm lead times and MOQ impacts.

Digital Build: Flats, Patterns, and 3D Simulation

- Draft flats in Illustrator with seam lines, panels, and construction callouts.[7]

- Develop base size pattern; add notches, seam allowances, grainlines, and lining pieces.

- Grade to target US/EU size sets; document measurements in a spec sheet.

- Set up CLO 3D dress or Browzwear scene: assign fabric properties and simulate drape.[4][8]

- Export assets: AI/PDF visuals, DXF patterns, OBJ/FBX/GLB 3D, CSV/XLSX measurements.

Fit Iteration: Digital → Physical

- Run virtual fit checks for stress points, hem balance, sleeve mobility, and lining behavior.

- Share a virtual sampling apparel pack with notes—then move to a physical sample for proof.

- Document corrections with tolerances (e.g., +/- measurements) to guide pattern updates.

Tech Pack Finalization & Handoff

- Cover page: style name, season, SKU, render, and contact details.

- BOM: fabrics, linings, interlinings, trims; supplier codes and tolerances.

- Measurement spec + grading: POMs, base size, graded increments, US/EU size charts.

- Construction notes: seam types, stitches, reinforcements, topstitch distances.

- Colorways: Pantone codes, lab dip approvals, and print placements.

- Testing: RSL checks for REACH/Prop 65, shrinkage, colorfastness, seam strength.[9][10]

- Labeling: care, fiber content, origin; align with FTC care labeling and EU 1007/2011.[5][6]

- QA plan: checkpoints, AQL levels, measurement tolerances, carton/packaging details.

| Section | Contents |

|---|---|

| Cover Page | Style name, season, SKU, hero render, contact |

| BOM (fabric/trim) | Material specs, suppliers, codes, tolerances |

| Measurement Spec | POMs, base size, fit notes |

| Grading | Size sets (US/EU), increments, charts |

| Construction Notes | Seams, stitches, reinforcements, lining instructions |

| Tolerances | Measurement ranges, accept/reject criteria |

| Colorways & Lab Dips | Pantone, approvals, print placements |

| Testing | RSL, shrinkage, seam strength, colorfastness |

| Packaging & Labeling | Care labels, fiber content, origin, carton specs |

| QA Plan & Version Control | Checkpoints, AQL, file versions |

Time, Cost, and ROI of Designing a Dress Online

Expect software subscriptions, training hours, and sampling costs. 3D can reduce sample rounds and compress lead times, especially with a factory that accepts 3D fit notes. Model ROI on fewer prototypes shipped, faster approvals, and fewer corrections to patterns and trims.[2]

Cost Inputs (Software, Training, Sampling)

- Software: 2D/3D licenses; plan for annual subscriptions.

- Training: 3D onboarding, pattern refreshers, PLM configuration.

- Sampling: proto, fit, and pre-production samples; courier costs and lab testing.

Time-to-Market Scenarios

- Traditional path: multiple physical samples, longer approval loops.

- Digital-first path: virtual sampling, targeted physical proofing, quicker PP sample approval.

ROI Model & Sensitivity

- Assumptions: fewer sample rounds, lower shipping, faster decision cycles.

- Sensitivity: fabric substitutions, factory capacity, and complexity of dresses.

- Validation: run a pilot on one silhouette and track weeks and samples saved.[2]

Pilot Project Plan

- Pick 1–2 dress silhouettes: similar complexity and fabric families.

- Define metrics: sample count, lead time, corrections, QA findings.

- Gate reviews: virtual fit, sample fit, PP sample; adjust methods based on outcomes.

Digital Fashion Trends: Virtual Sampling, AI Design, and Mass Customization

Brands are scaling DPC across categories while AI fashion design tools accelerate ideation and tech pack drafting. Mass customization dresses test flexible supply chains and on-demand production. The strongest outcomes connect online design to agile OEM/ODM garment services with clear factory handoff standards.[2]

- DPC adoption growth — 2024–2025 (Source: McKinsey State of Fashion)[2]

Virtual Sampling at Scale

- 3D-first workflows help reduce proto rounds for dresses by revealing drape and construction issues early.[4]

- Interoperability remains a constraint—file conversion errors can cause data loss without tight export profiles.[1]

AI-Assisted Ideation & Tech Pack Drafting

- AI can generate silhouette variations, stitch callouts, and starter BOMs; humans verify feasibility and compliance.

- Use PLM-connected templates to avoid version drift and maintain factory-ready documentation.

Product/Service Integration: Clothing Manufacturing OEM Service

Eton translates online dress designs into production with OEM/ODM garment services—file intake, fabric sourcing, sampling, compliance, and scalable manufacturing in China and Bangladesh. In our experience, approvals accelerate when files include clear tolerances, stitch types, and measurement specs; ambiguity in seams or missing lab dip notes slows intake.[11]

Use Case 1: Fast-Track Capsule Dress (Problem → Solution)

- Problem: tight launch window with two colorways and limited sampling time.

- Solution: accept 3D fit notes, pre-book fabric, run a single proto + PP sample; lock tolerances and labeling early.

Use Case 2: Performance Dress with Technical Fabrics (Problem → Solution)

- Problem: moisture-wicking knit with bonded seams and strict RSL requirements.

- Solution: material testing aligned to REACH and Prop 65, stitch/adhesive specifications, lab dips, and targeted fit trials.[9][10]

| User Needs | Capabilities |

|---|---|

| Rapid sampling | Dedicated intake review; single proto + PP path |

| 3D file intake | OBJ/FBX/GLB renders and fit notes accepted |

| Fabric matching | Mill sourcing, lab dips, swatch approvals |

| Compliance | REACH/Prop 65 RSL checks; FTC/EU labeling alignment[9][10][5][6] |

| Scalable production | China and Bangladesh bases; QA checkpoints and AQL |

Explore our Clothing Manufacturing OEM Service: Clothing Manufacturing OEM Service.

Risks, Compliance & Localization for US/EU Brands

Address IP and file security, fit and color accuracy, conversion errors, and vendor compliance expectations. Build controls: NDAs, vetted file formats, pre-production tests, documented QA criteria, and accurate US/EU labeling. Regulations evolve; consult current FTC, EU, and CPSC guidance for dresses sold in your markets.[5][6][12]

- Digital-first pros: faster approvals, fewer samples, clear documentation, mass customization potential.

- Digital-first cons: learning curve, file conversions, simulation limitations, vendor variation.

Risk Matrix

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| File conversion errors | Medium | Pattern/spec mismatches | Standardized exports; version control |

| Fit variance from 3D to physical | Medium | Extra sample rounds | Targeted fit tests; clear tolerances |

| Color accuracy issues | Medium | Re-dye; delays | Lab dips; bulk approvals |

| RSL non-compliance (REACH/Prop 65) | Low–Medium | Regulatory risk | Material testing and vendor audits[9][10] |

| Labeling errors (US/EU) | Low–Medium | Rework; compliance fines | FTC care labeling and EU 1007/2011 checks[5][6] |

| IP leakage | Low–Medium | Brand/design exposure | NDAs, controlled access, secure file sharing |

Regulatory Notes for US & EU

- US FTC care labeling dresses: clear care instructions; fiber content; identity of manufacturer or dealer.[5]

- EU textile labeling 1007/2011: fiber composition rules; language and format for EU markets.[6]

- CPSIA: product safety requirements for children’s apparel; verify when applicable.[12]

- REACH RSL apparel: restricted substances compliance; coordinate with labs and mills.[9]

Conclusion & Next Steps

Pick your 2D/3D stack, run a pilot on a single dress silhouette, and build a factory-ready tech pack. Validate fit digitally and physically, approve lab dips, and align labeling to US/EU regulations. Partner with an experienced custom dress manufacturer China for OEM/ODM garment services to compress timelines and reduce risk.

- Week 1–2: Tool selection, silhouette, fabric plan.

- Week 3–4: Flats, patterns, 3D simulation; first virtual fit.

- Week 5–6: Tech pack finalization; proto sample.

- Week 7–8: Corrections; PP sample approval; production booking.

- [1] Computer-aided design — Wikipedia, 2025. https://en.wikipedia.org/wiki/Computer-aided_design

- [2] The State of Fashion — McKinsey & Company, 2024/2025. https://www.mckinsey.com/industries/retail/our-insights/state-of-fashion

- [3] Fashion design — Wikipedia, 2025. https://en.wikipedia.org/wiki/Fashion_design

- [4] CLO 3D Blog — CLO Virtual Fashion, 2024/2025. https://blog.clo3d.com/

- [5] Threading Your Way Through Labeling Requirements — US FTC, 2023. https://www.ftc.gov/business-guidance/resources/threading-your-way-through-labeling-requirements-under-textile-fiber-products

- [6] Textile Labelling Regulation (EU) No 1007/2011 — EUR-Lex, European Union. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32011R1007

- [7] Adobe Illustrator — Adobe, 2025. https://www.adobe.com/products/illustrator.html

- [8] Browzwear — Vendor Site, 2025. https://browzwear.com/

- [9] Understanding REACH — European Chemicals Agency (ECHA), 2025. https://echa.europa.eu/regulations/reach/understanding-reach

- [10] Proposition 65 — California Attorney General, 2025. https://oag.ca.gov/prop65

- [11] Eton Garment Limited — Clothing Manufacturing OEM Service, 2025. https://china-clothing-manufacturer.com/garment-factory/

- [12] CPSIA Overview — US CPSC, 2025. https://www.cpsc.gov/Regulations-Laws--Standards/CPSIA

FAQs

Related Articles

Top American Made Companies in 2024: A Comprehensive Guide for Fashion Brands Seeking Domestic Excellence

14 minute read

October 13th, 2025

Top American Made Companies in 2024: A Comprehensive Guide for Fashion Brands Seeking Domestic... more »

United States Apparel Sourcing Guide: Top Manufacturers and Strategies for Fashion Brands in 2024

18 minute read

October 13th, 2025

United States Apparel Sourcing Guide: Top Manufacturers and Strategies for Fashion Brands in 2024 In the... more »

Custom Merch for Businesses: OEM Manufacturing Guide for US & EU Brands

6 minute read

October 13th, 2025

Custom Merch for Businesses: OEM Manufacturing Guide for US & EU Brands Custom merch for businesses... more »

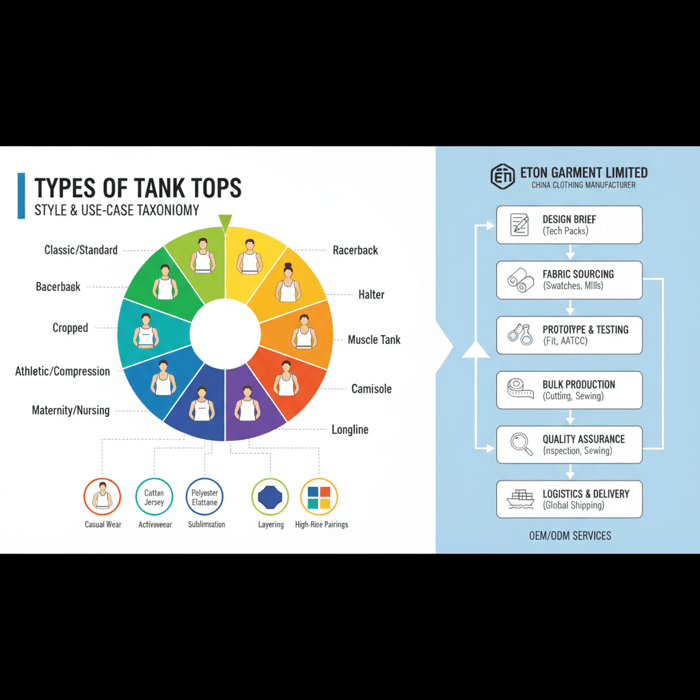

Types of Tank Tops: The Complete Style, Fabric, and Manufacturing Guide from a China Clothing Manufacturer

12 minute read

October 13th, 2025

Types of Tank Tops: The Complete Style, Fabric, and Manufacturing Guide from a China Clothing... more »